How Logistics Automation is Reshaping Global Supply Chain Dynamics in 2025

Logistics automation is changing supply chains around the world in 2025.

Companies use smart computers, sensors, and robots to work faster and better.

The logistics automation business is growing as new tools help track things right away and make systems stronger.

JUSDA is a top company with smart systems, making supply chains work better and be more open.

Key Takeaways

Logistics automation uses smart computers, robots, and sensors.

These tools help move products faster, cheaper, and with fewer mistakes.

Real-time tracking and smart tools help companies solve problems fast.

They also help deliver products on time.

Teaching workers and keeping data safe are very important.

These steps help companies use new automation tools well.

Logistics Automation Technologies

AI and Machine Learning

AI and machine learning are important in logistics today.

Companies use these tools to guess what people will buy.

They also help plan delivery routes and keep track of stock.

In 2025, G20 countries spent more money on AI for shipping.

This made their deliveries faster and better.

AI helps companies make smart choices and act fast.

Uber Freight uses AI to stop trucks from driving empty.

Now, trucks waste less time and fuel.

AI can solve delivery problems quicker than before.

These new tools help companies save money and work well.

AI and machine learning help companies work better.

They make supply chains easier to control.

AI helps use less energy and protect the planet.

Robotics and Automation

Warehouses use robots to move and pack items.

Amazon has over 750,000 robots in its buildings.

Robots help pick orders faster and save money on workers.

JD.com and Ocado use robot arms and smart carts.

These robots help do jobs more quickly and correctly.

Robots help companies sell things faster and pay less overtime.

New robots make shipping more reliable and cheaper.

IoT and Real-Time Data

IoT devices like sensors and tags track packages live.

This helps companies see where things are at all times.

In 2025, DHL uses smart tools to deliver on time more often.

They use 5G and data to make deliveries 15% faster.

Delivery is now 20% more efficient with these tools.

Real-time data helps companies fix problems quickly.

Faster decisions mean fewer mistakes and delays.

IoT makes supply chains easier to see and control.

Company/Technology | Benefit | Result |

|---|---|---|

DHL (smart data) | More on-time deliveries | |

DHL (5G tracking) | Faster deliveries | 20% better |

JD.com (robots) | More work done | 50% more |

JUSDA’s JusLink Platform

JUSDA’s JusLink is a special tool for shipping.

It uses sensors, cloud computers, and big data together.

JusLink lets companies see their whole supply chain.

It uses tags and smart systems to track inventory.

JusLink helps companies plan and react right away.

It lets teams work together in real time.

JusLink makes transport systems smarter and faster.

JUSDA’s new ideas help clients get better, clearer shipping.

Supply Chain Operational Impacts

Efficiency Gains

Logistics automation helps companies work faster and better.

Robots, AI, and sensors do warehouse jobs quickly.

Machines work all day and night, so goods move nonstop.

In 2025, the automation market was worth $82.1 billion.

It grew by about 11% each year.

Most of the market is for warehouse and storage tools.

This shows companies like using automated systems.

Efficiency Aspect | Statistic / Impact |

|---|---|

Market Growth | From $52.59B (2020) to $133.21B (2028), 12.4% growth each year |

Inventory Accuracy | Automation gives up to 99.99% accuracy |

Productivity | Machines working nonstop means more gets done |

Time Savings | Less checking by hand saves time in warehouses |

Cost Reduction | Fewer mistakes and less need for workers saves money |

Error Reduction | Barcodes and RFID tags stop lost packages and mistakes |

Data Management | Real-time data helps teams make smart choices fast |

JUSDA’s JusLink uses sensors and big data to help warehouses.

Teams can see changes right away and keep orders on track.

AI tools guess what people will buy and plan delivery routes.

This means fewer wasted trips and less waiting.

Deliveries are faster and customers are happier.

Companies using automation work 40% faster and process orders 15% quicker.

Automated picking and packing means less overtime and deadlines are easier to meet.

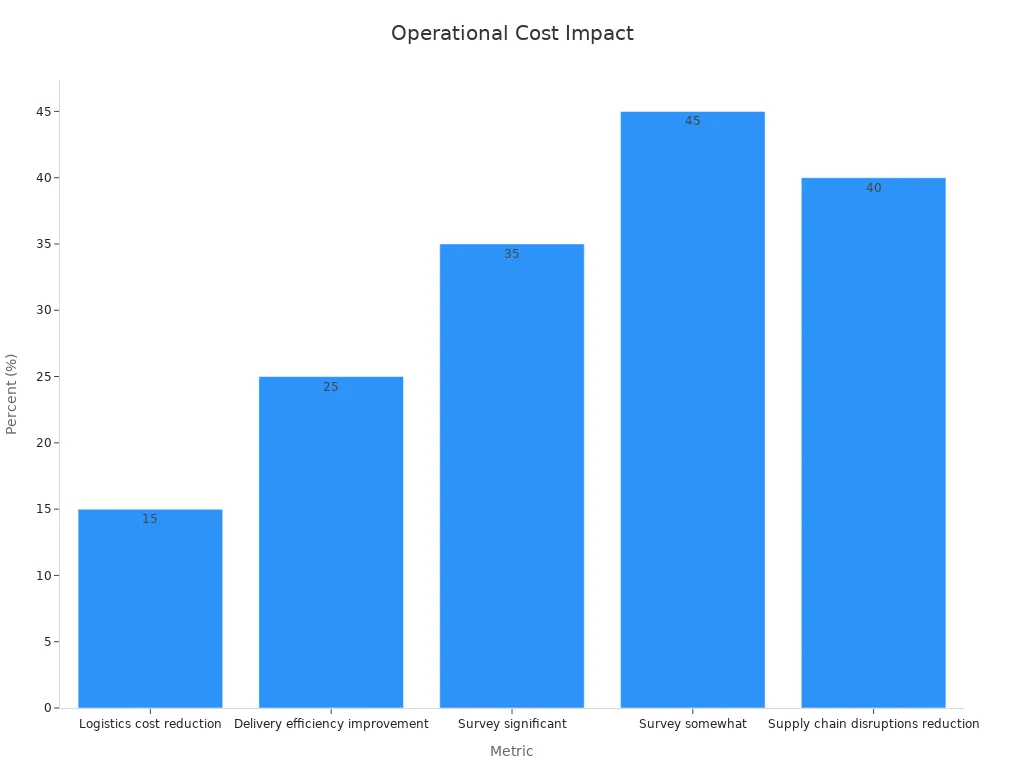

Cost Reduction

Automated systems help companies spend less money.

AI plans routes to use less fuel and drive shorter paths.

Robots in warehouses cut worker costs by 30%.

Some companies save up to 60% on operations.

In 2025, 35% of workers saw big cost drops with automation.

Another 45% saw some cost savings.

Reported Reduction Type | Percentage Reduction | Context/Details |

|---|---|---|

Warehousing and supply chain operational costs | 60% | Companies using automation |

Operational costs | 40% | Using smart automation |

Labor costs | Up to 30% | Fewer workers needed |

JUSDA uses smart tools to manage stock and cut waste.

JusLink helps avoid having too much or too little stock.

This saves space and helps companies keep more money.

Automation lets workers do more important jobs and saves even more.

Accuracy and Error Reduction

Automation makes fewer mistakes in every step.

Automated systems keep inventory almost perfect, up to 99.99%.

Barcodes and RFID tags stop lost items and wrong shipments.

AI tools help guess what people want to buy, with fewer errors.

Robots and AGVs stop people from making mistakes when moving things.

Metric | Error Reduction / Accuracy Improvement | Source Type |

|---|---|---|

Demand Forecasting Error | Reports and studies | |

Inventory Accuracy | Over 98% correct | Company data |

Predictive Maintenance | 35% fewer equipment failures | Research and case studies |

Package Visibility | Over 99% of packages tracked | Company data |

On-time Delivery Rates | 65% better service | Analyst reports |

Customer Satisfaction Scores | 22% higher | Vendor data and studies |

JUSDA’s JusLink does data entry and checks stock in real time.

This means fewer mistakes and the right products sent on time.

With these tools, companies give better service and build trust.

Automation stops mistakes from typing data.

Picking is easier and there are fewer errors.

Checking stock often and clear routes help teams work better.

Real-Time Visibility

Real-time tracking is now very important in logistics.

Sensors and cloud tools let companies see everything in the supply chain.

Teams can watch shipments, spot problems, and change routes fast.

Blockchain keeps records safe and cannot be changed.

Real-time data makes inventory 30% more accurate.

It also cuts response time to problems by half.

Tracking trucks live and changing routes saves 20% on fuel.

JUSDA’s JusLink lets teams see the whole supply chain and act fast.

With real-time alerts, companies stop delays and keep stock right.

This helps them stay quick and win in a fast-moving world.

Challenges in Logistics Automation

Workforce Adaptation

Many workers worry about losing jobs to machines.

Some fear they must learn new skills.

This worry can slow down new technology use.

In 2025, most companies had too few workers.

Over half used machines for easy, repeated jobs.

Training helps workers feel better about automation.

Talking openly about changes helps teams adjust.

Companies that teach new skills see better results.

Workers who learn can keep up with changes.

Some workers do not like automation.

Training and talking help teams get used to it.

Not enough workers makes companies use more machines.

Integration Issues

Adding new machines to old systems is hard.

It costs a lot and some people do not want change.

Biggest problems are high cost and not enough skilled workers.

Working with other companies can be tough.

Small businesses have the hardest time with this.

They have less money and fewer people to help.

Companies also worry about keeping data safe.

They must follow rules and make sure tools work together.

These problems can slow down new automation.

New machines cost a lot.

Some people do not want to change.

Working with partners is sometimes hard.

Keeping data safe is a worry.

Skilled workers are needed.

Cybersecurity Risks

Automation brings new dangers to computer safety.

Machines can be attacked or stop working.

In 2025, experts found many weak spots in systems.

Companies use strong safety steps to protect data.

They back up data and train workers often.

Quick plans help fix problems fast.

They check for strange devices and update software.

Good safety keeps the supply chain working well.

Training and strong tools keep data safe.

Acting fast helps stop big problems.

Trends in Global Supply Chains

Regional Adoption

The logistics automation market grows at different speeds in each area.

North America is the leader with 36.8% of the market.

This is because they spend a lot on AI and robots.

Online shopping is also very popular there.

Europe wants to be more efficient and protect the environment.

Many companies use new technology called Industry 4.0.

Asia Pacific is growing fast with online shopping and drones.

They also use tools to track things better.

The Middle East and Africa have more people shopping online now.

They are building smart cities with new technology.

Latin America is changing by using more digital tools.

They are also improving roads and buildings.

Region | Market Share / Value & Drivers |

|---|---|

North America | 36.8% market share; USD 12.92 billion; investments in AI, robotics, e-commerce growth |

Europe | Emphasis on efficiency and sustainability; adoption of Industry 4.0 and digital transformation |

Asia Pacific | Rapid e-commerce expansion; investments in drones and asset tracking |

Middle East & Africa | Growth due to e-commerce surge and smart city projects |

Latin America | Growth through digital transformation and infrastructure investments; USD 2,129.2 million market value in 2023 |

Industry Solutions by JUSDA

JUSDA helps many types of businesses with automation.

For electronics, JusLink tracks items and predicts needs.

This helps companies handle hard supply chains.

Car companies use JUSDA for smart warehouses and delivery plans.

This saves money and makes deliveries faster.

In healthcare, JUSDA uses sensors to keep goods safe.

Cloud tools help watch shipments all the time.

These special services help clients keep up with changes.

JUSDA helps businesses use new tech and meet customer needs.

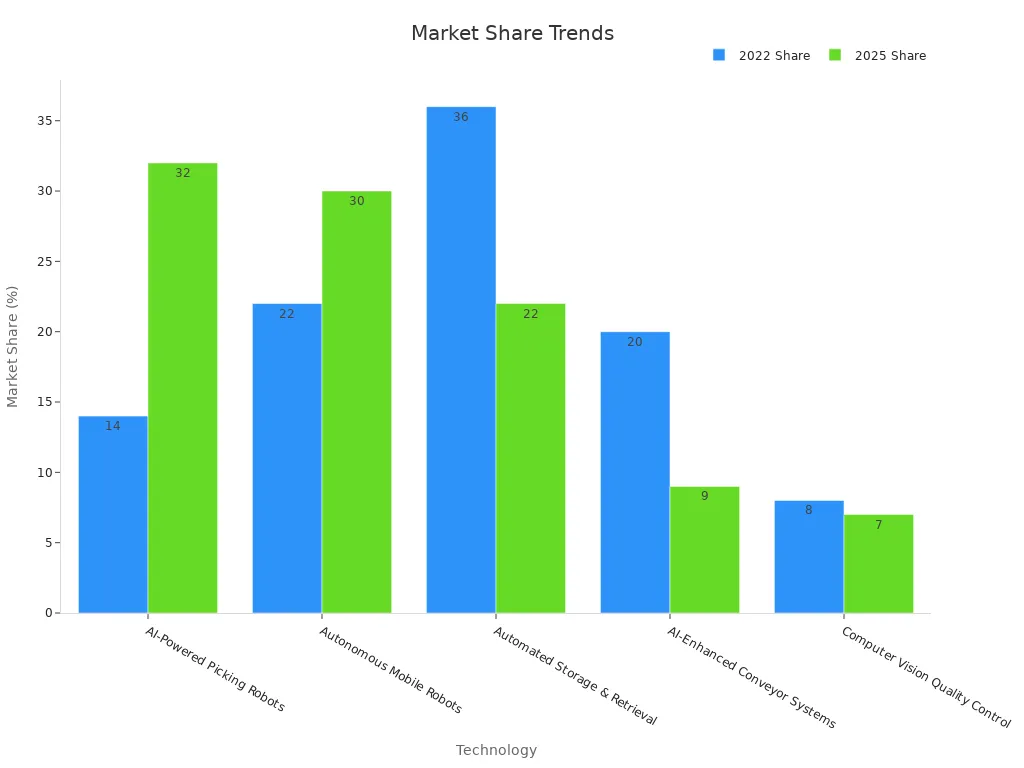

Future Outlook

Supply chains will get smarter and more connected soon.

Robots that pick items will be used even more.

Their share will grow from 14% to 32% by 2025.

Self-driving robots will also become more common.

By 2030, over half of supply planning will use AI.

This will make planning almost perfect.

Companies will fix problems faster and earn more money.

Logistics automation in 2025 has changed supply chains a lot.

It helps companies work faster and make fewer mistakes.

Supply chains are now stronger and can handle problems better.

Businesses should watch delivery times and how much things cost.

They should also check how their work affects the environment.

Using new tools helps companies stay quick and grow bigger.

JUSDA shows how smart systems can help supply chains improve.

These changes help companies grow and do well for a long time.

JUSDA Solutions

To provide you with professional solutions and quotations.

See Also

Artificial Intelligence Transforming The Future Of Logistics

Cloud-Based Supply Chain Technologies Changing Industry Landscapes

Innovations In Supply Chains Driving Logistics Transformation

Top Five Trends Improving Supply Chain Efficiency Tomorrow

Supply Chain Management Revolutionized By Cloud Technologies