How Logistics Cooperation Is Evolving in 2025

Logistics cooperation in 2025 is changing because of digitization, AI, and working together worldwide. JUSDA leads new ideas by using real-time data and smart digital tools. Big changes include more teamwork, better supply chain visibility, and helping workers learn new skills. Companies that follow logistics trends for 2025 use digitization to work faster and stay ahead in a fast-changing logistics world.

Teamwork with many groups shapes logistics plans.

Digitization and AI help people see the supply chain better.

E-commerce growth and new rules affect how people work together.

Key Takeaways

Digital tools like AI and IoT help teams work faster. These tools also help teams see supply chains better.

Good teamwork and partnerships help companies handle risks. They also help companies change quickly when needed.

Green logistics practices save money and help the environment. They also help customers trust the company.

Logistics Trends 2025

Key Drivers

The logistics industry is changing fast in 2025. Three big trends shape logistics: digital transformation, regionalization, and sustainability. Companies use automation, artificial intelligence, and the Internet of Things to work better and faster. These new tools help logistics companies react quickly to changes in the market.

Many businesses move their supply chains closer to customers. Nearshoring and regional partnerships help lower risks and make deliveries faster. E-commerce keeps growing, so companies must deliver faster and more reliably. People want to see where their packages are, so logistics companies buy digital tools for better tracking.

Other important drivers are new rules and economic pressures. Companies must follow new trade policies and sustainability laws. They use AI-powered tools to help with customs and pricing. Cybersecurity and keeping good workers are still big challenges as logistics networks get more complex.

Note: Companies that adjust to these changes build strong and flexible supply chains. They can handle problems from global events or changes in trade.

Technology Impact

Technology is changing how logistics works in 2025. Automation and robotics make warehouse jobs easier, cut mistakes, and help workers do more. Artificial intelligence and machine learning help companies predict demand and plan better routes. These tools help companies make smart choices and work more efficiently.

The table below shows some important technologies in logistics for 2025:

Technology | Impact on Logistics Cooperation in 2025 |

|---|---|

Automation and Robotics | Make warehouses faster and more accurate, with fewer mistakes and lower costs. |

Artificial Intelligence (AI) | Help with demand forecasting, route planning, and risk management. |

Blockchain | Make things more open and safe, so partners trust each other. |

Internet of Things (IoT) | Give real-time tracking and inventory management for better teamwork. |

Show real-time simulations for better warehouse planning and maintenance. | |

Autonomous Vehicles and Drones | Make deliveries faster and safer, especially for last-mile delivery. |

Sustainability Initiatives | Support green logistics and circular economy ideas. |

E-commerce logistics gets better with these new tools. Companies use AI to guess what people will buy and plan delivery routes. IoT sensors and digital twins give real-time data, so teams can manage inventory and shipments better. Warehouse robots help with picking, which solves worker shortages and saves money.

Big logistics companies spend money on technology to stay ahead. For example, Maersk opened a new air freight gateway to connect better. UPS bought special logistics companies to offer more services. These examples show how technology and new ways of working help logistics grow.

Sustainability Focus

Sustainability is very important for logistics in 2025. Companies want greener supply chains and try to lower their carbon footprint. They use electric and alternative-fuel vehicles, renewable energy in warehouses, and AI to plan routes that use less fuel.

Sustainable logistics also means using cleaner ways to move goods. Many companies use trains and ships because they pollute less than trucks or planes. They buy electric vehicles for city deliveries and use packaging that can be recycled or breaks down easily. Companies like DHL, IKEA, and FedEx lead with zero-emission vehicles and green energy.

Tip: Tracking and reporting on sustainability helps companies see their progress and follow the rules.

Working together is important for green logistics. Businesses team up with suppliers, customers, and governments to share ideas and resources. They use carbon tracking software and blockchain to watch emissions and keep things open. These actions help the circular economy and help companies reach their green goals.

Focusing on sustainability brings many good things. Companies save money, look better to customers, and follow the rules. As e-commerce grows, more people want eco-friendly delivery. Green transportation and supply chain management will stay important for the future of logistics.

New Cooperation Models

4PL Partnerships

Fourth-party logistics (4PL) partnerships are very important in 2025. Companies trust 4PL providers to handle the whole supply chain. This includes getting products and delivering them to customers. These providers use smart technology like AI and digital twins. This helps them see and control everything better. The table below explains how 4PL partnerships have changed and what they offer:

Aspect of 4PL Evolution and Benefits | Description | Real-World Examples |

|---|---|---|

Strategic, Technology-Driven Partnerships | 4PLs use AI and digital tools to manage many 3PLs and make fulfillment better. | Unilever and DHL, Flexport, HP, Starbucks, Cisco |

Documented Benefits | Save money, work faster, help customers more, be flexible, and manage risks better. | HP, Starbucks, Cisco |

Sustainability Focus | Green logistics and carbon-neutral delivery are now normal. | Maersk, Walmart |

Future Trends | More AI, blockchain, and digital twins for quick changes and custom solutions. | Siemens, Zara |

Nearshoring

Nearshoring means moving production closer to customers. This change gives many good results:

Companies save up to 40% on labor and 30% on logistics.

Delivery is faster because products are nearby.

Supply chains are stronger and can change quickly.

Companies build better relationships with suppliers and markets.

E-commerce and car companies work better after nearshoring. They are up to 20% more efficient and spend 15% less money. There are problems like culture differences and rules. But companies fix these with local experts and technology.

Digital Platforms

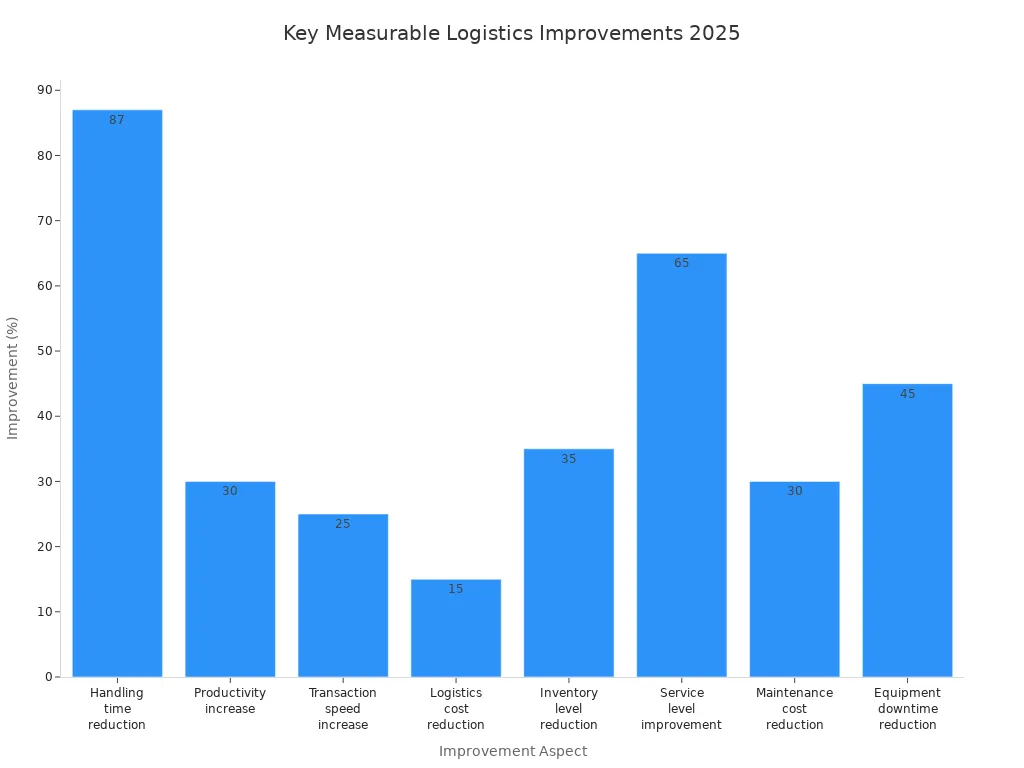

Digital platforms help partners work together in logistics. These platforms use AI, IoT, and automation to connect everyone. Sharing data in real time helps manage inventory and deliver faster. Companies spend 15% less on logistics and keep 35% less inventory. Service is 65% better, and deliveries are quicker. The chart below shows how digital platforms help logistics in 2025:

Companies that use these new models build stronger and greener logistics networks for the future.

Technology in Logistics Cooperation

AI and Automation

AI and automation are changing how people work together in logistics in 2025. Companies use AI to see what is happening in the supply chain right now. This helps teams make fast choices and follow new rules. AI-powered automation does simple jobs like handling orders and giving shipment updates. These tools help stop mistakes and make things move faster. Self-driving trucks help lower mistakes, keep people safe, and fix driver shortages. Many big companies now use AI control towers and chatbots to help with daily work. JUSDA’s JusAI platform uses smart analytics to make better guesses and manage inventory. Teams can spend more time helping customers while AI does the boring jobs.

AI looks at data from many partners so everyone can work together.

Predictive analytics help save money and make warehouses hold more goods.

Robots in warehouses pick and sort items faster.

By 2025, most choices in logistics use AI, making supply chains work better and stay strong.

IoT and Data Sharing

IoT and data sharing help people see more in logistics. Sensors, GPS trackers, and RFID tags collect real-time data from trucks, containers, and warehouses. AI uses this data to plan better delivery routes and watch shipments. JUSDA’s JusLink platform connects these devices and gives teams live updates and good delivery times. Real-time tracking helps companies change routes fast and tell customers what is happening. Smart fleet management with IoT uses less fuel and helps the environment. Warehouse managers use IoT data to make layouts and work steps better, saving time and money.

Cloud Warehousing

Cloud warehousing changes how companies handle inventory and share information. Cloud platforms break down data walls and use AI analytics to manage risks. JUSDA’s cloud warehousing gives real-time inventory checks and smooth data sharing. Teams can get information from anywhere, so logistics is more flexible. Blockchain and digital twins make things clear and help run warehouses better. Companies pay less, work faster, and have stronger supply chains. Better cybersecurity keeps important data safe on these platforms. As more things go digital, cloud warehousing is very important for good teamwork in logistics.

Supply Chain Trends

Risk Management

Companies deal with new risks in supply chains each year. In 2025, leaders care about risk management because of world events, rising prices, and not enough workers. Many supply chain workers say problems cost a lot of money. Changes in politics and tariffs make things unsure, especially in Asia-Pacific and China. To handle these risks, companies use different plans:

Strategy | Description |

|---|---|

Get supplies from many countries to avoid too much risk. | |

Building Strong Relationships | Work closely with suppliers to fix problems together. |

Insurance and Financial Tools | Use insurance and other tools to protect shipments and control costs. |

Leveraging Technology | Use digital platforms to see what is happening and manage work better. |

Monitoring Geopolitical Risks | Watch world events to change plans quickly if needed. |

Companies also teach workers to find risks and talk openly. They use AI-powered platforms to see how suppliers are doing right now. These steps help make supply chains safer and stronger.

Resilience Building

Making supply chains strong is a big trend in 2025. Companies spend money on digital tools, smart machines, and working together online. They map out their suppliers and use real-time data to spot risks early. Risk plans with alerts and backup ideas help them act fast in a crisis. Good supplier relationships and planning together help teams work better. Many companies keep extra stock of important items and use smart tools to guess problems. They also teach workers about data and technology. These actions help companies change quickly and do better than others.

Tip: Companies that are both strong and efficient get more customers and handle problems better.

Cybersecurity

Cybersecurity is the biggest worry for supply chain leaders in 2025. Recent attacks on shipping and transport show how bad these threats are. Companies use strong security like zero-trust systems, new firewalls, and protection for devices. Training workers all the time helps stop mistakes, which are a big risk. Real-time threat checks and fast response systems help fight cyber threats quickly. Logistics companies use strict rules with partners, like regular checks and safe data sharing. Experts say to keep training everyone and practice what to do in an attack. Using many layers of defense and working together helps companies stay safe from new threats.

JUSDA Warehouse Solutions

Global Network

JUSDA has warehouses in more than 15 countries. The company is in North America, Europe, and Asia. In the United States and Mexico, JUSDA helps with Vendor Managed Inventory (VMI) and consolidation centers. These places help companies move goods fast and safely. In Vietnam, JUSDA manages over 20,000 SKUs in special warehouses. These warehouses connect air and sea transport. In India, JUSDA supports electronics with smart storage and delivery systems. JUSDA Vietnam has the highest TAPA Class “A” certification. This means their warehouses are very safe and reliable. JUSDA uses local knowledge and global reach to make logistics work for each market.

Real-Time Tracking

JUSDA uses smart technology for real-time tracking. The JusLink platform uses AI and IoT to give instant updates. Sensors and GPS devices watch shipments and vehicles all the time. Teams get quick information about where things are and their condition. This helps companies make fast choices and work better. Real-time inventory systems show stock levels right away. This cuts down on mistakes and delays. The platform helps suppliers, makers, and customers work together. This makes the supply chain run smoother.

Value-Added Services

JUSDA gives many extra services to help different industries. These services include customs clearance, compliance management, and real-time tracking for shipments across borders. The company works in important places like Taoyuan International Airport Free Trade Zone. This helps electronics, medical products, and bicycle assembly. JUSDA’s services help companies grow and make trading easier. By joining process operations with air transport, JUSDA makes logistics faster. They also help with high-value products and after-sales services.

Adapting to Logistics Trends for 2025

Building Partnerships

Good partnerships help logistics work well. Companies pick partners who have the right skills and good reputations. They set goals together, like delivering on time and saving money. Teams talk openly and share information to fix problems fast. They make sure their business values match for easy teamwork. Teams meet often to check how things are going and find ways to get better. Technology like Warehouse Management Systems and tracking helps everyone work faster. Long partnerships give better prices and service. Companies join forces to solve problems and come up with new ideas. This makes the supply chain stronger.

Pick partners with strong technology and clear plans.

Use shared goals to check delivery and order success.

Talk openly to solve problems quickly.

Match values for better teamwork.

Check progress often and change with new trends.

Investing in Tech

Logistics leaders buy robots, AI, and automation to work better. Higher transport costs and trade problems make companies change how they store and send goods. AI helps plan routes and save money while keeping service good. Warehouses use cloud systems for more choices. Automation helps teams react fast and manage risks. Companies save up to 30% on costs and 20% on fuel with smart route planning. New digital tools help companies ship faster and grow bigger. More online shopping means companies need smart tech for quick deliveries.

Technology Investment | Benefit |

|---|---|

Robotics & Automation | Faster order handling |

AI & Predictive Tools | Lower costs, better plans |

Cloud Warehousing | Flexible, bigger operations |

IoT & Real-Time Data | Better tracking |

Sustainable Practices

Green logistics helps make supply chains better for the future. Companies use less packaging and plan routes to lower pollution. Electric trucks and sending more goods together help cut down carbon. Teams use live data and AI to watch emissions and make fast choices. Working with green suppliers helps the planet and builds trust. Online stores offer eco-friendly delivery and packaging that can be recycled. These steps help companies follow rules and make customers happy. Green supply chains are very important as trends move toward helping the environment.

Tip: Watching emissions and using smart tools helps companies reach green goals and deliver better.

JUSDA Solutions

To provide you with professional solutions and quotations.

Logistics cooperation in 2025 is changing with more digital tools and teamwork. The logistics industry uses AI, IoT, and automation for quick data and strong systems. Companies should remember these main points:

Key Aspect | 2025 Takeaway |

|---|---|

Digital Transformation | AI and IoT help work faster and see things clearly |

Proactive Collaboration | Teams join up to handle risks and adjust quickly |

Green choices help companies grow for a long time |

JUSDA is a leader by using smart technology and green ideas. Companies need to check their plans, try new things, and make good partnerships to stay ahead.

See Also

Best Five Logistics Courses To Explore In 2024

How Artificial Intelligence Is Transforming Supply Chains

Exploring Cutting-Edge Logistics Technology Innovations Ahead