International logistics industry trends in 2025

The logistics industry in 2025 will change fast. This is because of digital transformation, automation, and global growth. Companies use new trends and ideas to work better and save money.

Technology/Metric | Statistic | Impact/Note |

|---|---|---|

Companies planning to adopt automated transportation technology | To digitize workflows and reduce mistakes | |

Inventory optimization improvement from AI | 35% | Better inventory management |

Companies planning to integrate IoT | Over 80% | Real-time tracking and less loss |

JUSDA is a leader in logistics. They use smart solutions and focus on new ideas.

Key Takeaways

Digital tools like AI, IoT, and blockchain help companies work faster. They also help reduce mistakes. These tools make deliveries more reliable.

Green logistics and alternative fuels help lower costs. They also cut down on pollution. This helps companies follow new rules. It also meets customer needs for eco-friendly shipping.

Strong supply chains use many suppliers. They use real-time tracking and local factories. This helps handle risks. It also helps deliver products quickly and safely.

Digital Innovation

Digital innovation is making big changes in logistics in 2025. Companies use new technology to work faster and save money. These tools help supply chains get smarter. JUSDA leads with JusLink AI and smart warehouse tools. AI, IoT, and blockchain help companies handle global work and react fast to changes.

AI-Powered Predictive Logistics

AI-powered predictive logistics changes how companies plan shipments. AI looks at lots of data to guess delays and find better routes. DHL uses AI to watch for risks and change routes before problems happen. This helps companies stop late deliveries and keep customers happy.

Route | AI Prediction | Actual Outcome | Result/Impact |

|---|---|---|---|

Mumbai to Heathrow | 3-hour delay at Doha due to customs backlog | 2.5-hour delay | Proactive rerouting enabled on-time arrival |

Chicago to Santiago | High-risk delay from ground crew shortage (union strike signals) | 9-hour delay | AI predicted delay missed by humans, client upset |

Tokyo to LA | 85% risk of delay at LAX due to post-holiday surge | Partial delay avoided | Split shipment and dual carriers used, 50% early, 50% on time |

These examples show how predictive logistics spots risks early. Companies can act fast to stop shipment delays. JUSDA’s JusLink AI helps clients guess demand, manage inventory, and watch risks in real time. This tech makes deliveries more reliable and saves money.

Blockchain and Transparency

Blockchain gives more trust and safety in supply chains. Companies use blockchain to record each step of a shipment. The record cannot be changed, so everyone trusts the info. Some companies use blockchain with IoT sensors to track shipments across borders. The system records data right away and stops tampering.

Deloitte-led projects show blockchain helps track biosamples and patient consent in clinical trials. This builds trust and makes tracking easier. New tech makes blockchain faster and safer for logistics. Permissioned blockchains let companies control who sees and changes data, keeping info safe. JUSDA uses blockchain to share data safely and help partners work together.

IoT and Real-Time Data

IoT connects devices and sensors to collect real-time data from shipments, warehouses, and vehicles. This data helps companies track goods, watch conditions, and fix problems fast. IoT brings many benefits:

Better process efficiency and less downtime

Improved operations and lower costs

Following rules and safer workers

New product features and business ideas

Studies show the Industrial IoT market will reach $1.69 trillion by 2030. Growth comes from predictive maintenance, automation, and supply chain management. JUSDA’s warehouse tools use IoT for real-time tracking and inventory updates. Clients always know where their goods are and can make better choices. Automation in warehouses makes picking and packing faster, cuts mistakes, and boosts productivity.

Note: Digital innovation in 2025 gives companies real-time views and connected data. This cuts waste from running out or having too much stock. Tech like AI, automation, and IoT help companies handle complex supply chains and make customers happier. Digitizing supply chains also helps with sustainability and long-term flexibility.

Sustainability Trends

Green Logistics Initiatives

Green logistics is growing quickly in 2025. Companies spend money on eco-friendly ideas to lower pollution and save money. The world’s green logistics market could reach $1.69 trillion. It is growing by about 9% each year. Many companies now use sustainable transportation. More electric delivery vehicles are on the road, up 35% in five years. Big companies like DHL spend over €1 billion each year on green technology. In China, companies use electric vehicles and warehouses powered by renewable energy. These actions help companies cut costs by up to 30%.

Statistic Description | Value / Percentage |

|---|---|

Projected global green logistics market size in 2025 | USD 1.69 trillion |

Compound Annual Growth Rate (2025-2034) | 9.06% |

Percentage of logistics companies investing in sustainable transportation | 70% |

Increase in electric delivery vehicle adoption over past 5 years | 35% |

Operational cost reduction reported by companies implementing green logistics | 20-30% |

Alternative Fuels

Alternative fuels help make logistics cleaner. Transportation uses the most alternative fuels, with over half the market. Light commercial vehicles use these fuels the most, with more than half the share. Electric vehicles turn 60-70% of energy into movement. This is much better than gasoline vehicles. Companies save money, about $400-$700 per vehicle each year. North America is growing fast because of government help and new technology.

Alternative fuel vehicles make less greenhouse gas.

Electric vehicles use energy better.

Using more of these vehicles could lower CO2 by 1.3 gigatons by 2030.

Regulatory Shifts

Governments now have stricter rules for carbon emissions. Logistics companies must watch and report their emissions closely. Many use AI and IoT to check and lower emissions right away. Carbon tracking is now part of freight bills and buying. Working with green-certified partners helps companies follow the new rules. These changes make sustainability very important in logistics.

Supply Chain Resilience

Diversification Strategies

Companies want to be strong against problems. They use diversification strategies to help. Many businesses now work with more suppliers. This stops them from depending on just one source. A survey says 77% of companies will add more suppliers in two years. This helps them handle risks from disasters or political changes. Apple uses suppliers in many countries to keep making products. Companies also check their suppliers often. They build good relationships with them. These actions help keep products in stores, even when there are problems.

Measurable Indicator | Description | Supporting Example(s) |

|---|---|---|

Revenue Maintenance & Customer Service | Companies keep making money and serving customers during problems. | Procter & Gamble kept products in stores during the pandemic and grew sales by 4%. |

Return on Resilience Investment (RoRI) | This shows if spending on diversification saves money during problems. | It is a way to measure if being ready for trouble is worth the cost. |

Market Share Stability or Gain | Companies keep or grow their share when others have trouble. | Procter & Gamble got more customers during hard times. |

Operational Efficiency Improvement | Companies get better at planning and filling orders. | Genpact and Terex worked together and filled 95% more orders and planned 80% faster. |

Nearshoring and Regionalization

Nearshoring and regionalization are getting more popular. Companies move factories closer to customers. This helps lower risks and makes deliveries faster. Many businesses worry about tariffs and higher costs in Asia. About 75% of small and medium businesses fear tariffs from China. Automation and AI help make things closer to home. These changes help companies fix problems quickly. They also keep supply chains working well.

Real-Time Visibility

Visibility is very important for supply chain strength. Companies use technology to see what is happening right now. Real-time data lets them track shipments and manage inventory. It also helps them fix problems fast. GPS, RFID, and IoT devices make this possible. UPS uses a system that saves miles and money. Studies show real-time visibility can cut costs by up to 30%. It can also make deliveries 50% better. Companies manage inventory better and make customers happier. Predictive analytics help them see problems before they happen.

E-Commerce and Last-Mile

Cross-Border Growth

Cross-border e-commerce is growing very fast in 2025. The global market will rise from $119.29 billion in 2024 to $463.68 billion by 2030. This means it will grow by about 25% each year. Asia-Pacific is the top region, making over 42% of all sales. Clothes are the most popular items people buy. Same-day delivery is getting more popular and growing the fastest. Companies like Maersk and SEKO are working in more places to help with more shipping. Shoppers want free delivery and clear customs rules. They also look at reviews and social media before buying. More than half of shoppers use Buy Now Pay Later.

Metric/Aspect | Data/Forecast |

|---|---|

Market size (2024) | USD 119.29 billion |

Market size (2030) | USD 463.68 billion |

CAGR (2024-2030) | 25.4% |

Asia-Pacific market share (2023) | Over 42% of global revenue |

Leading segment | Apparel segment with over 37% global revenue share |

Same-day delivery growth | Highest growth rate projected (2024-2030) |

Last-Mile Delivery Tech

New last-mile delivery tech helps companies work better and cleaner. Route optimization software, like UPS’s ORION, saves a lot of fuel. Electric trucks and vans cut greenhouse gas by up to 70%. Small warehouses and e-cargo bikes make deliveries faster and cleaner. AI and real-time tracking help drivers deliver on time almost always. Machine learning guesses what people will buy. This moves goods closer to buyers and cuts last-mile costs by up to 20%. These tools help with more B2C packages and tricky cross-border shipping.

AI-powered route planning can make deliveries up to 40% faster and save 20% on fuel. Flexible fleets and smart time slots help deliver more packages per mile and lower costs.

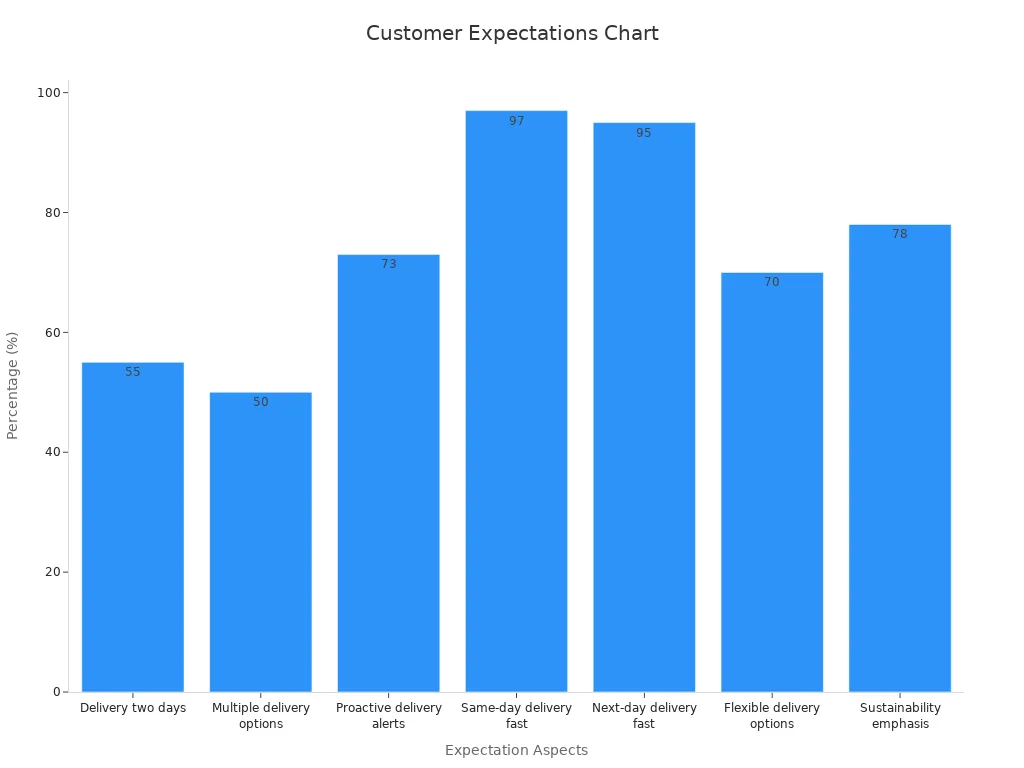

Customer Expectations

Customers want even faster shipping now. Most want their orders in two days or less. Over 70% want choices for delivery times. About 73% want updates about their deliveries. Almost everyone thinks same-day and next-day shipping are fast. Being eco-friendly is important to 78% of shoppers. Companies spend more money to meet these needs. They buy better tracking systems and use green methods.

Companies that meet these needs make customers happier and do better in the world market.

Warehousing and JUSDA Solutions

JUSDA runs warehouses all over the world. They use smart systems to change how logistics works. Their warehouse management uses Industry 4.0 technology. This makes things clearer, more reliable, and more efficient. Companies get big benefits from IoT, RFID, and robotics. These tools help track items, lower mistakes, and speed up orders.

Smart Warehouse Management

Smart warehouse management uses robots, self-driving vehicles, and real-time data. Companies like DHL use robots to make orders faster by 60%. GEODIS uses drones to check inventory in hours, not weeks. Most inventory mistakes happen because of people. Automation helps stop these errors and saves money. JUSDA’s systems help workers and support more automation. This makes supply chains around the world stronger.

Company | Technology Used | Efficiency Improvement |

|---|---|---|

DHL | Robots | |

GEODIS | Drones | Inventory-checking time cut to hours |

General | Automation |

Cloud Warehousing

Cloud warehousing helps logistics by giving real-time tracking. It also makes orders faster and saves money. The market for cloud logistics is growing quickly. Cloud systems help companies cut inventory by up to 30%. They also improve on-time delivery by 25%. JUSDA’s cloud warehousing works with IoT and AI. This gives clients better control and visibility. The technology helps businesses stay flexible and strong.

Value-Added Services

Value-added services help companies stand out in logistics. JUSDA offers picking, packing, labeling, and kitting. These services make inventory more accurate and picking orders better. They help raise perfect order rates and make orders faster. JUSDA also supports carbon-neutral warehousing. This helps clients reach their sustainability goals. By using robots and automation, JUSDA saves space and helps workers do more.

Geopolitical and Economic Shifts

Trade Policy Changes

Trade policy changes affect logistics in 2025. Companies deal with new tariffs and trade deals. They also face changing partnerships between countries. Geopolitical distance has grown by 10% in recent years. This makes trade drop by about 2%. Since 2018, friendly countries trade 6% more. Rival countries trade 4% less. Big events like the US-China tariff war and Russia’s invasion of Ukraine cause more trade rules. These events make companies change routes and warehouse plans. Companies buy new technology to follow rules and work better.

Aspect | Impact on Logistics Operations | Example / Detail |

|---|---|---|

Higher shipping costs and expenses | ||

Trade Wars | Rule changes, delays, and increased costs | 3PL pricing and operations disrupted |

Trade Agreements | Market access and compliance requirements | NAFTA/USMCA updated e-commerce and labor rules |

Customs Regulations | Border clearance speed and complexity | New rules can delay shipments |

Technology Adoption | Better compliance and efficiency | Real-time tracking reduces delays |

Emerging Markets

Emerging markets help global logistics grow fast. The international logistics area grows by 7.9% each year. Waterways transport grows by 7.5% yearly. This is because ports are better and greener. E-commerce logistics grows even faster at 8.2%. Online shopping and last-mile delivery make this happen. The global logistics market was $70.94 billion in 2023. It could reach $187.45 billion by 2032. Companies and governments spend money on digital tools and automation. They also invest in green logistics. These steps help meet demand and make work better.

E-commerce and electronics logistics grow the fastest.

Big companies open new warehouses in Mexico and North America for cross-border trade.

Governments help trade with new rules and better roads.

Customs Management

Customs management gets better with new technology. The World Customs Organization makes rules for sharing data and spotting risks. Customs offices use AI and data tools to find risks and clear goods faster. Blockchain, IoT, and robots help keep the supply chain safe and smooth. Programs like the WCO SAFE Framework support new tech and risk systems. These tools help customs move goods fast but keep borders safe. Training and learning are still very important for success.

Future of Logistics Workforce

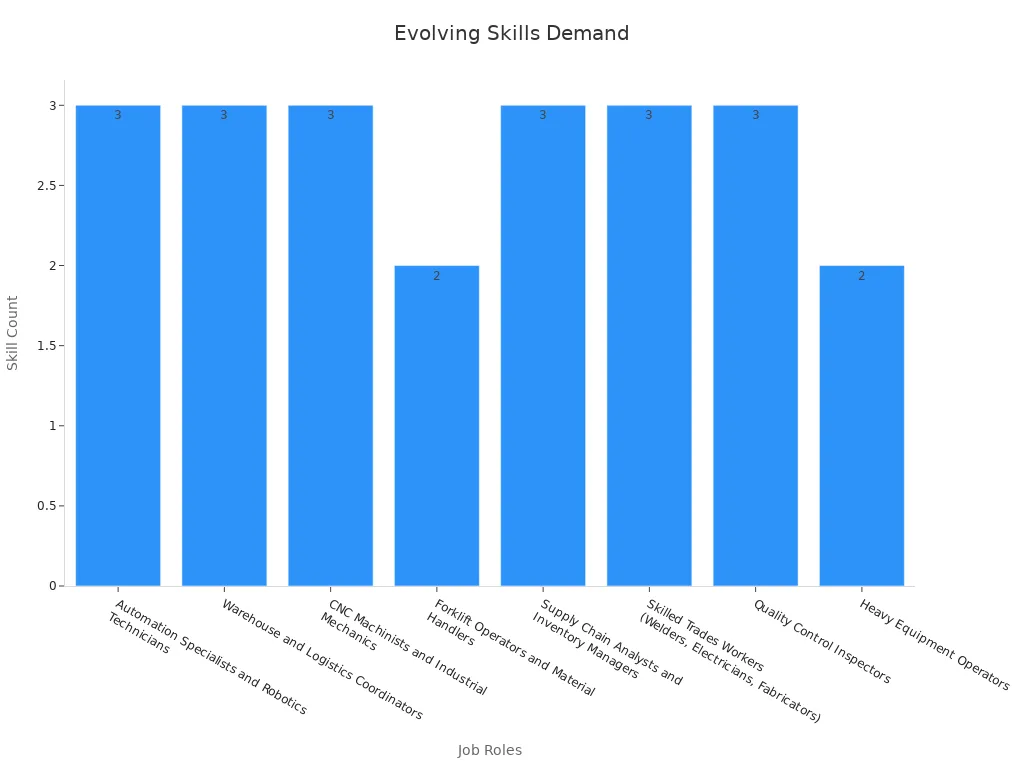

Skills Demand

In 2025, logistics workers will need new skills. Companies want people who know how to use technology. Many jobs now need skills in robotics, AI, and data analytics. The table below lists what is driving change, the jobs needed, and the skills for each:

Key Drivers | In-Demand Roles | Required Skills | Industries Hiring |

|---|---|---|---|

Automation and AI adoption | Automation Specialists, Robotics Tech | PLC programming, robotics, AI systems | Manufacturing, automotive, warehousing automation |

Supply chain resilience | Warehouse and Logistics Coordinators | Logistics planning, supply chain software, WMS | Retail, distribution centers, freight logistics |

Retiring workforce | CNC Machinists, Industrial Mechanics | Blueprint reading, CAD software | Aerospace, automotive, medical devices |

Higher production demands | Forklift Operators, Material Handlers | Forklift certification, warehouse safety | Warehousing, logistics, production plants |

- | Supply Chain Analysts, Inventory Managers | Data analytics, demand planning, ERP software | E-commerce, retail, logistics |

- | Skilled Trades Workers | Welding certifications, electrical knowledge | Construction, aerospace, industrial manufacturing |

- | Quality Control Inspectors | Regulatory compliance, attention to detail | Pharmaceuticals, automotive, precision manufacturing |

- | Heavy Equipment Operators | Equipment certification, safety procedures | Construction, energy, industrial development |

Companies also want workers who can learn new things. Many jobs now mix logistics and IT skills. Some new jobs are data scientists, green logistics managers, and last-mile delivery planners.

Automation Impact

Automation is changing jobs in logistics. Robots and AI now do many tasks people did before. This makes work faster and saves money. The table below shows how automation affects workers:

Metric / Statistic | Value / Impact |

|---|---|

Productivity increase within first year | |

Adoption surge of Automated Guided Vehicles (AGVs) | 47% increase in 2024 |

Reduction in order processing time | 32.6% decrease due to automated sortation |

Operational cost reduction | Average 28% across industries |

Labor costs as % of operational expenses | 50–70% in traditional logistics |

Growth rate of Autonomous Mobile Robots (AMRs) | 34% year-over-year |

E-commerce order volume growth | 5 times faster than traditional retail |

Increase in logistics costs due to labor shortages | Over 18% |

Percentage of logistics providers using AI | Approximately 62% |

Automation moves workers to better jobs. People now take care of machines and systems. There are fewer mistakes and orders get filled faster.

Remote Operations

Remote work is now normal in logistics. Many workers use cloud tools to manage supply chains from anywhere. Real-time data and IoT help teams track shipments and fix problems fast. Companies use video calls and dashboards to keep everyone in touch. This way of working is flexible and helps companies react quickly.

Tip: Keep learning and get new certificates to be ready for future logistics jobs.

JUSDA Solutions

To provide you with professional solutions and quotations.

The logistics industry will change a lot in 2025. Companies using digital tools and green ideas will be leaders. JUSDA helps businesses by giving them smart solutions. Leaders need to spend money on technology and think about the future to grow in logistics.

See Also

Top Five Trends Shaping Future Supply Chain Efficiency

How AI Is Transforming The Logistics Of Tomorrow

Latest Innovations In Sea Freight Logistics For 2024