Why Logistics Networks Matter for Modern Supply Chains

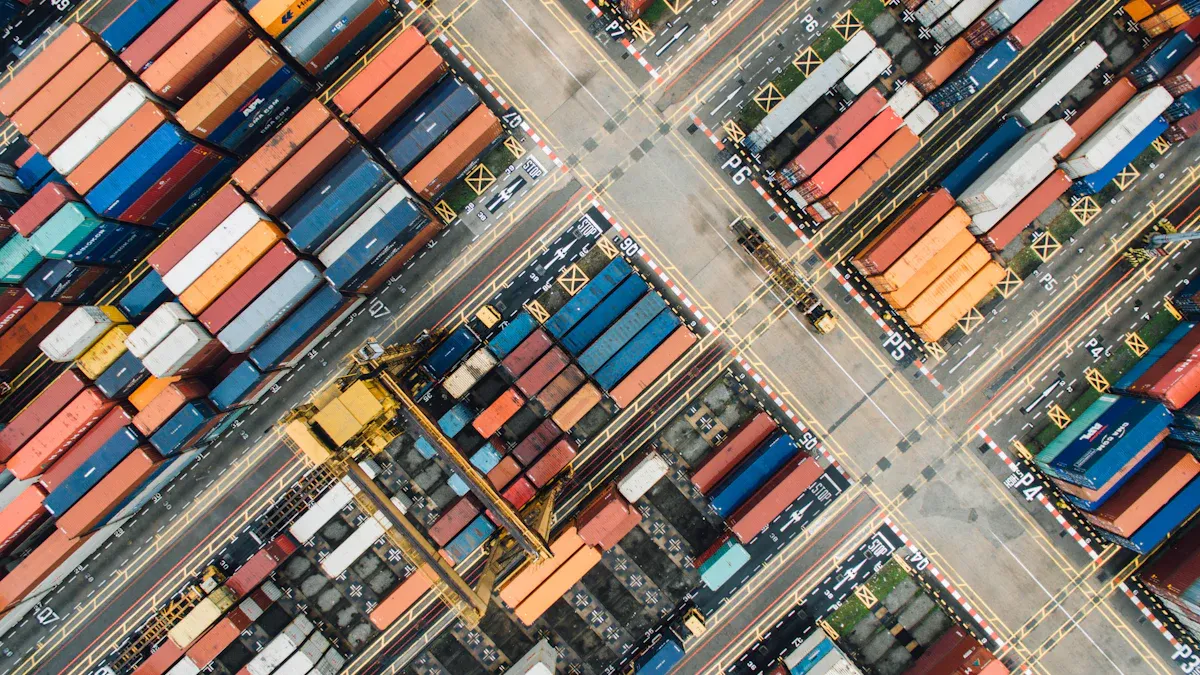

A strong logistics network is very important for supply chains today. Companies now use real-time visibility, new technology, and global network connections. These help make deliveries faster, work better, and keep customers happy. Modern supply chains use smart logistics to save money, stay strong, and manage everything better.

Key Takeaways

A strong logistics network links suppliers, warehouses, and customers. It helps move goods fast and in a reliable way. This helps companies save money. It also keeps customers happy.

Making a good logistics network needs smart planning. Companies use data and technology to plan well. They try to balance cost, speed, and service. They also change plans when needed and help the environment.

New digital tools and automation make supply chains easier to see. They help deliveries go faster and cut down on mistakes. These tools help companies react quickly to problems. They also help protect the environment.

Logistics Network Fundamentals

What Is a Logistics Network?

A logistics network is the main part of supply chains today. This system links suppliers, warehouses, and customers. All parts work together to move goods fast and well. Companies use these networks to control how products move from start to finish.

A logistics network has routes, storage places, inventory systems, and tech platforms.

It moves goods, checks inventory, and makes sure things arrive on time.

The network helps plan supply chains by cutting costs, making things faster, and helping companies handle changes.

New technology like AI and IoT makes logistics quicker and easier to see.

Good logistics help companies meet customer needs and stay ahead.

JUSDA is a top company in logistics network solutions. The company runs many warehouses and service spots around the world. JUSDA uses new technology to link every part of the network. This makes supply chain management smarter and more trustworthy.

Core Functions in Supply Chain Planning

Supply chain planning needs many key jobs in the logistics network. These jobs help companies organize, watch, and deliver products.

Component/Process | Description |

|---|---|

Logistics Management | Controls how goods move, fills orders, tracks inventory, packs, and stores using systems like WMS. |

Picks the best delivery routes to save time and money. | |

Visibility and Tracking | Uses real-time tools like RFID and GPS to watch shipments. |

Last-Mile Delivery | Handles the last step from warehouse to customer, focusing on speed and accuracy. |

Inventory Management | Checks stock levels to stop shortages or too much stock. |

Value-Added Services | Gives extra help like labeling and special packaging. |

Space Optimization | Uses warehouse space well with smart storage ideas. |

Technology Integration | Uses robotics, IoT, and automation to make things faster and more correct. |

Safety and Compliance | Makes sure goods are handled safely and rules are followed. |

Includes guessing demand, planning production, and managing risks. |

A strong logistics network helps all these jobs. It keeps supply chains working well and customers happy.

Logistics Network Design and Efficiency

Logistics Network Design Principles

Logistics network design shows how companies move goods to customers. This helps control costs and keeps customers happy. Companies set goals to save money and give better service. They choose where warehouses go and how to move products. Good data helps leaders make smart choices. They look at different plans and pick the best one.

A good logistics network makes supply chains stronger and quicker. Companies watch their networks and change them when needed. They do this if demand changes or problems happen. Many companies also try to help the planet. They want to lower their carbon footprint and use fair practices. This helps the earth and makes customers trust them more.

Tip: Using data for logistics network design helps companies work better, save money, and serve customers well.

Principle / Aspect | Description |

|---|---|

Changes fast when demand or supply changes. | |

Resilience | Bounces back from problems and keeps working. |

Sustainability & ESG | Cuts carbon footprint and uses fair methods. |

Cost vs. Service Level Trade-off | Saves money but still gives good service and fast delivery. |

Contingency Planning | Gets ready for problems with backup plans and risk checks. |

These parts of logistics network design help companies send the right product to the right place, even when things get hard.

How to Design a Logistics Network

Designing a logistics network has many steps. Companies use different plans to make sure their supply chain works well. First, they set project goals. Teams collect data about how things work now and what customers want. They study their current logistics and look for ways to do better. Then, they make new plans using this data.

Strategic network design makes long-term plans for where to put buildings.

Tactical network design makes short-term choices like picking suppliers and transport.

Operational network design handles daily routes, inventory, and shipments.

Important things to think about are cost, demand, supplier trust, inventory, transport, risk, product plans, technology, rules, and helping the planet. Companies use smart tools like AI to test ideas and make good choices. This helps them balance cost, speed, and customer happiness.

Note: Avoiding mistakes is key. Bad planning, poor inventory, and old tech can cause high costs and slowdowns. Companies should use real-time tracking, new software, and clear talks to keep their logistics network strong.

Improve Efficiency with JUSDA Warehouse Solutions

JUSDA is a leader in logistics with its global warehouse network and digital tools like JusLink and eVMI. These tools help companies work faster and see everything in their supply chain. JUSDA’s warehouses use automation, IoT, and AI to track inventory right away. This tech cuts mistakes, speeds up orders, and helps deliver on time.

Mobile barcoding and automation make inventory almost perfect.

Real-time data lets companies see all their stock and where it moves.

Automation and smart picking make orders faster and more correct.

Cloud systems link warehouses everywhere, helping logistics network design and supply chain planning work together.

JUSDA’s solutions help companies spend less, deliver better, and be more flexible. Their Vendor Managed Inventory (VMI) lets suppliers and buyers share real-time data. This makes it easy to manage stock and stop shortages or too much inventory. Smart analytics and AI help match inventory to demand, cut waste, and support the planet.

Companies using JUSDA’s logistics network get faster service, happier customers, and lower costs. Their network covers important places worldwide, so products reach customers quickly and safely.

New tech like drones, AGVs, and IoT tracking make things even better. These tools help check inventory, need less labor, and support green practices. By using these tools, JUSDA helps companies work better and keep high service in a changing world.

Overcoming Modern Supply Chain Challenges

Globalization and Complexity

Modern supply chain networks cover many countries and continents. This makes things more complicated and harder to control. Companies must deal with customs, quality checks, and higher shipping costs. Problems like storms or political changes can slow deliveries and cost more money. Each country has its own rules and paperwork, which adds more challenges. To handle these problems, companies put warehouses near borders and use bonded carriers. They also pick the best shipping methods for their products. Good partnerships with logistics providers help lower risks and make deliveries more reliable. Flexible planning also helps companies deal with surprises.

Technology and Real-Time Visibility

Technology is now very important in supply chain management. Digital tools, AI, and tracking systems give instant updates on shipments and inventory. These tools help companies plan better and fix problems quickly. Real-time visibility lets companies see delays and change delivery plans fast. It also keeps customers updated about their orders. Platforms like JusLink and eVMI help companies work together and use AI to make logistics better. These tools make data easier to manage, cut costs, and keep customers happy.

Sustainable and Resilient Logistics Networks

Sustainability and resilience are key for supply chains today. Companies build networks that can handle problems and use green practices. They plan routes carefully, use different suppliers, and choose green transport to cut pollution. Risk management means mapping supply chains and getting ready for emergencies. Companies use smart tools to predict problems and act fast. JUSDA’s solutions help companies build flexible networks that deliver on time and protect the environment. The Sharp case shows how digital planning and good logistics can save money and make deliveries more reliable, even when big problems happen.

JUSDA Solutions

To provide you with professional solutions and quotations.

A modern supply chain needs a strong network to work well. Companies use smart warehouses and digital tools to do better. These tools help them work faster and keep customers happy. New data shows that digitalization, automation, and real-time tracking help companies change quickly. These trends make networks very important for strong supply chains.

See Also

The Importance Of Security In Modern Supply Chains

How Innovations Are Transforming The Logistics Industry

The Critical Role Of Supply Chains In Global Trade