Everything You Need to Know About Freight Forwarding and Warehousing

Freight forwarding moves goods across borders, while warehousing stores and manages inventory. These services drive global trade, with the market projected to reach USD 285.60 billion by 2030. JUSDA leads in logistics management, offering integrated Logistics solutions that support industries such as electronics, automotive, and FMCG.

Key Takeaways

Freight forwarding organizes and manages cargo movement across borders, handling documentation, customs, and tracking to ensure timely and safe delivery.

Warehousing stores and manages inventory with advanced technology, improving accuracy, speed, and security in cargo handling and distribution.

Integrating freight forwarding and warehousing boosts efficiency, cuts costs, and enhances supply chain visibility, helping businesses deliver better service and grow.

Freight Forwarding in Logistics

What Is Freight Forwarding?

Freight forwarding in logistics refers to the process of organizing and managing the movement of cargo from one location to another, often across international borders. Freight forwarding companies act as intermediaries between shippers and transportation providers, ensuring that cargo reaches its destination efficiently and safely. These companies handle documentation, customs clearance, and compliance with regulations, making the process seamless for businesses.

The history of freight forwarding in logistics stretches back to ancient trade routes like the Silk Road, where intermediaries managed the transport of goods such as spices and silk. Over time, the industry evolved through the Age of Exploration, the Industrial Revolution, and the introduction of containerization. Today, digital platforms, automation, and artificial intelligence have transformed freight logistics, enabling real-time tracking and predictive analytics for cargo movement.

Freight forwarding in logistics plays a vital role in global trade. It connects manufacturers, suppliers, and customers by coordinating the movement of cargo through various modes of transport, including air, sea, rail, and road. The freight logistics industry now manages about 80% of international trade shipments, highlighting its importance in the global economy.

Key Functions of Freight Forwarders

Freight forwarding companies perform several essential functions to ensure smooth cargo movement. These functions include:

Cargo Booking and Coordination: Freight forwarders arrange transportation for cargo, selecting the best routes and carriers based on cost, speed, and reliability.

Documentation and Customs Clearance: They prepare and manage all necessary documents, such as bills of lading, commercial invoices, and customs declarations, to ensure compliance with international regulations.

Cargo Consolidation: Freight forwarding in logistics often involves combining smaller shipments into larger loads to optimize space and reduce costs.

Insurance and Risk Management: Companies offer insurance options to protect cargo against loss or damage during transit.

Tracking and Visibility: Advanced tracking systems provide real-time updates on cargo location and status, improving transparency and customer satisfaction.

Warehousing and Distribution: Many freight forwarding companies offer storage and distribution services, ensuring cargo is stored safely and delivered on time.

To measure the effectiveness of these functions, the freight logistics industry relies on key performance indicators (KPIs). The table below highlights some of the most important KPIs used in freight forwarding in logistics:

KPI Name | Description | Importance |

|---|---|---|

On-Time Deliveries | Percentage of shipments delivered on or before the estimated arrival date, including DIFOT. | Measures reliability and punctuality in delivery schedules. |

Average Wait Time | Time taken to load cargo onto trucks, measured from truck arrival to departure. | Identifies delays and helps manage carrier charges. |

Order Accuracy | Ratio of orders delivered without damage or customs issues. | Indicates shipment integrity and reduces costly returns. |

Lead Conversion Time | Time taken to convert a sales lead into a confirmed order. | Reflects sales efficiency and employee productivity. |

Average Freight Cost per Tonne | Average shipping cost per tonne, varying by route and season. | Helps optimize cost-effective shipping routes. |

Ratio of Value Added Costs | Percentage of surcharges over the base freight rate. | Assists in understanding and minimizing additional costs. |

Average Margin | Average profit margin per customer over time. | Provides insight into overall business profitability. |

Quote Conversion Ratio | Rate at which quotes are accepted and converted into orders. | Improves quote process efficiency and sales conversion. |

Number of New Sales Leads | Total new sales leads in the pipeline. | Measures sales performance and growth potential. |

Shipment Quantum and Capacity Utilization | Percentage of container or truck space utilized during shipping. | Enhances shipping efficiency by reducing space wastage. |

Freight forwarding in logistics also uses operational KPIs such as dwell time, freight billing accuracy, redelivery rate, pick and pack cycle time, and fuel consumption. These indicators help companies optimize routes, reduce costs, and improve service quality. For example, a low return rate signals high customer satisfaction and efficient cargo handling.

JUSDA’s Freight Forwarding Services

JUSDA stands out among freight forwarding companies with its global network and advanced technology. The company offers comprehensive freight forwarding services that cover air, sea, rail, and road transport. JUSDA manages cargo movement for industries such as electronics, automotive, FMCG, and more, ensuring reliable and cost-effective solutions.

JUSDA’s freight forwarding in logistics leverages digital platforms like JusLink, which integrates IoT, cloud computing, and big data. This technology provides real-time visibility into cargo status, streamlines documentation, and enhances collaboration across the supply chain. JUSDA’s services include customs clearance, cargo consolidation, insurance, and end-to-end tracking, making it a trusted partner for businesses with complex logistics needs.

The freight logistics industry is experiencing rapid change. Artificial intelligence, machine learning, and automation are optimizing supply chains and streamlining operations. Customer service models now offer personalized, on-demand support through AI-powered chatbots and 24/7 communication. Blockchain technology is improving security, speeding up customs clearance, and reducing fraud risks. The digital freight forwarding market is projected to grow at a CAGR of 23.1%, reaching $22.92 billion by 2030.

JUSDA’s expertise in freight forwarding in logistics ensures high performance across key metrics. The company tracks on-time deliveries, order accuracy, and capacity utilization to maintain operational excellence. JUSDA’s freight forwarding services help clients reduce costs, improve delivery times, and achieve greater transparency in cargo movement.

Note: JUSDA’s global presence and investment in technology position it as a leader among freight forwarding companies. The company’s commitment to innovation and customer satisfaction drives continuous improvement in freight logistics.

Warehousing and Distribution

Warehousing and distribution play a central role in the movement of cargo across global supply chains. Companies rely on these solutions to store, manage, and move cargo efficiently from origin to destination. Effective warehousing and distribution ensure that cargo remains secure, accessible, and ready for timely delivery. This process supports industries such as electronics, automotive, and FMCG, where speed and accuracy are critical.

Types of Warehousing Solutions

Modern logistics offers a wide range of warehousing and distribution solutions. Companies select the best option based on their cargo type, volume, and delivery needs. The main types include:

General Warehousing: Stores a variety of cargo, from raw materials to finished goods. This solution suits businesses with diverse inventory.

Bonded Warehousing: Holds imported cargo before customs clearance. Companies use bonded warehouses to delay duty payments and manage international distribution.

Distribution Centers: Focus on rapid movement of cargo. These centers receive, sort, and ship cargo to retailers or end customers, supporting just-in-time delivery.

Finished Goods Storage: Keeps completed products ready for distribution. This solution helps companies respond quickly to market demand.

Clean Room Facilities: Store sensitive cargo, such as electronics or medical devices, in controlled environments.

Statistical data shows that the picking process in warehouses uses more than 60% of resources and accounts for 55% of operating costs. Optimizing these processes in warehousing and distribution leads to higher productivity and significant cost savings. Companies that invest in advanced solutions can handle cargo more efficiently and improve their overall supply chain performance.

JUSDA Warehouse Technology

JUSDA stands out in warehousing and distribution with its advanced technology and global network. The company operates over 2.5 million square meters of warehouse space across Asia, North America, and Europe. JUSDA’s facilities support a wide range of cargo, from electronics to automotive parts.

JUSDA uses intelligent warehouse management systems like eVMI and JusLink. These systems provide real-time tracking and control of cargo. Clients can monitor inventory, check cargo status, and manage orders from any location. The technology ensures transparency and accuracy in every step of warehousing and distribution.

A typical JUSDA warehouse features:

Feature | Description |

|---|---|

Real-Time Inventory | Tracks cargo movement and stock levels instantly. |

Automated Sorting | Uses machines to sort cargo quickly and reduce errors. |

Clean Room Standards | Maintains strict conditions for sensitive cargo, such as electronics. |

Multi-Location Network | Connects warehouses in China, Vietnam, the US, and more for global reach. |

Integrated Platforms | Links warehouse, transport, and customs data for seamless distribution. |

JUSDA’s technology-driven approach allows companies to optimize warehousing and distribution. The systems help reduce delays, prevent cargo loss, and support fast, accurate distribution to customers worldwide.

Value-Added Services

Value-added services enhance warehousing and distribution by offering more than basic storage. These services help companies manage cargo more efficiently and improve customer satisfaction. JUSDA provides a wide range of value-added services, including picking, packing, labeling, kitting, repacking, and software upgrades.

Value-added warehousing services save costs by outsourcing tasks like kitting, assembly, and packaging. Companies avoid hiring and training extra staff.

These services streamline operations, reduce bottlenecks, and enable faster order fulfillment. Cargo moves quickly from warehouse to distribution points.

Customer satisfaction rises with faster delivery, custom packaging, and efficient returns. Studies show a 27% higher delivery satisfaction rate with value-added services.

Leading companies use AI and machine learning to improve sorting, demand forecasting, and delivery route planning.

Performance measurement with KPIs such as on-time delivery, order accuracy, and customer satisfaction shows clear gains from value-added services.

IoT technology enables real-time tracking and inventory management, making value-added services even more effective.

Companies gain a competitive edge by offering unique services and building customer loyalty.

JUSDA’s value-added services support industries with complex cargo needs. The company’s multilingual staff and close ties with customs authorities ensure smooth distribution across borders. Clients benefit from tailored solutions that fit their specific warehousing and distribution requirements.

Tip: Companies that combine advanced technology with value-added services in warehousing and distribution can achieve faster, more reliable cargo movement and stand out in a competitive market.

Logistics Solutions Integration

Combining Freight Forwarding and Warehousing

Integrated logistics solutions bring freight forwarding in logistics and warehousing together to optimize the movement of cargo. Companies that combine these services see major gains in efficiency and cost savings. For example, package consolidation can reduce shipping costs by up to 80%. This approach also improves inventory control and secure handling, which leads to better customer satisfaction. Businesses can track cargo from arrival at the warehouse to final distribution, ensuring every step is visible and controlled.

Metric Name | Definition | Significance |

|---|---|---|

Percentage of inventory items accurately recorded vs. actual physical count | Reduces stockouts and overstock situations | |

Order Picking Accuracy | Percentage of orders picked without errors | Enhances fulfillment efficiency and customer satisfaction |

Perfect Order Rate | Percentage of orders fulfilled without any errors | Boosts customer trust and minimizes costs from order discrepancies |

Order Cycle Time | Time taken from order placement to fulfillment | Helps meet delivery commitments and identifies bottlenecks |

Inbound Throughput | Rate at which warehouse processes incoming cargo | Supports smooth warehouse operations and timely inventory availability |

JUSDA’s JusLink Platform

JUSDA’s JusLink platform transforms logistics solutions by providing real-time updates and predictive analytics. This technology reduces communication costs and helps companies resolve issues before they disrupt cargo movement. JusLink integrates main and value-added services, allowing for customized distribution and freight forwarding in logistics. In a recent case, JusLink improved supply chain accuracy by 78% and increased inventory turnover for a global industrial company. These results show how digital platforms can enhance operational efficiency and precision in distribution.

Industry-Specific Solutions

Different industries require tailored logistics solutions to manage cargo and distribution. Key metrics validate the benefits of integrated services:

On-Time Delivery Rate ensures cargo reaches customers as scheduled.

Order Accuracy Rate tracks correct fulfillment, reducing returns.

Supplier Reliability avoids disruptions in distribution.

Cost Control identifies savings in transportation, warehousing, and inventory.

Inventory Accuracy provides real-time stock visibility.

Resource Optimization measures efficient use of assets and labor.

Industries like healthcare, e-commerce, and manufacturing rely on these metrics to ensure smooth cargo flow and effective distribution. Automation and real-time tracking further boost warehouse efficiency and support uninterrupted supply chain operations.

Benefits of Freight Forwarding Services

Cost Efficiency

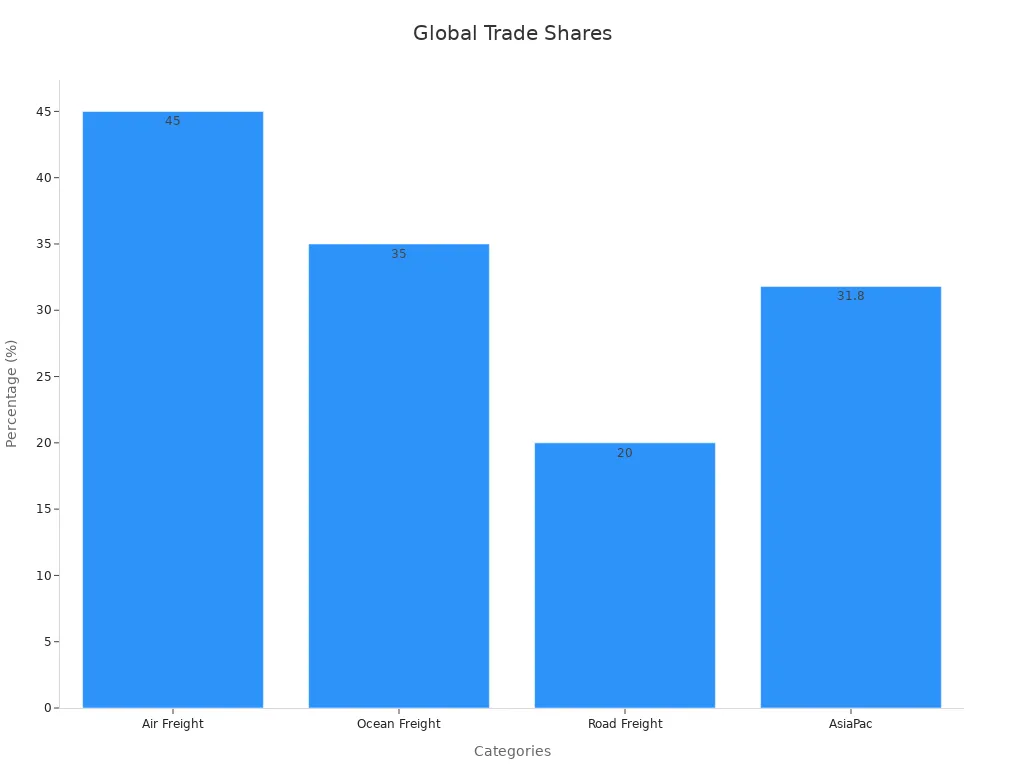

Freight forwarding services help companies control costs in freight logistics. Recent data shows a 45% growth in shipment brokerage and a 25% increase in rates for truckload and specialized transportation. These rising expenses make cost management essential. Businesses use contract freight pricing to lock in stable rates, which shields them from market swings. Freight forwarders negotiate carrier contracts based on shipment volume and delivery routes. They consolidate cargo to maximize truck or container space, reducing empty miles and saving money. Efficient strategies also lower demurrage charges and streamline invoice management. These actions improve profit margins and make supply chains more efficient.

Speed and Flexibility

Speed and flexibility matter in modern distribution. Studies show that 96% of consumers value delivery speed, and 80% want same-day shipping. Freight forwarding services use technology to track cargo in real time and optimize transportation routes. Automated carrier matching and AI-powered inventory management reduce delays. These tools help companies respond quickly to changes in demand or disruptions. Flexible distribution networks allow businesses to move cargo between warehouses and customers with ease. Customer testimonials highlight the importance of quick responses and personalized service in freight logistics.

Security and Transparency

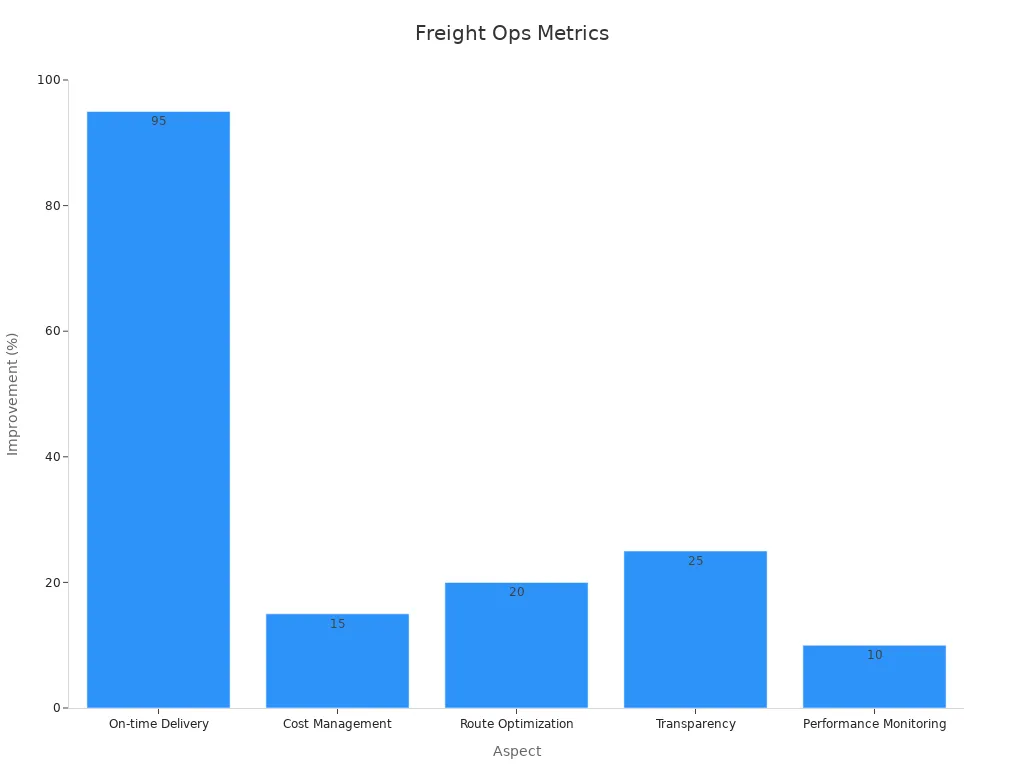

Security and transparency remain top priorities in cargo movement and distribution. Companies use GPS tracking, tamper-proof seals, and 24/7 monitoring to protect cargo. Real-time dashboards and cloud-based platforms provide visibility across the supply chain. Performance metrics such as on-time delivery, cost management, and route optimization help companies measure improvements. For example, delivery accuracy rates above 95% boost customer satisfaction. The chart below shows how these metrics drive better outcomes in freight logistics and distribution.

Case Study: Sharp and JUSDA

Challenges Faced

Sharp, a global leader in household appliances, encountered major obstacles in its supply chain. The company struggled with slow order processing and inefficient management of cargo from multiple suppliers. Sharp’s logistics team focused mainly on sales, which left gaps in procurement and production logistics. The company also faced difficulties in forecasting demand and managing inventory. These issues led to delays, higher costs, and reduced customer satisfaction. Sharp needed a solution that could handle complex cargo flows and improve overall efficiency.

Solution Implementation

JUSDA partnered with Sharp to transform its supply chain operations. The team established SHARP JUSDA LOGISTICS (SJL) as a joint venture. SJL introduced advanced supply chain services, including vendor-managed inventory and just-in-time delivery. The JusLink platform provided real-time visibility into cargo status and inventory levels. SJL integrated warehouse management and transportation systems, which allowed Sharp to track cargo at every stage. The team also automated data import and freight calculations, reducing manual work and errors.

Results and Impact

The partnership delivered impressive results. Sharp reduced logistics costs by 20% and labor costs by 70%. Order delivery times improved by 30%, and the accuracy of cargo shipments increased. The company achieved better inventory control and faster response to market changes. SJL’s approach enabled Sharp to expand its warehousing services and secure competitive transportation rates. The case demonstrates how integrated logistics solutions can optimize cargo movement and drive business growth.

JUSDA Solutions

To provide you with professional solutions and quotations.

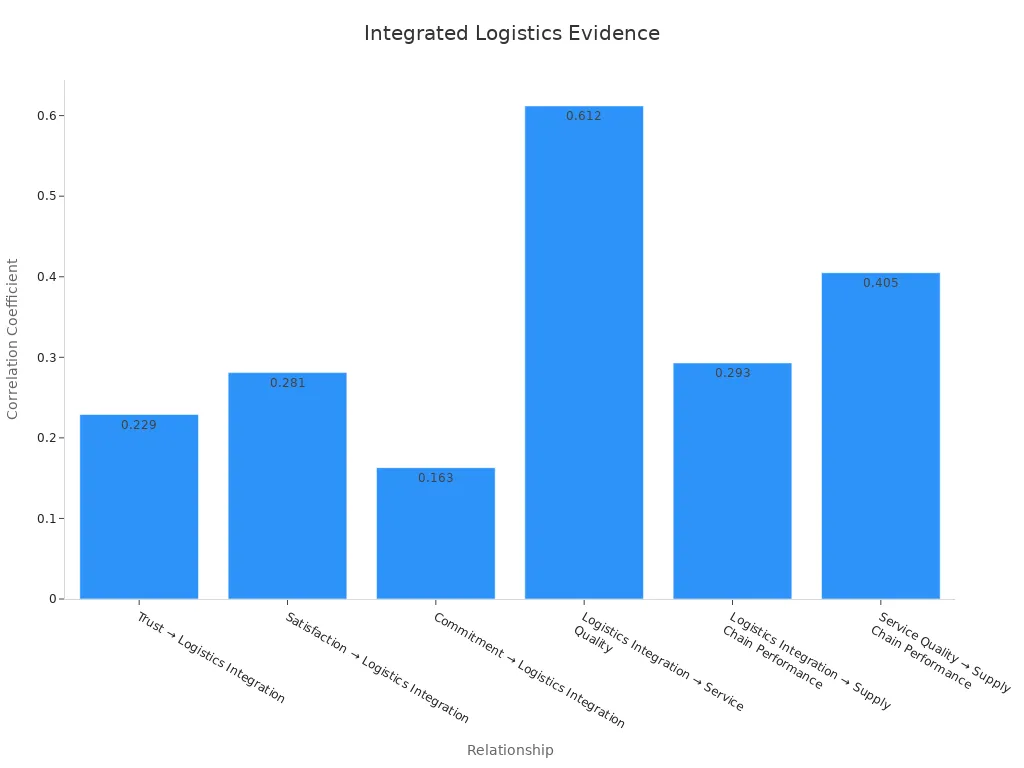

Integrated logistics solutions drive supply chain success. JUSDA’s expertise in freight forwarding and warehousing delivers efficiency and value. The table below highlights how logistics integration boosts service quality and performance.

Relationship | Correlation Coefficient | Significance Level |

|---|---|---|

Logistics Integration → Service Quality | p < 0.01 | |

Logistics Integration → Supply Chain Performance | 0.293 | p < 0.01 |

Explore JUSDA’s solutions to strengthen your supply chain. Visit JUSDA Global for more information.

See Also

Discover The Latest Trends In Sea Freight Logistics 2024

Top Reasons To Join Leading Logistics Webinars Today

How Digital Technology Is Shaping The Future Of Logistics