Effective Solutions for Logistics and Supply Chain Challenges in 2025

The logistics supply chain has more problems as industries grow worldwide. You need to solve these to stay ahead. For example:

The logistics field is growing fast. The US market may hit 1.62 trillion dollars by 2029.

More than 80% of warehouses do not use machines, causing delays in meeting needs.

Fixing these problems needs smart ideas and quick updates.

Key Takeaways

Logistics is growing fast, with the US market expected to hit $1.62 trillion by 2029. Companies need to change to stay ahead.

Using smart tools like AI and robots can cut mistakes and make supply chains work better. This saves businesses time and money.

Working closely with many suppliers makes supply chains stronger and more flexible. This helps companies deal with surprises or problems.

Key Challenges in Logistics Supply Chain

Economic Pressures and Rising Costs

Money problems are a big issue in logistics. Higher fuel prices, inflation, and changing interest rates raise costs. For example, inflation makes wages and materials more expensive. This makes it harder for companies to manage their money. Also, the US Total Capacity Utilization Rate shows more industrial work. This increases the need for logistics and raises costs.

Shipping costs and not enough drivers are other problems. These make it hard for companies to save money. Cross-border logistics is especially expensive. Businesses must spend wisely while keeping good service to compete globally.

Regulatory Changes and Compliance Issues

Following rules is another big problem in logistics. Governments are making stricter laws like GDPR in Europe and CCPA in California. These laws make companies handle data carefully and share their practices. Breaking these rules can lead to big fines, adding more costs.

New rules about being eco-friendly are also changing supply chains. Companies must follow these rules and deal with different customs policies. A study says 60% of supply chain leaders think the pandemic made following rules more important.

Regulation | What It Does | Effect on Logistics |

|---|---|---|

CCPA | Controls how California data is handled. | Companies must share data practices or face fines. |

GDPR | Protects data privacy in Europe. | Companies must follow rules for handling and sharing data. |

Technological Integration and Digital Transformation

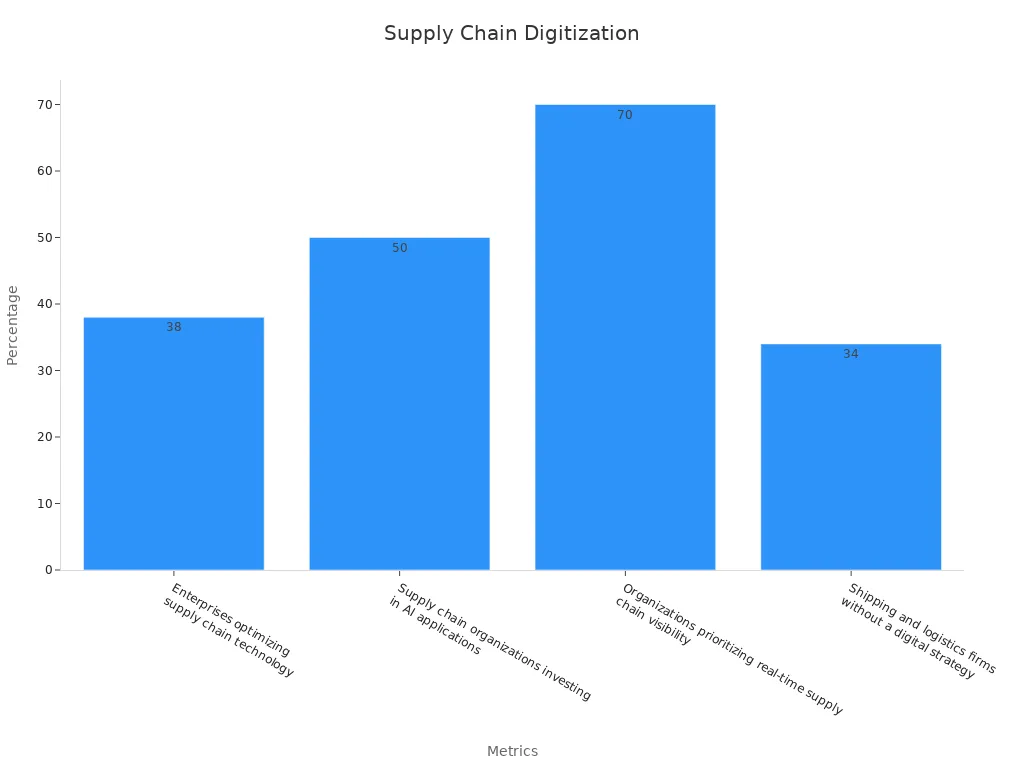

Using technology is key for modern logistics, but it’s hard for many. A report says 34% of shipping companies don’t have a tech plan. Another 38% are working on improving their tech. Real-time tracking is very important, with 70% of companies focusing on it.

Still, adding new tech to cross-border logistics is tricky. Companies need tools like AI and IoT to work better and faster. But the high cost and training needs slow things down.

Supply Chain Disruptions and Uncertainty

Global events like pandemics and political problems cause more disruptions. These show why strong supply chains are needed. A study says 60% of supply chain leaders now focus on being flexible to handle surprises.

Deloitte says supply chains need changes to deal with problems better. Companies should make their logistics networks flexible. This helps them keep working during tough times. It also makes cross-border supply chains smoother and reduces problems.

Actionable Solutions for Supply Chain Management

Using Advanced Technology and Automation

Automation and smart tools are changing supply chains. In 2023, most supply chain workers planned to use automation soon. Machines like Automated Guided Vehicles (AGVs) and case-picking systems are popular in consumer goods. By 2025, warehouse automation could be worth $69 billion. These tools save time, reduce mistakes, and let workers focus on important tasks. Adding IoT and AI helps track goods better and speeds up processes.

Improving Transportation and Logistics

Good transportation plans make supply chains work better. Just-in-Time (JIT) inventory saves storage space and uses resources wisely. Load planning software makes shipments safer and faster. Using energy-saving vehicles cuts costs and helps the environment. Grouping shipments and using TMS or WMS systems lowers expenses and boosts efficiency. Watching delivery times shows where to improve.

Strategy | What It Does |

|---|---|

Smart Inventory Management | Cuts storage costs and improves how goods are moved. |

Better Load Planning | Makes shipments safer and more efficient. |

Green Practices | Saves money and helps the planet. |

Tracking Performance | Finds ways to make better decisions. |

Strengthening Supply Chains with JUSDA

JUSDA uses IoT, cloud systems, and big data to stay strong. These tools give real-time updates on products and adjust to customer needs. JUSDA works in over 155 places worldwide. They offer custom solutions for industries like electronics. This helps companies make better choices and keeps supply chains strong.

Planning Demand and Managing Inventory

Guessing demand and managing stock are key for supply chains. Good planning helps sell items faster and avoids extra stock. Forecast accuracy KPIs match real demand with guesses, stopping shortages or too much stock. High turnover rates mean better sales and smarter management. This keeps supply chains quick and ready.

Evidence Type | What It Shows |

|---|---|

Faster Inventory Turnover | Frees up money by selling items quickly. |

Accurate Forecasts | Matches stock levels to real needs, avoiding problems. |

Adding Suppliers and Building Partnerships

Having more suppliers makes supply chains stronger. A study says 62% of companies became stronger by using suppliers from different countries. Working with many suppliers keeps things running during problems. Good partnerships build trust and help companies handle challenges faster.

Tip: Work with different suppliers to stay flexible and handle surprises.

The Role of Warehousing in Solving Logistics Problems

JUSDA's Warehouse Tools for Tracking Inventory in Real-Time

Warehouses are important for fixing logistics problems. Real-time tracking shows where your products are at all times. JUSDA uses tools like eVMI and JusLink to track items accurately. These tools prevent delays and cut down on mistakes. JUSDA has over 2.5 million square meters of warehouse space worldwide. They offer solutions that fit your specific needs.

Modern warehouses bring many benefits. Real-time tracking keeps operations fast and flexible. Automation reduces mistakes and lessens manual work. Cloud systems improve safety and allow easy scaling. Centralized document storage saves time and makes processes simple.

Benefit | What It Does |

|---|---|

Real-time tracking | Helps logistics stay quick and gives updated information. |

Automation | Cuts down on errors and frees workers for other tasks. |

Cloud systems | Makes operations safer, cheaper, and easier to grow. |

Better efficiency | Centralized documents save time and make finding info easier. |

Extra Services to Make Logistics Easier

JUSDA’s warehouses do more than store goods. They offer services like packing, labeling, and organizing items. These services save time and make work easier. For example, JUSDA’s cleanrooms meet strict rules to keep products safe. By improving processes, you can focus on growing your business.

Improving Visibility and Control with JusLink Technology

Seeing everything clearly is key in logistics. JUSDA’s JusLink technology gives full control of your supply chain. It uses IoT and big data to give real-time updates. You can track every step, from buying to delivery. This helps you make smart choices and solve problems fast. JusLink keeps your supply chain running smoothly and reliably.

Future Trends in Supply Chain Management

The Role of Artificial Intelligence and Machine Learning

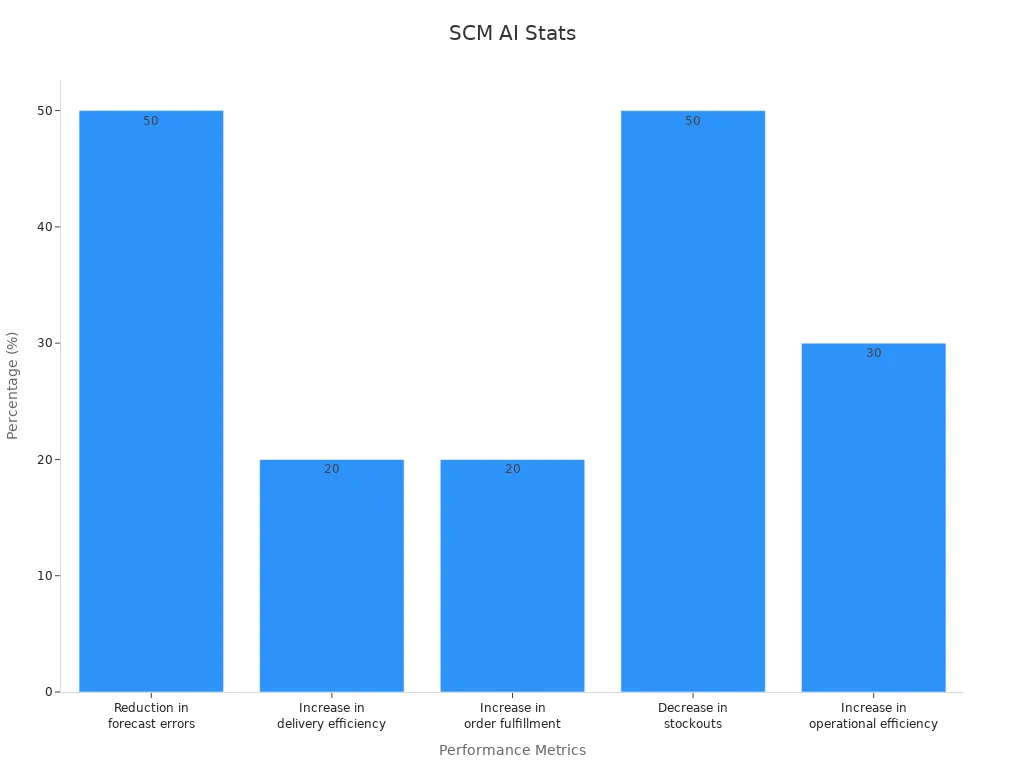

Artificial Intelligence (AI) and Machine Learning (ML) are changing supply chains. They make work faster and more accurate. These tools help guess demand, manage stock, and fix mistakes. For example, AI can cut guessing errors by half. This helps companies react quickly to market changes. Amazon improved delivery speed by 20% using AI. ML also lowers stock shortages by 50%, keeping customers happy.

Statistic Description | Value | Impact |

|---|---|---|

Reduction in forecast errors | 50% | Helps companies respond faster to market needs |

Increase in delivery efficiency | 20% | Speeds up shipping for companies like Amazon |

Decrease in stockouts | 50% | Makes customers happier and boosts sales |

AI also helps teams work better together. It gives live updates about supply chain activities. This keeps businesses competitive in a fast-changing world.

Sustainability and Green Supply Chain Practices

Being eco-friendly is now very important for supply chains. Green actions like cutting waste and saving energy make work better. Recycling and lowering harmful gases save money and help the planet. Quality checks also use fewer resources and improve products.

🌱 Tip: Green practices help the environment and save money too.

Adding eco-friendly ideas to supply chains solves problems like high costs and strict rules. It also helps businesses grow for the future.

The Impact of Blockchain on Transparency and Security

Blockchain is making supply chains safer and clearer. It tracks items at every step, stopping fake goods and fraud. For example, blockchain checks cryptocurrency deals and protects ideas with clear ownership records. It also helps follow rules by keeping safe and correct records.

Blockchain improves visibility and safety, making it great for global supply chains.

Preparing for Geopolitical and Economic Shifts

World events and money changes need strong planning. Trade problems and material shortages can slow supply chains. For example, in April 2024, getting materials took 79 days. This was 21% faster than before but still slower than in 2019.

Metric | Value (April 2024) | Change from Previous Period | Notes |

|---|---|---|---|

Average lead time of materials | 79 days | 21% reduction from peak | Still higher than 2019 average of 65 days. |

Proportion of manufacturers citing trade uncertainties | 36.8% | Increased from 25.8% in Q1 2024 | Reflects growing concerns over tariffs and geopolitical tensions. |

Supply chains must be flexible to handle these issues. Using more suppliers and smart tools can help businesses stay strong during tough times.

JUSDA Solutions

To provide you with professional solutions and quotations.

Solving supply chain problems is crucial for success. Businesses deal with high costs, disruptions, and strict rules. Using AI for inventory helps by cutting stockouts in half. Being eco-friendly is also important since supply chain emissions are 5-10 times higher than factory emissions. Invest in smart tools and strong systems. Work with JUSDA for custom and creative solutions to stay ahead.

Key Statistics:

Statistic

What It Means

Causes lost sales and high storage costs

20% boost in order completion with AI inventory tools

Shows how AI improves supply chain performance