Understanding the Difference Between Logistics and Supply Chain

Logistics supply chain management is about moving, storing, and delivering goods efficiently. The logistics supply chain encompasses the entire process, from sourcing to delivery. Understanding this difference helps you make better business choices.

Small changes in logistics supply chain operations can bring big benefits. The global logistics supply chain market might grow to $31 billion by 2026. This demonstrates how crucial these areas are for success.

Key Takeaways

Logistics is about moving, storing, and delivering goods quickly. It makes sure items arrive on time and in good shape.

Supply chain management handles everything from getting materials to delivering products. It links tasks like planning and making goods.

Better logistics can mean faster deliveries and saving money. Small fixes can make the whole supply chain work better.

Knowing how logistics and supply chain management differ helps businesses improve. It helps them make smarter choices and work better.

Both areas have many job options. Pick logistics for active work or supply chain for planning and strategy.

What Is Logistics Supply Chain?

Definition of Logistics

Logistics is about moving, storing, and delivering goods. It makes sure items get to the right place on time. This includes transportation, storage, and keeping track of inventory. For example, a company might use logistics to check shipments or organize warehouse stock. Good logistics management keeps things running smoothly and efficiently.

Definition of Supply Chain Management

Supply chain management handles a product's journey from start to finish. It links suppliers, factories, distributors, and stores. This involves planning, getting materials, making products, and delivering them. Tools like inventory checks and delivery times measure how well it works. For example, a business might use supply chain management to ensure materials arrive on time for production.

Standard | What It Does |

|---|---|

Improves quality and customer satisfaction. | |

ISO 27001 | Protects data and ensures security. |

ISO 27701 | Focuses on privacy and follows rules like GDPR. |

ISO 50001 | Saves energy and cuts costs. |

PAS 43 | Helps vehicle recovery services stay safe and efficient. |

PAS 2060 | Shows efforts to lower greenhouse gases. |

ISO 22301 | Prepares for and handles disruptions in business. |

How Logistics Fits Within the Supply Chain

Logistics is a part of the supply chain. The supply chain looks at the big picture, while logistics focuses on details. For instance, supply chain management plans where to get materials, and logistics moves and stores them. A study on warehouses showed better logistics cut order times by 15%. This proves logistics improves the whole supply chain.

Case Study | What Happened | Results | Key Numbers |

|---|---|---|---|

Warehouse Processing Optimization | A big center studied order times during shifts. | Cut order times by 15% and sped up work. | Lowered time differences and improved shift efficiency. |

Key Differences Between Logistics Management and Supply Chain Management

Scope and Focus

Logistics management is about moving, storing, and delivering goods. It ensures products arrive at the right place on time. Supply chain management, however, covers a bigger process. It manages everything from getting raw materials to delivering finished goods.

For example, logistics handles tasks like shipping and storage. Supply chain management organizes these tasks and also manages buying, production, and planning. The table below compares their focus and scope:

Aspect | Logistics Management | Supply Chain Management |

|---|---|---|

Scope | Internal tasks like shipping and storage. | All steps from sourcing to delivery. |

Functionality | Day-to-day tasks like inventory control. | Long-term planning across many teams. |

Objective | Fast delivery at low cost. | Adding value and staying competitive. |

Strategic vs. Operational Roles

Logistics focuses on daily operations. It works on short-term goals like meeting delivery deadlines. Supply chain management, on the other hand, focuses on long-term success. It improves the whole supply chain.

For instance, logistics ensures goods are shipped quickly. Supply chain management connects logistics with other areas like marketing and finance. Studies show using data for supply chain planning can boost efficiency by 25%.

Aspect | Logistics Role | Supply Chain Management Role |

|---|---|---|

Focus | Quick delivery of goods to customers. | Managing the full process from raw materials to products. |

Scope | Moving and storing goods within a company. | Includes planning, sourcing, and more. |

Objective | Delivering goods at low cost. | Gaining an edge through better operations. |

Interrelation Between Logistics and Supply Chain

Logistics is a key part of the supply chain. The supply chain looks at the overall process, while logistics handles specific tasks. For example, supply chain management decides where to get materials, and logistics ensures they arrive on time.

Using data can make logistics much better. A study showed that changing delivery schedules during busy times improved efficiency by 18%. This shows how logistics and supply chain management work together to succeed.

Tip: Combine logistics with your supply chain plan to improve teamwork and make processes smoother.

Examples of Logistics and Supply Chain Management

Real-World Examples of Logistics

Good logistics can make businesses work better. Companies like Zara and Walmart show this:

Zara: This clothing store delivers new styles to shops fast. It quickly adjusts to new fashion trends.

Walmart: Walmart uses data to manage warehouses. This helps it deliver items faster and keep stock organized.

Even small changes in logistics can help a lot. For example, cutting delivery time by 5% can make the supply chain 12% faster. Businesses also use tools like ANOVA to find problems and see how changes help.

Real-World Examples of Supply Chain Management

Supply chain management handles everything from raw materials to finished goods. Sunsweet Growers is a good example:

Problem: High costs from bad planning and too many warehouses.

Fix: Used better planning tools and improved demand predictions.

Results:

Forecasting got 15-20% better.

Overtime dropped from 25% to 8%.

Spoiled goods went down by 30%.

Warehouses reduced from 28 to 8.

KPIs (Key Performance Indicators) help check supply chain success. These include inventory turnover, on-time delivery, and costs compared to sales.

KPI | What It Tracks |

|---|---|

Inventory Turnover | How well stock is managed. |

On-Time Delivery | If products arrive when they should. |

Supply Chain Costs as % of Sales | Tracks costs compared to sales to find savings. |

Comparing Examples to Highlight Differences

Logistics handles tasks like shipping and storage. Supply chain management looks at the whole process. For example:

Logistics makes sure deliveries are on time.

Supply chain management plans materials, production, and delivery.

Here’s a comparison:

Logistics: Better delivery routes cut delivery times by 12%.

Supply Chain Management: Sunsweet Growers’ planning reduced spoiled goods by 30%.

Both areas work together. Logistics improves daily tasks, while supply chain management focuses on long-term success.

Why the Two Are Often Confused

Overlapping Functions and Terminology

Logistics and supply chain often seem the same. Logistics moves and stores goods. Supply chain management handles everything from materials to delivery. Logistics is a key part of the supply chain. This link makes them hard to separate.

For instance, logistics includes tasks like shipping and inventory checks. Supply chain management focuses on planning, buying, and predicting demand. A study shows many businesses mix up these roles because they depend on each other. This confusion can cause problems in how things run.

Aspect | Logistics Management | Supply Chain Management |

|---|---|---|

Scope | Tasks like shipping and storage. | |

Objective | Fast delivery at low cost. | Improving the whole supply chain for better results. |

Evolution of Supply Chain Management

Supply chain management has changed a lot over time. In the 1800s, trains made moving goods easier. By the 1940s, wars led to better shipping methods. The 1980s brought computers to help plan logistics. By the 2000s, logistics became a process, and supply chain management became about strategy.

These changes show how supply chain management grew to include logistics. Technology has made it easier to combine logistics with the supply chain. This has blurred the lines between them.

Misconceptions in Business Contexts

Some businesses confuse logistics with supply chain management. They think fixing logistics alone solves supply chain problems. But supply chain management needs more, like data and planning.

Confusion also comes from bad data or fear of change. To fix this, companies should use better data tools and train workers. Clear definitions and good communication can stop these mistakes.

Tip: Knowing the difference between logistics and supply chain management helps businesses work better and earn more.

Practical Advice for Career and Business Focus

Picking Logistics or Supply Chain Management Based on Goals

Think about your goals when choosing between logistics and supply chain management. If you like hands-on work like shipping, inventory, or managing warehouses, logistics might be a good fit. But if you enjoy planning, buying materials, and working with teams, supply chain management could be better for you.

Both fields are growing fast in industries like electronics and online shopping:

India’s electronics manufacturing may reach $300 billion by FY26.

India’s e-commerce market could grow to $120 billion in five years.

These careers also offer good salaries:

Global Logistics Manager: INR 7–11 LPA

Supply Chain Analyst: INR 6–9 LPA

Warehouse Manager: INR 8–10 LPA

Why Improving Logistics Helps

Better logistics can make businesses run smoother. For example, planning delivery routes well saves time and fuel. A study showed that better fuel use saved 10% yearly. Faster warehouse work also cut order times by 15%, helping businesses handle more orders.

Main benefits include:

Quicker deliveries, making customers happier.

Lower costs with smarter transport and stock management.

Fewer mistakes in handling inventory.

Case Study | Results | Key Metrics |

|---|---|---|

Route Planning | Regional route differences. | |

Stock Control | Lowered inventory costs. | Better F-statistic scores. |

Why Improving Supply Chain Management Helps

Good supply chain management boosts business success. It connects all steps, from getting materials to delivering products. Companies that improve supply chains often perform better. For example, cutting supply chain costs from 9% to 4% can double profits.

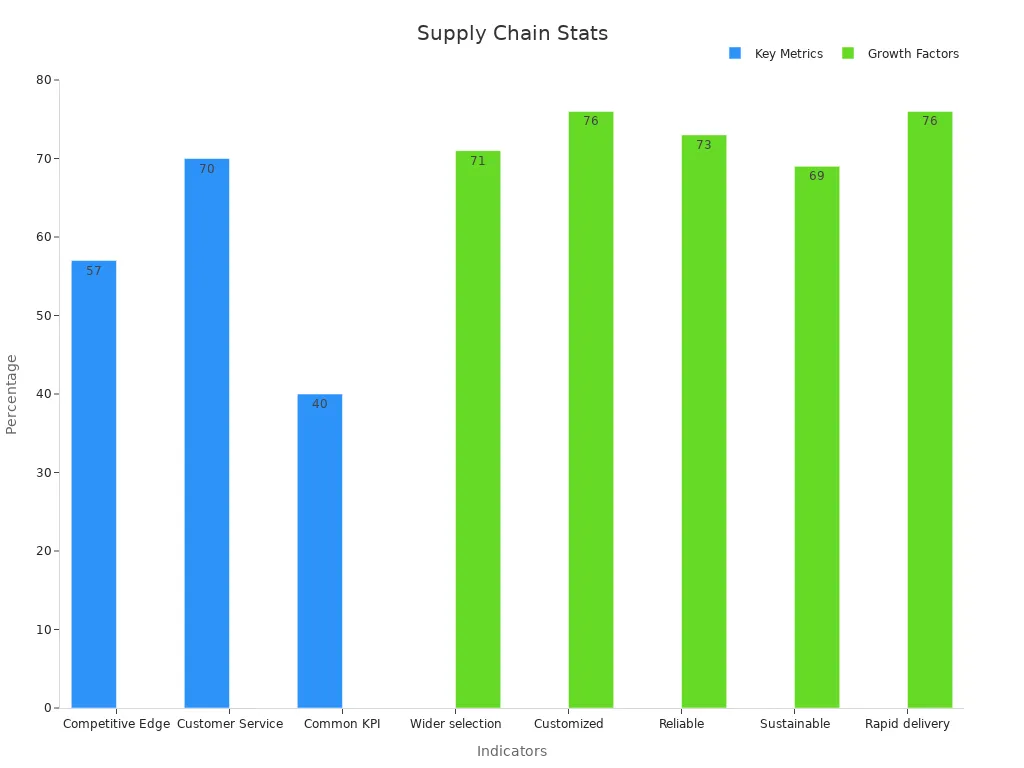

A strong supply chain also improves customer service. Research shows 70% of companies think supply chains are key to quality service. Growth factors include offering more products (71%) and faster delivery (76%).

Focusing on supply chain improvements can lead to:

Saving money and earning more profits.

Happier customers with faster, reliable deliveries.

A stronger and more competitive business.

Tip: Whether you choose logistics or supply chain management, keep learning and stay updated with industry trends to succeed.

JUSDA Solutions

To provide you with professional solutions and quotations.

Knowing how logistics and supply chain management differ is important. Logistics handles moving and storing goods quickly and safely. Supply chain management looks at the whole process, from getting materials to delivering products. The table below shows their differences:

Aspect | Logistics | Supply Chain Management |

|---|---|---|

Scope | Focuses on moving and storing goods well | Manages everything from sourcing to delivery |

Strategic Level | Plans daily transport and storage tasks | Makes big decisions about the supply network |

Timescales | Works on short-term goals | Plans for long-term success |

Value Creation | Saves money on transport and storage | Improves the whole process to add value |

Data Usage | Tracks delivery times and stock levels | Studies market trends and supplier performance |

Stakeholder Management | Manages transport and storage partnerships | Works with all partners in the supply chain |

Understanding these ideas helps businesses work better and grow. Whether you focus on logistics or the supply chain, this knowledge helps you succeed and make smart career moves.

See Also

Transforming Logistics Through Innovative Supply Chain Solutions

The Importance of Security in Modern Supply Chains

Understanding Cost Efficiency in Supply Chain Management