Understanding Logistics Technology and Its Emerging Trends

Logistics technology changes supply chains using smart tools for smooth work. It makes things faster and saves money. For example, Walmart spent $5 billion on cross-docking to lower inventory costs by 10%. Tools like AI help manage stock and predict needs, cutting mistakes by 50%. This leads to quicker deliveries and happier customers.

Key Takeaways

Logistics technology helps make supply chains faster and cheaper. Tools like AI lower mistakes by half, speeding up deliveries and making customers happier.

Transportation Management Systems (TMS) improve delivery by planning better routes and schedules. TMS saves money and makes customers happy with on-time deliveries.

Warehouse Management Systems (WMS) track inventory live, cutting mistakes and speeding up orders. Using tools like JUSDA can save a lot of money for businesses.

Core Parts of Logistics Technology in Supply Chain Management

Transportation Management Systems (TMS)

Transportation Management Systems (TMS) are important for moving goods. They help plan, manage, and improve transportation. TMS makes delivery smoother, saves money, and boosts performance. For example, TMS uses tools like KPIs and scorecards to pick good transport partners. It also helps with better schedules and routes, cutting costs and speeding up deliveries.

TMS improves customer happiness by managing delivery times and carrier work. With clear dashboards, you can use data to make smart choices. The table below shows how TMS helps save money and work better:

Evidence Type | Description |

|---|---|

Performance Metrics (KPIs) | Uses KPIs and scorecards to choose reliable transport partners. |

Dynamic Scheduling | Saves money by improving schedules. |

Efficient Route Planning | Cuts costs by finding the best delivery routes. |

Coordinated Delivery Windows | Helps lower costs and improve customer service with better timing. |

Improved Carrier Performance | Makes carriers more reliable and reduces late delivery fines. |

Increased Customer Satisfaction | On-time deliveries make customers happier and loyal. |

Data-Driven Decisions | Dashboards help make better decisions using data. |

Using TMS can save money and make logistics work better.

Warehouse Management Systems (WMS) and JUSDA's Warehouse Solutions

Warehouse Management Systems (WMS) help track inventory and run warehouses better. They show real-time stock levels, reducing mistakes. WMS also makes picking, packing, and shipping faster, meeting customer needs.

JUSDA improves WMS with advanced warehouse solutions. With over 2.5 million square meters of space, JUSDA serves industries like electronics and cars. Their warehouses include bonded areas, clean rooms, and distribution centers. JUSDA’s eVMI and JusLink systems track inventory live, giving full control of stock.

JUSDA also offers extra services like labeling and repacking. For example, their Vietnam warehouses cover 110,000 square meters and handle tasks like software updates. These features make JUSDA a great partner for improving logistics.

The table below shows how WMS boosts supply chain performance:

Metric | |

|---|---|

Reduction in Delivery Failures | 10-20% |

Enhanced Inventory Accuracy | Up to 25% |

Operational Cost Savings | 8-15% annually |

Using JUSDA’s solutions can help you save money and stay ahead in your field.

Supply Chain Visibility Tools

Supply chain visibility tools let you track goods in real time. They make the supply chain clear, so problems can be fixed early. For example, RFID and live tracking improve asset use and cut losses.

Companies like GAP and Scottish Courage use these tools to do better. GAP increased shelf availability and sales by 12% with RFID. Scottish Courage cut keg losses by 50% and saved four days on container cycles. The table below shows these results:

Company | Technology Used | Benefit Achieved |

|---|---|---|

Scottish Courage | RFID | Cut keg losses by 50% and saved 4 days on cycles. |

GAP, Inc. | RFID | Improved shelf stock and boosted sales by 12%. |

General Insight | Real-time monitoring | Better asset use and customer service at lower costs. |

Using visibility tools can save money, improve work, and make customers happy. These tools are key for modern logistics.

Emerging Trends in Logistics Technology

Connected Logistics and Real-Time Collaboration

Connected logistics changes how supply chains work. It helps suppliers, carriers, and customers work together better. Communication tools make operations faster and smoother. For example, tracking systems show shipment locations and fix delays quickly. This improves delivery and makes customers happy.

Connected logistics has clear benefits. Better teamwork leads to improved results. Advanced tools give more visibility for smoother operations. The table below shows how connected logistics helps:

Evidence Type | Description |

|---|---|

Collaboration | Working together improves results and reduces risks. |

Communication | Clear communication helps quick decisions and better responses. |

Visibility | Real-time tracking makes supply chains more efficient. |

Using connected logistics means faster deliveries, lower costs, and happier customers.

Automation and Robotics in Logistics Operations

Automation is now a must in logistics. High costs and fewer workers make robotics important. Robots and systems speed up order tracking and delivery. They also reduce mistakes and improve efficiency. For example, robots in e-commerce speed up order processing by 30%.

Robots also save space and time. A car parts company cut retrieval times from 30 minutes to 5 minutes using storage robots. The table below shows how automation improves logistics:

Case Study Description | Efficiency Gain | Metrics Improved |

|---|---|---|

E-commerce company using AI-driven robots | 30% faster order processing | Order speed |

Automotive parts manufacturer with AS/RS | 40% better space use | Retrieval time |

Logistics provider using IoT | 20% less downtime | Equipment monitoring |

Automation helps manage inventory and ensures deliveries are on time.

Artificial Intelligence and Machine Learning (AI/ML) for Enhanced Decision-Making

AI and machine learning are changing supply chain management. These tools use data to make smarter decisions. For example, AI predicts demand better, avoiding too much or too little stock. Companies using AI in supply chains grow faster and earn more than others.

AI also helps manage inventory. It lowers costs and keeps stock levels accurate. The table below shows how AI improves logistics:

Impact Area | Description |

|---|---|

Operational Efficiency | |

Demand Forecasting | Machine learning predicts demand more accurately. |

Inventory Management | AI keeps stock levels balanced and reduces waste. |

Decision-Making Capabilities | Data insights help make smarter choices. |

Adding AI to logistics software makes tracking and delivery easier and faster.

Internet of Things (IoT) for Smart Logistics

IoT makes logistics smarter. Devices give real-time updates on supply chain activities. For example, Maersk uses sensors to check container temperature and humidity. This keeps products safe during shipping.

IoT also helps track inventory. Walmart uses RFID tags to monitor stock levels in real time. This improves accuracy and reduces losses. The table below shows IoT uses in logistics:

Company | Application Area | Description |

|---|---|---|

Maersk | Logistics and Transportation | Sensors check temperature and humidity to protect goods. |

Walmart | Inventory Management | RFID tags track stock levels in stores and warehouses. |

IoT helps make better decisions, manage inventory, and improve deliveries.

SaaS Solutions for Logistics and Supply Chain Management

SaaS solutions are changing logistics software. Cloud platforms make managing supply chains easier. For example, small businesses using SaaS improve order times by 50%.

E-commerce growth has increased SaaS use. These tools help with tracking, routes, and inventory. Gartner says 85% of supply chain leaders prefer cloud-based logistics tools. The table below shows SaaS benefits:

Evidence Type | Description |

|---|---|

Cloud Adoption | Cloud tools save money and are flexible. |

Efficiency Improvement | Small businesses process orders 50% faster. |

Cost Reduction | SaaS cuts transport costs by 20%. |

Using SaaS solutions makes operations smoother, saves money, and keeps businesses competitive.

JUSDA Solutions

To provide you with professional solutions and quotations.

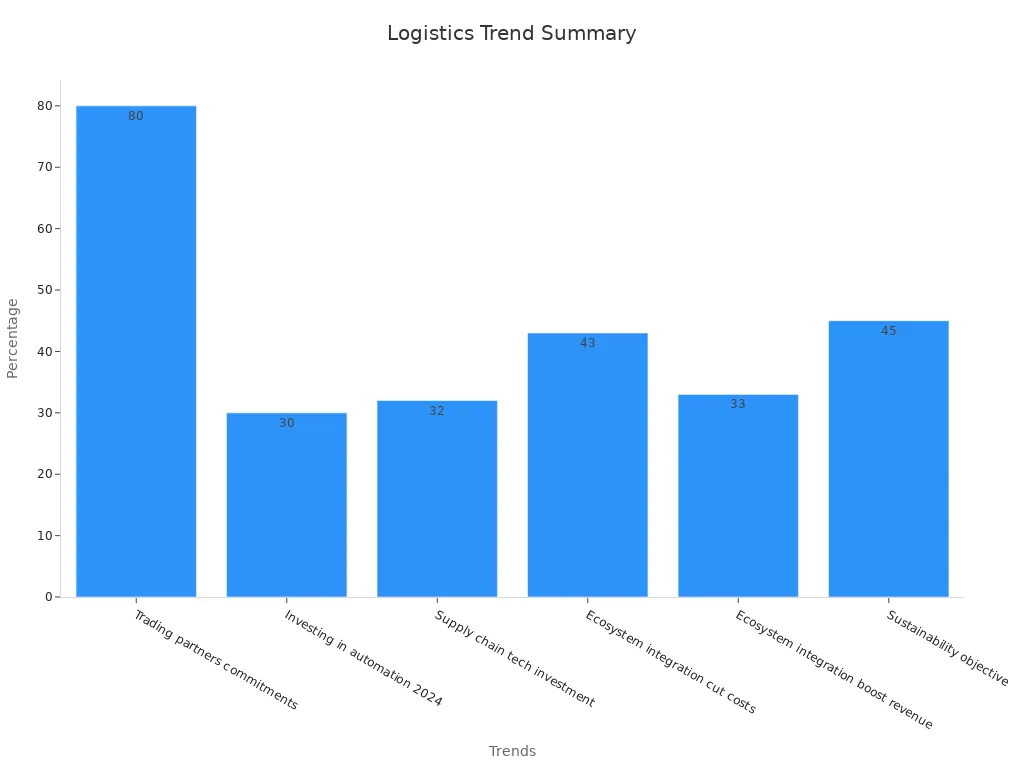

Logistics technology is key to today’s supply chains. It helps businesses work faster, save money, and keep customers happy. New trends like AI, robots, and live tracking are changing how things run. For example, 32% of companies plan to spend on supply chain tools in 2024 to save money and meet goals.

Statistic/Trend | What It Means |

|---|---|

80% | Trading partners failed to meet promises in 2023. |

30% | Companies want to use robots in 2024. |

43% | Businesses think teamwork will lower costs. |

45% | Companies see eco-friendly practices as very important. |

Stay ahead by using smart logistics tools and following best practices. JUSDA offers tools like JusLink, which uses AI to make better choices and connect supply chain tasks. Try these tools to improve your business and grow in a sustainable way.

See Also

Innovative Logistics Technologies Shaping Our Future Landscape

Transforming Logistics: The Role of Digital Innovations Ahead

Achieving Manufacturing Excellence Through Efficient Logistics Strategies

The Impact of AI on Future Supply Chain Logistics

Get Prepared: Discovering New Transport Technologies for Supply Chains