The Predicaments of Manufacturing Logistics Companies in 2025

Manufacturing logistics companies in 2025 face unprecedented challenges that threaten operational efficiency and profitability. Shipping delays, driven by geopolitical tensions, continue to disrupt supply chains. Labor shortages remain critical, with 76% of operations affected and 2.1 million manufacturing jobs projected to go unfilled by 2030. Rising raw material costs and evolving trade policies further complicate global logistics. These complex dynamics demand innovative solutions to ensure businesses can adapt, optimize, and thrive in a rapidly evolving landscape.

Key Takeaways

Manufacturing logistics companies need strong supply chains to handle problems like political issues and natural disasters.

Using smart tools like AI and robots can make work faster and cheaper in logistics.

Being eco-friendly is important; companies should use green methods to help the planet and stay ahead of others.

Training workers and hiring smartly are key to keeping up with the needs of modern logistics.

Quickly adjusting to new trends and tools will help companies succeed for a long time in the changing logistics world.

Emerging Challenges for Manufacturing Logistics Companies

Supply Chain Disruptions and Resilience

Manufacturing logistics companies are grappling with persistent supply chain disruptions in 2025, which have become a defining challenge for the industry. These disruptions stem from a combination of geopolitical tensions, natural disasters, and fluctuating market demands. Over 76% of European shippers reported experiencing supply chain disruptions in 2024, with nearly 25% encountering more than 20 disruptive incidents. One in three shippers struggled to secure essential materials for production, highlighting the fragility of global supply chains.

Volatility in transportation costs further complicates resilience efforts. For instance, the average air cargo spot rate from China to the US dropped nearly 50% from its peak in December 2024 to USD 2.98 per kg by March 9, 2025. However, this rate surged by over 20% to USD 3.67 per kg within two weeks, underscoring the unpredictability of logistics expenses. To mitigate these challenges, companies must prioritize building robust supply chain networks capable of adapting to sudden disruptions while maintaining operational efficiency.

Rising Costs and Economic Pressures

Economic pressures continue to mount for manufacturing logistics companies, driven by rising input costs and inflationary trends. Global supply chain disruptions have contributed to approximately 60% of the inflation surge since early 2021, significantly impacting the cost of goods production. This inflationary environment has led to higher transportation and shipping costs, creating historically long delivery times and backlogs.

The ripple effect of these economic pressures is evident in the operational challenges faced by logistics providers. Increased costs for raw materials, fuel, and labor have forced companies to reevaluate their pricing strategies and operational efficiencies. To remain competitive, businesses must adopt innovative cost-control measures and explore alternative logistics models that balance affordability with service quality.

Workforce Shortages and Skill Gaps

The manufacturing logistics sector faces a critical workforce shortage, exacerbated by a widening skills gap. Approximately 67% of transportation operations and 56% of warehouse operations are impacted by labor shortages. Additionally, 51% of transportation and inventory planning roles and 42% of customer service positions remain unfilled. This shortage extends to demand planning roles, with 37% of these positions experiencing significant gaps.

The industry’s shift toward Industry 4.0 has further highlighted the need for a technically skilled workforce. However, insufficient infrastructure and tools for future supply chain workers have hindered progress. If the skills gap remains unaddressed, the manufacturing sector could face a shortage of 1.9 million workers, jeopardizing its ability to meet growing demands. Companies must invest in upskilling initiatives and modernize their workforce strategies to attract and retain talent capable of navigating the complexities of a digitalized logistics landscape.

Adapting to Rapid Technological Advancements

The rapid pace of technological advancements has transformed the manufacturing logistics landscape in 2025. Companies are increasingly adopting innovative tools to enhance efficiency, reduce costs, and meet growing customer expectations. Nearly 80% of logistics companies plan to invest in robotics and automation technologies, while over 80% aim to integrate IoT for real-time tracking and inventory optimization. These investments reflect the industry's commitment to leveraging technology for operational excellence.

Automation has emerged as a cornerstone of modern logistics. By reducing human error and improving accuracy, automation enhances customer satisfaction and streamlines processes. Sophisticated data analytics tools provide actionable insights, enabling companies to make informed decisions and optimize operations. For example, AI integration has reduced logistics costs by 15%, improved inventory optimization by 35%, and increased service levels by 65%. These advancements underscore the critical role of technology in driving growth and competitiveness.

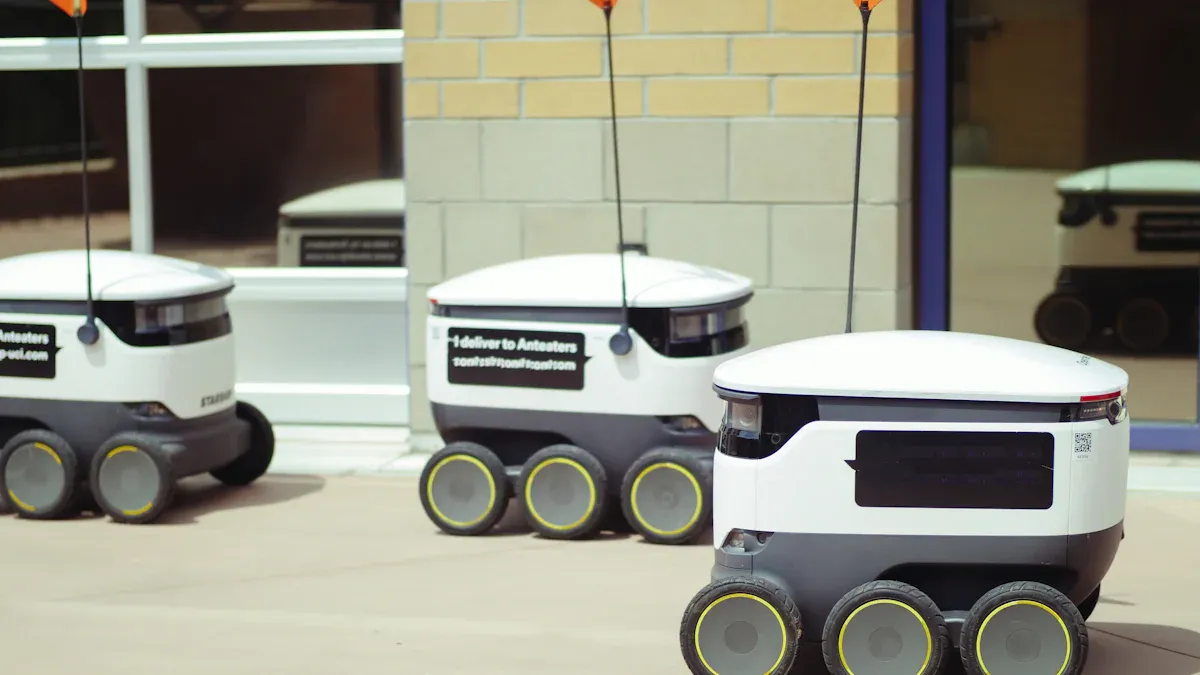

Emerging technologies like drones and IoT devices are also reshaping logistics operations. Drones offer faster and more cost-effective delivery options, particularly in remote areas. IoT devices enable real-time tracking of packages, optimizing delivery routes and reducing transit times. Faster data flow and comprehensive distribution systems, powered by these technologies, have significantly boosted revenue for many companies. As a result, manufacturing logistics companies are better equipped to navigate the complexities of global supply chains.

Geopolitical and Regulatory Complexities

Geopolitical and regulatory challenges continue to pose significant hurdles for manufacturing logistics companies. Policy-related uncertainties, such as those stemming from Brexit, have forced many UK multinational firms to relocate production and distribution facilities. These decisions often aim to capitalize on market and efficiency-seeking advantages, highlighting the intricate relationship between geopolitics and logistics operations.

Global instability, the growth of AI, and climate change are among the key disruptive trends influencing the industry. Approximately 98% of CEOs are actively adapting to these challenges, recognizing the need for flexible and resilient strategies. Securing key resources and addressing supply chain vulnerabilities have become top priorities for manufacturers. Companies must adapt their operational models and technology choices to mitigate risks and maintain efficiency in an unpredictable environment.

Regulatory complexities further complicate logistics operations. Diverse customs policies, cross-border transportation delays, and compliance requirements demand meticulous planning and execution. Companies that fail to address these challenges risk operational inefficiencies and increased costs. By adopting proactive measures and leveraging advanced technologies, manufacturing logistics companies can navigate these complexities and sustain their competitive edge.

Key Trends Shaping Manufacturing Logistics in 2025

AI and Automation in Logistics Operations

AI and automation have become transformative forces in logistics operations, enabling companies to achieve unprecedented levels of efficiency and adaptability. These technologies empower businesses to optimize routes, schedules, and inventory management in real time. For instance, AI-driven systems uncover hidden patterns in data, providing actionable insights that traditional methods often overlook. Automation reduces human error and enhances operational precision, leading to improved customer satisfaction and cost savings.

Aspect | Traditional Methods | AI-Driven Systems |

|---|---|---|

Adaptability | Rigid, slow to adjust to changes | Dynamic, adjusts routes and schedules in real-time |

Insight Discovery | Limited by human capacity, slow decision-making | Uncovers hidden patterns, provides data-driven insights |

Cost-Effectiveness | Requires proportional increase in resources | Scalable without linear resource increase |

Operational Improvements | Often reactive and inefficient | Proactive, enhances service levels and customer satisfaction |

Sustainability | Limited impact on carbon emissions | Optimizes transport, reduces waste, supports circular economy |

The manufacturing logistics market, projected to grow from $146.97 billion in 2024 to $162.17 billion in 2025, reflects the increasing reliance on advanced logistics solutions. Companies adopting AI and automation position themselves to thrive in this rapidly evolving landscape.

Nearshoring and Regionalization of Supply Chains

Nearshoring and regionalization have emerged as pivotal strategies for mitigating supply chain risks. The COVID-19 pandemic and geopolitical tensions have prompted companies to reduce reliance on distant suppliers. The share of imports from the Far East decreased from 60% to 40%, while reliance on regional partners in Europe and the US rose from 30% to 40%. Local supply chains also grew from 10% to 20%, particularly for critical raw materials.

This shift enhances supply chain resilience by reducing transit times and exposure to global disruptions. Manufacturing logistics companies increasingly collaborate with nearby partners to streamline operations and improve service delivery. By prioritizing regionalization, businesses can adapt to changing market dynamics and ensure continuity in their operations.

Sustainability and Green Logistics Initiatives

Sustainability has become a cornerstone of modern logistics, with companies striving to minimize their environmental impact. Green logistics initiatives focus on reducing carbon footprints, optimizing resource usage, and adopting circular economy practices. Key performance indicators (KPIs) such as carbon footprint, water usage, and waste generation help measure progress toward sustainability goals.

KPI | Description |

|---|---|

Carbon Footprint | Measures total greenhouse gas emissions associated with a product or service over its life cycle. |

Water Usage | Tracks water consumption to identify inefficiencies and minimize impact on ecosystems. |

Waste Generation | Measures waste produced to implement reduction strategies and move towards a circular economy. |

Eco-efficiency Ratios | Compares outputs to inputs to assess resource efficiency and environmental performance. |

Certifications like ISO 14001 and eco-labels such as Energy Star demonstrate a company’s commitment to environmental stewardship. As sustainability becomes a competitive differentiator, businesses that embrace green logistics gain a significant edge in the market.

The Role of Digital Twins and Predictive Analytics

Digital twins and predictive analytics have revolutionized manufacturing logistics by enhancing operational efficiency and decision-making. A digital twin, a virtual replica of a physical asset or process, enables companies to simulate, monitor, and optimize supply chain operations in real time. Predictive analytics, powered by AI and machine learning, uses historical data to forecast future trends and identify potential disruptions.

These technologies empower logistics companies to anticipate challenges and implement proactive measures. For instance, digital twins allow businesses to simulate various scenarios, such as demand surges or transportation delays, and evaluate their impact on the supply chain. This capability reduces downtime and enhances resource allocation. Predictive analytics complements this by providing actionable insights, such as identifying optimal shipping routes or predicting equipment failures.

The integration of digital twins and predictive analytics has led to measurable improvements in logistics performance. Companies leveraging these tools report a 20% reduction in operational costs and a 30% improvement in delivery accuracy. By adopting these technologies, manufacturing logistics companies can achieve greater agility and resilience in an increasingly complex global market.

Demand for End-to-End Supply Chain Visibility

End-to-end supply chain visibility has become a critical requirement for manufacturing logistics companies. This capability ensures real-time tracking of goods, enabling businesses to monitor every stage of the supply chain, from production to delivery. Enhanced visibility improves transparency, reduces risks, and fosters trust among stakeholders.

Several companies have demonstrated the tangible benefits of end-to-end visibility. Unilever reduced forecasting errors by 30% and maintained 98% service levels during COVID-19 disruptions. Target modernized its supply chain, cutting backroom inventory by 40% and increasing on-shelf availability by 20%. Merck achieved a 35% improvement in forecast accuracy and 99.9% on-time delivery for critical medications.

The advantages of supply chain visibility extend beyond operational efficiency. It enables early risk identification, allowing companies to address potential disruptions before they escalate. Access to real-time data also enhances decision-making, ensuring timely and informed responses to market changes. As the demand for transparency grows, businesses that prioritize end-to-end visibility will gain a competitive edge in the logistics industry.

Strategies for Overcoming Challenges in Manufacturing Logistics

Leveraging JUSDA's JusLink Intelligent Supply Chain Platform

JUSDA's JusLink Intelligent Supply Chain Platform has emerged as a transformative solution for addressing the complexities faced by manufacturing logistics companies. This platform integrates cutting-edge technologies such as IoT, cloud computing, and big data to provide real-time visibility and collaboration across the supply chain. By enabling seamless communication between suppliers, manufacturers, and logistics providers, JusLink enhances operational efficiency and decision-making.

The platform's impact is evident in its ability to improve key performance metrics. For instance, companies utilizing JusLink have reported significant advancements in forecasting accuracy and inventory turnover. The table below highlights these improvements:

Metric | Improvement |

|---|---|

Forecasting Accuracy | |

Inventory Turnover | Significant boost |

These enhancements empower businesses to anticipate demand fluctuations, optimize inventory levels, and reduce waste. By leveraging JusLink, companies can build resilient supply chains capable of adapting to disruptions while maintaining high service levels.

Investing in Advanced Digital Tools and Technologies

Investing in advanced digital tools has become a cornerstone for improving efficiency in manufacturing logistics. Digitization streamlines various processes, from quoting to inventory management, reducing manual errors and saving time. Automation systems, in particular, have proven to be game-changers, enabling companies to cut costs and enhance operational efficiency.

A study by Boston Consulting Group revealed that implementing advanced logistics automation systems could reduce in-plant logistics and warehousing costs by approximately 30%. These systems also provide real-time data, allowing manufacturers to make informed decisions and respond swiftly to market changes. Key benefits of digital tools include:

Increased efficiency across multiple steps in the manufacturing workflow.

Cost reductions in traditionally cumbersome processes like quoting.

Enhanced resource allocation through intelligent scheduling and transportation optimization.

Predictive analysis capabilities for proactive risk management, minimizing production disruptions.

By adopting these technologies, manufacturing logistics companies can achieve greater agility and competitiveness in a rapidly evolving market.

Building Resilient and Agile Supply Chains

Resilience and agility are essential for navigating the uncertainties of modern supply chains. Companies must focus on creating networks that can withstand disruptions while adapting to changing market conditions. This involves diversifying suppliers, investing in regional partnerships, and leveraging advanced technologies for real-time monitoring and decision-making.

Agile supply chains prioritize flexibility, enabling businesses to scale operations up or down based on demand. For example, predictive analytics tools allow companies to forecast potential disruptions and adjust their strategies accordingly. Additionally, end-to-end visibility ensures that stakeholders can monitor every stage of the supply chain, from production to delivery, reducing risks and enhancing transparency.

Building resilient supply chains also requires a commitment to sustainability. By adopting green logistics practices, companies can minimize their environmental impact while improving operational efficiency. These practices include optimizing transportation routes, reducing waste, and implementing circular economy principles. A resilient and agile supply chain not only ensures business continuity but also positions companies as leaders in a competitive global market.

Enhancing Collaboration Across the Supply Chain

Collaboration across the supply chain is essential for achieving operational efficiency and meeting customer expectations. Manufacturing logistics companies must foster strong partnerships with suppliers, distributors, and other stakeholders to ensure seamless operations. Effective collaboration reduces delays, minimizes errors, and enhances overall performance.

Key performance indicators (KPIs) provide measurable insights into the success of collaborative efforts. The following table highlights critical KPIs that companies should monitor:

KPI | Description |

|---|---|

On-time delivery rates | Measures the percentage of orders delivered on time. |

Inventory turnover | Indicates how often inventory is sold and replaced over a period. |

Order accuracy | Assesses the correctness of orders fulfilled. |

To enhance collaboration, companies should adopt the following practices:

Establish clear communication channels to ensure all stakeholders remain informed.

Set mutual expectations to align goals and objectives across the supply chain.

Conduct regular check-ins and performance reviews to address challenges proactively.

Invest in understanding suppliers' capabilities and challenges to build trust and reliability.

Additionally, structured approaches can further strengthen collaboration. For example:

Schedule regular cross-functional meetings with stakeholders to discuss forecasts, inventory levels, and production schedules.

Utilize shared planning tools to enable real-time data exchange and improve decision-making.

Develop contingency plans to address potential disruptions and maintain operational continuity.

By implementing these strategies, manufacturing logistics companies can create a more integrated and resilient supply chain, ensuring long-term success in a competitive market.

Upskilling the Workforce for the Digital Age

The rapid digital transformation of the manufacturing logistics industry has created an urgent need for a skilled workforce. Employees must adapt to emerging technologies such as artificial intelligence, automation, and IoT to meet modern operational demands. However, a significant talent gap and misaligned academic programs have hindered the transition of students into the workforce.

The World Economic Forum reports that 44% of current work skills will be disrupted due to technological innovations. This statistic underscores the importance of reskilling programs to prepare employees for the future. Companies adopting a skills-based approach focus on aligning workers with roles that match their abilities, rather than traditional job titles. This strategy not only enhances productivity but also improves employee retention, as workers who feel empowered to acquire new skills are 2.7 times less likely to leave their organization.

To address the workforce challenges, companies should prioritize the following initiatives:

Develop comprehensive training programs to equip employees with digital skills.

Partner with academic institutions to align curricula with industry needs.

Invest in mentorship and on-the-job training to bridge the skills gap.

Leverage e-learning platforms to provide flexible and accessible learning opportunities.

By upskilling their workforce, manufacturing logistics companies can ensure they remain competitive in an increasingly digitalized industry. A skilled workforce not only drives innovation but also enhances operational efficiency and customer satisfaction.

Prioritizing Sustainability and Circular Economy Practices

Sustainability has become a cornerstone of modern manufacturing logistics. Companies are under increasing pressure to minimize their environmental impact while maintaining operational efficiency. Adopting circular economy practices, which focus on reducing waste and reusing resources, offers a viable solution to these challenges.

Key performance indicators (KPIs) help measure progress toward sustainability goals. These include:

Carbon footprint: Tracks greenhouse gas emissions associated with logistics operations.

Water usage: Monitors water consumption to identify inefficiencies.

Waste generation: Measures waste produced to implement reduction strategies.

Eco-efficiency ratios: Assesses resource efficiency by comparing outputs to inputs.

Certifications such as ISO 14001 and eco-labels like Energy Star demonstrate a company's commitment to environmental stewardship. Companies can further enhance their sustainability efforts by:

Optimizing transportation routes to reduce fuel consumption and emissions.

Implementing energy-efficient technologies in warehouses and distribution centers.

Encouraging the use of recyclable packaging materials.

Collaborating with suppliers to adopt green practices across the supply chain.

By prioritizing sustainability, manufacturing logistics companies can not only reduce their environmental impact but also gain a competitive edge. Customers increasingly prefer businesses that demonstrate a commitment to eco-friendly practices, making sustainability a key driver of long-term success.

Future Outlook for Manufacturing Logistics Companies

The Role of Innovation in Shaping the Future

Innovation continues to redefine the manufacturing logistics landscape, driving efficiency and resilience. Companies increasingly prioritize technological advancements to address challenges and capitalize on opportunities. Several key trends highlight the growing importance of innovation:

Manufacturing contributes approximately 16% of global GDP, equating to over $13 trillion in value.

Over 71% of manufacturing executives now prioritize supply chain resilience over cost minimization, reflecting a strategic shift since 2020.

Industrial robot installations reached a record 422,000 units in 2022, with a projected annual growth rate of 12% through 2025.

By 2025, more than 75% of enterprise-generated data will be created and processed outside traditional data centers.

These statistics underscore the critical role of innovation in shaping the future. Companies that embrace emerging technologies and data-driven strategies position themselves to thrive in an increasingly competitive market.

The Impact of Emerging Technologies on Logistics

Emerging technologies such as artificial intelligence, blockchain, and IoT are revolutionizing logistics operations. These tools enhance visibility, streamline processes, and improve decision-making. For instance, IoT devices enable real-time tracking, reducing delays and optimizing delivery routes. Blockchain ensures secure and transparent transactions, fostering trust among stakeholders.

Automation also plays a pivotal role. Industrial robots, with their growing adoption, reduce labor dependency and improve operational precision. Predictive analytics, powered by AI, allows companies to anticipate disruptions and adjust strategies proactively. These advancements not only lower costs but also enhance customer satisfaction by ensuring timely deliveries and accurate forecasting.

Predictions for Global Supply Chain Evolution

The global supply chain is poised for significant transformation. Companies adopting proactive strategies will achieve measurable improvements in key performance metrics. The table below illustrates the potential benefits:

KPI | Pre-Adaptive Method | Post-Adaptive Method | Improvement |

|---|---|---|---|

Lead Time (days) | 15 | 11 | |

Operating Costs (million $) | 12 | 8.5 | 29% |

Customer Satisfaction (score) | 78/100 | 88/100 | 13% increase |

These projections highlight the importance of adaptability. Businesses that invest in resilience, sustainability, and advanced technologies will lead the next wave of supply chain evolution, ensuring long-term success in a dynamic global environment.

The Importance of Proactive Adaptation for Long-Term Success

Proactive adaptation has become a cornerstone for long-term success in the manufacturing logistics industry. Companies that anticipate challenges and implement forward-thinking strategies position themselves to thrive in an ever-changing global market. This approach not only mitigates risks but also fosters innovation and resilience.

Tip: Businesses that adapt proactively often outperform competitors by responding swiftly to market shifts and customer demands.

Key Benefits of Proactive Adaptation

Enhanced Resilience: Companies that adopt proactive measures can better withstand disruptions caused by geopolitical tensions, natural disasters, or economic fluctuations. For example, diversifying supplier networks reduces dependency on single sources, ensuring continuity during crises.

Operational Efficiency: Proactive adaptation streamlines processes and eliminates inefficiencies. By leveraging predictive analytics and digital twins, businesses can optimize inventory management, reduce lead times, and improve delivery accuracy.

Competitive Advantage: Early adoption of emerging technologies, such as AI and IoT, enables companies to stay ahead of industry trends. This fosters customer loyalty and strengthens market positioning.

Practical Steps for Proactive Adaptation

Action Plan | Expected Outcome |

|---|---|

Invest in advanced technologies | Improved efficiency and cost savings |

Build agile supply chains | Faster response to market changes |

Prioritize workforce upskilling | Enhanced employee productivity and innovation |

Embrace sustainability | Reduced environmental impact and regulatory risks |

Proactive adaptation also involves fostering a culture of continuous improvement. Companies must encourage collaboration across departments and with external partners to identify opportunities for growth. Regular performance reviews and scenario planning further enhance preparedness for future challenges.

Manufacturing logistics companies in 2025 operate in a dynamic environment that demands innovative strategies to overcome challenges and seize opportunities. Key trends such as AI integration, nearshoring, and sustainability initiatives are reshaping the industry, driving efficiency and growth. Solutions like JUSDA's JusLink platform have proven transformative, enabling a threefold increase in operational efficiency and reducing costs by five times. Smart forecasting and replenishment have boosted inventory turnover and improved accuracy by 78%. Collaborative logistics further enhance agility, customer satisfaction, and innovation. Resilience, technological advancement, and strategic partnerships will define the future success of these companies.

FAQ

What are the key challenges manufacturing logistics companies face in 2025?

Manufacturing logistics companies encounter supply chain disruptions, rising costs, workforce shortages, and regulatory complexities. Rapid technological advancements also demand continuous adaptation. These challenges require innovative strategies, such as leveraging AI, enhancing collaboration, and adopting sustainable practices, to maintain efficiency and competitiveness.

How does JUSDA's JusLink platform improve supply chain operations?

JUSDA's JusLink platform integrates IoT, cloud computing, and big data to provide real-time visibility and collaboration. It enhances forecasting accuracy, optimizes inventory turnover, and reduces operational inefficiencies. By streamlining communication across the supply chain, JusLink empowers businesses to adapt to disruptions and improve decision-making.

Why is sustainability important in manufacturing logistics?

Sustainability minimizes environmental impact while improving operational efficiency. Green logistics practices, such as optimizing transportation routes and adopting circular economy principles, reduce waste and emissions. Companies prioritizing sustainability gain a competitive edge, as customers increasingly prefer eco-friendly businesses.

How can companies address workforce shortages in logistics?

Companies can address workforce shortages by investing in upskilling programs, adopting automation, and modernizing recruitment strategies. Partnerships with academic institutions and e-learning platforms help bridge skill gaps. A skilled workforce ensures businesses can meet the demands of a digitalized logistics landscape.

What role does technology play in overcoming logistics challenges?

Technology drives efficiency and resilience in logistics. AI, IoT, and predictive analytics optimize operations, reduce costs, and enhance decision-making. Digital twins simulate supply chain scenarios, while automation improves accuracy and speed. Companies leveraging these tools gain agility and a competitive advantage.

See Also

Mastering Efficient Logistics for Success in High-Tech Manufacturing

Enhancing Supply Chain Strategies for High-Tech Manufacturing Challenges

Transforming Future Logistics Through Artificial Intelligence Supply Chains

Paving the Way for Future Logistics Using Digital Innovations

Exploring Technological Advances in Logistics for Future Success