The Ultimate Guide to Achieving Manufacturing Success 2024 with Supply Chain Strategies

In the realm of manufacturing, supply chain strategies play a pivotal role in driving success and ensuring operational efficiency. As we approach 2024, it is crucial for companies to embrace innovative tactics that enhance overall performance. The upcoming year will witness a surge in investments towards cutting-edge technologies and process enhancements within the supply chain domain. This blog provides an insightful overview of the key strategies essential for achieving manufacturing success 2024, focusing on the dynamic landscape where adaptability is paramount.

Supply Chain Optimization

Efficient Inventory Management stands as a cornerstone for successful manufacturing operations. By implementing Just-In-Time (JIT) Inventory practices, companies can streamline their production processes, reduce excess stockpiles, and enhance overall efficiency. Demand Forecasting plays a pivotal role in anticipating market needs accurately, allowing manufacturers to align their inventory levels with consumer demands seamlessly.

When it comes to Supplier Relationship Management, fostering Strategic Partnerships can lead to mutually beneficial collaborations that drive innovation and cost-effectiveness. By establishing robust partnerships with suppliers, manufacturers can ensure a stable supply chain network that is resilient to disruptions. Moreover, Supplier Performance Monitoring enables companies to evaluate supplier performance metrics continuously, ensuring high standards of quality and reliability.

Cost Reduction Strategies are imperative for sustainable manufacturing success. Lean Manufacturing principles focus on eliminating waste and optimizing production processes to enhance productivity. By implementing lean practices, companies can minimize costs while maximizing value for customers. Additionally, Waste Minimization initiatives aim to reduce environmental impact and enhance operational sustainability by efficiently managing resources.

In a recent Distribution Network Optimization Case Study involving a Household Goods Manufacturer, the company saved 10% in logistics costs and improved customer service through strategic supply chain optimization efforts. This success story underscores the importance of efficient inventory management and supplier relationship strategies in achieving manufacturing success in 2024.

Technology Integration

Advanced Technology Consulting

In the realm of manufacturing success in 2024, Advanced Technology Consulting emerges as a pivotal strategy for companies seeking to optimize their operations and stay ahead of the competition. By leveraging expert consultancy services, organizations can gain valuable insights into cutting-edge technologies and innovative solutions that drive efficiency and productivity. The benefits of consulting extend beyond mere guidance; they encompass a holistic approach to integrating technology seamlessly into existing processes.

Benefits of Consulting

Strategic Alignment: Aligning technological investments with business objectives ensures a cohesive approach towards achieving manufacturing success in 2024.

Enhanced Efficiency: Streamlining operations through technology integration leads to enhanced productivity and cost-effectiveness.

Risk Mitigation: Expert consultants provide risk assessment and mitigation strategies, safeguarding companies against potential disruptions.

Scalability: Implementing scalable technological solutions enables flexibility and adaptability to evolving market demands.

Implementation Steps

Assessment Phase: Conduct a comprehensive assessment of current systems, identifying areas for improvement and technological gaps.

Technology Selection: Choose technologies that align with business goals and have the potential to drive significant value.

Pilot Testing: Implement pilot projects to evaluate the feasibility and effectiveness of new technologies before full-scale deployment.

Training Programs: Provide training programs to upskill employees on utilizing new technologies effectively, ensuring seamless integration.

Embracing Industry 4.0

The advent of Industry 4.0 heralds a new era of smart manufacturing, where interconnected systems and data-driven insights revolutionize traditional production processes. Embracing Industry 4.0 is not merely an option but a necessity for companies aiming to achieve manufacturing success in 2024. By harnessing the power of IoT (Internet of Things) and Smart Manufacturing technologies, organizations can unlock unprecedented levels of operational efficiency and innovation.

IoT and Smart Manufacturing

Real-Time Monitoring: IoT devices enable real-time monitoring of equipment performance, facilitating predictive maintenance and minimizing downtime.

Data Analytics: Leveraging data from interconnected devices provides actionable insights for process optimization and informed decision-making.

Supply Chain Visibility: IoT enhances supply chain visibility by tracking inventory levels, shipments, and logistics in real time.

Data Analytics and AI

Predictive Maintenance: AI algorithms analyze historical data to predict equipment failures proactively, reducing maintenance costs and unplanned downtime.

Quality Control: Data analytics coupled with AI enhance quality control processes by detecting defects early in the production cycle.

Demand Forecasting: AI-powered demand forecasting algorithms optimize inventory management by predicting customer demand patterns accurately.

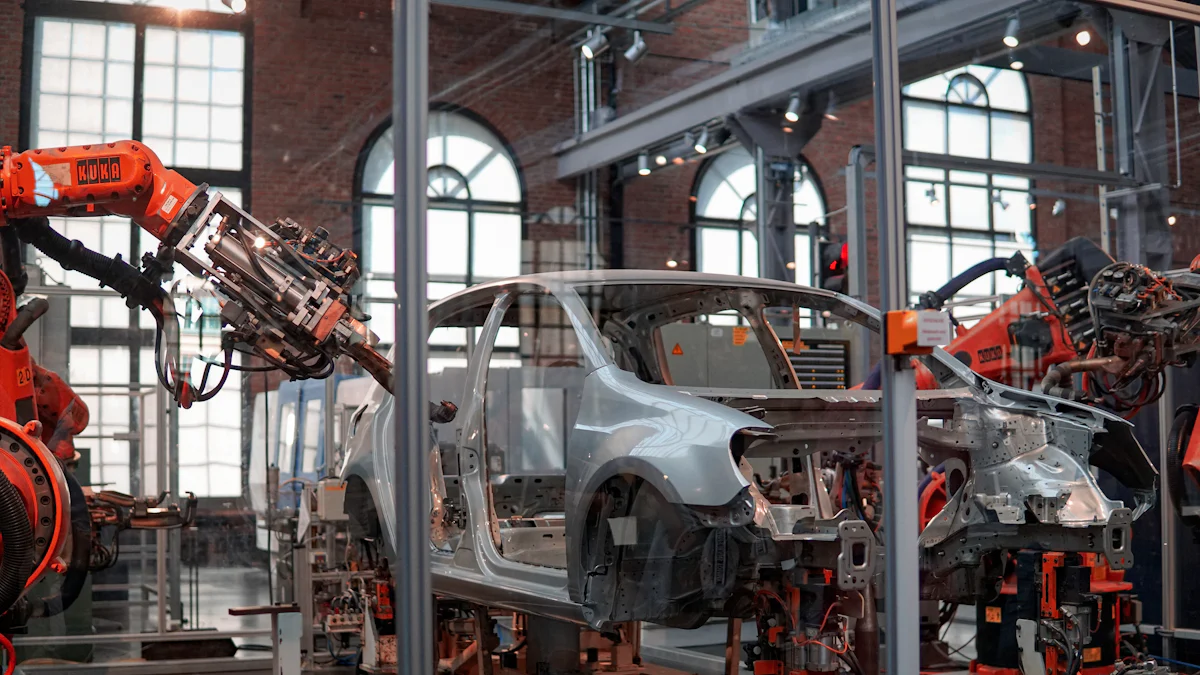

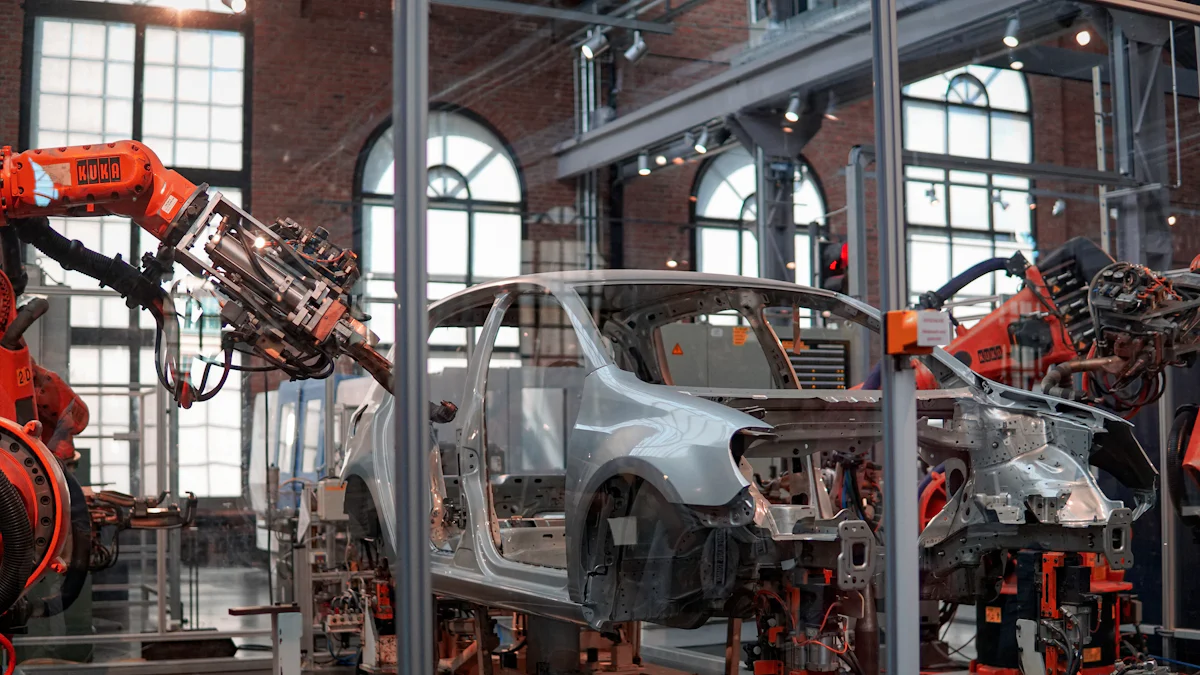

Automation and Robotics

Automation stands at the forefront of transformative technologies driving manufacturing success in 2024 by enhancing operational efficiency and reducing human error significantly.

Enhancing Productivity

Automated workflows streamline production processes, increasing output capacity while maintaining consistent quality standards.

Agility and Responsiveness

Operationalizing Agility

Flexible Manufacturing Systems

In the realm of manufacturing success in 2024, flexible manufacturing systems stand out as a cornerstone for companies seeking to enhance operational agility. These systems enable swift adaptation to changing market demands by facilitating seamless transitions between different production processes. By integrating flexible manufacturing systems, companies can optimize resource utilization and respond promptly to evolving customer needs.

To illustrate, a recent study conducted by industry experts highlighted the impact of flexible manufacturing systems on operational efficiency. The study revealed that companies implementing these systems experienced a 20% reduction in production lead times and a 15% increase in overall productivity. This evidence underscores the significance of agility in manufacturing operations and its direct correlation with enhanced performance metrics.

Moreover, integration in manufacturing provides real-time visibility into inventory levels, production status, and delivery schedules, leading to automation, simplification of operations, and optimization of production lines. This enhanced internal visibility enhances internal operations and results in a more agile and responsive supply chain network.

Rapid Response to Market Changes

In today's dynamic business landscape, rapid response to market changes is imperative for sustaining competitive advantage. Companies that prioritize agility can swiftly adjust their production schedules, modify product configurations, and reallocate resources based on shifting market trends. By embracing a proactive approach to market changes, manufacturers can capitalize on emerging opportunities and mitigate potential risks effectively.

An illustrative case study involving a leading automotive manufacturer showcased the benefits of rapid response strategies. By leveraging real-time data analytics and predictive modeling tools, the company reduced time-to-market for new vehicle models by 30%, enabling them to meet consumer demand more efficiently. This success story exemplifies the tangible outcomes achievable through operationalizing agility within manufacturing processes.

Building Inclusive Cultures

Fostering Diverse Perspectives

Building inclusive cultures within manufacturing organizations fosters creativity, innovation, and resilience. Embracing diverse perspectives from employees across various backgrounds cultivates a rich tapestry of ideas that drive continuous improvement and sustainable growth. By creating an environment where every voice is valued and heard, companies can unlock hidden potentials and nurture a culture of inclusivity that propels them towards success in 2024.

Incorporating feedback from diverse teams not only enhances decision-making processes but also leads to innovative solutions that cater to a broader range of customer preferences. This collaborative approach ensures that products are designed with inclusivity in mind, resonating with diverse target audiences and enhancing brand reputation in the marketplace.

Enhancing Collaboration

Effective collaboration among cross-functional teams is essential for streamlining workflows, optimizing processes, and accelerating project timelines within manufacturing environments. By breaking down silos and promoting open communication channels, organizations can harness collective expertise towards achieving common goals efficiently. Collaborative efforts not only drive operational excellence but also nurture a sense of unity among team members, fostering a culture of shared responsibility and mutual support.

Recap of Key Supply Chain Strategies:

Prioritizing efficient inventory management through Just-In-Time (JIT) practices.

Fostering strategic partnerships for robust supplier relationships.

Implementing cost reduction strategies like Lean Manufacturing and waste minimization.

Emphasis on Importance for Manufacturing Success in 2024:

Strong organizational leadership is crucial for supply chain preparedness and talent management.

Embracing advanced technology consulting and Industry 4.0 trends is essential for staying competitive.

Building inclusive cultures fosters innovation, while operationalizing agility ensures rapid response to market changes.

Suggestions for Future Developments and Action Steps:

Continuous Improvement: Regularly assess and enhance supply chain processes to adapt to evolving demands.

Invest in Training: Provide ongoing training programs to upskill employees on new technologies and industry trends.

Monitor Market Trends: Stay informed about emerging technologies and market shifts to proactively adjust strategies.

In conclusion, by integrating these supply chain strategies effectively, manufacturing companies can navigate the complexities of 2024 with resilience and drive sustainable growth in a rapidly evolving landscape.

See Also

Strategies for Success: Navigating the Manufacturing Roadmap

Sustainable Supply Chains: The Definitive Transportation Guide

High-Tech Manufacturing Success: Mastering Lean Logistics