Mastering Inventory Management: Your Next Ten Years Guide

Inventory management stands as the cornerstone of operational success for businesses, with inefficiencies costing eCommerce industries a staggering $1.75 trillion annually. The journey of inventory control began in the early 1900s with mechanical systems, paving the way for innovative technologies like barcodes, RFID, and cloud computing. Today, advancements in AI and machine learning empower businesses to predict demand accurately, optimize stock levels efficiently, and combat fraudulent activities effectively.

Understanding Inventory Management

Definition and Importance

What is Inventory Management?

Inventory management refers to the systematic process of overseeing the flow of goods into and out of a company's inventory. It involves efficiently handling the ordering, storing, and usage of raw materials, work-in-progress, and finished products.

Why is it crucial for businesses?

Efficient inventory management is vital for businesses as it directly impacts their operational efficiency, customer satisfaction levels, and overall profitability. By maintaining optimal stock levels, businesses can reduce storage costs, prevent stockouts, and enhance their ability to meet customer demands promptly.

Key Concepts and Terminology

Types of Inventory

Raw Materials: Essential components used in manufacturing processes.

Work-in-Progress (WIP): Goods that are in the production phase but not yet completed.

Finished Goods: Products ready for sale or distribution to customers.

Inventory Turnover

Inventory turnover measures how many times a company sells and replaces its inventory within a specific period. A high turnover rate indicates efficient sales and restocking processes.

Safety Stock and Reorder Points

Safety Stock: Extra inventory held to mitigate the risk of stockouts due to unexpected demand fluctuations or supply chain disruptions.

Reorder Points: The predetermined inventory level at which new orders should be placed to replenish stock before it runs out.

By understanding these key concepts and terminologies in inventory management, businesses can streamline their operations, minimize costs, and maximize customer satisfaction levels effectively.

Inventory Management Processes

Inventory Planning

Demand Forecasting

Effective inventory management hinges on accurate demand forecasting. By analyzing historical data and market trends, businesses can anticipate customer needs, optimize stock levels, and enhance operational efficiency. Utilizing advanced algorithms and predictive analytics, companies can minimize excess inventory costs while ensuring product availability to meet consumer demands promptly.

Inventory Optimization

Inventory optimization plays a pivotal role in maintaining the right balance between supply and demand. By leveraging sophisticated algorithms and real-time data analysis, businesses can streamline their inventory processes, reduce carrying costs, and prevent stockouts. Implementing automated reorder systems based on demand patterns enables companies to enhance their overall supply chain efficiency.

Inventory Control

Stock Audits

Conducting regular stock audits is essential for verifying inventory accuracy and identifying discrepancies. By physically counting and cross-referencing stock levels with digital records, businesses can detect errors early, prevent theft or loss, and maintain optimal inventory integrity. These audits facilitate informed decision-making regarding restocking strategies and inventory adjustments.

Cycle Counting

Cycle counting involves the periodic counting of a subset of inventory items within a specific timeframe. This method allows businesses to continuously monitor stock levels without disrupting daily operations significantly. By categorizing items based on value or turnover rate, companies can prioritize cycle counts effectively to ensure accurate inventory records and efficient replenishment processes.

Inventory Tracking

Barcode Systems

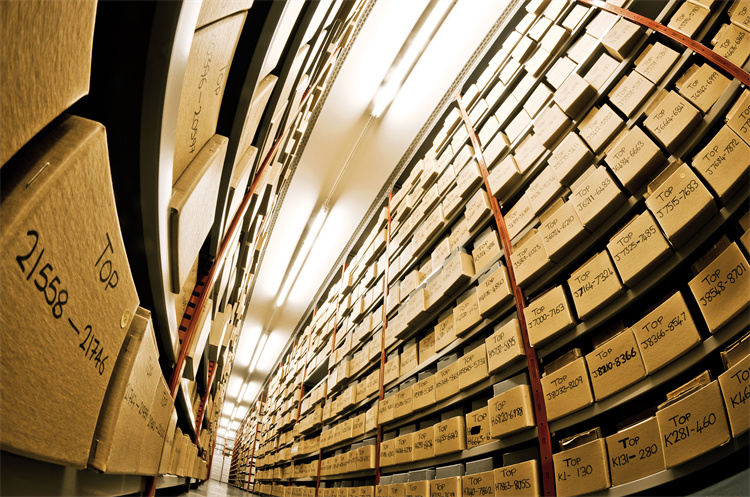

Implementing barcode systems revolutionizes inventory tracking by providing real-time visibility into stock movements throughout the supply chain. Barcodes enable quick identification of products, accurate data capture, and seamless integration with inventory management software. By scanning barcodes at various touchpoints, businesses can enhance order accuracy, reduce manual errors, and improve overall operational efficiency.

RFID Technology

RFID technology offers advanced tracking capabilities by using radio frequency signals to identify and track individual items automatically. Unlike barcodes, RFID tags do not require line-of-sight scanning, enabling rapid bulk scanning of multiple items simultaneously. This technology enhances inventory visibility, minimizes human intervention in tracking processes, and optimizes warehouse operations for increased productivity.

Tools and Technologies

Inventory Management Software

Features to Look For

Inventory Tracking: Ensuring real-time monitoring of stock levels.

Reports and Analytics Capabilities: Providing insights for informed decision-making.

User-Friendly Interface: Enhancing ease of use for efficient operations.

Integration with Other Systems: Facilitating seamless data exchange.

Popular Software Options

Warehouse Inventory Management Software:

Helps companies organize their products in storage efficiently.

Best Inventory Management Software:

Backed by customer testimonials for its effectiveness.

ConnectPOS:

Offers a cloud-based POS solution with comprehensive inventory management features.

Lightspeed:

Provides a robust POS system with advanced inventory management functionality.

Automation and AI

Benefits of Automation

Streamlining Operations: Automating repetitive tasks for increased efficiency.

Enhanced Accuracy: Minimizing human errors in inventory-related processes.

Improved Productivity: Allowing staff to focus on strategic tasks.

AI in Inventory Management

Predictive Demand Forecasting: Utilizing AI algorithms for accurate predictions.

Dynamic Reordering Systems: Implementing AI-driven systems for optimized stock levels.

Fraud Detection: Leveraging AI to identify irregular patterns and prevent fraudulent activities.

JUSDA's Advanced Inventory Management Solutions

Cloud Warehouse Service

Unified Inventory Management

In the realm of inventory management, unified inventory management is a pivotal aspect that ensures seamless coordination between various inventory types. By integrating Vendor Managed Inventory (VMI) and Customer Managed Inventory (CMI), businesses can optimize stock levels, enhance operational efficiency, and mitigate the risks associated with stockouts or overstocking.

Personalized VMI Services

Tailoring services to meet specific client needs is at the core of JUSDA's personalized VMI services. These customized edge-of-production-line services cater to individual requirements, ensuring precise inventory control right at the production line. By offering tailored solutions, businesses can streamline their operations, reduce costs, and improve overall supply chain performance.

Seamless System Integration

The ability to seamlessly integrate systems is a hallmark of JUSDA's cloud warehouse service. Through its proprietary VMI management system, JUSDA enables clients to integrate existing systems effortlessly. This integration facilitates smooth data exchange, operational continuity, and enhanced decision-making processes across the entire supply chain network.

JusLink Technology Supply Chain Management Solutions

End-to-End Supply Chain Visibility

JusLink Technology offers end-to-end visibility into the supply chain through its platform-based management approach. By monitoring all link nodes in real-time, businesses gain comprehensive insights into their inventory movements, risks, and opportunities. This visibility empowers companies to make informed decisions, optimize inventory levels, and enhance overall supply chain efficiency.

Integrated System Solutions

Through its integrated system solutions, JusLink Technology provides a holistic approach to supply chain management. From purchase order creation to final delivery, every aspect of the process is covered seamlessly. This includes PO management, transportation coordination, inventory optimization, and exception handling. By offering an all-encompassing solution suite, JusLink Technology ensures operational cohesion and efficiency throughout the supply chain network.

Data-Driven Improvements

Data lies at the heart of continuous improvement in inventory management processes. Leveraging extensive data accumulation capabilities,** JusLink Technology** utilizes advanced data analysis techniques to help clients refine their supply chain operations continuously. Through data-driven insights and recommendations,** JusLink Technology** assists businesses in optimizing their inventory strategies for improved performance and enhanced customer satisfaction.

Best Practices for Inventory Management

Efficient Stock Management

Just-In-Time (JIT) Inventory

Implementing Just-In-Time (JIT) inventory practices involves receiving goods only as they are needed in the production process. This method reduces excess stock holding, minimizes storage costs, and enhances operational efficiency by ensuring a continuous flow of materials.

JIT inventory systems help companies streamline their supply chain processes by synchronizing production with demand. By reducing lead times and eliminating unnecessary inventory buffers, businesses can respond swiftly to changing market demands and minimize waste throughout the production cycle.

ABC Analysis

ABC analysis categorizes inventory items into different priority groups based on their value and contribution to overall sales. Classifying items as A (high-value), B (medium-value), or C (low-value) enables businesses to allocate resources effectively, prioritize stock management efforts, and optimize inventory control strategies.

By focusing on high-priority items through stringent monitoring and replenishment processes, companies can prevent stockouts of critical products while efficiently managing lower-priority items to reduce carrying costs and enhance profitability.

Cost Management

Reducing Holding Costs

Minimizing holding costs is essential for optimizing inventory management practices. By reducing excess stock levels, improving turnover rates, and implementing efficient storage solutions, businesses can lower holding costs associated with warehouse maintenance, insurance, and obsolescence.

Holding costs directly impact a company's bottom line; therefore, adopting lean inventory practices such as JIT systems or vendor-managed inventories can significantly reduce capital tied up in unsold goods while enhancing cash flow and profitability.

Minimizing Stockouts

Preventing stockouts is crucial for maintaining customer satisfaction levels and sustaining business operations. Utilizing accurate demand forecasting techniques, setting appropriate safety stock levels, and establishing reliable reorder points are key strategies to minimize the risk of stockouts.

Stockouts not only result in lost sales opportunities but also damage a company's reputation. By implementing robust inventory control measures like real-time tracking systems or automated reorder mechanisms, businesses can ensure product availability, meet customer demands promptly, and avoid costly disruptions in their supply chains.

Continuous Improvement

Lean Inventory Practices

Embracing lean inventory practices focuses on eliminating waste from the supply chain while maximizing operational efficiency. By reducing excess inventory levels, minimizing lead times, and optimizing order quantities through data-driven insights, companies can enhance productivity and profitability.

Lean principles emphasize continuous improvement through regular monitoring of key performance indicators (KPIs) like inventory turnover rates or fill rates. By identifying inefficiencies in the supply chain processes proactively and implementing corrective actions promptly, businesses can achieve sustainable growth and competitive advantages in dynamic market environments.

Regular Training and Development

Investing in ongoing training programs for employees is essential for fostering a culture of excellence in inventory management. Continuous education on industry best practices, technological advancements in supply chain systems, or effective communication strategies enhances staff competencies and ensures optimal performance levels.

Regular training sessions not only empower employees with the necessary skills to navigate complex inventory challenges but also promote collaboration across departments. By encouraging knowledge sharing among team members and providing professional development opportunities, businesses can build resilient supply chains capable of adapting to evolving market trends effectively.

Future Trends in Inventory Management

Emerging Technologies

IoT in Inventory Management

The integration of Internet of Things (IoT) technology in inventory management is revolutionizing the way businesses track and manage their stock. By connecting physical devices and sensors to the internet, companies can monitor inventory levels in real-time, automate replenishment processes, and enhance overall operational efficiency. IoT-enabled devices provide valuable data insights that enable businesses to make informed decisions, optimize supply chain processes, and meet customer demands promptly.

Blockchain for Supply Chain Transparency

Blockchain technology offers unparalleled transparency and security in supply chain management by creating an immutable ledger of transactions across the entire network. By implementing blockchain solutions, businesses can ensure traceability of products from point of origin to final delivery, verify authenticity, and prevent counterfeiting. The decentralized nature of blockchain enhances data integrity, reduces fraud risks, and fosters trust among stakeholders within the supply chain ecosystem.

Sustainability and Green Practices

Eco-friendly Inventory Practices

Embracing eco-friendly inventory practices is becoming increasingly crucial for businesses aiming to reduce their environmental impact. By adopting sustainable sourcing methods, minimizing packaging waste, and optimizing transportation routes, companies can contribute to a greener future while reducing operational costs. Implementing energy-efficient technologies and recycling initiatives further promote sustainability efforts within the inventory management process.

Reducing Waste

Efficient inventory management plays a significant role in reducing waste throughout the supply chain. By optimizing stock levels, minimizing overstock situations, and implementing just-in-time inventory practices, businesses can prevent excess waste generation while maximizing resource utilization. Additionally, leveraging data analytics tools for demand forecasting helps companies align production with actual consumer needs, thereby reducing unnecessary waste and promoting sustainable business practices.

Effective inventory management ensures that businesses have the right materials, in the right quantities, at the right time, and in the right place. By mastering this essential aspect of operations, companies can reduce costs, improve efficiency, and ultimately boost their bottom line. Success lies in continuous improvement through regular audits, accurate record-keeping, and seeking new efficiencies. Continuous improvement helps identify areas for enhancement and makes the inventory management process more efficient. Implementing these strategies will pave the way for sustainable growth and success in the dynamic landscape of inventory management.

See Also

Enhance Your Company Using Advanced Inventory Methods

Conquering Supply Chain Interruptions: An In-Depth Manual

The Definitive Manual for Attaining Manufacturing Excellence in 2024

Becoming Proficient in Supply Chain Risk Control: Professional Advice

The Evolving Supply Chain: A Route to Professional Advancement