Five-Minute Quick Guide to MRP and ERP Systems

Imagine you run a bakery and need to make hundreds of flatbreads each morning. MRP and ERP Systems help you plan materials, track inventory, and improve efficiency. With these systems, you can reduce costs, boost production speed, and respond quickly to supply chain changes.

- Lower inventory by up to 35%

Increase production output by 20%

Improve on-time delivery by 25%

Key Takeaways

MRP systems help you plan materials and manage inventory for production, reducing costs and avoiding shortages.

ERP systems connect all parts of your business, improving efficiency, decision-making, and supporting growth.

Choose MRP for simple, single-factory needs and ERP for larger, multi-department businesses that want full control.

MRP Overview

What Is MRP?

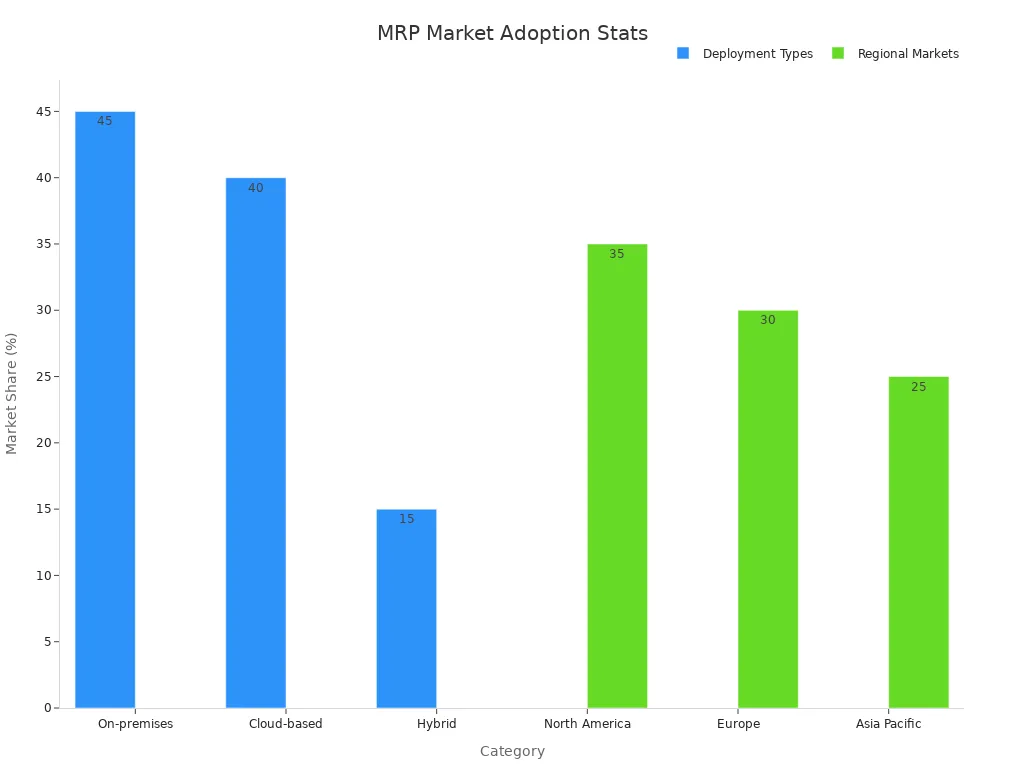

You use Material Requirement Planning (MRP) to make sure you have the right materials at the right time for production. MRP helps you plan, schedule, and control inventory. It works by using information like your bill of materials (BOM), current inventory, and production schedules. This system tells you what to order, how much to order, and when to order it. Manufacturing companies rely on MRP to avoid running out of parts or having too much stock. In fact, manufacturing industries account for about 40-45% of all MRP system use, with strong adoption in automotive, electronics, and food production.

Key Features

MRP systems give you several important tools:

Inventory tracking: You always know what materials you have and what you need.

Production scheduling: You can plan when to start each job.

Order management: The system tells you when to buy more materials.

Lead time calculation: You see how long it takes to get each part.

Real-time updates: You adjust plans quickly when things change.

Company | Key Improvements |

|---|---|

Fewer stockouts, better schedules, less idle time | |

General Electric | More material available, faster delivery, less delay |

Benefits

When you use MRP, you cut costs and speed up your operations. Many companies report a 14% drop in inventory levels after using MRP. This means you spend less money storing extra parts. You also avoid overtime and keep production running smoothly. MRP helps you deliver products on time and keep customers happy. As more companies move to digital systems, cloud-based MRP is growing fast, especially for small and medium businesses.

ERP Overview

What Is ERP?

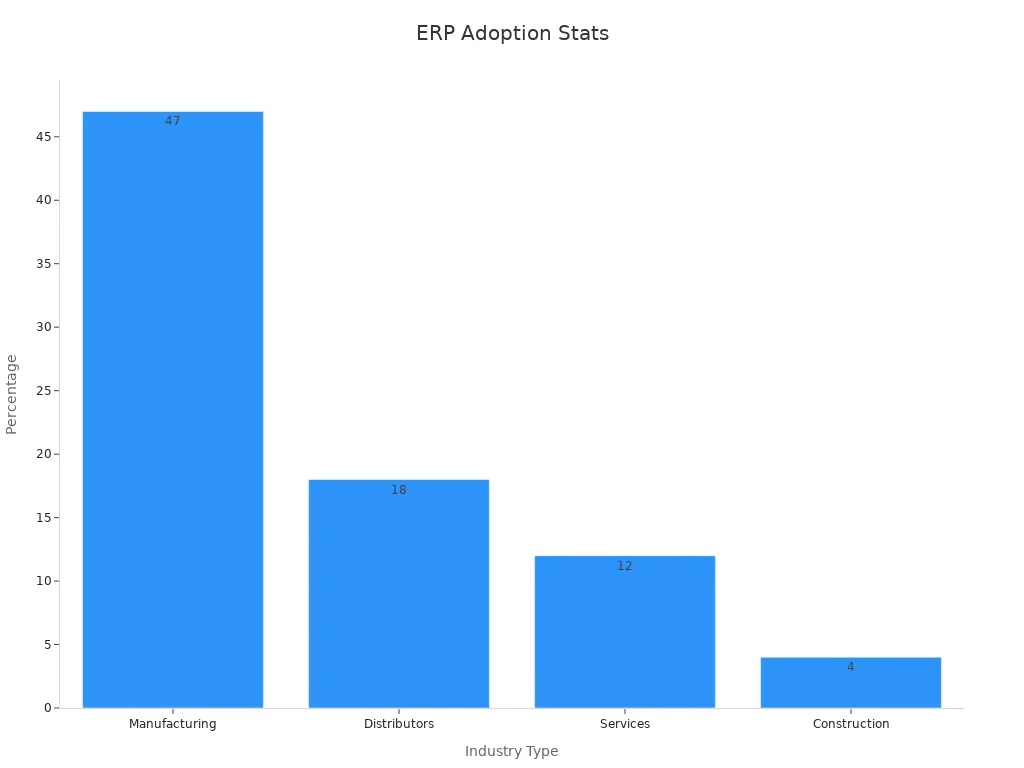

You use Enterprise Resource Planning (ERP) systems to connect all parts of your business. ERP brings together information from sales, finance, inventory, human resources, and more. When you use ERP, you see everything in one place. This helps you make better decisions and respond faster to changes. Many industries rely on ERP to stay organized and competitive. For example, almost half of manufacturing companies look to purchase ERP systems, while distributors, service providers, and construction firms also see strong adoption.

Industry | Percentage of Companies Looking to Purchase ERP Systems |

|---|---|

Manufacturing | 47% |

Distributors | 18% |

Services | 12% |

Construction | 4% |

Key Features

ERP systems give you powerful tools to manage your business:

Shared database for all departments

Financial management and reporting

Human resources and payroll modules

Most companies say accounting is the most important ERP function. You also get better inventory control and faster access to information.

Benefits

When you use ERP, you see big improvements in how your business runs. Studies show that 96.6% of companies report better operational efficiency after using ERP. About 50% see major improvements in their business processes. You can also expect strong financial returns. One manufacturer gained $665,000 in benefits over three years, with a 90% return on investment.

Benefit | Year 0 | Year 1 | Year 2 | Year 3 | Total |

|---|---|---|---|---|---|

Sales growth | $0 | $50,000 | $80,000 | $100,000 | $230,000 |

Productivity gains | $0 | $30,000 | $40,000 | $90,000 | $160,000 |

Cost savings | $0 | $60,000 | $100,000 | $115,000 | $275,000 |

Total benefits | $0 | $140,000 | $220,000 | $305,000 | $665,000 |

You also gain softer benefits, like better teamwork, faster decisions, and happier customers. ERP helps you grow your business with confidence.

MRP and ERP Systems Compared

Scope and Integration

You need to understand how MRP and ERP Systems differ in scope and integration. MRP focuses on materials and production planning. It helps you track raw materials, components, and finished goods within a single factory. You use MRP to make sure you have what you need for production, but it does not connect all parts of your business.

ERP covers a much wider scope. You use ERP to connect every department in your company. It brings together sales, finance, inventory, human resources, and more. ERP systems let you see all your business data in one place. You can manage multiple factories, suppliers, and even customers. This integration helps you make faster and smarter decisions.

Tip: If you want to manage only production and inventory, MRP is enough. If you want to connect your whole business, choose ERP.

Here is a quick comparison:

Feature | MRP | ERP |

|---|---|---|

Scope | Production and inventory | All business functions |

Integration | Single department/factory | Company-wide, multi-department |

Data Sharing | Limited | Real-time, across all departments |

Users | Production planners, buyers | Everyone in the company |

Functional Differences

You will see clear differences in how MRP and ERP Systems work. MRP helps you with:

Calculating material needs

Scheduling production jobs

Planning purchase orders

ERP gives you all the above, plus:

Financial management and accounting

Human resources and payroll

Customer relationship management (CRM)

Sales and order tracking

Supplier and logistics coordination

You use MRP to answer, "What do I need to buy or make, and when?" You use ERP to answer, "How is my whole business running right now?"

Note: ERP includes MRP as one of its modules, but it adds many more features for your entire business.

Use Cases

You should choose between MRP and ERP Systems based on your business needs. Here are some common use cases:

MRP:

You run a single factory and need to plan materials.

You want to reduce inventory and avoid shortages.

You focus on production efficiency.

ERP:

You manage several factories or business units.

You need to connect sales, finance, HR, and supply chain.

You want real-time data for the whole company.

You plan to grow or merge with other businesses.

If your business is growing or you need to manage more than just production, ERP gives you the tools to scale up.

Here is a side-by-side summary:

Scenario | Best Fit |

|---|---|

Single factory, simple products | MRP |

Multiple sites, complex business | ERP |

Need for full business insight | ERP |

Focus on inventory and production | MRP |

You can see that MRP and ERP Systems serve different needs. You should match the system to your business goals and complexity.

Choosing a System

Business Needs

You should start by looking at your business size, industry, and how you make products. Small companies with simple production often find MRP systems fit their needs. If you run a single factory and focus on managing materials and inventory, MRP gives you the right tools.

Larger companies or those with many departments usually need ERP systems. ERP connects sales, finance, HR, and production. This helps you see the whole business at once. Your production strategy also matters. If you use a Make-To-Order (MTO) approach, you may find ERP systems harder to fit. Many MTO companies report that ERP does not always match their needs. On the other hand, Make-To-Stock (MTS) companies use ERP planning tools more and see better results.

A study found that company size and production strategy strongly affect ERP adoption.

MTO companies often struggle with ERP fit, while MTS companies benefit more from ERP planning features.

The type of business activity and company size also influence how well ERP works for you.

Tip: If you want to manage only materials and production, MRP is often enough. If you need to connect many parts of your business, ERP is the better choice.

Implementation Factors

When you choose between MRP and ERP systems, you need to think about more than just features. Implementation can be complex. You must consider how the new system will fit with your current processes and staff skills. Many companies see big improvements after implementing ERP. In one survey, 95% of companies reported better business processes after ERP rollout. Some companies finished their ERP projects on time and within budget, leading to higher efficiency and profits.

You should also look at integration. ERP systems often replace many smaller systems, bringing all your data together. This can lower costs and improve customer satisfaction. For example, one company unified its systems with ERP and saw better inventory management and happier customers.

ERP use in small and medium businesses improves decision-making and business success.

The most popular ERP solutions for small businesses show strong adoption across different sectors.

The success of your project depends on the vendor’s reputation and the skills of your partners.

You also need to think about supply chain trade-offs. MRP systems use a "time fence" to freeze production plans for a set period. A longer time fence makes planning easier but reduces flexibility. A shorter time fence gives you more flexibility but requires a very responsive supply chain. You must balance stability and flexibility based on your business needs.

Scalability

You should plan for growth when choosing between MRP and ERP systems. If you expect your business to expand, ERP systems offer more scalability. You can add new modules for sales, logistics, or even new factories as your company grows. ERP lets you manage more complex operations and connect with suppliers and customers worldwide.

MRP systems work well for stable, single-site operations. If your business stays the same size, MRP can serve you for years. But if you plan to add more products, locations, or business units, ERP gives you the flexibility to scale up.

Factor | MRP System | ERP System |

|---|---|---|

Best for | Single factory | Multi-site, growing firms |

Growth support | Limited | High |

Module expansion | Basic | Extensive |

Global coordination | Minimal | Strong |

🚀 Choose a system that not only fits your needs today but also supports your future plans.

You can see that the right choice depends on your business goals, size, and how much you want to grow. MRP and ERP Systems both help you improve efficiency, but you need to match the system to your unique situation.

Decision Checklist

Evaluation Steps

You can use a clear checklist to guide your decision when choosing between MRP and ERP systems. A step-by-step approach helps you avoid mistakes and makes sure you cover all important points.

Define Your Goals

Write down what you want to achieve. Do you need better inventory control, or do you want to connect all business functions?List Your Requirements

Gather input from every department. Make a list of features you need. Missing requirements often lead to project problems.Assess Your Current Processes

Map out how you work today. Identify gaps and areas for improvement.Evaluate Vendors

Research software providers. Compare their solutions to your needs.Check for Integration

Make sure the new system works with your existing tools.Plan for Training and Support

Decide how you will train your team and get help when needed.

Studies show that over 70% of ERP project failures come from poor or incomplete requirements. A structured checklist helps you avoid these costly mistakes.

Statistic Description | Percentage / Range |

|---|---|

ERP project failures triggered by flawed requirements | 70% |

Software defects attributed to bad requirements | 40-60% |

Common Pitfalls

You should watch out for common mistakes during system selection:

Skipping the requirements step

Not involving all departments

Underestimating training needs

Ignoring integration with current systems

Many companies face problems because they rush or miss steps. Careful planning and a detailed checklist help you choose the right system and avoid setbacks.

You can see clear differences between MRP and ERP Systems. MRP improves manufacturing control and reduces workload. ERP gives you broad business control and big inventory savings. Review the checklist and match your needs. For more insight, check these real-world results:

System Type | Company | Outcome / Benefit |

|---|---|---|

ERP | WDS Component Parts Ltd | |

MRP | Paddock Gear & Eng. | 40%-50% less workload pressure |

FAQ

What is the main difference between MRP and ERP?

MRP helps you plan materials for production. ERP connects all business areas, including sales, finance, and HR, for complete company management.

Can small businesses use ERP systems?

Yes! Many small businesses use ERP. You can start with basic modules and add more as your company grows.

How does MRP help reduce inventory costs?

MRP tracks your inventory.

It tells you when to order materials.

You avoid buying too much or too little.

See Also

How Robotics Revolutionize Warehouse Efficiency And Productivity

Understanding Robotic Automation To Improve Warehouse Efficiency

Implementing Lean Logistics Strategies For Advanced Manufacturing

Effective Supply Chain Solutions For High-Tech Manufacturing Challenges

Proven Strategies To Manage Risks In Supply Chain Operations