Multi-Channel Supply Chain Service Capability in the Manufacturing Industry

Manufacturers now face rising demand for efficient, responsive supply chain operations. The global multichannel order management market is projected to reach 15.5 billion USD by 2032, showing strong growth as companies embrace new technology. Leading manufacturers adopt multi-channel strategies to serve customers through online stores, retailers, and traditional outlets. More than 37% of manufacturing companies use artificial intelligence systems to boost inventory management and customer experience. These trends reflect growing customer expectations for speed, transparency, and sustainability in supply chain services.

Key Takeaways

Manufacturers must coordinate multiple sales channels to improve inventory management, order fulfillment, and customer service, leading to faster responses and higher satisfaction.

Integrated order management systems centralize processes, reduce errors, and provide real-time updates, helping companies grow and keep customers loyal.

Real-time inventory tracking and channel transferability allow manufacturers to balance stock efficiently, avoid shortages or excess, and respond quickly to demand changes.

Offering multi-channel customer support and streamlined returns builds trust, improves satisfaction, and encourages repeat business.

Using technology like data analytics, IoT, and automation boosts supply chain efficiency, reduces costs, and supports sustainability, giving manufacturers a competitive edge.

Supply Chain Integration

Channel Coordination

Manufacturers operate in a complex environment with multiple sales channels, including online platforms, retail partners, and direct sales. Seamless coordination across these channels ensures that inventory, order fulfillment, and customer service remain consistent. When manufacturers synchronize their processes, they can respond quickly to changes in demand and market conditions.

Empirical research on manufacturing firms shows that integrated supply chain systems improve production planning, on-time delivery, and service responsiveness. Digital transformation enables real-time data sharing, which reduces transaction costs and supports better decision-making. For example, in the Dutch floriculture sector, sensor-equipped containers allow partners to monitor product quality and shelf-life. This technology helps reduce spoilage and waste by optimizing transportation and storage decisions. In the pharmaceutical industry, serialization technology tracks drug packages in real time, improving inventory management and product availability.

Industry reports provide numerical evidence that improved coordination leads to better cooperation and collaboration. Strategies such as information sharing, electronic data interchange, and revenue-sharing contracts help manufacturers and their partners align goals. These strategies reduce channel conflicts and increase profitability. Game-theoretic models show that coordinated pricing and cost-sharing contracts result in measurable improvements for both manufacturers and retailers.

Manufacturing sector statistics confirm that integrated supply chain models deliver operational efficiency and higher customer satisfaction. Companies like Toyota and Amazon use just-in-time inventory management and efficient logistics to reduce costs and improve service levels. These examples highlight the value of channel coordination in a multi-channel environment.

Tip: Manufacturers should invest in digital tools that enable real-time communication and data exchange across all channels. This investment supports faster decision-making and greater agility.

Order Management

Integrated order management systems (OMS) play a critical role in multi-channel supply chain operations. These systems centralize order processing, inventory tracking, and customer interactions. Companies with advanced OMS experience higher growth rates and improved customer retention. For instance, businesses with strong omnichannel strategies retain 89% of customers, compared to only 33% for those with weak strategies. Customers who shop across multiple channels spend three to four times more than single-channel shoppers.

OMS integration provides real-time inventory visibility, reducing stockouts and overselling. Automated order processing eliminates manual errors and speeds up fulfillment. When manufacturers synchronize orders and inventory across all sales channels, they deliver a seamless customer experience. Real-time updates and transparent order tracking increase customer satisfaction and reduce service inquiries.

Best practices for unified order management include:

Implementing integrated order tracking for real-time updates.

Establishing clear communication between sales, warehouse, and customer service teams.

Using advanced demand forecasting to minimize stockouts and overstock.

Automating returns management for faster processing and fewer errors.

Employing technologies like pick-to-light to boost picking accuracy and speed.

Optimizing labor scheduling with workforce management software.

Integrating multi-channel fulfillment strategies to synchronize inventory and orders.

Case studies in electronics manufacturing show that system integration enhances supply chain responsiveness. Manufacturers with high levels of integration can adapt quickly to market changes and disruptions. This agility strengthens their ability to deliver timely product-related services, such as maintenance and repair.

Note: A unified OMS not only improves operational efficiency but also supports business growth by adapting to increased order volumes without disruption.

Inventory and Logistics

Real-Time Visibility

Manufacturers need real-time visibility to manage inventory across multiple channels. Advanced tracking systems, such as RFID and barcoding, help companies monitor stock levels and product movement instantly. For example, an aviation safety equipment manufacturer used RFID-based tracking to automate compliance and inventory tasks. This system improved audit accuracy, reduced manual errors, and provided real-time product information. The company also streamlined packaging and shipping by integrating RFID tags during manufacturing and inspection.

Many leading companies have adopted similar solutions.

Zara uses advanced tracking to reduce turnaround time and markdowns, which increases profit margins.

Amazon relies on robotics and real-time tracking in warehouses, cutting labor costs by 20% and speeding up fulfillment.

A German electronics retailer reduced surplus stock by 15% after integrating real-time tracking, which lowered storage costs and improved customer satisfaction.

Manufacturers benefit from integrating real-time inventory tracking with ERP and supply chain management platforms. This integration provides up-to-the-minute visibility, automates replenishment, and improves demand forecasting. Companies that follow best practices—such as setting clear objectives, collaborating between IT and operations, and training users—see better accuracy and efficiency.

Tip: Real-time visibility helps manufacturers respond quickly to changes in demand and avoid costly stockouts or overstocking.

Channel Transferability

Channel transferability allows manufacturers to move inventory between sales channels efficiently. This flexibility helps companies balance stock levels and meet customer needs. Industry benchmarks show that effective inventory management includes ABC analysis, warehouse optimization, regular audits, and automation. Companies use centralized inventory management systems to synchronize stock across all channels and reduce discrepancies.

A study of nearly 1,000 UK manufacturing firms found that adjusting inventory through trade receivables and payables channels leads to better operational and stock performance. Firms that optimize inventory by transferring it between channels reduce risk and improve overall performance. Robustness tests confirm that these benefits persist over time.

Manufacturers also track key performance indicators, such as inventory turnover ratio and order accuracy rate, to measure success. Automation and strong supplier relationships further support efficient channel transferability.

Note: Channel transferability ensures that inventory remains balanced, reducing risk and supporting a responsive supply chain.

Customer Service

Multi-Channel Support

Manufacturers recognize that customers expect support across many channels. They provide help through phone, email, live chat, social media, and self-service portals. This approach gives customers the freedom to choose their preferred method of communication. Companies that offer multi-channel support see higher satisfaction and loyalty.

Research shows that the quality of channel integration plays a key role in customer satisfaction. Well-integrated channels allow customers to switch between support options without repeating information. This seamless experience builds trust and encourages repeat business. Studies in the banking sector confirm several important findings:

Service quality and customer satisfaction have a strong link.

High-quality integration between channels increases satisfaction.

Customer loyalty grows when companies manage channel integration well.

Customers value convenience, time savings, and reliability from multi-channel service.

A study of retail bank clients also found that satisfaction with both traditional and technology-based channels shapes customer behavior. For routine questions, customers prefer quick answers from digital channels. For complex issues, they rely on skilled service employees. Companies that balance both types of support meet a wider range of needs.

Tip: Manufacturers should train support teams to handle requests from all channels and invest in technology that connects these channels for a smooth customer journey.

Returns Management

Efficient returns management forms a vital part of customer service in manufacturing. Customers expect easy and transparent return processes, especially when buying through multiple channels. Manufacturers who streamline returns build stronger relationships and reduce costs.

Best practices include clear return policies, automated return labels, and real-time tracking of returned items. Companies use centralized systems to process returns from any channel, which reduces errors and speeds up refunds or replacements. Data analytics help identify common reasons for returns, allowing manufacturers to improve product quality and reduce future returns.

Manufacturers also monitor key metrics such as return rate, processing time, and customer feedback. These measures help companies refine their processes and deliver better service. By making returns simple and hassle-free, manufacturers increase customer trust and encourage repeat purchases.

Note: A strong returns management system not only improves customer satisfaction but also supports sustainability by enabling product recycling and responsible disposal.

Technology in Supply Chain

Data and Analytics

Manufacturers rely on data and analytics to make better decisions and improve operations. Advanced analytics help companies track key performance indicators such as order fulfillment rate, inventory turnover, and delivery time. Walmart, for example, reduced costs by optimizing inventory and transportation. A global cement manufacturer saved $1.5 million by using analytics to find bottlenecks. Unicsoft improved traceability and forecasting, which led to lower inventory costs and higher customer loyalty. An aircraft sensor manufacturer saved $10 million each year by maximizing capacity with analytics.

AI-driven demand forecasting uses information from social media and weather to predict trends. Real-time dashboards update key metrics, allowing managers to act quickly and prevent stockouts. Predictive analytics and machine learning help companies manage risks, optimize inventory, and reduce costs. Visualization tools like dashboards and charts make it easier to understand and use this information.

An empirical study shows that investments in Industry 4.0 technologies—such as AI, IoT sensors, and big data analytics—improve supply chain visibility and efficiency. These tools support predictive maintenance and better production schedules, which reduce downtime and boost customer satisfaction. Experts agree that balancing investment with financial goals helps companies stay resilient and competitive.

Tip: Companies should use real-time analytics to spot problems early and keep their supply chain running smoothly.

IoT and Automation

IoT and automation transform manufacturing by connecting machines, products, and people. Smart machines with sensors can operate and maintain themselves. IoT devices like GPS trackers and RFID tags provide real-time tracking and condition monitoring of shipments. This end-to-end visibility improves efficiency and customer satisfaction.

Advantage Category | Description & Impact |

|---|---|

Quality Improvement | IoT and automation reduce defects by over 65%, improving product quality. |

Cost Reduction | Predictive maintenance cuts maintenance costs by up to 25%. |

Scalability | Automated systems adapt quickly to changes, increasing agility. |

Real-time Monitoring | Sensors detect problems early, reducing downtime and improving efficiency. |

Energy Optimization | IoT monitoring lowers energy use by up to 40%, supporting sustainability. |

Manufacturers use IoT to track assets, monitor equipment health, and automate warehouse tasks. Automation lowers labor costs and improves safety. Industry leaders like Microsoft and Cisco offer IIoT solutions that help factories become more efficient and secure. A recent survey found that 76% of companies plan to use digital tools for better supply chain visibility. These technologies help manufacturers respond faster to disruptions and keep operations running smoothly.

Collaboration and Sustainability

Partner Relationships

Strong partner relationships help manufacturers build a more responsive and efficient Supply Chain. Companies work closely with suppliers, distributors, and technology providers to share resources, exchange knowledge, and reduce risks. Research shows that collaboration leads to better performance and competitive advantage. The table below highlights key findings from a large-scale survey of U.S. manufacturing firms:

Evidence Aspect | Description |

|---|---|

Research Method | Large-scale web survey using advanced analysis |

Key Findings | Collaboration enables resource sharing, knowledge exchange, and risk reduction |

Critical Dimensions | Information sharing, goal alignment, decision synchronization, incentive alignment, resource sharing, communication, joint knowledge creation |

Conceptual Distinction | Collaboration creates joint value beyond simple integration |

Practical Examples | Hewlett-Packard, IBM, Dell, and Procter & Gamble use long-term partnerships for competitiveness |

Challenges Noted | Miscommunication and unmet expectations can cause collaborations to fail |

Strategic alliances help firms access new resources and improve financial and operational results. For example, small firms in telecommunications use partnerships to adopt new technology and expand their customer base. Manufacturing companies also benefit from buyer-supplier partnerships, which improve customer service and reduce costs. Electronic commerce strengthens these relationships by making processes more efficient.

Collaboration brings measurable results. Studies show that collaborative supply chains reduce operational costs by 15-25%. About 63% of manufacturers report on-time delivery rates above 95% when they work closely with partners. Companies with strong partner relationships experience fewer disruptions and higher growth.

Sustainable Practices

Sustainable practices are now essential for long-term success in manufacturing. Companies focus on reducing environmental impact, improving efficiency, and building a positive reputation. Key sustainability metrics include:

Careful selection of products and services to lower environmental harm.

Green manufacturing to cut material costs and boost efficiency.

Eco-friendly packaging and efficient logistics.

Lowering emissions with fuel-efficient transport and better routing.

Monitoring carbon footprint to find waste reduction opportunities.

Benchmarking performance against industry standards.

Optimizing reverse logistics for reuse and recycling.

Using environmental publicity to build customer loyalty.

Green production reduces waste and pollution, improving both economic and social outcomes.

Cooperation with customers encourages green practices and better results.

Green logistics focuses on recycling and waste reduction, lowering pollution and raising efficiency.

Important metrics include carbon footprint, waste minimization, and recycling rates.

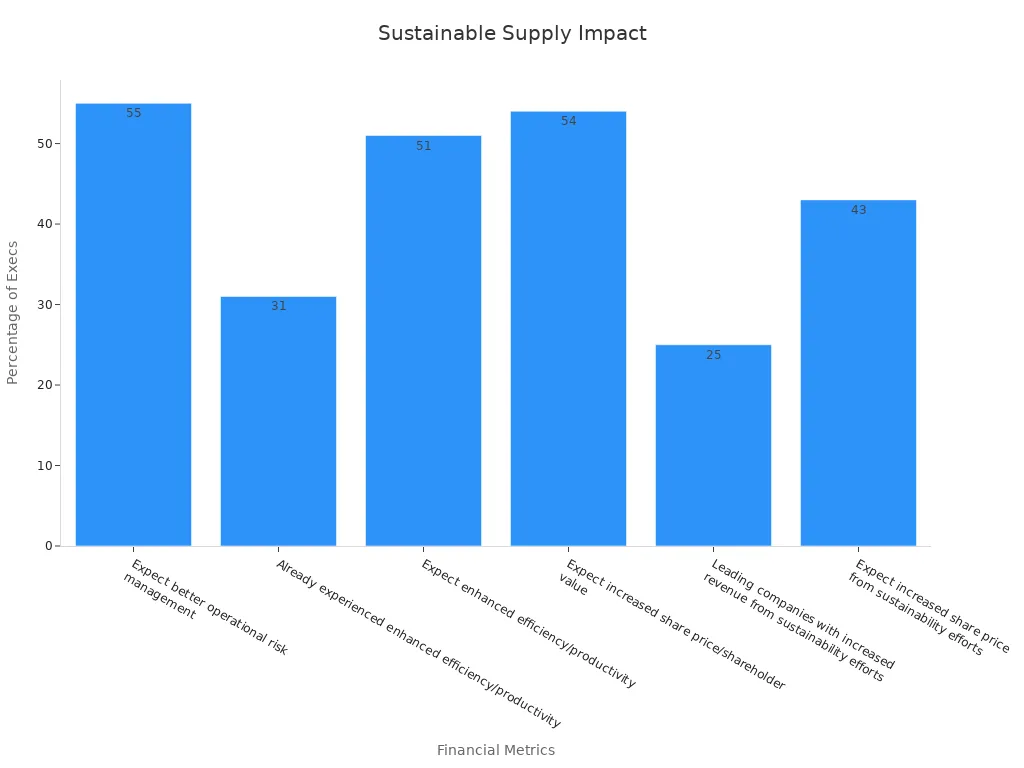

Research confirms the benefits of sustainable practices. Studies show that a sustainable strategy leads to better supply chain practices and a stronger competitive edge. Companies that adopt green methods see improved performance and stability. The table below shows how executives view the financial impact of sustainability:

Financial Impact Metric | Percentage of Supply Chain Executives | Timeframe |

|---|---|---|

Expect better operational risk management | 55% | Next 1-3 years |

Already experienced enhanced efficiency/productivity | 31% | Current |

Expect enhanced efficiency/productivity | 51% | Next 1-3 years |

Expect increased share price/shareholder value | 54% | Next 3-5 years |

Leading companies with increased revenue from sustainability efforts | 25% | Current |

Expect increased share price from sustainability efforts | 43% | Next 1-3 years |

Tip: Companies that invest in sustainability not only help the environment but also gain a competitive advantage and improve financial results.

Manufacturers can boost competitiveness by adopting multi-channel supply chain strategies. Key actions include investing in digital transformation, strengthening partner collaboration, and prioritizing sustainability. The table below highlights how digital transformation improves supply chain efficiency:

Aspect | Impact Summary |

|---|---|

Faster operations, lower costs, better inventory turnover, and higher quality | |

Mechanisms | Stronger governance and market positioning |

Economic Consequences | Reduced transaction costs and improved financial results |

Smart factory investments and AI adoption drive future growth.

Multi-channel supply chains increase resilience, speed, and customer loyalty.

Manufacturers should regularly assess and upgrade their supply chain operations to stay ahead in a changing market.

FAQ

What is a multi-channel supply chain?

A multi-channel supply chain lets manufacturers sell and deliver products through several channels, such as online stores, retail partners, and direct sales. This approach helps companies reach more customers and respond quickly to market changes.

Why do manufacturers need real-time inventory visibility?

Real-time inventory visibility helps manufacturers track stock levels and product movement instantly. This ability reduces errors, prevents stockouts, and supports faster order fulfillment. Companies can make better decisions and improve customer satisfaction.

How does technology improve supply chain efficiency?

Technology, such as automation and data analytics, streamlines operations. It speeds up order processing, improves accuracy, and lowers costs. Manufacturers use these tools to monitor performance, predict demand, and respond quickly to disruptions.

What role does sustainability play in supply chain management?

Sustainability helps manufacturers reduce waste, lower emissions, and use resources wisely. Companies that focus on green practices improve their reputation and meet customer expectations. Sustainable supply chains also support long-term business growth.

How can manufacturers handle returns from multiple channels?

Manufacturers use centralized systems to manage returns from all channels. These systems automate return labels, track items, and process refunds quickly. Clear policies and real-time tracking make returns easier for customers and reduce costs for companies.

See Also

Improving Supply Chain Efficiency Through Cloud-Based Technologies

Streamlining High-Tech Manufacturing Supply Chains With Smart Solutions

The Impact Of Cloud Solutions On Modern Industry Supply Chains

Transforming Supply Chain Management With Cloud-Driven Innovations

Maximizing Automotive Supply Chain Performance Through Advanced Strategies