Optimizing Your Supply Chain with Warehousing Solutions

Supply chain optimization holds significant importance for businesses aiming to achieve higher revenue growth. Companies with high-performing supply chains often surpass industry averages in revenue growth. Warehousing solutions play a crucial role in effective supply chain management by providing efficient storage and distribution of goods. Effective warehousing can lead to numerous benefits, such as reduced operational costs and improved customer satisfaction.

Understanding Warehousing Solutions

Types of Warehousing Solutions

Public Warehouses

Public warehouses offer storage services to multiple businesses. These facilities provide flexible and cost-effective warehousing solutions. Companies can rent space as needed, making public warehouses ideal for businesses with fluctuating inventory levels.

Private Warehouses

Private warehouses are owned and operated by individual companies. These facilities offer customized warehousing solutions tailored to specific business needs. Companies benefit from greater control over operations and can implement specialized storage systems.

Bonded Warehouses

Bonded warehouses store imported goods before customs duties are paid. These facilities allow businesses to defer taxes until the merchandise is sold or moved. Bonded warehouses provide secure storage and help manage cash flow effectively.

Smart Warehouses

Smart warehouses use advanced technologies to automate processes and improve efficiency. Automated material handling systems, real-time data insights, and intelligent software enhance operational workflows. Smart warehousing solutions reduce labor costs, shorten order processing times, and optimize resource usage.

Key Components of Warehousing Solutions

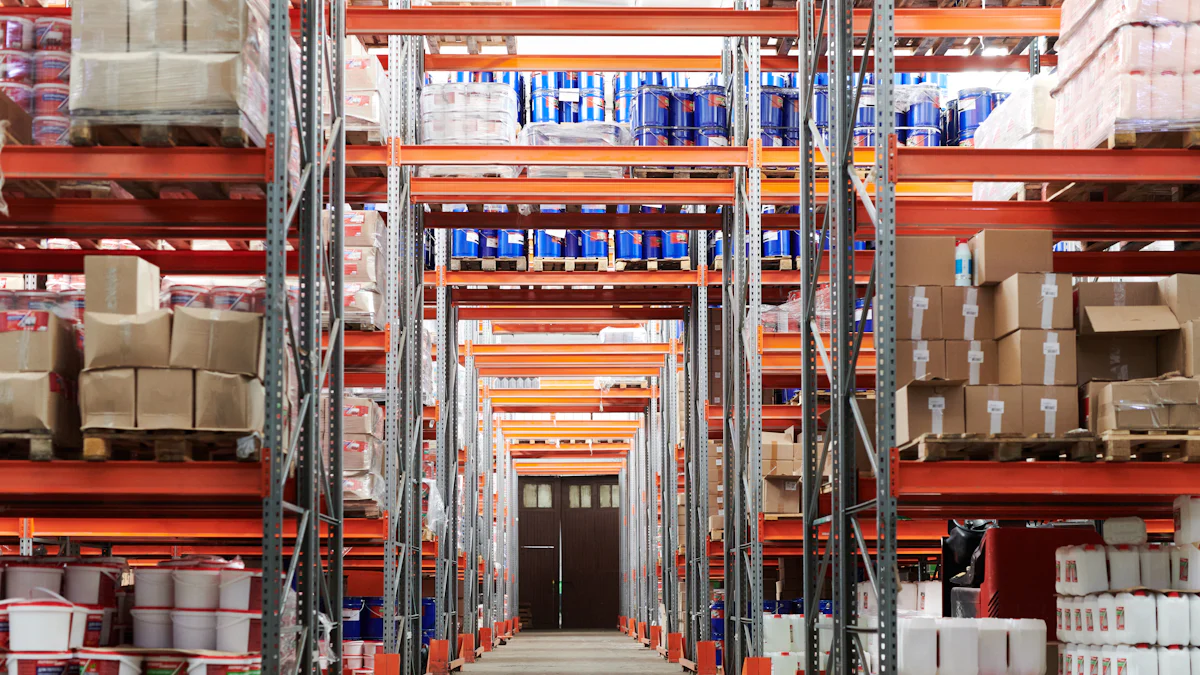

Storage Systems

Storage systems include shelves, racks, and bins designed to maximize space utilization. Efficient storage systems facilitate easy access to inventory and streamline warehouse operations.

Inventory Management

Inventory management involves tracking stock levels, orders, sales, and deliveries. Advanced inventory management systems ensure accurate record-keeping and prevent stockouts or overstock situations.

Material Handling Equipment

Material handling equipment includes forklifts, conveyors, pallet jacks, and automated guided vehicles (AGVs). This equipment enhances the movement of goods within the warehouse, improving overall productivity.

Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) oversee daily warehouse operations. WMS software manages tasks such as receiving, putaway, picking, packing, shipping, and inventory control. Effective WMS implementation leads to streamlined processes and reduced errors in warehousing operations.

Benefits of Optimizing Your Supply Chain with Warehousing Solutions

Improved Efficiency

Faster Order Fulfillment

Warehousing solutions enhance the speed of order fulfillment. Advanced automation systems streamline picking, packing, and shipping processes. Cardinal Health revolutionized operations through advanced automation. This led to optimized order efficiency in healthcare services.

Reduced Lead Times

Efficient warehousing solutions reduce lead times significantly. Real-time inventory tracking ensures quick restocking and minimizes delays. Materialogic's partnership with Tough Mudder streamlined inventory ordering processes. This resulted in significant annual savings of $200K.

Cost Savings

Lower Storage Costs

Effective warehousing solutions lower storage costs by optimizing space utilization. Smart warehouses use automated storage systems to maximize capacity. Companies can avoid unnecessary expenses related to excess inventory.

Reduced Transportation Costs

Strategically located warehouses reduce transportation costs by minimizing travel distances for deliveries. Integrated logistics services offer customized storage and distribution solutions, particularly excelling in home appliance assembly and delivery.

Enhanced Customer Satisfaction

Accurate Order Processing

Accurate order processing is a key benefit of optimized warehousing solutions. Warehouse Management Systems (WMS) ensure precise tracking and management of orders. This leads to fewer errors and higher customer satisfaction rates.

Timely Deliveries

Timely deliveries are crucial for maintaining customer trust and loyalty. Efficient warehousing solutions enable faster dispatching of goods, ensuring that customers receive their orders on time.

Practical Tips for Implementing Warehousing Solutions

Assessing Your Current Supply Chain

Identifying Bottlenecks

Identifying bottlenecks in the supply chain is crucial. Start by analyzing each step in the process. Look for delays, inefficiencies, and areas where resources get wasted. Use data analytics to pinpoint specific issues. Addressing these bottlenecks will enhance overall performance.

Evaluating Warehouse Performance

Evaluating warehouse performance involves several key metrics. Measure order accuracy, inventory turnover rates, and storage utilization. Regular audits help maintain high standards. Implementing a Warehouse Management System (WMS) can provide real-time insights into operations.

Choosing the Right Warehousing Solution

Factors to Consider

Several factors influence the choice of warehousing solutions. Consider the type of goods stored, required storage conditions, and expected volume fluctuations. Proximity to suppliers and customers also plays a significant role. Evaluate whether public, private, or specialized warehouses best meet business needs.

Cost-Benefit Analysis

Conduct a cost-benefit analysis before selecting a warehousing solution. Compare costs related to rent, labor, equipment, and technology against potential benefits like improved efficiency and customer satisfaction. Automated systems may have higher initial costs but offer long-term savings through reduced labor expenses.

Integrating Technology

Automation

Automation transforms warehouse operations by increasing efficiency and reducing errors. Automated storage systems optimize space utilization and streamline workflows. Technologies like robotics and automated guided vehicles (AGVs) enhance material handling processes.

"Warehouse automation improves space utilization, service levels, and reduces operating costs." — International Journal of Logistics Management

Data Analytics

Data analytics plays a pivotal role in modern warehousing solutions. Real-time data helps track inventory levels accurately and predict demand patterns. Advanced analytics tools enable better decision-making by providing actionable insights into operational performance.

"Tech-driven solutions optimize workflows, reduce labor costs, and improve operational efficiency."

Implementing these practical tips will lead to more efficient warehousing solutions, ultimately enhancing supply chain performance.

Case Studies and Real-World Examples

Successful Implementations

Company A

Materialogic’s Partnership with Tough Mudder

Materialogic collaborated with Tough Mudder to implement a tailored Warehouse Management System (WMS). The partnership focused on innovative supply chain solutions. Materialogic streamlined inventory ordering processes, resulting in significant annual savings of $200K. This collaboration also enabled the expansion of Tough Mudder's event portfolio.

Swisslog Customer Case Studies

Swisslog provided customized warehousing solutions to various clients. Each solution addressed specific warehouse and distribution challenges. Swisslog's implementations led to increased profitability and improved operations for their clients. The use of advanced technologies played a crucial role in these successes.

Company B

Cardinal Health

Cardinal Health revolutionized its warehousing operations through advanced automation systems. These systems optimized order efficiency within healthcare services. The implementation resulted in faster order fulfillment and reduced lead times. Cardinal Health achieved significant improvements in operational workflows.

Lucas Systems

Lucas Systems introduced voice recognition technology for warehouse optimization. This technology enhanced material handling processes and improved accuracy in order picking. Lucas Systems' solution led to higher productivity levels and reduced operational costs for their clients.

Lessons Learned

Common Challenges

Integration Issues

Companies often face difficulties integrating new WMS with existing systems.

Ensuring compatibility between different software platforms poses a challenge.

Training Requirements

Employees need extensive training to adapt to new technologies.

Lack of proper training can lead to errors and inefficiencies.

Initial Costs

High initial costs associated with implementing advanced warehousing solutions.

Budget constraints may hinder the adoption of necessary technologies.

Best Practices

Comprehensive Planning

Conduct thorough planning before implementing new warehousing solutions.

Assess current processes, identify bottlenecks, and set clear objectives.

Employee Training Programs

Invest in comprehensive training programs for employees.

Ensure staff members understand how to operate new systems effectively.

Phased Implementation

Implement new technologies in phases rather than all at once.

Monitor progress closely and make adjustments as needed during each phase.

Regular Audits

Perform regular audits to evaluate the performance of warehousing solutions.

Use data analytics tools to gain insights into operational efficiency.

"Implementing a WMS requires careful consideration of integration, training, costs, and ongoing evaluation." — Gartner Peer Insights

By learning from these case studies and best practices, businesses can overcome common challenges and achieve successful implementations of warehousing solutions that optimize their supply chains effectively.

Effective warehousing solutions play a pivotal role in optimizing supply chains. Businesses can achieve significant cost savings and enhanced customer satisfaction through strategic warehouse management. Practical implementation of advanced technologies, such as automation and data analytics, ensures streamlined operations.

"To meet customers' expectations on shorter lead times, high product availability, flexibility, and variation in delivery and return options, retailers have turned their attention to warehousing and are making big investments in technology."

Taking actionable steps towards optimizing the supply chain will result in improved efficiency and competitive advantage.

See Also

Cloud-Based Solutions for Optimizing Supply Chain Efficiency

Boosting Warehouse Efficiency with Robotics in Logistics

Optimizing Supply Chain Costs: An Economic Perspective

Exploring Robotic Automation for Enhanced Warehouse Efficiency

Unveiling 5 Cutting-Edge Techniques for Supply Chain Optimization