Key Innovations Shaping Overseas Warehousing Services in 2025

Overseas warehousing services in 2025 are growing fast. The market will reach $150 billion. It grows by 8% each year. Global warehouse trends focus on automation, AI, IoT, and sustainability. These are the main reasons for growth. E-commerce and cross-border e-commerce are changing warehouse logistics. Industry trends show new ideas help warehouses work better. Innovation makes global warehouse operations stronger and more efficient.

Key Takeaways

AI, robotics, and IoT technologies are changing overseas warehouses. They help workers do jobs more accurately. They make work faster and help save money.

Sustainability efforts like green logistics and energy efficiency help warehouses spend less. These efforts also help protect the environment.

Digital tools and local micro-fulfillment centers help make deliveries faster. They help keep better track of inventory. They also make global supply chains safer.

AI & ML in Overseas Warehousing

Smarter Inventory

Artificial intelligence and machine learning are changing overseas warehousing in 2025. Companies use computer vision, IoT sensors, and robotics to keep track of inventory. These tools help them be very accurate. JUSDA’s JusAI and JusLink platforms help do simple warehouse jobs automatically. This makes work faster and more dependable. These systems let workers see inventory in real time. They can make quick choices.

AI-powered warehouses can:

Make fewer mistakes when picking and packing.

Use data to guess what will run out or pile up.

Work smoothly with warehouse management systems.

JUSDA works with Sharp to use these new technologies. After using AI, Sharp spent 20% less on logistics. Labor costs dropped by 70%. Orders got delivered 30% faster. These changes show how new ideas help warehouses.

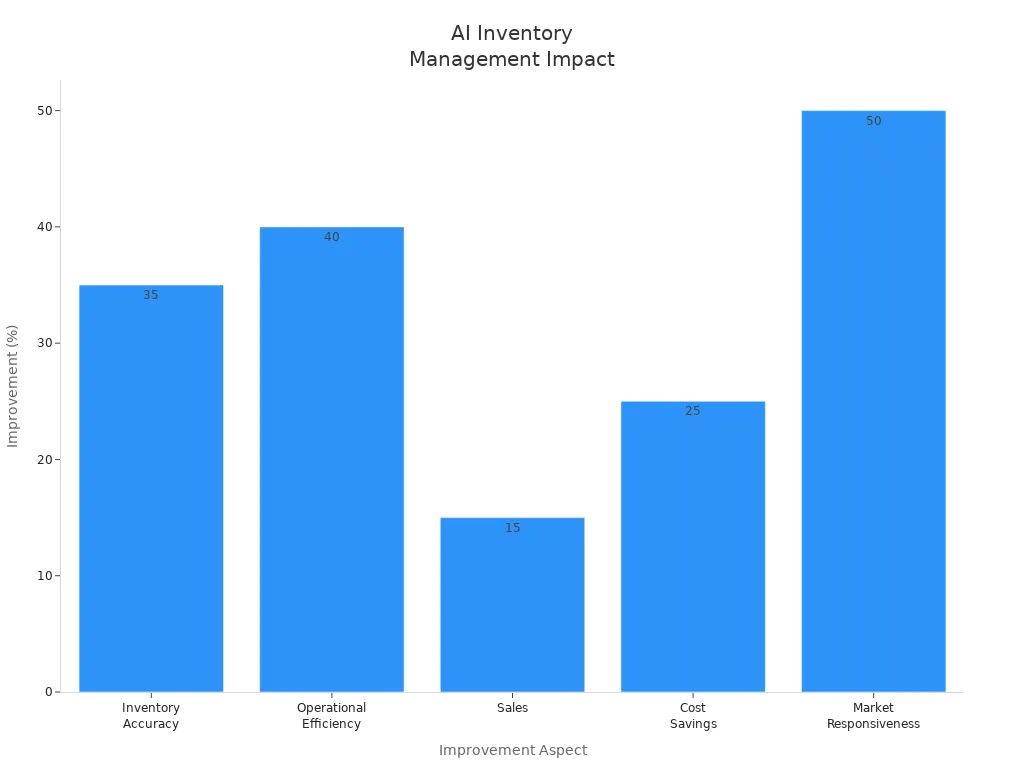

Aspect | Improvement/Impact |

|---|---|

Inventory Accuracy | |

Operational Efficiency | Processing time reduced by 40% |

Sales | Increased by 15% |

Cost Savings | Reduced excess inventory by 25% |

Market Responsiveness | Improved by 50% |

Demand Forecasting

Machine learning looks at sales, seasons, and world events to guess demand. JUSDA’s technology helps overseas warehouses by reading data in many languages and currencies. This lets companies put the right products in the right place. It saves money and makes customers happier. AI demand forecasting can lower warehouse costs by 10%. It can also cut office costs by 40%. These tools help overseas warehouses work better and support global supply chains with smart technology.

Robotics & Warehouse Innovation

Automation Trends

Warehouse automation is changing how warehouses work in 2025. Companies use robots like AMRs and AGVs for simple jobs. These robots move things, sort boxes, and help load or unload. Many warehouses use cloud systems to track and control things right away. Digital twin technology lets people test changes before doing them in real life.

Key automation trends in overseas warehousing include:

Using robots to help with not enough workers and to speed up orders.

Adding AI and machine learning for better choices.

Using teleoperations to control machines from far away, making things safer.

Caring about the environment by using less energy with automation.

JUSDA uses robotics in its warehouses all over the world. This helps warehouses work better, make fewer mistakes, and give fast, good service to many clients.

Collaborative Robots

Collaborative robots, called cobots, work with people in today’s warehouses. They do jobs like picking, packing, and sorting, which makes work faster by about 40%. Cobots have smart sensors and AI to keep people safe and move carefully. This means people can do harder jobs while cobots do the easy, repeating ones.

Reports say cobots help stop accidents and lower worker costs. Warehouses in Asia-Pacific use more cobots as online shopping grows. Companies get faster orders, fewer mistakes, and safer workplaces. This makes cobots very important for warehouse automation.

IoT & Shipment Tracking

Real-Time Visibility

IoT technology has changed how companies track shipments. Now, smart sensors and GPS trackers watch shipments all the time. JUSDA’s JusLink platform gives live updates on global shipments. This platform connects IoT devices with transport systems. Logistics teams get instant news about where shipments are, their temperature, and if containers are open or closed.

Smart containers check temperature, door use, and strange events.

IoT sensors watch inventory levels to stop too much or too little stock.

Watching in real time helps everyone see what is happening and builds trust.

Many top logistics companies, like JUSDA, use these tools to stop delays and missed deliveries. Customers get correct updates, so they feel happy and trust the company more. Real-time tracking also helps manage inventory and guess demand, making warehouses work better.

Predictive Maintenance

IoT systems do more than just track shipments. They also help keep warehouse machines working well. Sensors on forklifts, conveyor belts, and sorting machines check how things are running and spot problems early. This is called predictive maintenance and it stops machines from breaking and saves money on repairs.

Sensors always watch for changes in temperature or odd shaking.

Early warnings help fix things fast and stop long breaks.

Fixing things before they break makes machines last longer and keeps workers safe.

JUSDA uses AI-powered analytics with IoT devices to help warehouses run smoothly. Predictive maintenance saves money and helps warehouses stay safe and steady.

Warehouse Sustainability

Green Logistics

Green logistics is very important for companies that want to help the planet. Many warehouses now use less energy by using smart lights and solar panels. These changes help them make less pollution. JUSDA shows others how to be green by cutting waste and recycling more. They also use green packaging to help save resources.

Companies that care about warehouse sustainability teach workers to help the environment. They use smart route planning to use less fuel and make less pollution. Warehouses pick packaging that can break down or be used again. This helps cut down on trash and supports a circular economy.

A study found that green ideas in warehouses make supply chains better. DHL’s sorting hub in Germany makes over 1,000 MWh of solar power each year. This helps them use less fossil fuel and make less pollution.

Energy Efficiency

Energy efficiency is a big part of being a green warehouse. Warehouses use smart inventory systems and IoT sensors to watch how much energy they use. JUSDA uses these tools to work better and help the planet.

Metric | Result |

|---|---|

Renewable energy self-consumption | |

Reduction in energy use | 110 MWh per year |

CO2e emissions cut | 67.8 tons per year |

Many warehouses want to become Net-Zero Energy Buildings. This helps them save money and protect nature. By using less energy, companies can meet new rules and be leaders in warehouse sustainability.

Digitalization in Overseas Warehouse Logistics

Advanced WMS

Digital changes are making overseas warehouse logistics better. Companies use advanced Warehouse Management Systems like JUSDA’s JusLink and eVMI. These systems help manage inventory and track orders. They also make workflows smoother. Barcode scanning, RFID, and IoT devices help track things in real time. These systems connect with ERP and TMS. Managers get instant updates and more control. New WMS technology lowers mistakes and makes work faster.

Feature/Capability | Description | Benefits |

|---|---|---|

Barcode/RFID, IoT for instant data capture | Fewer stockouts, better order accuracy | |

Data Synchronization | Updates with ERP/TMS systems | Improved visibility, faster decisions |

Streamlined Fulfillment | Automated order validation, barcode scanning | Fewer errors, happier customers |

Workforce Management | Task assignment, performance tracking | Higher productivity, less idle time |

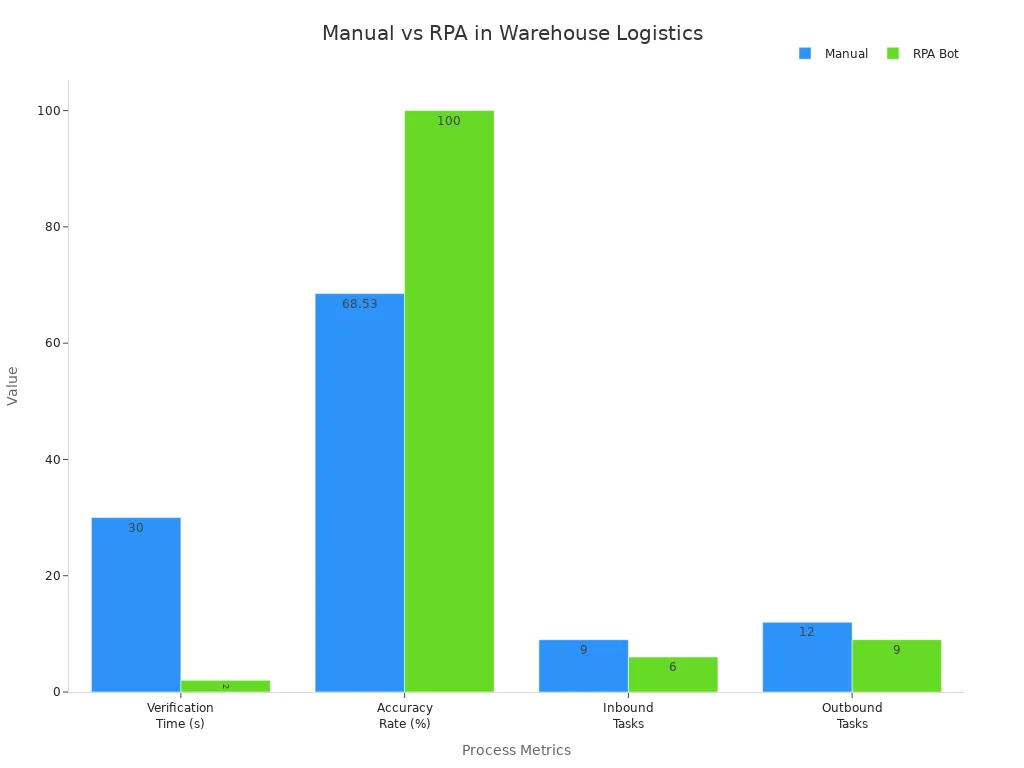

RPA bots check data much faster than people. They take only 2 seconds for each row. Manual entry took 30 seconds before. Accuracy went up from 68.53% to 100%. Inbound and outbound jobs are now easier and quicker.

Data-Driven Decisions

Data helps managers make better choices in warehouse logistics. Real-time dashboards and analytics show trends and help plan jobs. This saves money and time. Priority scheduling helps managers react faster. Delaying order cut-off times gives more options without slowing delivery. Simulation models help pick the best way to work.

Managers find and fix waste in logistics steps.

IoT and analytics help watch and control things better.

Always improving makes logistics faster and more reliable.

JUSDA’s technology lets companies change quickly and stay ahead in global markets.

Micro-Fulfillment & Decentralization

Local Hubs

Micro-fulfillment centers are changing how companies handle logistics. North America is leading in using these centers. The United States and China spend a lot on automation and robotics. Many online stores use local hubs to keep products near customers. These hubs are close to airports, highways, or railroads. This makes moving goods fast and easy. Real-time inventory systems help staff ship orders in one day. Automated order processing speeds up the work. Local couriers use special tools to find the best routes. This helps them deliver packages faster and saves time. Using local hubs lowers warehousing costs for online stores. It also helps companies get money back faster. Keeping products close to buyers gives businesses a big edge.

Local fulfillment hubs make cross-border shipping easier. They help companies skip customs delays and pay fewer duties. Regional warehouses help with quick and steady international deliveries. This is very important for growing online shopping.

Fast Delivery

Decentralized warehousing puts products in many places. This helps companies react fast when more people buy in some areas. Shorter trips mean lower transport costs and faster last-mile delivery. These warehouses have safety features to protect goods and keep them high quality. Big companies like Amazon and Walmart use these networks for fast shipping. They can offer same-day or next-day delivery. Flexible warehousing lets businesses grow or shrink as needed. They do not need long contracts. E-commerce growth means companies need faster and better logistics. Micro-fulfillment centers and local hubs help meet customer needs for speed and good service.

Security & Compliance

Digital Security

Digital security is very important for overseas warehouses in 2025. Companies like JUSDA work hard to keep data safe from cyber threats. They use strong network security to protect information. This includes firewalls, encryption, and strong passwords. Each step helps stop hackers and keeps data safe.

Warehouse teams also train workers to spot fake emails. Workers learn to keep their passwords secret. Training helps stop cyber attacks before they happen. Software and systems get regular updates to stay safe. Updates fix weak spots that hackers could use.

Note: Digital security needs both good technology and careful people. Workers help keep warehouses safe from cyber threats.

A safe warehouse management system builds trust with clients. It also helps warehouses run well, even when new risks appear.

Automated Compliance

Automated compliance tools help warehouses follow global rules. These tools check shipments, customs papers, and safety records. They warn managers if something breaks the rules. This helps stop mistakes and saves time.

JUSDA uses digital platforms to track compliance right away. Automated systems update records and make reports for audits. This helps companies follow new laws in different countries. Companies avoid fines and delays by using these tools.

Compliance Feature | Benefit |

|---|---|

Real-time monitoring | Faster response to issues |

Automated reporting | Easier audits |

Rule-based alerts | Fewer compliance mistakes |

Automated compliance helps overseas warehouses work smoothly. It keeps companies ready for new rules and changes in global trade.

JUSDA Solutions

To provide you with professional solutions and quotations.

Global warehouse trends help warehouses change and work better. They also help them care for the planet. JUSDA uses new technology and special services in many places. Industry trends show that green ideas and digital tools help companies avoid problems. These trends also help them do a better job. Global warehouse trends will keep changing. They will help make the future smarter and safer.

See Also

Top Five Trends Shaping Supply Chain Efficiency Future

How Artificial Intelligence Is Transforming Logistics Tomorrow

Discover The Latest Sea Freight Logistics Updates For 2024