Top Innovations Transforming Global Warehousing and Logistics

Rapid innovation changes warehousing and logistics around the world every day. Companies spend money on new technology. About 80% of organizations want to upgrade to work better. Customers are happier because real-time tracking and predictive analytics are now common. JUSDA is a leader by using new technology and Overseas Warehousing Services. They set new trends in efficiency and sustainability for the whole industry.

Key Takeaways

New technologies like AI, automation, and big data help warehouses work faster. They also make them safer and more efficient. These tools help companies deliver orders quickly. This keeps customers happy.

Green logistics and sustainable practices help cut down pollution. They also save money for companies. Strict environmental rules make companies use cleaner vehicles. They also make them choose smarter routes.

Strong supply chains need many different suppliers. They also need digital teamwork and real-time data. These things help handle risks. They keep products moving smoothly all over the world.

Logistics Trends 2025

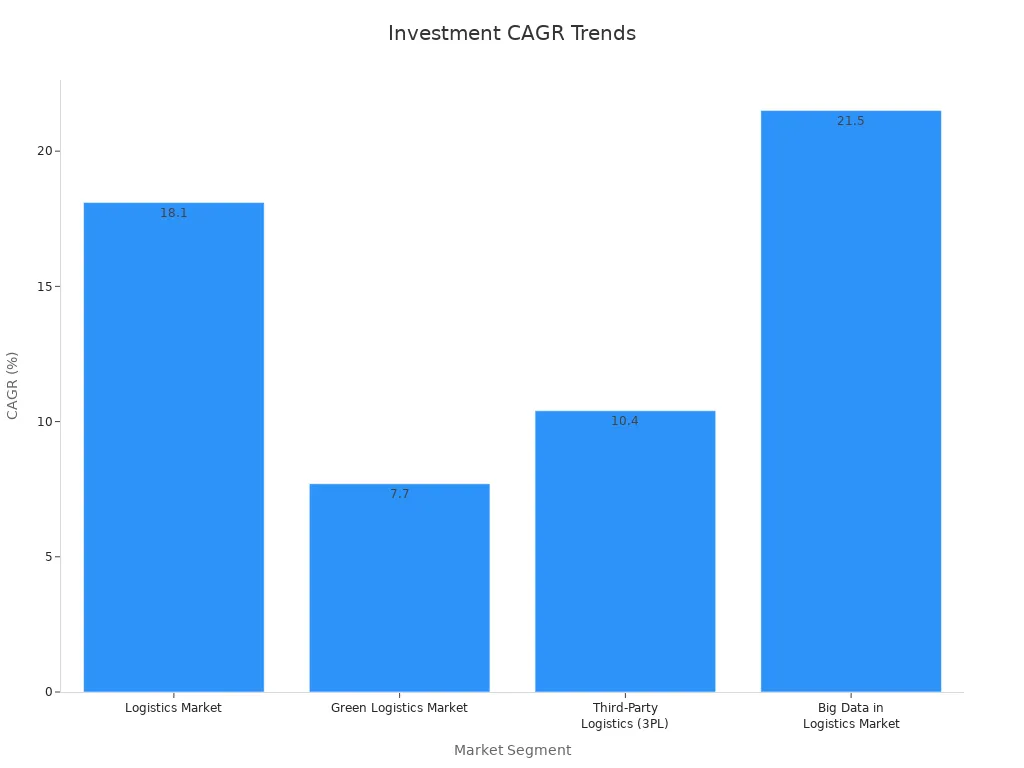

The logistics industry is changing fast. New technology is making global supply chains different. Companies want to be quick, clear, and efficient to win. The table below shows the top logistics trends for 2025:

Trend | Description | Quantitative Impact / Evidence |

|---|---|---|

Agility and Resilience | Agile supply chain strategies help stop problems and recover faster. | 50% fewer disruptions; 30% faster recovery. |

Visibility and Traceability | Blockchain and IoT let people track shipments in real time and see everything clearly. | 80% of executives value real-time visibility; 35% better on-time delivery. |

Digital Integration | Cloud systems and AI analytics make things work better and help customers more. | 40% less administrative work; 25% higher operational efficiency. |

Workforce Evolution | Automation and AI mean workers need new skills and can do more. | 50% more demand for AI/robotics skills; 35% productivity increase. |

Greener fuels and electric vehicles help the planet. | $10 billion investment by 2025; 20% annual growth in sustainable logistics. |

Automation

Automation is a big trend for 2025. Companies use robots and machines to pick and pack faster. This helps cut mistakes and lets work happen all day and night. Automated systems do dangerous jobs, so workers are safer. Warehouse Management Systems and automated belts remove extra steps. They help warehouses work together better. These changes mean orders get filled faster and customers are happier.

AI and IoT

Artificial intelligence and IoT are changing logistics. They help track things in real time and fix problems before they happen. AI robots and IoT sensors make warehouses work up to 33% better. JUSDA uses the JusLink platform to connect AI and IoT. This gives real-time views of inventory and helps manage supply chains. These tools stop lost shipments, make better guesses, and keep things running all the time.

Big Data

Big data analytics helps companies make smart choices. It shows what is happening with inventory, shipments, and problems right now. Most third-party logistics companies use big data to watch and improve their work. Machine learning and AI look at delivery times, routes, and inventory. This helps companies plan better and spot issues early. More clear information and smart guesses help companies react fast and save money.

Note: New trends in logistics show that digital change, being green, and using smart data are very important. JUSDA leads with AI solutions and the JusLink platform, setting a high standard for others.

Overseas Warehousing Services

JUSDA Global Network

JUSDA runs one of the largest overseas warehousing networks in the world. The company has over 155 service points and more than 2.5 million square meters of warehouse space. These warehouses are in important places like China, Vietnam, India, the United States, Mexico, Japan, and Europe. Because of this, JUSDA can help many different industries and meet the need for overseas warehouse logistics.

The overseas warehouse market is growing very fast. Experts think the global warehouse market will go from $150 billion in 2025 to over $280 billion by 2033. This growth happens because e-commerce is rising, supply chains are spreading worldwide, and smart warehouse technology is being used more. Companies like JUSDA help businesses use supply chains in many countries. This helps lower risks from trade problems and other disruptions. Using warehouses in many places also helps companies react quickly to changes in demand or local issues.

JUSDA’s global network uses new technology to work better and stay strong. Automation and smart data systems help with tough trade rules and customs. These tools make sure international work goes smoothly and keeps running during busy times. Good partnerships and technology platforms like JusLink help partners talk and solve problems. This network gives clients strong overseas warehousing services and helps keep global supply chains working well.

Smart Warehouse Solutions

JUSDA spends money on smart warehouse solutions to do better in overseas warehouse logistics. The company uses advanced management systems like eVMI and JusLink. These systems let clients see their inventory in real time. Clients always know what they have, which builds trust and makes things clear.

Smart warehouse solutions use automation, AI, and IoT to work faster. Robots and machines pick, pack, and sort items. This cuts down on mistakes and makes orders go out quicker. AI analytics help guess what customers will want and keep the right amount of stock. IoT sensors watch warehouse conditions and track shipments as they move. These tools help track shipments well and make supply chain management better.

JUSDA’s smart warehouses also help companies follow strict safety and environmental rules. Clean rooms in places like Vietnam meet the needs of big tech brands. Using technology makes sure overseas warehousing services stay strong and work well. Clients get better control of their inventory, can react faster to changes, and track shipments more easily.

Value-Added Services

JUSDA gives many value-added services as part of its overseas warehousing. These services include picking, packing, labeling, kitting, repacking, and software upgrades. Special care for things like frozen or cold goods keeps them safe and meets industry rules. These services help companies do more steps in one place and cut down on extra handling.

Value-added services make supply chains work better by handling inventory well and saving money. Advanced Warehouse Management Systems connect these services with main warehouse and delivery jobs. This helps companies deliver faster and makes customers happier. Overseas warehouse logistics let companies keep goods closer to buyers, so deliveries often take just one to three days.

JUSDA’s value-added services help many industries like retail, e-commerce, food and drink, and consumer packaged goods. Small and medium businesses can reach global markets without spending a lot on buildings. Working with third-party logistics providers makes packaging, customer service, and order filling even better. The fast growth of the overseas warehouse market shows that more people want cheap and quick shipping.

Note: Overseas warehousing services are very important in today’s supply chains. JUSDA’s global network, smart warehouse solutions, and value-added services help businesses work better, be more open, and keep customers happy.

Green Logistics

Sustainable Operations

Green logistics tries to help the planet and work better. Companies use green procurement and eco-friendly transportation. They also plan delivery routes to save energy. These steps help stop pollution and save money. Many companies check their carbon footprint with the Greenhouse Gas Protocol. Big carriers measure and share their emissions data. This helps them set and reach net-zero goals. Companies change routes, use new fuel vehicles, and try automated routing tools. These actions lower fuel use and emissions. This helps warehouses be more green and makes logistics more responsible.

Green logistics helps use less fossil fuel and cuts CO₂.

Tough rules make companies use greener ways.

Faster customs and better freight help green growth.

Energy Efficiency

Energy efficiency is very important for green logistics. Companies buy electric vehicles and use renewable energy. They also use smart routing systems. These choices help use less energy and make less waste. The table below shows how top companies get good results:

Company | Sustainable Results |

|---|---|

Unilever | 40% less CO₂, all renewable electricity, 18% fewer empty miles |

IKEA | 17.3% lower climate footprint, electric deliveries in 30 cities |

Nestlé | 30% less packaging, biogas trucks, blockchain for sustainability |

These results show that using less energy helps the planet and saves money.

Environmental Standards

International standards guide logistics around the world. Groups like the International Maritime Organization and the European Union make strict rules. These rules are for emissions and safety. Companies must use clean vehicles and renewable packaging. They also need to plan better routes to follow the rules. Some places tax emissions or want clean carrier certificates. Some platforms offer services with lower emissions and carbon offsets. These standards help the industry be more green and work better.

Blockchain in Logistics

Transparency

Blockchain helps everyone see what happens in logistics. Each partner can watch every step, from making to delivering products. The technology makes records that no one can change. This helps everyone trust each other more. Walmart uses blockchain to track food. They can find problems in seconds, not days. IBM and Maersk's TradeLens help people work together better. They also help everyone see what is happening in the supply chain.

Everyone can track shipments right away.

Records are always clear and cannot be changed.

This stops fraud and mistakes.

People can check where food and medicine come from.

More transparency saves money and makes things faster.

Blockchain helps companies share information safely and work together better.

Security

Blockchain makes logistics safer by keeping a record of every move. No one can change these records. This stops fraud and fake products. VeChain and De Beers use blockchain to check if products are real. This cuts fake goods by half. Smart contracts do deals automatically and make them safer. They also help stop mistakes. Blockchain lowers paperwork costs and solves problems faster. The safe ledger keeps private data safe and helps everyone trust each other.

Real-Time Data

Blockchain lets everyone share shipment and inventory data right away. This means changes are recorded as soon as they happen. It helps stop mistakes and missing items. Smart contracts pay right after a delivery is done. This makes things go faster. No one can change the data, so tracking is always right. Watching shipments and inventory in real time helps companies fix problems fast. This makes logistics work better for everyone.

Last-Mile Supply Solutions

Autonomous Delivery

Autonomous delivery is changing how packages reach people. Companies use robots and drones to bring packages any time of day. These machines help save money on workers. They also let deliveries happen all day and night. AI helps drivers find the best roads and skip traffic. Packages arrive faster and on time. Real-time tracking lets people see where their package is. Proof of delivery builds trust, especially for medicine.

Walgreens and Domino’s now deliver in less than 30 minutes. Before, it took 90 minutes. They use autonomous vehicles to do this.

Over 15,000 robots and drones work in cities like Los Angeles and London.

Truck robots can cut last-mile delivery costs by up to 68%.

GPS and IoT sensors track packages. This means more packages arrive on the first try. Fewer customers complain.

Cameras and weight sensors keep packages safe and make customers happier.

Micro-Fulfillment

Micro-fulfillment centers are small, smart warehouses near customers. They use machines to fill orders fast. These centers help city supply chains work better. The market for micro-fulfillment could grow a lot by 2032.

Each center can fill up to 15,000 orders every week.

Automation in these centers can lower order costs by almost 75%.

The last mile is 41% of supply costs. Micro-fulfillment centers help lower these costs by being close to people.

By 2030, there may be one center for every 10 grocery stores in the U.S.

88% of online shoppers want same-day delivery. Micro-fulfillment makes this possible.

Customer Experience

Customer experience is very important for last-mile delivery. Companies watch delivery times, order accuracy, and how happy customers are. Real-time tracking and clear messages help customers feel cared for.

Metric | Description & Measurement Method | Impact on Customer Experience and Logistics Improvement |

|---|---|---|

Surveys and feedback forms measure this score. It is the number of happy responses divided by all responses, times 100. | A higher CSAT means customers are happier and more loyal. Good scores show better service and happier customers. | |

Order Accuracy | This is the percent of orders shipped correctly. Companies compare correct orders to all orders. | High accuracy means fewer returns and complaints. Customers trust the company more and costs go down. |

Delivery Times | This is how long it takes to deliver. Real-time tracking helps make this faster. | Faster and reliable deliveries make customers happier. They also know when to expect their package. |

Transportation Costs | This is the total cost for shipping divided by the number of shipments. It includes fuel, workers, and repairs. | Lower costs mean better prices and better service for customers. |

Inventory Turnover Rate | This is the cost of goods sold divided by average inventory. | Fast turnover means less money spent holding products. It also means products are always ready for customers. |

When companies use technology to improve logistics, customers are happier. Business results also get better.

Space Optimization

Vertical Storage

Warehouses use vertical storage to save space. They put up tall racks and shelves. This lets them store more things without a bigger building. Automated vertical storage systems help track inventory right away. This means fewer mistakes and better records. These systems also make picking faster and need less manual work. Many industries, like automotive and healthcare, use vertical storage. It helps keep things safe and manage inventory better.

Vertical storage uses space above the floor to hold more items.

Automated systems show inventory updates right away and cut mistakes.

These solutions save money by not needing more floor space or extra workers.

Vertical lift modules and automated retrieval systems make vertical storage work even better.

Good tips are to check inventory needs, pick the right tools, and train workers.

Dynamic Layouts

Dynamic layouts help warehouses use space in smart ways. Flexible shelves can change as inventory changes. This can make space use better by 20-40%. Warehouses can hold many types of items without getting bigger. Forward pick areas help workers grab popular items fast. Different racks help workers pick items quicker. Flexible layouts can change every day based on what is needed. This means workers walk less in the warehouse. This way works well for just-in-time and cross-docking jobs. Dynamic layouts make it easy to get to inventory and store it well.

Maximizing Capacity

Maximizing capacity means using all parts of the warehouse. Companies save money and fill orders better when they use space well. Automation lets warehouses have narrow aisles and stack things higher. This makes more room for inventory.

Metric | Quantitative Benefit |

|---|---|

Storage capacity increase | 15-30% more space with better design |

Picking time reduction | Up to 50% less time needed |

Vertical space utilization | Can double storage in the same area |

Use of high-bay racking systems | Stores more by going up, not out |

Vertical storage systems and narrow aisles help warehouses hold more and pick faster. These ideas help companies avoid spending more on bigger buildings and keep inventory moving well.

Supply Chain Resilience

Diversification

Supply chains can have problems from things happening around the world. Companies use diversification to make their supply chains stronger. Many businesses add more suppliers to be more flexible. About 77% want to have more suppliers in two years. More than half have started new work in other countries. Some companies move factories closer to home to lower risk. Multi-sourcing and multi-shoring help avoid trouble in one area. They also use different ways to move goods and keep inventory in many places. This helps supply chains stay steady and keeps products moving during hard times.

Diversification Trend | Description | Impact on Supply Chain Resilience |

|---|---|---|

Multi-sourcing | Multiple suppliers in different regions | Quick response to disruptions |

Multi-shoring | Production in several countries | Reduces risk from regional events |

Production Flexibility | Adjusting production to meet demand | Adapts to market changes |

Diverse Transport | Using many transport options | Avoids bottlenecks |

Inventory Spread | Inventory in many places | Keeps supply steady |

Risk Management

Risk management means looking for weak spots and making plans. Companies check for risks like delays, shortages, or political problems. They make backup plans and keep extra inventory in important places. Many use networks that do not depend on just one supplier or place. This helps them act fast if something goes wrong. Checking often and talking with partners helps lower risk. Spending money on resilience saves more by stopping big losses from delays or unhappy customers.

Digital Collaboration

Digital collaboration tools help supply chains be stronger and more flexible. These tools let companies share real-time data with partners. Platforms like SAP, Oracle SCM Cloud, and Manhattan help track shipments and manage inventory. Cloud systems, IoT, and blockchain make things clearer and build trust. Working together online can cut costs by up to 25%. Over 60% of manufacturers now deliver on time more than 95% of the time because of better teamwork. Decentralized digital platforms help teams plan, guess demand, and fix problems fast. This teamwork means better products, faster deliveries, and happier customers.

JUSDA Solutions

To provide you with professional solutions and quotations.

New ideas in AI, automation, and big data change supply chains. Companies now deliver faster and spend less money. Customers are happier with these improvements. JUSDA’s smart solutions help businesses stay ahead of others. Leaders should buy digital tools and use green methods. They also need to see what is happening in real time. This helps make supply chains strong and ready for problems.

See Also

Artificial Intelligence Transforming The Future Of Logistics

How Supply Chain Innovations Are Changing Logistics Forever

Digital Technologies Paving The Way For Future Logistics

Exploring Cutting Edge Technology Advancements In Logistics

Cloud-Based Supply Chain Systems Transforming Various Industries