Packaging Solutions in Manufacturing Supply Chain

Packaging plays a vital role in ensuring smooth operations within the manufacturing supply chain. It protects products, reduces waste, and cuts costs. For example, lightweight materials like plastics, which accounted for over 43% of the market in 2023, lower transportation costs and carbon emissions. Sustainable practices are also gaining momentum. The global sustainable packaging market, valued at USD 272.93 billion in 2023, is projected to grow at 7.6% annually until 2030. Adopting innovative packaging solutions not only enhances efficiency but also aligns with environmental goals, making it a cornerstone of modern supply chains.

Key Takeaways

Good packaging keeps items safe and in good shape. This lowers returns and builds customer trust.

Eco-friendly packaging reduces trash and pollution. It matches what people want and helps the brand look better.

Smart packaging saves space and is easy to handle. It lowers shipping costs and makes work faster.

Technology in packaging helps track items live. It also makes managing stock easier.

Custom packaging makes shopping special for customers. This builds loyalty and brings them back to buy again.

The Role of Packaging Solutions in the Supply Chain

Protecting Products and Ensuring Quality

Packaging serves as the first line of defense for your products. It shields items from physical damage, contamination, and environmental factors during transportation and storage. For instance, durable packaging materials like corrugated cardboard or molded pulp ensure that fragile goods remain intact. By maintaining product quality, packaging reduces the risk of returns and enhances customer trust.

You can also rely on packaging to preserve the integrity of perishable goods. Temperature-controlled packaging, such as insulated boxes or gel packs, keeps food and pharmaceuticals fresh. This ensures compliance with industry standards and safeguards your reputation.

Tip: Investing in high-quality packaging materials upfront can save you money by minimizing product damage and waste.

Streamlining Logistics and Operations

Efficient packaging solutions simplify logistics and improve operational workflows. Packaging optimizes space utilization, allowing you to transport more products in fewer shipments. This reduces transportation costs and carbon emissions.

The table below highlights how packaging contributes to logistics and operations:

Benefits | |

|---|---|

Logistical role | - Protects products during transportation, minimizing damage and maintaining ideal conditions. |

- Optimizes distribution by allowing more products in the same box, reducing costs. | |

- Facilitates efficient warehousing through better stacking and storage. | |

Marketing role | - Communicates brand identity and enhances customer experience through thoughtful design. |

- Contributes to environmental sustainability by optimizing resources and minimizing waste. | |

- Supports lean manufacturing principles, enhancing operational efficiency. |

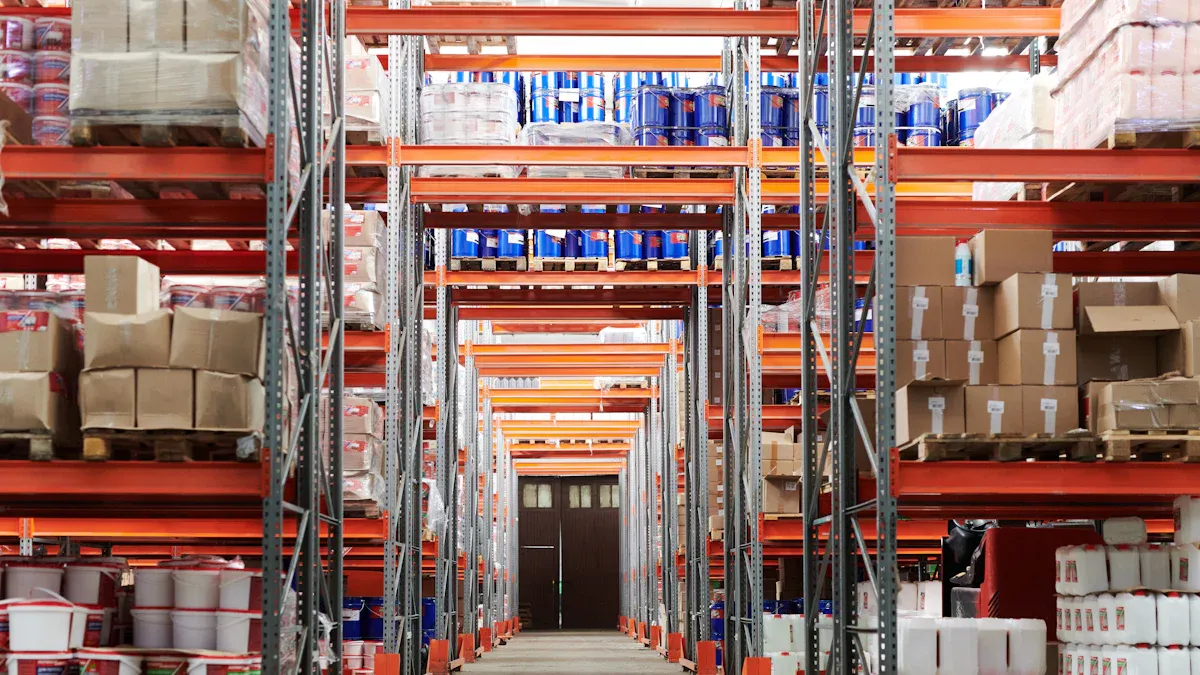

Packaging also plays a role in warehousing. Stackable designs and standardized dimensions make storage more efficient, saving you time and space. By adopting lean manufacturing principles, you can further streamline operations and reduce waste.

Enhancing Brand Value and Customer Experience

Packaging is more than just a protective layer; it’s a powerful branding tool. Thoughtful packaging design communicates your brand identity and creates a memorable unboxing experience for customers. For example, sleek and visually appealing packaging can boost brand recognition and customer loyalty.

The table below illustrates measurable factors that highlight packaging’s impact on brand value and customer experience:

Measurable Factor | Description |

|---|---|

Packaging design effectiveness | Assessed through brand recognition, visual appeal, and memorability, ensuring the design is attractive and consistent with brand values. |

Customer satisfaction and feedback | Measured via surveys and focus groups to determine if packaging is user-friendly and appealing. |

Sales performance and revenue generation | Evaluated by analyzing sales growth rates and revenue changes post-packaging redesign. |

Market share and brand recognition | Indicates the product's market segment percentage compared to competitors, reflecting brand visibility and competitive strength. |

You can use packaging to differentiate your products in a crowded market. Custom designs, eco-friendly materials, and user-friendly features enhance customer satisfaction. When customers associate your packaging with quality and innovation, they are more likely to choose your brand over competitors.

Note: Packaging solutions that align with your brand values can significantly improve customer retention and drive sales growth.

Sustainable Packaging Solutions

Eco-Friendly Materials and Their Applications

Eco-friendly materials are transforming packaging solutions by offering sustainable alternatives to traditional options. These materials, such as biodegradable plastics, recycled paper, and plant-based fibers, reduce environmental harm while maintaining functionality. You can use these materials to create packaging that aligns with consumer preferences for sustainability.

Here are some key insights into the effectiveness of eco-friendly materials:

Consumers value sustainable packaging when they perceive it as beneficial to the environment.

Many customers are willing to pay more for eco-friendly packaging, making it a profitable choice.

People with higher environmental concerns show greater interest in purchasing products with sustainable packaging.

Positive attitudes toward eco-friendly packaging significantly boost purchase intentions.

By adopting these materials, you not only meet consumer expectations but also contribute to a greener planet. For example, plant-based packaging made from cornstarch or bamboo offers durability and biodegradability, making it ideal for food and beverage industries.

Tip: Explore partnerships with suppliers who specialize in sustainable materials to enhance your packaging solutions.

Reducing Waste and Environmental Impact

Sustainable packaging plays a crucial role in minimizing waste and reducing environmental impact. You can achieve this by using designs that extend product shelf life and reduce damage during transportation. Studies show that packaging can lower food waste by up to 20%, especially for items like broccoli, grapes, and papaya.

Packaged broccoli and grapes demonstrated reduced environmental impacts in seven out of eight categories evaluated.

Packaged cut papaya showed lower impacts across all eight categories, highlighting the importance of packaging in waste reduction.

Proper packaging decreases handling damage and allows the sale of previously unusable product parts.

These findings emphasize the need for thoughtful packaging designs that balance functionality and sustainability. For instance, vacuum-sealed packaging for fresh produce can preserve quality while reducing spoilage.

Note: Implementing waste-reducing packaging solutions not only benefits the environment but also improves your operational efficiency.

Meeting ESG Goals Through Packaging

Sustainable packaging solutions help you align with Environmental, Social, and Governance (ESG) goals. Industry benchmarks provide clear indicators for assessing the sustainability performance of packaging options.

KPI | Description |

|---|---|

Sustainable Material Usage | Percentage of materials that are sustainably sourced (e.g., FSC certified, post-consumer recycled). |

End-of-Life Product Management | Percentage of packaging that is biodegradable or recyclable. |

Energy Consumption | Total energy consumed by packaging operations. |

Manufacturing Waste Diversion | Percentage of waste diverted from landfills through reuse, recycling, or composting. |

Sustainable Sourcing | Percentage of suppliers meeting sustainability criteria, including GHG emissions and resource usage. |

A scoring tool evaluates packaging sustainability based on three pillars: materials, functionality, and post-usage fate. Each criterion is scored from 0 (worst) to 1 (best), helping you make informed decisions about packaging solutions. By adopting packaging that meets these benchmarks, you can enhance your brand’s reputation and contribute to global sustainability efforts.

Callout: Prioritize packaging solutions that score high on sustainability metrics to meet ESG goals effectively.

Cost and Efficiency Benefits of Packaging Solutions

Optimizing Design for Space and Handling

Efficient packaging design helps you maximize space and simplify handling. By using stackable or collapsible packaging, you can store and transport more products in less space. This reduces storage costs and improves warehouse organization. For example, modular packaging designs allow you to fit items neatly into shipping containers, minimizing wasted space.

Lightweight packaging materials also make handling easier. Workers can move products quickly, reducing labor time and improving productivity. You can use ergonomic designs to ensure safe handling, preventing injuries and damage.

Tip: Evaluate your current packaging designs to identify opportunities for space optimization and better handling.

Cutting Costs in Materials and Transportation

Choosing cost-effective materials can significantly lower your expenses. Recycled or lightweight materials reduce production costs without compromising quality. For instance, using thinner yet durable cardboard can cut costs while maintaining product protection.

Transportation costs also decrease with efficient packaging. Compact designs allow you to ship more products in fewer trips, saving fuel and reducing emissions. Bulk packaging solutions, such as shrink wraps or pallets, further streamline transportation.

Benefits of cost-efficient packaging:

Lower material expenses.

Reduced shipping costs.

Improved environmental sustainability.

Callout: Partner with suppliers who offer affordable, high-quality materials to optimize your packaging solutions.

Leveraging Technology for Efficiency

Technology plays a key role in enhancing packaging efficiency. Automated packaging systems speed up production, reducing labor costs and errors. You can use smart packaging technologies, such as RFID tags, to track products and improve inventory management.

Digital tools also help you design better packaging. Software programs can simulate packaging layouts, ensuring optimal space utilization and durability. These tools allow you to test designs before production, saving time and resources.

Note: Investing in technology can improve your packaging processes and boost overall supply chain efficiency.

Challenges and Risks in Packaging Solutions

Addressing Supply Chain Disruptions

Supply chain disruptions can significantly impact your packaging operations. Delays in material delivery or sudden shortages can halt production and increase costs. For example, relying on a single supplier for packaging materials exposes you to risks if that supplier faces operational issues. Diversifying your supplier base can help you mitigate these risks.

You should also consider the role of technology in addressing disruptions. Digital tools like supply chain management software provide real-time insights into inventory levels and supplier performance. These tools allow you to anticipate potential bottlenecks and take proactive measures.

Tip: Build strong relationships with multiple suppliers to ensure a steady flow of materials during unforeseen disruptions.

Ensuring Quality Control and Compliance

Maintaining quality control and compliance in packaging is essential for protecting your brand and meeting regulatory standards. Poorly designed packaging can lead to product damage or customer dissatisfaction. For instance, a company that redesigned its packaging for brand consistency received complaints from pharmacists about dispensing errors. This underscores the importance of considering functionality alongside aesthetics.

Many organizations rely heavily on Failure Mode and Effects Analysis (FMEA) as their primary quality risk management tool. However, neglecting other elements like risk communication and review can result in compliance issues. Risk assessments must also have a logical basis to withstand regulatory scrutiny.

Note: Regularly review your quality control processes to ensure they align with industry standards and customer expectations.

Mitigating Risks with Strategic Planning

Strategic planning helps you identify and address potential risks in your packaging operations. Start by conducting thorough risk assessments to evaluate vulnerabilities in your supply chain, design, and compliance processes. For example, consider how changes in packaging design might affect usability or regulatory compliance.

You can also use tools like scenario planning to prepare for unexpected challenges. This approach allows you to test different strategies and choose the most effective one. By planning ahead, you can minimize disruptions and maintain operational efficiency.

Callout: Incorporate strategic planning into your packaging processes to reduce risks and improve long-term outcomes.

Future Trends in Packaging Solutions

Smart Packaging Technologies and Automation

Smart packaging technologies are revolutionizing the way you manage products in the supply chain. These solutions integrate advanced features like sensors, RFID tags, and QR codes to enhance functionality. For example, RFID smart labels provide real-time visibility and traceability, making supply chain management more efficient.

The global smart packaging market is projected to grow from $26.42 billion in 2024 to $35.69 billion by 2029, with a compound annual growth rate (CAGR) of 6.2%. This growth reflects the increasing demand for innovative solutions that improve product tracking and inventory management. Automation also plays a key role by streamlining packaging processes, reducing errors, and saving time.

Tip: Consider adopting smart packaging to improve efficiency and meet the growing demand for advanced solutions.

Customization and Personalization Trends

Customization and personalization are becoming essential in modern packaging. E-commerce growth has made packaging a critical part of the online shopping experience. Custom boxes not only protect products but also enhance brand presentation, leading to higher customer satisfaction.

Personalized packaging creates a unique experience for your customers. It boosts brand loyalty and encourages repeat purchases. However, meeting the demand for personalized offerings can be challenging. Complex designs often require more materials, which may increase waste. Balancing personalization with sustainability is key to maintaining operational efficiency.

E-commerce growth has made packaging vital for customer satisfaction.

Custom designs improve product protection and brand visibility.

Positive packaging experiences lead to repeat purchases and higher marketing ROI.

Note: Focus on creating personalized packaging that aligns with your sustainability goals.

Collaborative Innovations in Packaging

Collaboration is driving innovation in packaging solutions. Companies are working together to develop sustainable materials and integrate digital technologies. For instance, the convergence of sustainability and digitalization has led to the adoption of biodegradable materials and smart technologies like NFC and RFID. These innovations reduce waste and improve traceability.

Collaborative efforts also help you stay ahead of market trends. By partnering with suppliers and technology providers, you can create packaging that meets consumer demands while enhancing efficiency. This approach fosters innovation and ensures long-term success in the competitive market.

Callout: Collaborate with industry leaders to develop cutting-edge packaging solutions that benefit your business and the environment.

Effective packaging solutions are essential for a streamlined supply chain. They protect products, reduce waste, and enhance brand value. Innovation plays a key role in addressing challenges like sustainability and operational efficiency. For instance, compostable packaging and cross-sector collaboration improve supply chain sustainability, as noted by Keränen et al. (2021).

Adopting advanced strategies also supports long-term growth.

Trend Description | Statistical Insight |

|---|---|

Demand for Miniaturization | Global electronics/ICT output expected to grow by 5.3% in 2024 and 6.3% in 2025. |

Market Size | In 2024, the global semiconductor packaging market size surpassed 70 billion units. |

Regional Dominance | Asia-Pacific accounts for approximately 60% of global advanced packaging consumption. |

You can leverage these trends to stay competitive and meet evolving consumer demands.

Tip: Embrace innovative packaging to drive growth and sustainability in your supply chain.

FAQ

1. What are the key benefits of using sustainable packaging?

Sustainable packaging reduces waste, lowers carbon emissions, and aligns with environmental goals. It also enhances your brand image by appealing to eco-conscious consumers. By adopting sustainable materials, you can cut costs and improve operational efficiency.

Tip: Highlight your use of eco-friendly packaging in marketing to attract environmentally aware customers.

2. How can smart packaging improve supply chain efficiency?

Smart packaging integrates technologies like RFID tags and sensors to track products in real time. It enhances inventory management, reduces errors, and ensures product safety. These features streamline your operations and improve decision-making.

Note: Smart packaging can also provide valuable data for optimizing logistics.

3. What materials are best for reducing packaging costs?

Lightweight and recycled materials, such as corrugated cardboard or biodegradable plastics, are cost-effective. They lower production and transportation expenses while maintaining product protection. Modular designs also help reduce material usage.

Callout: Partner with suppliers offering affordable, high-quality materials to maximize savings.

4. How does packaging impact customer satisfaction?

Thoughtful packaging design improves the unboxing experience, communicates brand values, and ensures product safety. Customers associate high-quality packaging with reliability and care, which boosts loyalty and repeat purchases.

Emoji Insight: 📦 A well-designed package can turn a simple delivery into a memorable experience!

5. What steps can you take to ensure packaging compliance?

Regularly review industry regulations and conduct quality checks on your packaging. Use risk assessment tools like FMEA to identify potential issues. Collaborate with compliance experts to ensure your packaging meets all legal and safety standards.

Tip: Document your compliance processes to avoid regulatory challenges.

See Also

Enhancing High-Tech Manufacturing Through Supply Chain Optimization

Addressing Global Supply Chain Growth Challenges Effectively

The Impact of Cloud Solutions on Supply Chain Dynamics