Problems Facing Overseas Warehouse Development in 2025

Overseas warehouse development in 2025 faces urgent challenges. Cybersecurity risks, stricter fire safety rules, and disruptions from climate change threaten stability. Labor shortages and high turnover push companies toward automation and wearable technology. Space constraints demand vertical storage and better organization. The rise of e-commerce increases product returns, making reverse logistics more complex. Success in global supply chains depends on solving these issues.

Challenge Aspect

Explanation

Cluttered inventory and poor layout cause delays and incorrect counts; audits and automation reduce lead times.

Fragmentation & visibility

Disjointed global operations hide inefficiencies; integrated data sharing and collaboration improve visibility.

Technology adoption

Automated sorting, picking robots, and centralized cloud solutions enable faster fulfillment and better data access.

Communication & integration

Open communication and data integration across international teams streamline operations and improve customer satisfaction.

JUSDA leads the way by using advanced technology and integrated solutions to address these critical problems.

Key Takeaways

Overseas warehouses face many challenges in 2025, including labor shortages, strict regulations, and rising costs.

Using advanced technology like AI, automation, and real-time tracking helps improve efficiency and reduce delays.

Choosing the right warehouse location and managing costs carefully supports faster delivery and smoother operations.

Strong compliance with customs, safety, and environmental rules prevents fines and keeps supply chains running.

Sustainability and social responsibility are essential for long-term success and meeting new global standards.

Logistics Challenges

Cross-Border Issues

Overseas Warehouse Development in 2025 faces many cross-border logistics challenges. Companies must deal with complex customs regulations, which often cause delays and fines. Language and cultural barriers can lead to misunderstandings between teams and partners. Many regions still struggle with poor transport systems and outdated technology, making it hard to move goods efficiently.

Complex customs rules delay shipments and increase costs.

Language and culture differences create confusion.

Weak infrastructure and old tools slow down operations.

Recent data shows a 20% rise in costs for moving goods across borders. Customs delays now make up 25% of these costs, while transport costs account for 32%. Experts say that customs compliance, risk management, and flexible supply chains are more important than ever. JUSDA’s global network and smart tools like JusTrade help clients manage these issues by using AI and IoT for better tracking and faster customs clearance.

Transportation Delays

Transportation delays can disrupt production schedules and cause inventory problems. These delays often lead to higher costs and can hurt a company’s reputation. The main causes include:

Supply chain disruptions from natural disasters or economic changes.

Extreme weather events that stop carriers from moving goods.

Traffic jams, port closures, and infrastructure failures.

Customs problems, such as missing documents or extra inspections.

Peak season demand that overwhelms logistics networks.

Mechanical failures and labor shortages.

These problems create bottlenecks that slow down deliveries and make it harder to manage inventory. JUSDA uses multimodal transport solutions and real-time tracking to help clients avoid these delays and keep their operations running smoothly.

Last-Mile Delivery

Last-mile delivery remains one of the toughest parts of logistics. Urban congestion, limited parking, and strict city rules make city deliveries slow and costly. Rural areas face long distances and fewer deliveries per trip, which increases costs. Failed deliveries from wrong addresses or missed timings waste resources.

Urban traffic and parking issues slow down deliveries.

Rural deliveries cost more due to distance and fewer stops.

High delivery costs make up over half of total transport expenses.

Failed deliveries lead to repeated trips and wasted time.

Environmental concerns grow as more delivery vehicles hit the road.

To solve these problems, companies use route optimization, micro-fulfillment centers, and real-time tracking. JUSDA’s advanced technology and local expertise help clients improve last-mile delivery in different regions, making Overseas Warehouse Development more efficient and reliable.

Location & Cost

Site Selection

Choosing the right site shapes the success of any overseas warehouse project. Industry experts highlight several key factors:

Regulatory compliance ensures smooth operations and avoids legal trouble.

Proximity to suppliers and customers shortens lead times and builds stronger relationships.

Access to major transportation networks, such as highways and ports, supports fast and cost-effective shipping.

Workforce availability and labor costs influence daily operations and long-term growth.

Real estate costs and space availability affect both current needs and future expansion.

Infrastructure, including reliable power, water, and internet, keeps warehouses running efficiently.

Special requirements for certain goods, like clean rooms or temperature control, may limit location options.

Awareness of changing regulations helps companies adapt quickly and avoid extra costs.

Technology integration boosts efficiency and keeps operations competitive.

JUSDA uses these criteria to guide site selection across its global network. The company’s experience in China, Vietnam, the United States, and Europe shows the value of balancing location, cost, and market needs.

Real Estate Costs

High real estate prices challenge Overseas Warehouse Development in many regions. Limited new developments and rising demand for warehouse space push costs even higher. Companies must weigh the benefits of prime locations against the strain on budgets. In cities with expensive land, JUSDA often recommends vertical storage solutions and advanced warehouse management systems to maximize every square meter.

Note: Real estate costs can change quickly. Companies should monitor local markets and stay flexible in their planning.

Market Access

Easy access to target markets remains a top priority. Warehouses near major cities or transport hubs help companies reach customers faster and reduce shipping costs. JUSDA’s global footprint allows clients to enter new markets with confidence. The company’s local teams understand regional regulations and customer needs, making market entry smoother and more efficient.

Regulatory Risks

Compliance

Regulatory risks have become a major concern for companies involved in Overseas Warehouse Development. In 2025, new rules and stricter enforcement make compliance more complex. Companies must follow local, national, and international laws, which often change without much notice. For example, the UK will require more detailed safety declarations for EU imports starting January 31, 2025. The EU’s Carbon Border Adjustment Mechanism will also demand emissions reporting for imports.

Non-compliance can lead to severe fines, shipment delays, and even loss of trading privileges. Companies may also face reputational damage and legal liabilities.

Common compliance challenges include:

Navigating different zoning and safety rules in each city or country.

Keeping up with changing chemical storage and labeling laws.

Managing complex customs regulations and export controls.

Ensuring staff receive proper training on new requirements.

Many companies now appoint compliance officers, use compliance management systems, and conduct regular audits. Technology, such as real-time tracking and automated reporting, helps reduce errors and improve safety. JUSDA supports clients by offering expert guidance and digital tools that keep operations up to date with the latest regulations.

Tariffs & Trade

Tariffs and shifting trade policies directly impact the cost and efficiency of warehouse operations. In 2025, the U.S. plans to increase tariffs on imports from China, Canada, and Mexico by up to 20%. These changes force companies to rethink their inventory and sourcing strategies.

Tariffs raise the cost of imported goods, leading companies to stockpile inventory and increase warehouse space.

Higher demand for storage drives up rental and labor costs.

Customs delays and supply chain disruptions require new contingency plans.

Companies often diversify suppliers and invest in warehouse management systems to stay efficient.

JUSDA helps clients adapt by providing advanced analytics and risk management solutions. Their global network and strong logistics partnerships allow businesses to respond quickly to new trade rules and minimize disruptions.

Customs

Customs procedures remain a major obstacle for Overseas Warehouse Development. Each country has its own rules for classifying, valuing, and declaring goods. Mistakes can cause shipment delays, fines, or even seizure of goods.

JUSDA addresses these challenges with a team skilled in local languages, cultures, and customs regulations. They offer bonded warehousing and cross-border transport services designed to speed up customs clearance. Their warehouses, located near key industrial zones, help clients store and move goods efficiently while meeting all customs requirements.

Tip: Regular staff training and up-to-date documentation help prevent customs issues and keep supply chains moving smoothly.

Technology & Security

Digital Platforms

Digital platforms now play a central role in overseas warehouse development. Companies rely on real-time data to manage inventory, shipments, and customer orders. JUSDA’s JusLink and eVMI platforms give businesses full visibility into their supply chains. These tools use cloud computing and IoT to track goods, automate inventory updates, and share information instantly with partners. With these systems, managers can spot problems early and make quick decisions. Automation and data analytics help reduce errors and speed up order processing. As a result, companies improve efficiency and keep customers satisfied.

JusLink and eVMI support seamless collaboration between suppliers, warehouses, and customers. This level of integration helps businesses adapt to changing market demands and avoid costly delays.

SMART JusLink

Supply Chain Management Solution

Cybersecurity

Cybersecurity has become a top concern for overseas warehouse operations in 2025. Digital systems face many threats that can disrupt business and put sensitive data at risk. Common threats include ransomware, supply chain cyber disruptions, and attacks on third-party software. Hackers may use phishing, steal credentials, or exploit zero-day vulnerabilities. Even insider threats and attacks on physical systems can cause major problems.

To protect operations, companies use several strategies:

Employee security training on phishing, password safety, and incident reporting

Zero-Trust security models with multi-factor authentication and role-based access

AI-driven threat detection and automated response tools

Outsourcing to cybersecurity experts and ongoing staff development

Blockchain technology for secure and transparent supply chain management

Strong incident response plans, regular data backups, and business continuity planning

These steps help companies defend critical infrastructure and keep operations running smoothly.

Data Privacy

Data privacy regulations shape how companies handle personal and business information in overseas warehouses. Laws like GDPR and CCPA set strict rules for collecting, storing, and sharing data. Companies must process data lawfully, stay transparent with customers, and secure information during cross-border transfers.

Non-compliance can lead to heavy fines—up to €20 million or 4% of global revenue under GDPR. Companies also risk losing customer trust, as most people will stop doing business with firms that fail to protect their data. Managing compliance is complex because of different laws and many stakeholders.

Best practices include:

Clear data handling rules for all partners

Strong contracts and regular audits

Encryption and advanced cybersecurity tools

Using data management platforms for better visibility

These measures help companies balance efficiency with legal and ethical responsibilities in global supply chains.

Sustainability & ESG

Green Logistics

Sustainability has become a core focus for overseas warehouse development. Companies now invest in green logistics to reduce their environmental impact. Many warehouses use renewable energy sources like rooftop solar panels and on-site wind turbines. Energy-efficient lighting, smart sensors, and improved insulation help lower energy use. Some organizations partner with green-certified companies, such as those with ISO 14001 or LEED certifications, to improve resource management and reduce waste. Reverse logistics models allow for the retrieval and recycling of returned goods, cutting down on landfill waste. Technology, including AI and IoT, enables real-time carbon tracking and route optimization, which lowers emissions and supports carbon neutrality goals.

Companies that adopt green logistics often see measurable results. For example, some global brands have reduced freight-related CO2 emissions by up to 18% and landfill waste by 23% through smarter logistics and packaging changes.

Compliance

New sustainability regulations create complex compliance challenges for overseas warehouses. Companies must navigate different rules in each country and keep up with frequent regulatory changes. The table below outlines common challenges and how leading companies respond:

Compliance Challenge | Description | Leading Company Responses |

|---|---|---|

Jurisdictional Differences | Regulations vary across regions. | Centralized oversight and compliance calendars. |

Missing Regulatory Changes | Hard to track new rules. | Annual reviews and regulatory roadmaps. |

Poor Permit Management | Multiple permits with different renewal dates. | EHS/EMS software for tracking and reminders. |

Data Collection Difficulties | Environmental data from many sources. | Centralized data systems and clear roles. |

Process Changes | Operational changes may trigger new requirements. | Evaluate impacts before changes and update permits. |

Lack of Internal Audits | Gaps go unnoticed without regular checks. | Scheduled audits and corrective action tracking. |

Financial Constraints | Limited budgets for compliance staff or tools. | Prioritize training and use compliance calendars. |

JUSDA maintains a strong compliance framework. The company uses advanced data systems and regular audits to ensure all warehouses meet global standards.

Social Impact

ESG requirements now extend beyond the environment. Companies must also address social factors, such as ethical labor practices and community engagement. Many organizations set up compliance teams to monitor labor standards and maintain transparent communication with stakeholders. JUSDA embeds sustainability and social responsibility into daily operations. The company supports local communities, ensures fair working conditions, and builds trust with partners and customers. These efforts help strengthen supply chain resilience and enhance competitiveness in the global market.

Inventory Management

Demand Fluctuations

Global volatility creates major challenges for inventory management in overseas warehouses. Sudden changes in demand, unpredictable lead times, and supply chain instability disrupt planning and fulfillment. Many warehouse leaders identify supply chain instability as a top concern. Poor inventory management cost retailers $818 billion last year. Losses often result from spoilage, damage, misplacement, or obsolete stock, tying up valuable capital and space. Gaps in inventory visibility across multiple locations cause fulfillment delays and overselling. SKU proliferation increases complexity and slows down cycle counts, reducing accuracy and speed.

Companies can address these issues by diversifying suppliers, using inbound tracking tools, and implementing dynamic safety stock calculations. Automation and real-time tracking improve resilience and visibility, helping warehouses adapt to rapid demand shifts.

JUSDA’s advanced warehouse solutions, such as eVMI and JusLink, provide real-time inventory tracking and data sharing. These systems help clients respond quickly to demand changes and maintain optimal stock levels.

Stock Control

Effective stock control ensures that warehouses maintain the right inventory levels and avoid costly errors. Best practices include efficient warehouse layout, regular audits, and ABC analysis to prioritize high-demand items. Technology plays a key role. Warehouse Management Systems (WMS), IoT sensors, barcode and RFID systems, and automation reduce human error and provide real-time stock visibility. Automated Storage and Retrieval Systems (ASRS) maximize space and minimize product damage.

JUSDA integrates these technologies into its global warehouses. For example, clients using JusLink and eVMI experience faster order fulfillment, fewer stockouts, and lower carrying costs. Ongoing staff training and regular audits further enhance accuracy and accountability.

Supply Chain Disruptions

Supply chain disruptions can lead to shipping delays, excess or insufficient inventory, and higher costs. These disruptions may result from natural disasters, geopolitical events, labor strikes, or transportation delays. Companies reduce risk by diversifying supplier networks, nearshoring production, and maintaining safety stock. Real-time tracking tools, such as IoT and RFID, allow early detection and response to issues.

Real-time tracking improves visibility.

Integrated technology platforms enhance coordination.

JUSDA’s technology-driven approach, including integrated ERP, TMS, and WMS platforms, helps clients manage disruptions and maintain efficient inventory control across global operations.

Overseas Warehouse Development Trends

Digital Transformation

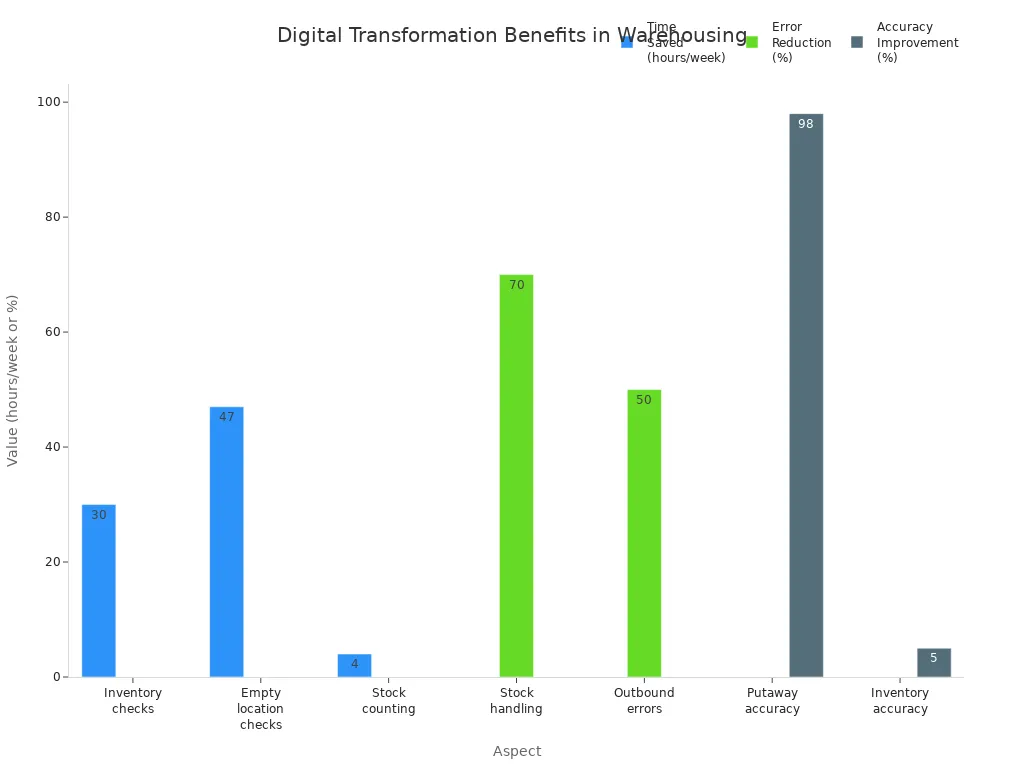

Digital transformation shapes the future of global warehousing. Companies now use automation, robotics, real-time data, and cloud platforms to improve efficiency. These technologies help warehouses operate faster and with fewer mistakes. The table below highlights the main benefits:

Aspect of Digital Transformation | Description | Measurable Benefits / Impact |

|---|---|---|

Technologies Integrated | Automation, robotics, real-time data capture, AI analytics, digital twins, cloud platforms | Improved operational efficiency, accuracy, and agility |

Time Savings | Example: Saved over 30 hours per week in inventory audits | |

Error Reduction | Stock handling errors reduced by up to 70% | Fewer stock discrepancies, reduced claims, improved customer satisfaction |

Accuracy Improvements | Putaway accuracy improved to 98% | Inventory accuracy improved by 5% in 8 weeks; manual stock investigations reduced by 41% |

Automation Scale | Robots scanning up to 10,000 locations per hour vs. 150 manually | Enabled daily automated audits replacing annual manual ones |

Operational Efficiency | Empty location checks saved 47 hours per week; outbound errors dropped by 50+ per month | Investigation time reduced from 24+ hours to 10 hours weekly |

Stock Counting | Monthly stock counting reduced from 100+ hours to 2 hours daily | Annual savings of 205 hours; improved warehouse cleanliness and stock placement |

AI & Automation

AI and automation drive major changes in warehouse operations. Companies use AI for predictive maintenance, which cuts machine downtime by up to 50% and extends equipment life. Autonomous vehicles, such as tuggers and forklifts, improve safety and boost productivity by up to 33%. Drones automate inventory checks, saving time and money. AI also helps with demand forecasting and inventory optimization, reducing overstock and stockouts by 35%. Cloud-based warehouse management systems and digital twins support real-time decisions and make operations more agile.

Key trends include:

Strategic warehousing to manage risks from global tariffs and trade changes

AI-powered customs and logistics processes for faster compliance

Digital passports for goods to speed up customs clearance

Collaborative robots and autonomous mobile robots for safer, more productive workplaces

Overseas Warehouse Development in 2025 brings many challenges, from labor shortages to strict regulations. Companies need strong planning and digital tools to stay ahead. JUSDA offers advanced technology and global experience to help businesses succeed. Their solutions improve efficiency and reduce risks. Companies should review their current strategies and look for partners who drive innovation.

FAQ

What are the biggest risks for overseas warehouses in 2025?

Cybersecurity threats, labor shortages, and stricter regulations top the list. Companies also face rising real estate costs and unpredictable supply chain disruptions. JUSDA’s advanced technology and global network help reduce these risks.

How does JUSDA support compliance with international regulations?

JUSDA uses digital platforms for real-time tracking and automated reporting. Their experts monitor regulatory changes and provide guidance. Clients benefit from regular audits and up-to-date compliance tools.

Why is real-time inventory tracking important?

Real-time tracking prevents stockouts and overstock. It helps companies respond quickly to demand changes. JUSDA’s JusLink and eVMI platforms give clients full visibility and control over inventory.

How can companies improve last-mile delivery?

Companies use route optimization, micro-fulfillment centers, and real-time tracking. JUSDA’s local teams and advanced technology help clients deliver faster and reduce costs.

What role does sustainability play in warehouse operations?

Sustainability reduces environmental impact and meets new regulations. Companies use renewable energy, efficient lighting, and recycling programs. JUSDA integrates green logistics and compliance into daily operations.

See Also

How Automation Is Shaping The Future Of Manufacturing Warehouses

Addressing Supply Chain Growth Issues In Today’s Global Market

Understanding How Robotics Enhance Warehouse Efficiency And Operations

Inside JUSDA’s Latest Warehousing Facilities Driving Greater Efficiency

Improving Supply Chain Solutions For Advanced Manufacturing Challenges