6 Steps to Build a Resilient Semiconductor Supply Chain

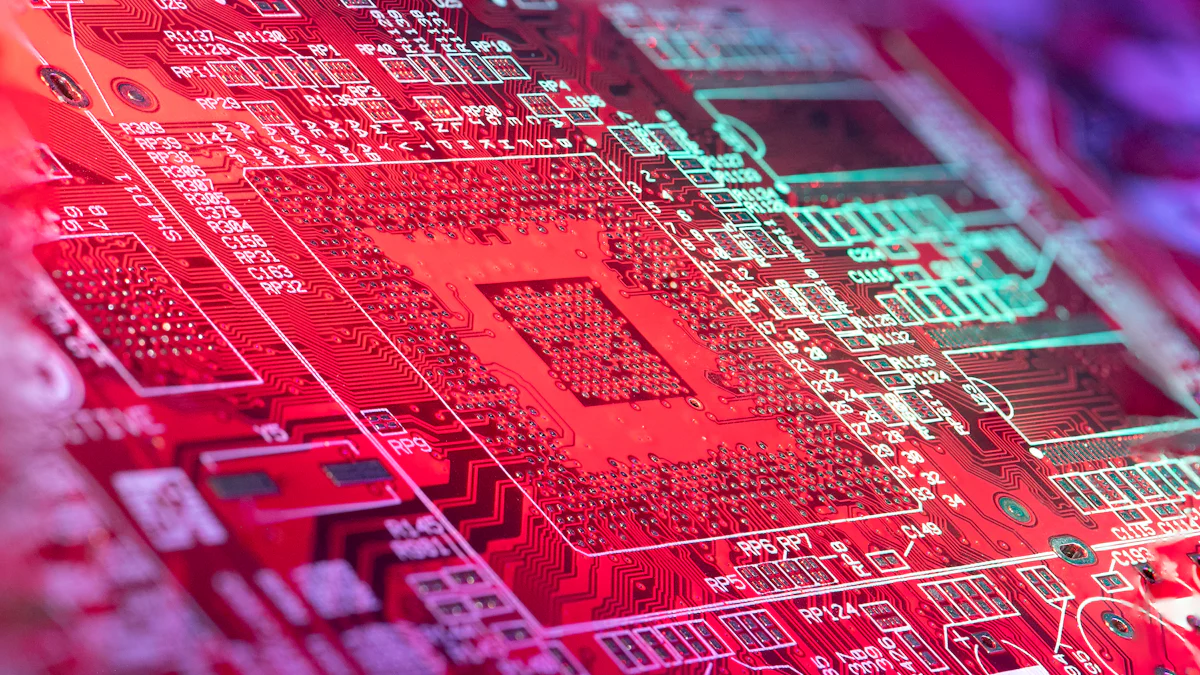

Semiconductors form the backbone of the global manufacturing chain, powering industries like automotive, electronics, and telecommunications. However, the industry faces persistent supply chain issues, including raw material shortages and production delays. Geopolitical tensions, such as trade restrictions and regional conflicts, further disrupt operations, exposing vulnerabilities in supply chain management. The semiconductor shortage has highlighted the need for robust strategies to mitigate risks. Building resilience in the supply chain ensures stability, enhances competitiveness, and safeguards industries reliant on these critical components.

Step 1: Map and Analyze Your Semiconductor Manufacturing Chain

Understanding the intricacies of the semiconductor manufacturing chain is essential for building a resilient supply chain. Mapping and analyzing the entire process provides clarity on potential risks and opportunities for improvement. This step lays the foundation for effective decision-making and risk mitigation.

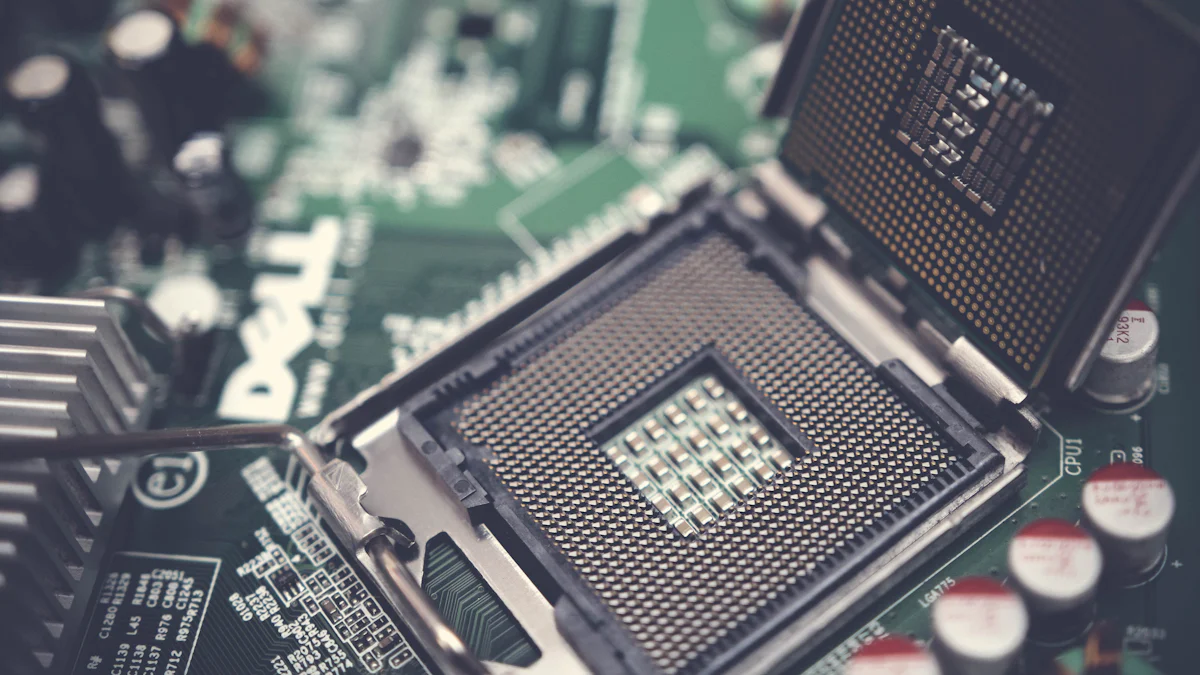

Identify Key Suppliers and Dependencies in the Semiconductor Ecosystem

The semiconductor supply chain relies on a network of suppliers, each contributing to different stages of production. Companies must identify their key suppliers and assess their roles within the ecosystem. This includes evaluating raw material providers, chip manufacturers, and assembly partners. By pinpointing dependencies, businesses can uncover areas where overreliance on a single supplier or region may pose risks. For instance, geopolitical tensions or natural disasters in a specific region can disrupt operations. Diversifying sources ensures a more stable supply chain and reduces vulnerability to external shocks.

Assess Vulnerabilities and Risks Across the Supply Chain

Supply chain vulnerabilities often stem from a lack of preparedness for disruptions. Companies should conduct a thorough risk assessment to identify weak points. This involves evaluating factors such as supplier reliability, transportation routes, and regulatory compliance. Geopolitical risks, trade barriers, and industry reliance on limited suppliers exacerbate these challenges. A proactive approach to risk assessment enables businesses to develop contingency plans and safeguard operations. For example, creating alternative sourcing strategies or stockpiling critical components can mitigate potential disruptions.

Leverage Data Analytics for Enhanced Supply Chain Visibility

Data analytics plays a pivotal role in enhancing visibility and collaboration across the semiconductor supply chain. Advanced tools allow companies to monitor real-time data on inventory levels, production schedules, and supplier performance. This level of transparency helps identify inefficiencies and optimize processes. Predictive analytics can also forecast demand fluctuations, enabling businesses to adjust their strategies accordingly. By leveraging data-driven insights, companies can make informed decisions and improve overall supply chain efficiency.

"Visibility is the cornerstone of a resilient supply chain. Without it, businesses operate in the dark, unable to anticipate or respond to challenges effectively."

Mapping and analyzing the semiconductor manufacturing chain is not just about identifying problems; it is about creating opportunities for innovation and growth. This step empowers businesses to build a robust foundation for the remaining strategies.

Step 2: Diversify Your Supplier Base to Mitigate Supply Chain Issues

Diversifying the supplier base is a critical strategy for addressing supply chain issues in the semiconductor industry. By reducing dependency on single suppliers and exploring alternative sourcing options, businesses can enhance flexibility and resilience. This approach minimizes risks associated with disruptions and ensures a steady flow of components essential for industries like automotive.

Reduce Overreliance on Single Suppliers in the Semiconductor Industry

Overreliance on a single supplier or region creates significant vulnerabilities in the supply chain. Events such as the 2011 earthquake and tsunami in Japan and the recent earthquakes in Taiwan and Japan in early 2024 have demonstrated how natural disasters can disrupt semiconductor production. Similarly, the COVID-19 pandemic and ongoing geopolitical tensions have exposed the fragility of supply chains dependent on limited sources.

To mitigate these risks, companies must evaluate their supplier networks and identify areas of overdependence. Establishing relationships with multiple suppliers reduces the likelihood of production halts caused by unforeseen events. For example, diversifying raw material providers ensures that disruptions in one region do not paralyze operations. This strategy is particularly vital for the automotive supply chain, where delays in semiconductor availability can halt vehicle production.

"A diversified supplier base acts as a safety net, protecting businesses from the cascading effects of supply chain disruptions."

Explore Regional and Local Sourcing Options for Greater Flexibility

Global supply chains often face challenges such as transportation delays, regulatory hurdles, and geopolitical tensions. Exploring regional and local sourcing options can address these issues while enhancing flexibility. For instance, sourcing semiconductors from nearby regions reduces lead times and transportation costs. It also minimizes exposure to risks associated with international trade conflicts or extreme weather events.

The automotive supply chain, heavily reliant on semiconductors, benefits significantly from regional sourcing. Local suppliers can respond quickly to demand fluctuations, ensuring timely delivery of critical components. Additionally, regional sourcing supports economic growth in local markets, fostering stronger partnerships and reducing dependency on distant suppliers.

Build Strategic Relationships with Alternative Suppliers

Building strong supplier relationships is essential for creating a resilient supply chain. Companies must actively seek out and collaborate with alternative suppliers to ensure continuity during disruptions. Strategic partnerships enable businesses to negotiate favorable terms, secure priority access to materials, and improve overall supply chain efficiency.

For industries like automotive, where semiconductors play a pivotal role, these relationships are invaluable. Collaborating with suppliers who share similar values and goals fosters trust and reliability. For example, during the global semiconductor shortage, businesses with established partnerships were better positioned to navigate challenges and maintain production schedules.

"Strategic supplier relationships transform transactional interactions into collaborative partnerships, driving long-term success."

Diversifying the supplier base is not just a defensive measure; it is a proactive approach to strengthening the supply chain. By reducing reliance on single suppliers, exploring regional options, and building strategic partnerships, businesses can safeguard operations and thrive in an increasingly unpredictable environment.

Step 3: Invest in Advanced Supply Chain Technology

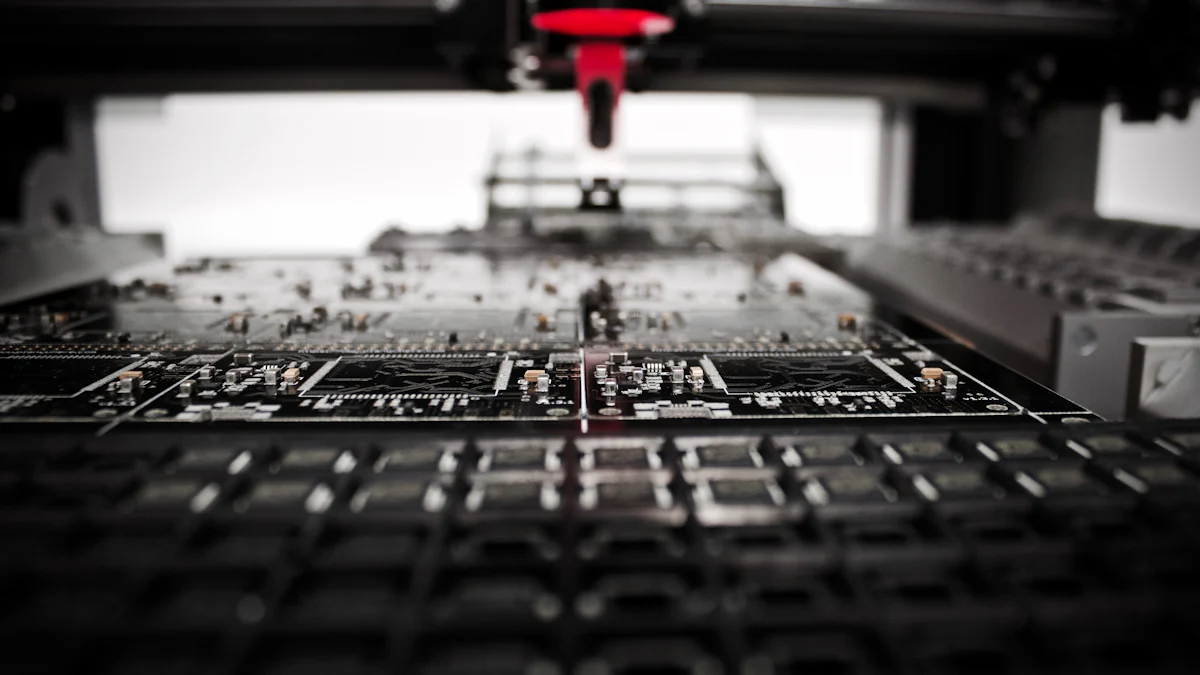

Investing in advanced technology transforms the semiconductor manufacturing chain by enhancing efficiency, visibility, and decision-making. Modern tools empower businesses to address challenges, streamline operations, and build resilience against disruptions. By integrating cutting-edge solutions, companies can optimize processes and maintain a competitive edge.

Implement Real-Time Tracking Systems for Semiconductor Logistics

Real-time tracking systems revolutionize logistics management by providing end-to-end visibility across the manufacturing chain. These systems enable companies to monitor shipments, track inventory levels, and anticipate delays. For semiconductors, where precision and timing are critical, real-time tracking ensures smooth operations and minimizes disruptions.

Advanced tools like Real-time Data Analytics Tools allow businesses to make prompt decisions and optimize supply chain processes. For example, tracking systems integrated with a transport management system provide real-time updates on shipment locations, helping companies adjust schedules and avoid bottlenecks. This level of transparency enhances operational efficiency and ensures timely delivery of critical components.

"Visibility across the supply chain is no longer optional; it is a necessity for maintaining stability and meeting customer expectations."

By implementing real-time tracking, businesses can improve logistics management, reduce lead times, and enhance overall supply chain performance.

Use AI and Machine Learning for Accurate Demand Forecasting

AI and machine learning have become indispensable in the semiconductor industry. These technologies analyze vast amounts of data to predict demand patterns, optimize inventory, and identify potential risks. Accurate demand forecasting ensures that businesses can align production schedules with market needs, reducing waste and improving efficiency.

AI Technology for Supply Chain Efficiency enhances operational planning by identifying vulnerabilities before disruptions occur. Predictive analytics tools, such as those used in Optimization-based Planning Systems, integrate asset and order management data to balance workloads and streamline production. For instance, AI-driven models can forecast demand fluctuations, enabling businesses to adopt just-in-time inventory management strategies and maintain stable inventory flow.

"AI transforms supply chain management from reactive to proactive, allowing businesses to anticipate challenges and act decisively."

By adopting agile operations powered by AI, companies can enhance their forecasting capabilities, reduce costs, and ensure a steady supply of semiconductors.

Integrate Blockchain for Transparency and Security in the Manufacturing Chain

Blockchain technology addresses critical challenges in the semiconductor manufacturing chain by ensuring transparency, traceability, and security. This decentralized ledger system records every transaction, creating an immutable trail of data that enhances trust among stakeholders.

For semiconductors, blockchain integration improves collaboration between suppliers, manufacturers, and distributors. It ensures that all parties have access to accurate information, reducing errors and enhancing accountability. Platforms like Collaborative Semiconductor Supply Chain Solutions leverage blockchain to build traceability into the supply chain, fostering seamless operations and stronger partnerships.

Additionally, blockchain enhances security by protecting sensitive data from cyber threats. It ensures that intellectual property and proprietary designs remain secure throughout the manufacturing process. By integrating blockchain, businesses can safeguard their operations while improving efficiency and trust.

"Blockchain is not just a tool for transparency; it is a cornerstone for building a resilient and secure supply chain."

Incorporating blockchain technology into the manufacturing chain strengthens relationships, enhances data integrity, and ensures long-term success.

Step 4: Build Strategic Partnerships Across the Semiconductor and Automotive Supply Chain

Strategic partnerships form the backbone of a resilient supply chain. Collaboration across the semiconductor and automotive industries fosters innovation, mitigates risks, and ensures operational efficiency. By working closely with suppliers, customers, and industry stakeholders, businesses can address supply chain issues and achieve supply chain excellence.

Collaborate with Suppliers, Customers, and Industry Stakeholders

Collaboration drives success in the semiconductor and automotive supply chain. Companies must engage with suppliers, customers, and stakeholders to create a seamless flow of information and resources. This approach strengthens relationships and enhances problem-solving capabilities.

Shozo Saito, President of Nippon Electronic Device Industry Association, emphasized the importance of treating suppliers as business partners. He stated, “Companies must move beyond the concepts of supplier and purchaser and approach suppliers as business partners.”

By adopting this mindset, businesses can involve suppliers in design, development, and production stages. For example, automotive manufacturers can work with semiconductor suppliers to co-develop chips tailored to specific vehicle requirements. This level of collaboration reduces inefficiencies and ensures that both industries remain aligned in their goals.

Engage in Industry Consortia and Alliances to Share Best Practices

Industry consortia and alliances provide platforms for sharing knowledge and best practices. These groups bring together experts from the semiconductor and automotive sectors to address common challenges and develop innovative solutions.

Participation in such alliances enables companies to stay informed about emerging trends and technologies. For instance, consortia focused on automotive supply chain solutions often explore ways to integrate advanced technologies like AI and blockchain. These innovations enhance transparency and streamline operations, benefiting all participants.

Additionally, alliances foster a sense of community and shared responsibility. Members can pool resources to tackle large-scale supply chain issues, such as global semiconductor shortages. This collective effort strengthens the entire ecosystem and ensures long-term sustainability.

Share Data and Insights to Improve Coordination and Efficiency

Data sharing plays a pivotal role in optimizing the semiconductor and automotive supply chain. Companies must prioritize transparency by exchanging real-time data on inventory levels, production schedules, and demand forecasts. This practice improves coordination and minimizes disruptions.

Blockchain technology offers a secure way to share data across the supply chain. By creating an immutable record of transactions, blockchain ensures accuracy and builds trust among stakeholders. For example, automotive manufacturers can use blockchain to track the origin and quality of semiconductors used in their vehicles.

"Transparency is the foundation of supply chain excellence. Accurate data empowers businesses to make informed decisions and respond swiftly to challenges."

Sharing insights also promotes continuous improvement. Companies can analyze shared data to identify inefficiencies and implement targeted solutions. This collaborative approach enhances overall performance and strengthens the resilience of the supply chain.

Building strategic partnerships requires commitment and collaboration. By fostering strong relationships, participating in industry alliances, and sharing data, businesses can overcome supply chain issues and achieve excellence in the semiconductor and automotive industries.

Step 5: Develop a Comprehensive Risk Management Plan

A robust risk management plan is essential for navigating the complexities of the semiconductor supply chain. By identifying potential disruptions, creating contingency strategies, and regularly updating mitigation plans, businesses can safeguard operations and maintain stability.

Identify Potential Disruption Scenarios in the Semiconductor Supply Chain

The semiconductor supply chain faces numerous risks, including natural disasters, geopolitical tensions, and cyberattacks. Companies must proactively identify scenarios that could disrupt operations. For instance, earthquakes in regions like Taiwan or Japan have historically impacted semiconductor production. Similarly, trade restrictions and regulatory changes can create bottlenecks in the supply chain.

To address these risks, businesses should conduct comprehensive risk assessments. This involves analyzing historical data, monitoring geopolitical developments, and evaluating supplier reliability. A semiconductor manufacturer, for example, partnered with Sphera to consolidate its operational risk management. By mapping nine interrelated risk factors into a global context matrix, the company gained a holistic view of potential disruptions. This approach enabled them to anticipate challenges and prepare accordingly.

"Understanding the full spectrum of risks allows businesses to act decisively and minimize the impact of disruptions."

Create Contingency Plans and Backup Strategies for Critical Components

Contingency planning ensures that businesses can respond effectively to unexpected disruptions. Companies should develop backup strategies for critical components, such as sourcing alternatives or maintaining safety stock. For example, diversifying suppliers across multiple regions reduces dependency on a single source and mitigates risks associated with localized disruptions.

A centralized system for managing contingency plans enhances coordination and efficiency. Businesses can use digital platforms to track inventory levels, monitor supplier performance, and identify alternative sourcing options in real time. These tools streamline decision-making and ensure that operations continue smoothly during crises.

"Preparedness is the cornerstone of resilience. A well-crafted contingency plan transforms uncertainty into manageable challenges."

Regularly Test and Update Risk Mitigation Plans to Address Emerging Challenges

Risk mitigation plans must evolve to address new challenges and changing market conditions. Regular testing ensures that these plans remain effective and relevant. Businesses should conduct simulations and drills to evaluate their response capabilities. For instance, testing the supply chain's ability to adapt to sudden demand spikes or transportation delays can reveal areas for improvement.

Continuous updates to risk management strategies are equally important. Emerging technologies, such as AI and blockchain, provide new opportunities for enhancing risk mitigation. By integrating these tools, companies can improve transparency, predict potential disruptions, and respond more effectively.

The semiconductor industry benefits significantly from centralized systems that eliminate information silos. As demonstrated by Sphera's collaboration with a semiconductor manufacturer, a unified approach to risk management enables businesses to see the global impact of risks. This level of visibility fosters better decision-making and strengthens the overall supply chain.

"Adaptability is key to resilience. Businesses that regularly refine their risk mitigation plans stay ahead of challenges and maintain a competitive edge."

Developing a comprehensive risk management plan requires foresight, preparation, and adaptability. By identifying potential disruptions, creating contingency strategies, and continuously refining their approach, businesses can build a resilient semiconductor supply chain capable of withstanding even the most unpredictable challenges.

Step 6: Focus on Sustainability and Resilience in the Semiconductor Supply Chain

Sustainability and resilience have become critical priorities in the semiconductor supply chain. As industries like automotive increasingly rely on semiconductors, adopting sustainable practices ensures long-term viability while addressing environmental and social responsibilities. Companies must integrate innovative strategies to reduce waste, minimize environmental impact, and align with ESG (Environmental, Social, and Governance) goals.

Adopt Circular Economy Practices to Reduce Waste

The semiconductor industry generates significant waste during manufacturing. Adopting circular economy practices can mitigate this issue by promoting resource efficiency and waste reduction. Companies can implement recycling programs for raw materials such as silicon wafers and rare earth metals. These materials, essential for semiconductor production, often end up discarded after use. Recycling reduces dependency on virgin resources and lowers production costs.

For example, manufacturers can repurpose defective chips or recover valuable metals from discarded components. This approach not only reduces waste but also creates a more sustainable supply chain. The Semiconductor Research Corporation’s Environment, Safety, and Health (ESH) program has demonstrated the potential of sustainable manufacturing solutions. Over nearly three decades, it has invested in projects aimed at reducing waste across integrated circuit (IC) manufacturing stages.

"Circular economy practices transform waste into opportunity, fostering both environmental and economic benefits."

By embracing these practices, businesses in the semiconductor and automotive supply chain can enhance sustainability while maintaining operational efficiency.

Minimize Environmental Impact Across the Manufacturing Chain

Semiconductor manufacturing is resource-intensive, consuming large amounts of water, energy, and chemicals. This process contributes to greenhouse gas emissions and environmental degradation. Companies must take proactive steps to minimize their environmental footprint. For instance, adopting energy-efficient technologies and renewable energy sources can significantly reduce emissions.

Research by Imec highlights that IC manufacturing could account for 3% of total greenhouse gas emissions by 2040. Advanced R&D facilities, like Imec’s, provide valuable insights into mitigating these impacts. Additionally, companies like Intel have collaborated with cleanup agencies to detoxify facilities, addressing the industry’s toxic legacy. These efforts demonstrate the importance of environmental stewardship in the semiconductor supply chain.

In the automotive supply chain, minimizing environmental impact is equally crucial. Automotive manufacturers can work with semiconductor suppliers to develop eco-friendly production methods. For example, using low-impact materials and optimizing manufacturing processes can reduce emissions and conserve resources.

"Sustainability in manufacturing is not optional; it is a responsibility that ensures the future of industries and the planet."

By prioritizing environmental sustainability, businesses can build a resilient supply chain that supports both economic growth and ecological preservation.

Align Supply Chain Strategies with ESG (Environmental, Social, and Governance) Goals

Aligning supply chain strategies with ESG goals enhances corporate responsibility and strengthens stakeholder trust. ESG frameworks guide companies in addressing environmental challenges, promoting social equity, and ensuring ethical governance. For the semiconductor industry, this alignment involves reducing emissions, improving labor conditions, and ensuring transparency across the supply chain.

Companies can integrate ESG principles by adopting technologies like blockchain for traceability. Blockchain ensures transparency in sourcing and production, enabling stakeholders to verify compliance with ESG standards. For example, automotive manufacturers can use blockchain to track the origin of semiconductors, ensuring ethical sourcing and reducing risks associated with supply chain disruptions.

Social responsibility also plays a vital role. Businesses must ensure fair labor practices and safe working conditions throughout the supply chain. This commitment fosters trust among employees, partners, and consumers. Furthermore, governance practices, such as regular audits and compliance checks, ensure accountability and adherence to ESG objectives.

"ESG alignment transforms supply chains into ethical and sustainable ecosystems, driving long-term success."

By embedding ESG principles into their strategies, companies in the semiconductor and automotive supply chain can achieve resilience while meeting the demands of an increasingly conscious market.

The six steps outlined above provide a comprehensive roadmap for building a resilient semiconductor supply chain. From mapping the manufacturing chain to focusing on sustainability, these strategies address critical challenges and ensure long-term stability. JUSDA's innovative solutions, such as centralized supply chain management and modular integration strategies, empower businesses to navigate complexities with precision. By leveraging advanced technologies and proactive issue resolution, JUSDA enhances efficiency and adaptability across the automotive supply chain. Industry professionals must adopt these strategies to mitigate supply chain issues and secure a competitive edge in an evolving market.

See Also

5 Key Strategies for Supply Chain Success via Trends

5 Crucial Guidelines for Cybersecurity in Supply Chains

Enhancing Solutions for Supply Chain Challenges in Tech

Understanding Risks: Protecting Your Supply Chain Effectively

Overcoming Automotive Supply Chain Hurdles: Professional Advice