The Roadmap to Manufacturing Success: Key Strategies

Manufacturing success stands as a cornerstone in today's competitive landscape, driving businesses towards prosperity. The quest for excellence demands a strategic approach that optimizes quality while minimizing costs and waste. Agile Manufacturing, with its adaptability to market shifts and technological advancements, emerges as a catalyst for sustained growth. Embracing the right strategies is not merely beneficial; it is imperative for long-term viability and profitability.

Embrace Technology and Innovation

In the realm of manufacturing success, the integration of technology and innovation serves as a pivotal force propelling businesses towards unparalleled growth. The strategic adoption of cutting-edge solutions like Automation and Robotics and Data Analytics has become imperative for companies aiming to thrive in today's competitive landscape.

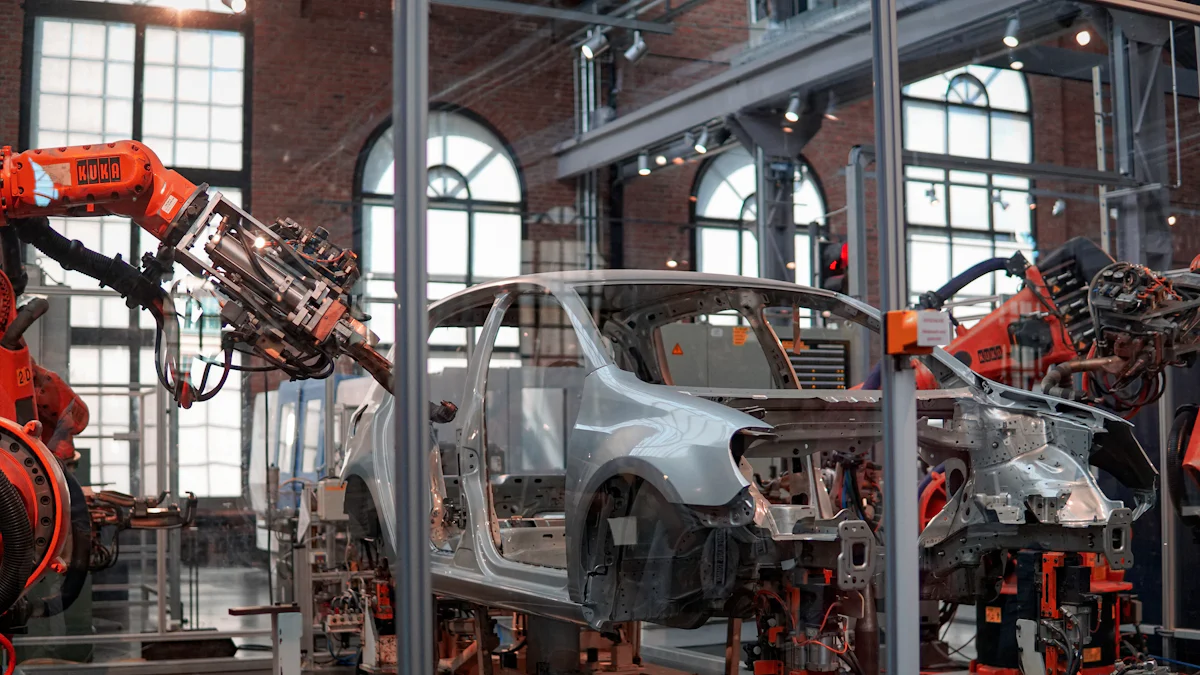

Automation and Robotics

Benefits of Automation

The implementation of automation in manufacturing processes revolutionizes operational efficiency, leading to a surge in productivity levels. By automating repetitive tasks, companies can significantly reduce human errors while accelerating production timelines. This not only enhances the overall quality of products but also streamlines workflows, resulting in substantial cost savings.

Case Studies of Successful Implementation

Increased Productivity: A renowned automotive manufacturer embraced automation in its assembly line, resulting in a 30% boost in productivity within the first quarter.

Enhanced Quality Control: A leading electronics company integrated robotics for quality checks, reducing defects by 25% and enhancing customer satisfaction.

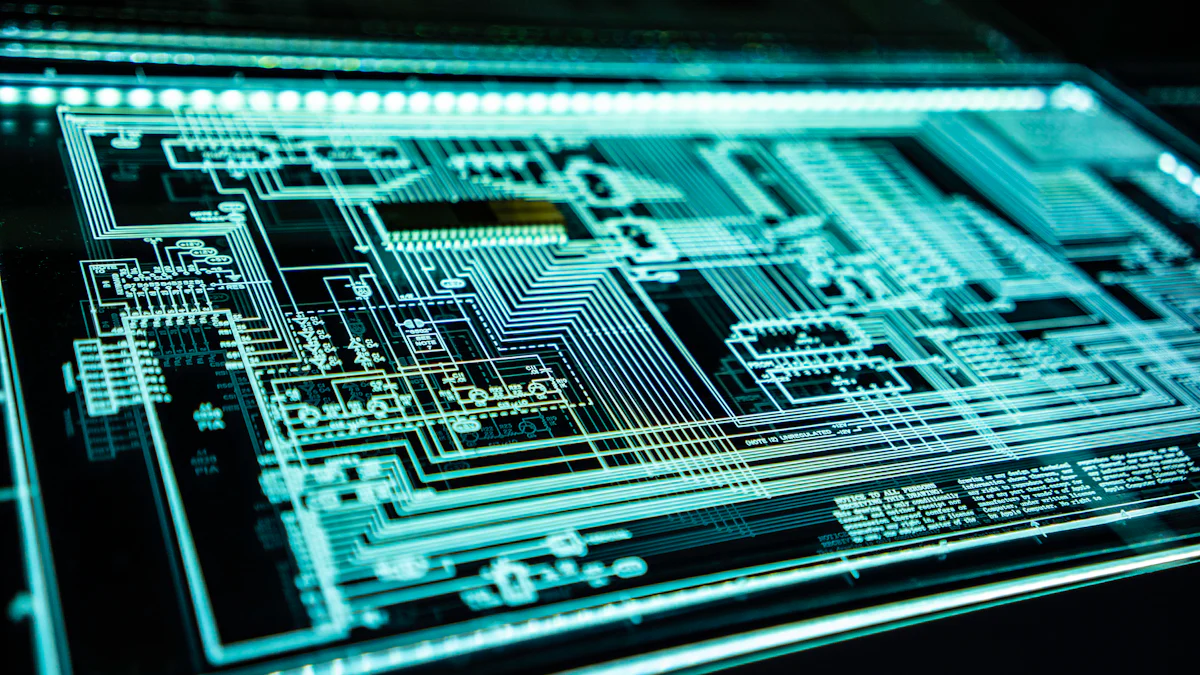

Data Analytics

Role of Data in Decision Making

Data analytics plays a pivotal role in empowering manufacturers with actionable insights for informed decision-making. By leveraging data-driven strategies, companies can optimize production processes, identify market trends, and forecast demand accurately. This enables proactive decision-making based on real-time information rather than intuition alone.

Examples of Data-Driven Success

Operational Efficiency: A pharmaceutical giant utilized data analytics to streamline its supply chain operations, resulting in a 15% reduction in lead times.

Market Expansion: An electronics manufacturer harnessed data insights to identify new market segments, leading to a 20% increase in sales revenue.

As manufacturing landscapes evolve rapidly, embracing technology and innovation emerges as a non-negotiable strategy for sustainable success. By harnessing the power of automation and data analytics, companies can navigate challenges effectively while unlocking new avenues for growth.

Focus on Quality Assurance

Importance of QA in Manufacturing

QA Systems and Processes

Quality Assurance (QA) stands as the cornerstone of manufacturing excellence, ensuring that products meet stringent quality standards before reaching the market. By implementing robust QA systems and processes, companies can safeguard their reputation, build customer trust, and drive sustainable growth.

Case Studies of QA Success

Examples from Various Sectors

Pharmaceutical Industry: A leading pharmaceutical company implemented a comprehensive QA framework, resulting in a 20% reduction in product recalls and a significant increase in customer satisfaction.

Automotive Sector: An automotive manufacturer integrated advanced QA technologies, leading to a 30% improvement in defect detection rates and a notable decrease in warranty claims.

Electronics Manufacturing: A prominent electronics brand adopted stringent QA protocols, resulting in a 25% reduction in manufacturing defects and a substantial boost in brand loyalty.

In today's competitive landscape, prioritizing Quality Assurance is not just a choice; it is a strategic imperative for sustained success. By investing in robust QA practices across diverse sectors, companies can enhance product reliability, minimize risks, and ultimately elevate their market position.

Implement Lean Manufacturing

Principles of Lean Manufacturing

Reducing Waste

Lean Manufacturing, a transformative approach to production, focuses on optimizing operations by minimizing waste at every stage. By identifying and eliminating non-value-added activities, companies can enhance efficiency and drive cost savings. This strategic methodology enables organizations to streamline processes, reduce excess inventory, and deliver value to customers promptly.

Increasing Efficiency

Efficiency lies at the core of Lean Manufacturing principles, emphasizing the importance of maximizing output while minimizing input. Through continuous improvement initiatives and employee empowerment, companies can enhance productivity levels and achieve operational excellence. By fostering a culture of innovation and collaboration, organizations pave the way for sustainable growth and competitive advantage in dynamic market environments.

In the realm of manufacturing success, embracing Lean Manufacturing practices is not just an option; it is a strategic imperative for companies seeking to thrive amidst evolving industry landscapes. By adhering to Lean principles, businesses can unlock new opportunities for growth, optimize resource utilization, and establish themselves as industry leaders committed to operational excellence.

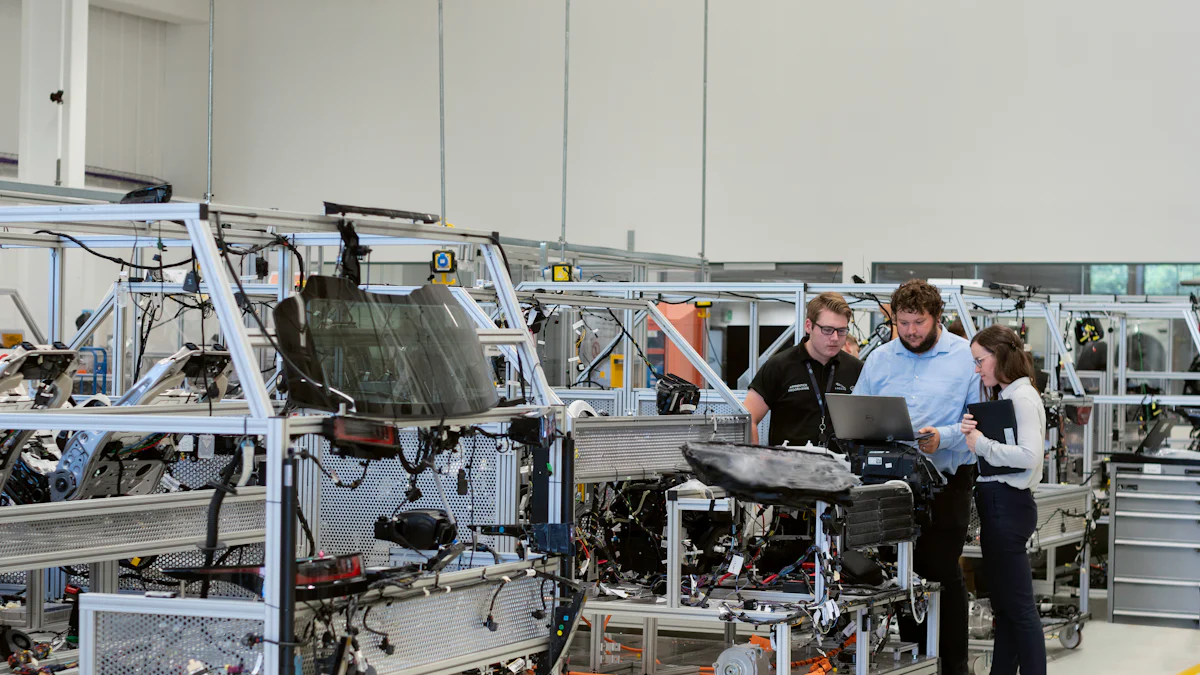

Leverage Contract Manufacturing

Benefits of Contract Manufacturing

Streamlining Production

Contract manufacturing offers a strategic solution for companies seeking to optimize their production processes. By outsourcing specific manufacturing tasks to third-party experts, businesses can streamline their operations and focus on core competencies. This streamlined approach enhances efficiency by leveraging the specialized skills and resources of contract manufacturers, leading to accelerated production timelines and improved output quality.

Enhancing Efficiency

One of the key advantages of contract manufacturing is its ability to enhance operational efficiency significantly. By partnering with external manufacturing partners, companies can tap into advanced technologies and industry best practices without incurring substantial investments. This collaboration not only boosts production efficiency but also enables rapid scalability to meet evolving market demands. As a result, businesses can achieve greater flexibility, cost-effectiveness, and competitiveness in today's dynamic business landscape.

Manufacturers must heed the roadmap to success by embracing technology and innovation, focusing on quality assurance, implementing lean manufacturing, and leveraging contract manufacturing. The key strategies discussed pave the way for enhanced efficiency, streamlined production processes, and sustainable growth. By adopting these strategies, companies can optimize operations, drive profitability, and establish themselves as industry leaders committed to excellence. It is imperative for manufacturers to take action now and integrate these proven strategies into their business models to thrive in today's competitive landscape.

See Also

Simplified Strategies for Supply Chain Challenges in High-Tech Manufacturing

Cutting-Edge Innovations in Logistics: Exploring Tomorrow's Trends

Seamless Success: Ensuring Supply Chain Consistency

Transforming Transportation: How Supply Chain Advancements are Changing the Game

Proactive Planning: Safeguarding Supply Chains with JUSDA Risk Management