Why Robotics Is Indispensable for Intelligent Logistics in 2025

Robots are transforming intelligent logistics by addressing significant challenges. A shortage of workers and rising costs are prompting companies to adopt robotic solutions. By 2025, approximately 80% of warehouses are expected to implement robots. These machines enhance efficiency, accuracy, and sustainability. For instance, robots can pick 1,600 items per hour, reducing errors and saving valuable time.

Key Takeaways

Robots help logistics by working faster and more accurately. They can pick 1,600 items each hour, cutting mistakes and saving time.

Renting robots through Robotics-as-a-Service (RaaS) lowers costs. This lets companies adjust easily and improve their work.

Robots make workplaces safer by doing heavy lifting jobs. This lowers injury risks and saves money on injuries.

Current Problems in Smart Logistics

The logistics industry has many problems that make it hard to keep up with growing needs. These problems include not enough workers, slow supply chains, and the pressure to deliver faster and more accurately.

Worker Shortages and High Costs

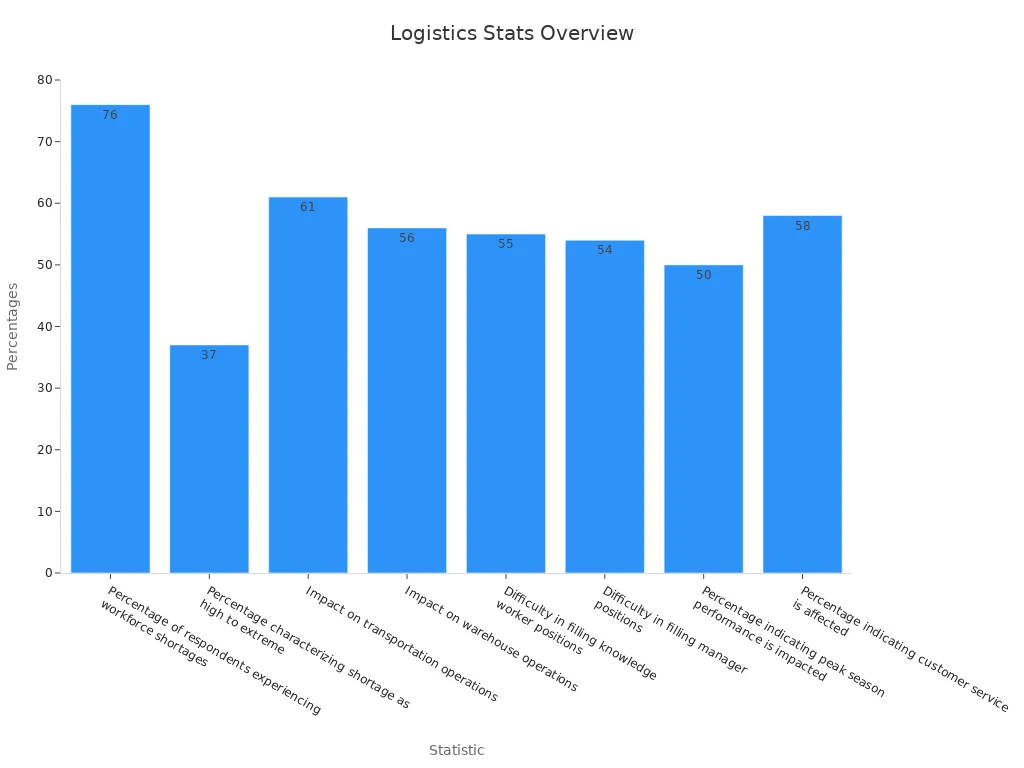

Not having enough workers is a big problem in logistics. A study showed 76% of companies struggle to find workers, and 37% say the problem is very serious. This affects transportation (61%) and warehouse work (56%), causing delays and mistakes. The table below shows how bad these issues are:

Problem | Percentage |

|---|---|

Companies with worker shortages | 76% |

Companies calling shortage very serious | 37% |

Transportation problems due to shortages | 61% |

Warehouse problems due to shortages | 56% |

Hard to hire skilled workers | 55% |

Hard to hire managers | 54% |

Peak season performance affected | 50% |

Customer service affected | 58% |

Robots and machines can help solve these problems. They can do tasks like sorting and packing faster and more accurately than people.

Problems in Supply Chains

Supply chains often have issues that slow things down and cost more money. These problems include bad communication, poor tracking, and supplier troubles. Security risks and network problems make things worse. Studies show only 2% of companies can track all their suppliers, and companies with bad inventory systems are only 63% accurate.

Robots and drones can fix these problems by improving tracking and managing inventory better. Drones can deliver items quickly, avoiding delays from regular methods. Better tracking systems give real-time updates, helping companies make smarter choices.

Keeping Up with Customer Demands

People now want faster deliveries and more updates on their orders. A survey found 70% of companies aim for real-time tracking, but only 6% have achieved it. This shows a big gap in meeting customer needs.

Drones and robots are key to solving this. Drones can deliver packages faster by skipping traffic. Robots in warehouses make sure orders are correct, keeping customers happy.

To stay competitive, the logistics industry must use these new technologies to solve its problems and improve services.

Why Robots Are Key to Solving Logistics Problems

Making Work Faster and More Productive

Robots are changing logistics by making work faster and easier. In regular warehouses, workers spend 30% of their time walking. Robots can remove this wasted time. They handle tasks like picking, packing, and sorting quickly and accurately.

A 2021 study showed factories using robots worked faster and cheaper.

Robots can boost worker productivity by up to 85%.

They also help complete orders faster, keeping customers happy.

Using robots in logistics makes work smoother and meets growing needs easily.

Keeping Workers Safe and Preventing Injuries

Robots not only work fast but also make jobs safer. In logistics, heavy lifting and repeated tasks can hurt workers. Robots can take over these jobs and lower injury risks.

Studies show robots reduce injuries by 1.2 per 100 full-time workers.

This saves $1.69 billion yearly in injury-related costs.

OSHA data proves robots make workplaces safer for everyone.

By using robots, you protect workers and save money on injury costs.

Helping the Planet with Energy-Saving Robots

Energy-saving robots are making logistics better for the planet. These robots use less energy and create less waste, cutting pollution.

Feature | Benefit |

|---|---|

Biodegradable parts | |

Smart energy use | Save 10–40% energy. |

Battery-powered robots | Work at 85–90% efficiency. |

Renewable energy use | Lower carbon output by up to 80%. |

Green robots improve energy use by 10–20%. They help the planet and cut costs, making logistics eco-friendly.

New Trends in Robotics for Smart Logistics

Robots and Automation After COVID-19

The COVID-19 pandemic changed how logistics works. It showed the need for faster and safer systems. Many companies started using robots to meet these needs. Autonomous Mobile Robots (AMRs) became important for contactless deliveries. These robots do jobs like picking and sorting without extra labor costs.

Popular tools include robotic palletizers, picking systems, and AGVs (Autonomous Guided Vehicles).

Fact | Percentage |

|---|---|

Companies focusing on stronger supply chains | 28% |

Businesses seeing robots as vital soon | 72.8% |

This proves automation is no longer a choice. It’s now a must to stay ahead in logistics.

Small Fulfillment Centers and Robots

Small fulfillment centers are changing how orders are handled. These centers are close to customers, making deliveries faster. Robots help by managing stock and speeding up work.

For example:

Walgreens uses robots to fill prescriptions, helping pharmacists.

Gopuff grew quickly by using robots for faster orders.

ShopRite improved online shopping with robotic systems.

Company | How Robots Help in Fulfillment Centers |

|---|---|

Walgreens | Uses robots to make prescription filling easier. |

Gopuff | Grew fast by using robots for quick order handling. |

ShopRite | Made online shopping better with robotic tools. |

Fabric | Used robots and AI to save space and boost efficiency. |

These centers show how robots make logistics faster and better.

Renting Robots with RaaS

Robotics-as-a-Service (RaaS) lets companies use robots without big costs. Businesses can rent robots and pay only for what they use. This makes it easy to adjust to their needs.

Benefits of RaaS:

Lower starting costs.

Access to the newest robot technology.

Easy to scale during busy times.

Even small companies can use robots with RaaS. This helps them improve logistics while saving money.

JUSDA’s Role in Smart Logistics with Robots

Using JUSDA’s Warehouse Tools for Robot Integration

JUSDA’s warehouse tools help you add robots to your logistics. They have over 2.5 million square meters of warehouse space worldwide. These spaces are ready for robots to work. Robots can do tasks like picking, packing, and managing inventory. For example, JUSDA uses systems like eVMI and JusLink to track inventory live. This helps robots work better and make fewer mistakes. By using JUSDA’s tools, you can boost productivity and improve your supply chain.

How JusLink Makes Robots Work Better

The JusLink system makes robots even more efficient. It connects robots with IoT, cloud systems, and big data. This lets you watch and control operations live. For example, JusLink helps robots find the best routes in warehouses. This saves time and energy. It also predicts problems, helping you plan smarter. With JusLink, your robots can work their best, cutting costs and improving accuracy.

JUSDA’s Worldwide Network for Smart Logistics

JUSDA’s global network makes your logistics stronger. They have 155 service points and warehouses in key areas. This helps you use robots in many places. For example, JUSDA’s sites in China, the U.S., and Europe are ready for advanced robots. This global setup helps you meet customer needs faster. By working with JUSDA, you get strong support for smart logistics.

JUSDA Solutions

To provide you with professional solutions and quotations.

Robots are changing logistics by solving big problems and helping businesses get ready for the future. The robotics market in logistics is expected to grow from $9.5 billion in 2025 to $40.2 billion by 2034. This growth is due to the need for faster deliveries and better efficiency. Robots like autonomous mobile robots and automated guided vehicles make supply chains stronger, save energy, and increase productivity. JUSDA’s smart tools, such as its warehouse services and JusLink system, show how robots can improve logistics. The future of logistics will be automated, fast, and eco-friendly, with JUSDA leading the way.

FAQ

How do robots help in warehouses?

Robots make picking, packing, and sorting faster. They lower mistakes, save time, and boost work by 85%.

Can small companies use robots?

Yes! With RaaS, you can rent robots. You only pay for use, skipping big costs and getting new tech.

Are robots good for the environment?

Today’s robots save energy and use renewable power. They reduce waste and cut carbon by 80%, helping the planet.

See Also

Harnessing Robotics To Boost Efficiency In Warehousing

Understanding Robotic Automation For Improved Warehouse Efficiency

Sustainable Practices: Robotics Innovations Shaping Supply Chains

Transforming Logistics: The Role Of AI In Supply Chains

Revolutionizing Supply Chains Through Advanced Robotics Technology