How Robots Are Revolutionizing Warehouse Operations

Robots revolutionizing warehouse operations have transformed how you manage tasks like picking, packing, and inventory checks. Automation improves accuracy, speeds up order fulfillment, and reduces costs. For example:

Businesses adopting robotics report a 66.67% boost in worker productivity.

Robotic systems free up 85% of storage space, allowing you to store more inventory efficiently.

Pick accuracy reaches 99.9%, minimizing errors and returns.

These advancements also create safer environments, addressing the 4.7 workplace injuries per 100 workers reported in 2023. By embracing robotics, you unlock efficiency, safety, and innovation.

Key Takeaways

Robots increase work speed by 66.67%, helping warehouses finish orders faster.

Automation lowers worker costs by 25-30%, letting companies focus on bigger goals.

Robots make work safer by doing dangerous jobs, cutting injuries by 60%.

Using AI and IoT in warehouses makes work faster and more accurate.

Working with robots lets people handle harder tasks, boosting happiness and work quality.

Robots Revolutionizing Efficiency and Accuracy

Faster Order Fulfillment

Robots revolutionizing warehouse operations have drastically improved order fulfillment speed. Automation allows robots to handle critical tasks like picking, sorting, and packing orders. These machines operate 24/7 without breaks, ensuring continuous productivity. For example:

Automated picking systems can reduce picking errors by up to 70%.

Robotics can enhance throughput by 2-3 times, enabling faster order processing.

Automation boosts order processing speed by up to 300%.

Additionally, robots improve accuracy during order picking, reducing errors that could lead to customer dissatisfaction. The ability to work around the clock ensures that your warehouse meets tight deadlines and handles high order volumes efficiently.

Evidence Type | Description |

|---|---|

Automation of Tasks | Robotics automates critical fulfillment tasks like order picking and sorting, leading to faster processing. |

24/7 Operation | Robots can work continuously without breaks, increasing order processing speed and throughput. |

Order Picking Accuracy | Improved accuracy reduces errors, which can lead to customer dissatisfaction and lost sales. |

Reducing Inventory Errors

Robots equipped with advanced sensors and real-time tracking capabilities significantly reduce inventory errors. Mobile robots scan and track inventory levels with precision, ensuring accurate stock records. This eliminates discrepancies caused by manual counting.

Automating warehouse tasks minimizes human errors in inventory management. For instance, technologies like barcode scanning and RFID tagging enhance tracking accuracy. These tools ensure that your warehouse maintains optimal stock levels, avoiding overstocking or shortages.

Metric | Improvement Rate |

|---|---|

Inventory Accuracy | |

Stock Counting Speed | Up to 60% faster |

By leveraging robotics, you can achieve near-perfect inventory accuracy and faster stock counting, which are essential for smooth operations.

Streamlining Repetitive Tasks

Repetitive tasks like sorting, packing, and labeling consume significant time and resources. Robots revolutionizing warehouse operations streamline these tasks, allowing you to focus on more strategic activities. Automation technologies, such as barcode scanning and real-time data tracking, ensure faster and more accurate task completion.

For example, warehouse automation boosts operational efficiency by reducing manual labor. Robots handle repetitive tasks with precision, minimizing errors and delays. This optimization reduces operational costs, including labor and storage expenses.

By automating repetitive tasks, you can improve productivity and allocate resources more effectively. Robots not only save time but also enhance the overall efficiency of your warehouse operations.

Robots Revolutionizing Safety in Warehouses

Taking Over Hazardous Tasks

Robots revolutionizing warehouse operations have transformed how you handle hazardous tasks. These machines take over physically demanding activities like lifting heavy loads, bending, and repetitive motions. By automating these tasks, robots reduce the risk of injuries caused by strain or fatigue. For example, robotic systems can handle dangerous tasks such as operating forklifts or working in high-temperature environments, minimizing human exposure to risks.

Robots also improve operational efficiency. They process goods faster and handle higher volumes, allowing you to focus on strategic activities. Additionally, robots enhance accuracy, reducing errors in inventory management. This combination of safety and efficiency creates a safer and more productive warehouse environment.

📌 Tip: Automating hazardous tasks not only protects workers but also boosts productivity, helping your warehouse achieve higher safety standards.

Reducing Workplace Injuries

Robots play a crucial role in reducing workplace injuries. Studies show that robotic systems can lower injury rates by as much as 60% in third-party logistics (3PL) operations. Most warehouse injuries occur due to lifting, bending, repetitive motion, or forklift accidents. Robots mitigate these risks by taking over physically demanding tasks.

A study monitoring 9,108 employees across 47 companies revealed significant safety improvements after robot integration. For every DKK 1 million invested in robots, injury rates decreased by 1.3 per 1,000 employees, equating to a 4.7% reduction overall. In physically demanding roles, the reduction was even more pronounced at 6.7%.

Metric | Value |

|---|---|

Increase in robot exposure | |

Reduction in injury rates | 1.2 injuries per 100 full-time workers |

Estimated savings in injury costs | $1.69 billion per year (2007 dollars) |

Reduction in manufacturing injury rates | 1.75 injuries per 100 full-time workers |

By deploying robots, you can significantly lower injury rates and create a safer working environment for your employees.

Enhancing Employee Safety

Robots revolutionizing warehouse operations enhance employee safety by eliminating repetitive and hazardous tasks. Case studies highlight how robots improve working conditions. For instance, one study reported that integrating robots reduced safety hazard scores from 69 to 8. Employees expressed positive feedback, noting reduced fatigue and improved conditions, such as avoiding welding fumes and cumbersome safety gear.

Robots also reduce the likelihood of slips, strains, and collisions. By handling physically demanding tasks, they allow workers to focus on less strenuous activities. However, automation introduces new challenges. Reduced task variety may lead to less attentiveness, and the fast pace of operations could compel workers to prioritize speed over safety. Addressing these challenges requires proper training and monitoring to ensure a balanced and safe work environment.

💡 Note: While robots enhance safety, you should implement measures to maintain worker attentiveness and prioritize safety protocols in automated environments.

Robots Revolutionizing Cost Savings

Lowering Labor Costs

Labor costs often account for 40-60% of warehouse expenses, making them a significant financial burden. Robots revolutionizing warehouse operations help you reduce these costs by automating repetitive and labor-intensive tasks. Automation minimizes the need for manual labor, allowing you to reassign workers to more strategic roles. This shift not only lowers wage and training expenses but also enhances overall efficiency.

Although the initial investment in robotics can be high, the long-term savings are substantial. Automation can reduce labor costs by 25-30%, while also minimizing picking costs, which represent 55% of operational expenses. In high-wage regions like the US and EU, where labor costs have risen by 4.5% and 9.5% respectively, robotic systems offer a cost-effective alternative.

Optimizing Resource Utilization

Robots optimize resource utilization by improving accuracy and reducing waste. For example, warehouses using robotic systems report order accuracy rates exceeding 98%. Automated tracking systems also lower return rates by nearly 20%, saving time and resources.

A comparison of pre- and post-automation metrics highlights these benefits:

Metric | Pre-Automation | Post-Automation |

|---|---|---|

Labor Cost (% of Total Expenses) | 35% - 40% | 20% - 25% |

Overtime Hours per Month | 120+ Hours | 80-100 Hours |

Redeployment to Value-Added Tasks | Limited | Significant Increase |

By reallocating resources to value-added tasks, you can achieve greater productivity and profitability.

Reducing Operational Expenses

Robots reduce operational expenses by enhancing efficiency and minimizing errors. Automated systems streamline processes, leading to a 25-30% increase in operational efficiency within the first year of implementation. Energy-efficient robotics also cut utility bills by up to 30%.

Additionally, automation reduces costs associated with manual errors and resource mismanagement. Warehouses implementing robotics report cost reductions of 40-60%, primarily due to decreased labor expenses and improved accuracy. These savings contribute to a more sustainable and profitable operation.

💡 Tip: Investing in robotics may seem costly upfront, but the long-term financial benefits make it a worthwhile decision for your warehouse.

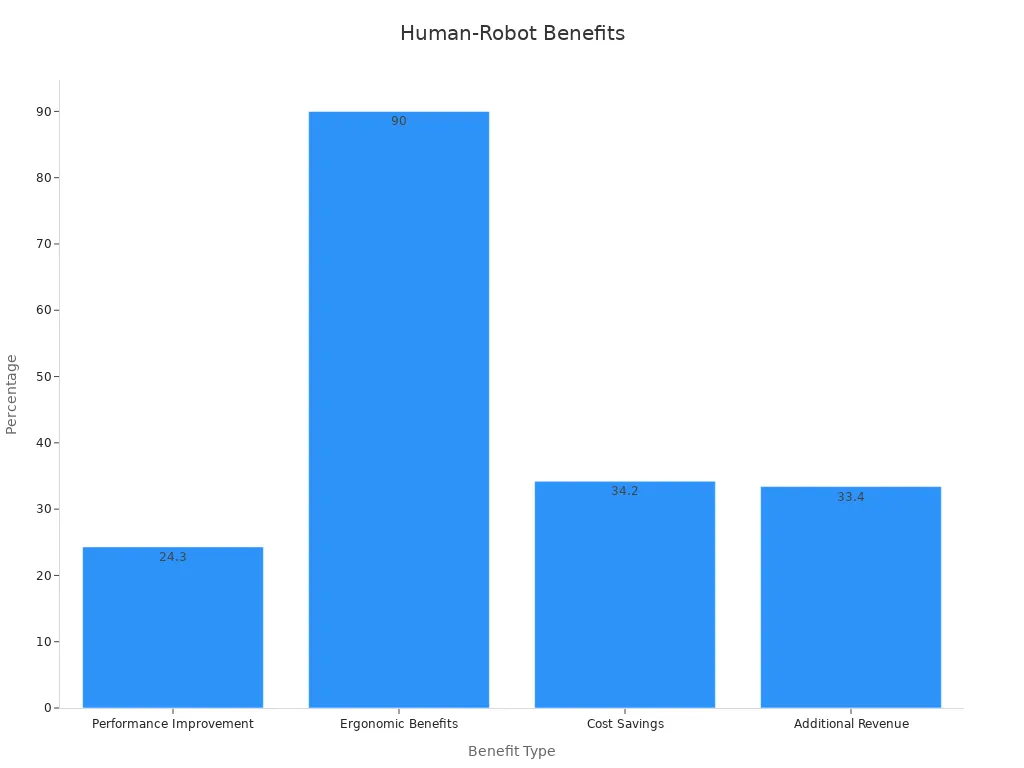

Human-Robot Collaboration in Warehouses

Combining Human Skills with Robotic Precision

Human-robot collaboration combines your unique skills with the precision of robotics to create a more efficient warehouse. Robots excel at repetitive tasks, while you bring judgment, creativity, and problem-solving abilities. For example, autonomous mobile robots (AMRs) handle monotonous tasks like transporting goods, freeing you to focus on complex duties requiring decision-making.

Collaborative robots (cobots) assist with quality inspections and packaging, improving order accuracy and speeding up processes. These cobots come equipped with smart sensors, allowing them to navigate safely around you and reduce physical strain. This synergy enhances productivity and safety in your warehouse.

Example Type | Description |

|---|---|

Autonomous Mobile Robots (AMRs) | AMRs work alongside human operators, performing monotonous tasks to allow humans to focus on complex duties that require judgment and cognitive skills. |

Cobots assist with quality inspections and packaging, improving order processing and facilitating movement within the warehouse. | |

Safety Features of Cobots | Cobots are equipped with smart sensors to navigate around humans, enhancing safety and reducing physical strain on workers. |

Upskilling Workers for Robotics Integration

As robots take over repetitive tasks, you have the opportunity to upskill and take on more strategic roles. Training programs help you learn how to operate, maintain, and program robotic systems. These skills not only make you more valuable but also prepare you for the future of work in automated environments.

Upskilling also fosters job satisfaction. By learning new technologies, you can transition from physically demanding tasks to roles that require critical thinking and technical expertise. This shift benefits both you and your employer, as it leads to higher productivity and innovation.

💡 Tip: Embrace training opportunities to stay ahead in the evolving landscape of warehouse automation.

Building Collaborative Work Environments

Robotics integration transforms your workplace into a collaborative environment. Companies are investing in better working conditions, creating a positive shift in the supply chain. For instance, the Zebra study highlights that 80% of respondents have embraced automation due to modernization efforts.

Autonomous mobile robots (AMRs) are becoming a common sight, with 27% of warehouses already deploying them. This number is expected to rise to 90% in the next five years. These advancements not only improve efficiency but also foster acceptance of automation, making your work environment more dynamic and forward-thinking.

Evidence | Description |

|---|---|

Improved Working Conditions | Companies are investing in better working conditions for warehouse associates. |

Increased Acceptance of Automation | 80% of respondents reported modernization of warehouse operations. |

Deployment of AMRs | 27% of warehouses have deployed AMRs, with expectations to reach 90% soon. |

By embracing collaboration, you can thrive in a workplace that values both human ingenuity and robotic precision.

Technological Innovations Driving Robotics

AI for Smarter Operations

Artificial intelligence (AI) is transforming warehouse operations by making them smarter and more efficient. AI-powered systems analyze vast amounts of data to optimize workflows and reduce errors. For example, companies like Amazon Robotics use AI-driven robots to pick, pack, and sort items, speeding up order fulfillment and improving customer satisfaction. Similarly, Ocado employs AI for automated storage and retrieval, maximizing space utilization and accelerating processing times.

AI also enhances decision-making. It identifies patterns in inventory and order trends, helping you predict demand and manage stock levels effectively. This reduces overstocking and shortages, saving costs and improving operational efficiency.

Key Benefits of AI in Warehouses:

Increased accuracy in inventory tracking and order fulfillment.

Faster processing times through automated workflows.

Cost savings from predictive analytics and proactive maintenance.

By integrating AI, you can streamline operations and stay ahead in a competitive market.

IoT for Connected Warehouses

The Internet of Things (IoT) connects devices and systems in your warehouse, creating a seamless flow of information. IoT sensors monitor environmental factors like temperature and humidity, ensuring optimal conditions for sensitive goods. If conditions deviate, the system sends proactive alerts and adjusts climate controls automatically.

Aspect of IoT Impact | Description |

|---|---|

Enables accurate stock tracking and reduces errors. | |

Operational Indicators | Provides data to optimize workflows and monitor performance. |

Customer Satisfaction | Improves service quality through better inventory management. |

Environmental Impact | Reduces paper usage and minimizes waste. |

IoT also improves efficiency by providing real-time data across multiple locations. This connectivity helps you forecast sales trends and manage inventory more effectively, leading to higher customer satisfaction and reduced costs.

Machine Learning for Predictive Analytics

Machine learning (ML) takes predictive analytics to the next level by using algorithms to analyze historical and real-time data. It helps you plan labor, predict demand, and identify trends in consumer behavior. For instance, ML models continuously learn from new data, improving their accuracy over time.

How Machine Learning Enhances Predictive Analytics:

Feature Selection: Identifies key variables for better predictions.

Model Training: Learns patterns from past data to forecast future needs.

Anomaly Detection: Spots unusual trends, allowing proactive measures.

By leveraging ML, you can make data-driven decisions that optimize resources and improve warehouse performance. This technology ensures you stay prepared for market changes and customer demands.

Environmental Impact of Robots in Warehouses

Reducing Energy Usage

Robots in warehouses help you save energy by operating more efficiently than traditional systems. Automated Storage and Retrieval Systems (ASRS) can function in low-light conditions, cutting electricity usage and lowering carbon emissions. Robots also conserve energy by entering a "sleep" mode when idle. This feature ensures that no power is wasted during downtime.

Energy-optimized motion planning further reduces energy consumption by 10–40%. Battery-powered mobile robots operate with an impressive efficiency of 85–90%, making them a sustainable choice. Additionally, programming robots with eco-modes can save up to 18% in energy use. These advancements not only lower your energy bills but also contribute to a greener planet.

Evidence Description | Energy Savings |

|---|---|

AS/RS increases storage density, reducing energy consumption. | 50% reduction |

Energy-optimized motion planning | |

Battery-powered mobile robots | 85–90% efficiency |

Eco-mode programming | Up to 18% reduction |

Minimizing Waste Through Automation

Robots reduce waste in your warehouse by improving accuracy and minimizing errors. Automated systems handle picking and packaging tasks with precision, which reduces the need for repacking. This saves packaging materials and lowers fuel consumption for returns.

By automating processes, you can also avoid overstocking and understocking, which often lead to wasted resources. Robots equipped with real-time tracking systems ensure that inventory levels remain optimal. This level of precision helps you cut down on unnecessary waste, making your operations more sustainable.

💡 Tip: Using robots for repetitive tasks not only saves time but also reduces the environmental impact of your warehouse.

Supporting Sustainable Supply Chains

Robots play a key role in building sustainable supply chains. Companies like IKEA use solar panels in their warehouses to power robotic systems, aligning with their goal to become climate-positive by 2030. This approach reduces energy costs and carbon footprints.

Amazon has deployed over 200,000 mobile robots to enhance efficiency and lower energy consumption. These robots streamline operations, reducing the environmental impact of warehouse activities. By adopting similar strategies, you can make your supply chain more eco-friendly and future-ready.

Examples of Sustainable Practices:

IKEA integrates solar energy to power robotic systems.

Amazon uses mobile robots to improve efficiency and reduce energy use.

By leveraging robotics, you can align your warehouse operations with sustainability goals, benefiting both your business and the environment.

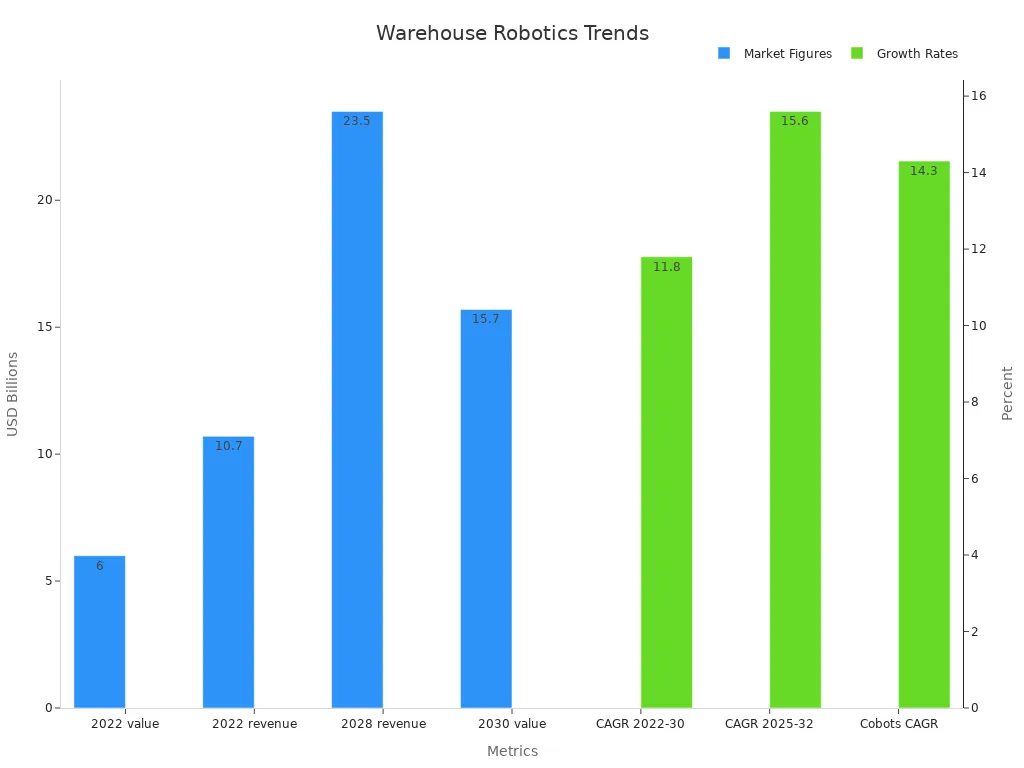

Future Trends in Robots Revolutionizing Warehouses

Autonomous Mobile Robots (AMRs) and Drones

Autonomous Mobile Robots (AMRs) and drones are reshaping warehouse operations with their advanced capabilities. AMRs navigate warehouse floors independently, adapting to dynamic layouts without predefined paths. These robots use sensors and AI to transport goods efficiently, reducing bottlenecks and improving workflow.

Drones, on the other hand, excel in inventory management. Equipped with cameras and scanning technology, they perform stock audits quickly and accurately. This eliminates the need for manual inventory checks, saving time and reducing errors. By integrating AMRs and drones, you can streamline operations and enhance productivity.

Technology | Role in Warehouse Operations | Key Features |

|---|---|---|

Autonomous Mobile Robots (AMRs) | Enhance mobility and adaptability in warehouse layouts. | Utilize advanced sensors and AI for autonomous navigation without predefined paths. |

Drones (UAVs) | Primarily used for inventory management, performing stock audits quickly and accurately. | Equipped with cameras and scanning technology for efficient inventory checks. |

Advanced AI for Decision-Making

Advanced AI is transforming how you manage warehouse operations. AI-powered systems analyze data to optimize workflows, predict demand, and improve decision-making. For example, robots equipped with AI can learn from their environment, adapting to changes and enhancing efficiency.

This technology also enables predictive maintenance, reducing downtime and extending the lifespan of your equipment. By leveraging AI, you can make smarter decisions, minimize errors, and stay competitive in a rapidly evolving market.

Expanding Robotics to Smaller Warehouses

Robotics is no longer exclusive to large-scale operations. Smaller warehouses can now adopt automation thanks to advancements in technology and affordability. Labor shortages and the need for higher productivity make robotics a practical solution for smaller setups.

Robotics technology is now accessible for smaller warehouses, countering the belief that only large operations like Amazon can implement it.

The COVID-19 pandemic has heightened awareness of supply chain vulnerabilities, prompting organizations to invest in automation.

Conducting a robotics feasibility study helps minimize financial risks associated with new investments in automation.

By integrating robotics, even smaller warehouses can improve efficiency and reduce operational costs. A well-designed strategy ensures successful implementation, making automation a viable option for businesses of all sizes.

Robots revolutionizing warehouse operations have transformed how you manage efficiency, safety, and costs. These machines streamline picking, packing, and shipping, operating continuously to reduce downtime. Equipped with sensors, they ensure accurate item selection, minimizing errors and improving customer satisfaction. By taking over hazardous tasks, robots create safer environments for workers.

Technological advancements like AI and IoT drive innovation, while sustainability efforts reduce environmental footprints. Human-robot collaboration fosters a productive workforce, combining your skills with robotic precision. As robotics evolve, they promise exciting opportunities for warehouses of all sizes.

Benefit | Description |

|---|---|

Efficiency | Robots streamline picking, packing, and shipping, operating continuously to reduce downtime. |

Accuracy | Equipped with sensors, robots ensure correct item selection, minimizing human errors in fulfillment. |

Safety | Robots take over dangerous tasks, reducing accidents and allowing human workers to focus on safer jobs. |

Financial Benefits | Robots lower labor costs and increase productivity, leading to faster order processing and happier customers. |

Environmental Impact | Robots are energy-efficient and optimize space usage, contributing to a reduced environmental footprint. |

FAQ

What types of robots are commonly used in warehouses?

You’ll find autonomous mobile robots (AMRs), collaborative robots (cobots), and drones in warehouses. AMRs transport goods, cobots assist with tasks like packing, and drones handle inventory checks. Each type improves efficiency and reduces manual labor.

How do robots improve warehouse safety?

Robots take over hazardous tasks like lifting heavy items or working in extreme conditions. They reduce workplace injuries by minimizing physical strain and accidents. This creates a safer environment for you and your coworkers.

Are robots expensive to implement in warehouses?

While upfront costs can be high, robots save money in the long run. They lower labor expenses, reduce errors, and improve efficiency. Smaller warehouses can now afford robotics due to advancements in technology and cost reductions.

Can robots work alongside humans in warehouses?

Yes, robots collaborate with you to enhance productivity. Cobots assist with repetitive tasks while you focus on strategic roles. Smart sensors ensure safe navigation, fostering a balanced and efficient work environment.

How do robots contribute to sustainability?

Robots optimize energy use, reduce waste, and support eco-friendly practices. For example, they operate in low-light conditions and minimize packaging errors. These features help you align warehouse operations with sustainability goals.

See Also

Understanding Robotic Automation's Impact on Warehouse Efficiency

Maximizing Warehouse Productivity Through Logistics Robotics Innovations

The Importance of Warehouse Automation for Business Success

Advantages of Automation in Modern Manufacturing Warehousing

Transforming Supply Chains with Advanced Robotics Technology