What Is Smart Logistics and Why It Matters Today

Smart logistics uses digital tools like IoT, AI, and real-time data. These tools help make logistics faster and smarter. The global smart logistics market was about USD 36.12 billion in 2024. This market is still growing very fast.

Digital technologies have changed how companies manage supply chains. They help companies see more, move faster, and work better. JUSDA is a leader in this area. They use advanced solutions to help businesses face new problems.

Key Takeaways

Smart logistics uses digital tools like IoT, AI, and automation. These tools help move goods faster and safer. They also make moving goods more accurate than old ways.

Companies that use smart logistics can save money. They make fewer mistakes and deliver products faster. This helps customers feel happier with their service.

Smart logistics helps the environment too. It uses better planning and technology to cut fuel use. This also lowers pollution.

Smart Logistics Overview

Key Differences

Smart logistics uses digital tools to help move goods better. Companies use sensors and trackers to get real-time data. This data helps them make quick and smart choices. Automation, artificial intelligence, and the Internet of Things (IoT) help manage the supply chain.

Traditional logistics uses manual work and paper records. Workers track shipments by hand and use past experience. This way can cause mistakes and slow actions. Smart logistics uses machines and software to do jobs faster and with fewer errors.

Here are some main differences between smart logistics and traditional logistics:

Component/Technology | Role in Smart Logistics | Contrast with Traditional Logistics |

|---|---|---|

Internet of Things (IoT) | Real-time tracking, condition monitoring, inventory management | Manual tracking, no real-time data |

Artificial Intelligence (AI) | Predictive analytics for demand forecasting, route optimization, automation | Human-based decision making, limited forecasting |

Machine Learning (ML) | Data pattern analysis to improve inventory and operations | No automated pattern recognition |

Blockchain | Enhances transparency, security, and trust in transactions | Paper-based, prone to fraud and errors |

Robotics | Automates repetitive warehouse tasks, increases speed and accuracy | Manual labor, slower and error-prone |

ERP, SCM, TMS, WMS Systems | Digital tools for integrated supply chain management and operational efficiency | Disconnected, manual systems |

Cloud Platforms & Intelligent Systems | Enable real-time collaboration, data analysis, and resource optimization | Limited integration and data sharing |

Autonomous Vehicles & Drones | Automate transportation and last-mile delivery | Human-driven vehicles, slower delivery |

Smart logistics uses predictive analytics to guess demand and plan deliveries. Companies can track shipments live and change routes to avoid delays. Automation helps reduce mistakes and makes warehouse work faster. These changes make things work better and save time.

Note: Automation lets robots move goods, sort packages, and manage inventory. This cuts down on mistakes and saves time. Companies use real-time data to plan staff and resources. This lowers costs and makes customers happier.

Why It Matters

Smart logistics is very important for businesses today. Events like the COVID-19 pandemic and trade problems show supply chains must be strong. Companies face new problems, like sudden changes in demand and transport issues. Smart logistics helps them react fast and keep working well.

Many companies use smart logistics to watch materials and products at every step. Real-time data helps stop shortages and delays. Some companies use sensors to check cargo and keep it safe. Others use blockchain to track goods and waste less. These tools make things better, cheaper, and clearer.

Automation and digital tools help companies save money. Robots and smart systems do jobs faster and with fewer mistakes. This means lower costs and better results. Companies like Amazon and DHL use smart logistics to deliver faster and make fewer errors. These changes help them meet customer needs and stay ahead.

Smart logistics also helps the environment. Using data to plan routes and manage inventory saves fuel and cuts pollution. This matters as more companies want to be eco-friendly.

The future for smart logistics is bright. As technology gets better, more companies will use these tools to compete. JUSDA is a leader in this area. They offer new services, like regular freight trains in Europe and smart warehouse management. Their focus on efficiency and smart logistics helps customers do better in supply chain management.

Smart Logistics Technologies

Smart Logistics Platforms

Smart logistics platforms use new technology to link the supply chain. These platforms depend on smart logistics IoT, smart logistics sensors, and real-time tracking. They collect and share data quickly. Companies use digital logistics platforms to watch shipments and warehouse work. They also check inventory. Teams can see problems early with real-time visibility. This helps them make fast choices. Smart logistics tracking tools show where goods are right now. These platforms help suppliers, carriers, and customers work together. Using smart logistics systems breaks down data walls. It also helps people talk to each other better.

Technology | Adoption Rate / Impact | Examples / Benefits |

|---|---|---|

Automation & Robotics | Robots in warehouses boost productivity by up to 100% and increase throughput by 30% | |

Artificial Intelligence (AI) & Machine Learning (ML) | Early adopters cut logistics costs by 15%, optimize inventory by 35%, improve service by 65% | AI helps with route planning and demand forecasting |

Internet of Things (IoT) | Over 80% of logistics companies willing to adopt | IoT sensors track vehicle health and temperature, improving warehouse management |

Big Data | Market worth $4.3B in 2023, growing at 21.5% CAGR | Analytics help with route optimization and asset control |

Digital Twins | 30% decrease in supply chain disruptions | Simulate and improve logistics operations |

Smart Logistics Solutions

Smart logistics solutions help fix common problems in the industry. They use smart logistics IoT, smart logistics sensors, and smart logistics tracking for real-time and shipment tracking. These solutions have warehouse management system tools. These tools link sensors, trackers, and robots. Companies use data analytics and dashboards to manage stock and space. Automation makes order processing faster and cuts mistakes. AI and machine learning help guess demand and plan routes. Blockchain adds safety and lets people trace goods. These smart logistics systems make things work better, cost less, and help companies meet customer needs.

Real-time tracking and visibility help stop delays.

Automation and analytics make warehouse jobs faster.

Smart logistics systems help with rules and keep data safe.

Companies can deliver up to 30% faster and process 20% more orders each hour.

JUSDA Warehouse Integration

JUSDA uses smart logistics systems to link its warehouses around the world. The JusLink digital logistics platform uses smart logistics IoT, smart logistics sensors, and data analytics. This helps everything work smoothly. JUSDA’s warehouse management system uses automation and analytics to make workflows better. Real-time tracking and smart logistics tracking tools let clients see inventory and shipments right away. JUSDA’s warehouses use advanced warehouse management system features. These include automated picking and packing to make things more accurate and faster. The company’s global warehouse network helps with good logistics and lets clients handle complex supply chains.

Smart Supply Chains and Networks

Benefits

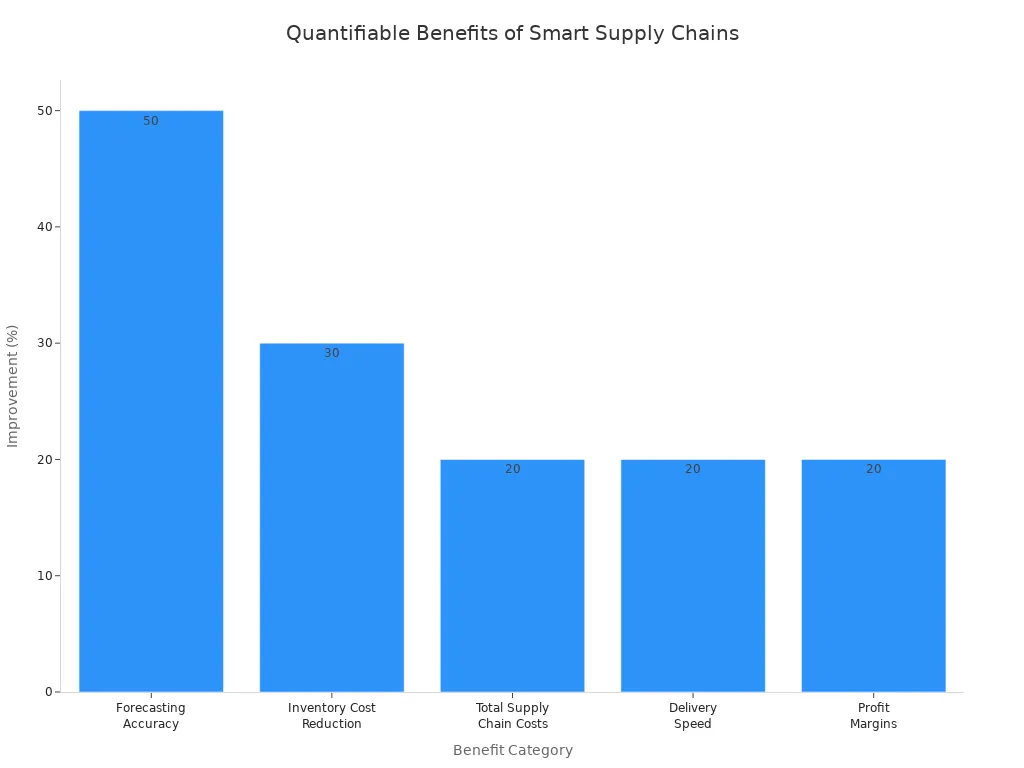

Smart supply chains help businesses in many ways. Automation cuts down on mistakes and speeds up simple jobs. This makes work more efficient. Companies spend less on labor and overhead as tasks get easier. Orders are processed faster, and inventory updates happen quickly. This leads to quicker deliveries and better smart logistics tracking. Customers can track orders better and get updates sooner. A Gartner survey says 63% of companies using mobile supply chain solutions talk better and respond faster.

Benefit Category | Quantifiable Improvement | Supporting Source/Example |

|---|---|---|

Forecasting Accuracy | Deloitte report | |

Inventory Cost Reduction | Up to 30% reduction | McKinsey, DP World |

Total Supply Chain Costs | Up to 20% reduction | DP World |

Delivery Speed | 20% increase | Case studies referenced |

Profit Margins | 10-20% higher margins | Deloitte report |

Customer Satisfaction | Improved through faster delivery and better tracking | Gartner survey (63% report improved communication) |

Smart supply chains also help the planet. Companies use electric vehicles and AI-powered route planning. Green warehouses help lower pollution and waste.

Challenges

Businesses face some problems with smart logistics networks. It is hard to connect new systems to old ones. More devices mean more risks for data safety and privacy. Teams need new skills for smart logistics tracking and smart freight logistics. High costs and training can slow things down. Companies must handle lots of data and keep it good.

Note: Companies often have trouble with IT and operations teams talking to each other. They also need flexible systems and must fix device connection issues.

Implementation

Companies can take steps to build smart supply chains:

Hire and train skilled workers for warehouse and logistics jobs.

Get teams to work together and use the same processes.

Build strong supplier partnerships and use different sources.

Use demand forecasting and manage inventory in each warehouse.

Track important numbers like perfect order rate and warehouse use.

Use real-time smart logistics tracking for better visibility.

Keep documents in one place for more accuracy.

Use technology like AI, IoT, and automation in warehouses.

Plan smart freight logistics routes to save money and cut pollution.

JUSDA shows how smart logistics solutions and smart logistics networks help companies work better and make customers happy. Their global warehouse network and digital tools let teams work together and adapt fast in supply chain operations.

JUSDA Solutions

To provide you with professional solutions and quotations.

Smart logistics helps businesses do better than others. Companies use new technology to make logistics better and save money. This also helps customers feel happier. JUSDA’s smart logistics services and global warehouse network help companies work quickly and compete around the world. Companies should look at their logistics plans and think about using smart solutions to grow in the future.

See Also

The Importance Of Security In Modern Supply Chains

How Artificial Intelligence Is Transforming Future Logistics

Innovations In Supply Chains Driving Logistics Transformation