What is a Smart Supply Chain and How Does It Work

A smart supply chain represents a revolutionary approach to managing logistics and operations. It integrates advanced technologies like IoT, AI, and blockchain to create interconnected, intelligent, and self-organizing systems. These systems enhance efficiency, responsiveness, and flexibility across all levels of the supply chain. By leveraging real-time data and predictive analytics, businesses can optimize inventory, reduce costs, and improve decision-making. Digital transformation projects have further accelerated this evolution, enabling companies to adapt swiftly to market changes while maintaining superior performance and customer satisfaction.

What is a Smart Supply Chain?

Definition and Core Concept of a Smart Supply Chain

A smart supply chain represents the integration of advanced technologies into traditional supply chain processes. It leverages tools like IoT, AI, and Big Data Analytics to create interconnected systems that operate with precision and intelligence. These systems enable businesses to monitor, analyze, and optimize their operations in real time. By utilizing predictive analytics, companies can anticipate demand, mitigate risks, and streamline workflows. This approach fosters innovation and efficiency, transforming supply chain management into a dynamic and responsive ecosystem.

"Smart supply chains fuel a dynamic ecosystem where innovation thrives." This statement underscores their role in driving progress and adaptability in modern industries.

The core concept revolves around connectivity and automation. Sensors, networks, and intelligent platforms work together to provide end-to-end visibility. This ensures that every stage, from procurement to delivery, operates seamlessly. The result is a supply chain that not only reacts to changes but also predicts and prepares for them.

Key Differences Between Smart and Traditional Supply Chains

Smart supply chains differ significantly from traditional ones in their approach and capabilities. Traditional supply chains rely heavily on manual processes and static data, which often lead to inefficiencies and delays. In contrast, smart supply chains utilize real-time data and automation to enhance decision-making and operational efficiency.

Key distinctions include:

Data Utilization: Traditional supply chains depend on historical data, while smart supply chains use real-time data for accurate forecasting and immediate adjustments.

Technology Integration: Smart supply chains incorporate IoT, AI, and blockchain, enabling advanced tracking, predictive analytics, and secure transactions.

Flexibility and Responsiveness: Traditional models struggle to adapt to sudden changes. Smart supply chains respond quickly to market fluctuations and disruptions.

Visibility: Smart supply chains provide end-to-end transparency, ensuring stakeholders have access to critical information at every stage.

These differences highlight the transformative potential of smart supply chains in addressing modern business challenges.

The Role of Technology in Modern Supply Chain Management

Technology serves as the backbone of modern supply chain management. It enables businesses to achieve unprecedented levels of efficiency, accuracy, and scalability. IoT devices collect and transmit data from various points in the supply chain, providing real-time insights into inventory levels, transportation status, and production schedules.

AI plays a pivotal role by analyzing vast amounts of data to identify patterns and trends. This allows companies to optimize resource allocation, reduce waste, and improve customer satisfaction. Blockchain technology enhances security and transparency by creating immutable records of transactions, ensuring trust among stakeholders.

Automation further revolutionizes supply chain operations. Robotics streamline repetitive tasks, while automated systems ensure consistent quality and faster processing times. These advancements collectively empower businesses to stay competitive in an increasingly complex global market.

How Does a Smart Supply Chain Work?

Real-Time Tracking and Monitoring Across the Supply Chain

Real-time monitoring forms the foundation of a smart supply chain. By leveraging IoT devices and sensors, businesses can track goods, vehicles, and inventory at every stage of the supply chain. These technologies provide continuous updates on location, condition, and status, ensuring complete visibility. For instance, sensors installed in shipping containers monitor temperature and humidity levels, safeguarding perishable goods during transit.

This level of transparency enables proactive decision-making. Companies can identify potential delays or disruptions and implement corrective measures instantly. Enhanced visibility also fosters trust among stakeholders by providing accurate and timely information. According to industry insights, real-time monitoring not only improves operational efficiency but also reduces risks associated with lost or damaged goods.

"Data analytics and monitoring devices have revolutionized supply chain management," as highlighted in a recent study. This underscores the transformative impact of real-time tracking on modern logistics.

Predictive Analytics for Demand Forecasting and Risk Management

Predictive analytics plays a pivotal role in optimizing supply chain management. By analyzing historical and real-time data, businesses can forecast demand with remarkable accuracy. Advanced analytics tools identify patterns and trends, enabling companies to adjust production schedules and inventory levels accordingly. This minimizes overstocking and stockouts, leading to significant cost savings.

Risk management also benefits from predictive analytics. By evaluating potential disruptions, such as supplier delays or market fluctuations, businesses can develop contingency plans. For example, AI-driven models assess weather patterns to predict transportation challenges, allowing companies to reroute shipments proactively. A report from DHL highlights that AI-enabled supply chains reduce logistics costs by 15% and improve inventory levels by the same margin.

The integration of predictive analytics ensures that supply chains remain resilient and adaptive, even in unpredictable environments. This capability enhances both efficiency and customer satisfaction.

Automation and Robotics in Supply Chain Operations

Automation and robotics revolutionize supply chain operations by streamlining repetitive tasks and improving accuracy. Automated systems handle processes such as sorting, packaging, and inventory management with unmatched precision. Robotics, particularly in warehouses, accelerate order fulfillment while reducing labor costs.

For instance, robotic arms equipped with AI algorithms sort and pack items faster than manual labor. Automated guided vehicles (AGVs) transport goods within warehouses, ensuring seamless operations. These technologies not only enhance productivity but also maintain consistent quality across all processes.

Automation extends beyond physical tasks. Software solutions automate administrative functions, such as order processing and shipment tracking. This reduces human error and accelerates workflows. Industry 4.0 technologies, including robotic process automation (RPA), enable supply chains to operate efficiently and scale effortlessly.

By adopting automation and robotics, businesses achieve higher operational efficiency and maintain a competitive edge in the global market.

Integration of IoT, Cloud Computing, and Big Data

The integration of IoT, cloud computing, and big data forms the backbone of a smart supply chain. These technologies work in unison to create a connected, intelligent, and data-driven ecosystem that enhances operational efficiency and decision-making.

1. IoT: Connecting the Supply Chain

IoT devices, such as sensors and RFID tags, enable real-time tracking and monitoring across the supply chain. These devices collect and transmit data on inventory levels, transportation conditions, and equipment performance. For example, sensors in shipping containers monitor temperature and humidity, ensuring the safe transport of perishable goods. This connectivity provides businesses with end-to-end visibility, enabling them to identify inefficiencies and address potential disruptions proactively.

"Data analytics and monitoring devices have revolutionized supply chain management," as noted in a study by Tech Stack. This highlights the transformative role of IoT in modern logistics.

2. Cloud Computing: Centralizing Data and Enhancing Collaboration

Cloud computing serves as the central hub for storing and processing the vast amounts of data generated by IoT devices. It allows stakeholders to access real-time information from anywhere, fostering seamless collaboration across the supply chain. By centralizing data, cloud platforms eliminate silos and ensure that all parties operate with the same accurate and up-to-date information. This improves coordination and accelerates decision-making processes.

Additionally, cloud-based solutions offer scalability, enabling businesses to adapt to fluctuating demands without significant infrastructure investments. Companies can integrate advanced analytics tools into their cloud systems, further enhancing their ability to analyze data and derive actionable insights.

3. Big Data: Transforming Insights into Action

Big data analytics plays a pivotal role in making sense of the massive volumes of information collected through IoT and cloud computing. Advanced algorithms process this data to uncover patterns, trends, and anomalies. For instance, predictive analytics tools analyze historical and real-time data to forecast demand, optimize inventory levels, and mitigate risks. According to NuVenture Connect, these capabilities make supply networks more efficient and robust.

Big data also supports autonomous decision-making by providing actionable insights. AI-driven models use this data to recommend optimal routes, adjust production schedules, and allocate resources effectively. This level of intelligence ensures that supply chains remain agile and responsive in dynamic market conditions.

Key Features of a Smart Supply Chain

Advanced Fleet Management and Logistics Solutions

Advanced fleet management systems redefine logistics by integrating IoT and AI technologies. These systems enable businesses to monitor vehicle performance, optimize routes, and ensure timely deliveries. IoT sensors installed in vehicles provide real-time data on fuel consumption, engine health, and location. This data allows companies to reduce operational costs and improve delivery accuracy.

AI-powered route optimization tools analyze traffic patterns and weather conditions to determine the most efficient paths. For example, logistics companies use predictive analytics to avoid delays caused by roadblocks or adverse weather. This ensures that goods reach their destinations on time, enhancing customer satisfaction.

Fleet management also incorporates blockchain technology to secure transactions and maintain transparent records. By leveraging these innovations, businesses achieve supply chain optimization, reducing inefficiencies and fostering operational excellence.

"IoT and AI have transformed fleet management, enabling businesses to deliver goods with precision and efficiency," as highlighted in a recent industry report.

Smart Warehousing and Inventory Management Systems

Smart warehousing systems revolutionize inventory management by automating processes and enhancing accuracy. IoT devices, such as RFID tags and sensors, track inventory levels in real time. These devices provide continuous updates, ensuring that businesses maintain optimal stock levels and avoid overstocking or stockouts.

Automation plays a critical role in modern warehouses. Robotic systems handle tasks like sorting, picking, and packing with unmatched speed and precision. For instance, companies like Amazon utilize robotic arms and automated guided vehicles (AGVs) to streamline operations. This reduces labor costs and accelerates order fulfillment.

Cloud computing further enhances inventory management by centralizing data. Stakeholders access real-time information, enabling seamless collaboration and decision-making. Businesses also use AI-driven tools to predict inventory needs based on historical data and market trends. This approach minimizes waste and ensures that resources are allocated efficiently.

"Smart warehousing systems powered by IoT and AI have set new benchmarks for efficiency and accuracy in inventory management," according to a study by Tech Insights.

AI-Powered Demand Forecasting and Replenishment

AI-powered demand forecasting tools enable businesses to anticipate customer needs with remarkable accuracy. These tools analyze historical sales data, market trends, and external factors to predict demand patterns. By understanding future requirements, companies can adjust production schedules and inventory levels proactively.

Replenishment processes benefit significantly from AI integration. Intelligent systems automate stock replenishment by analyzing real-time inventory data. For example, AI algorithms identify low-stock items and trigger orders to suppliers, ensuring uninterrupted operations. This reduces the risk of stockouts and enhances supply chain efficiency.

Predictive analytics also play a vital role in mitigating risks. Businesses use AI models to evaluate potential disruptions, such as supplier delays or market fluctuations. This allows them to implement contingency plans and maintain smooth operations. Companies like Mitsubishi Heavy Industries have successfully implemented AI-driven solutions to optimize their supply chains, achieving significant cost savings and operational improvements.

"AI-powered demand forecasting transforms supply chain management by enabling businesses to stay ahead of market demands," as noted in a report by Supply Chain Today.

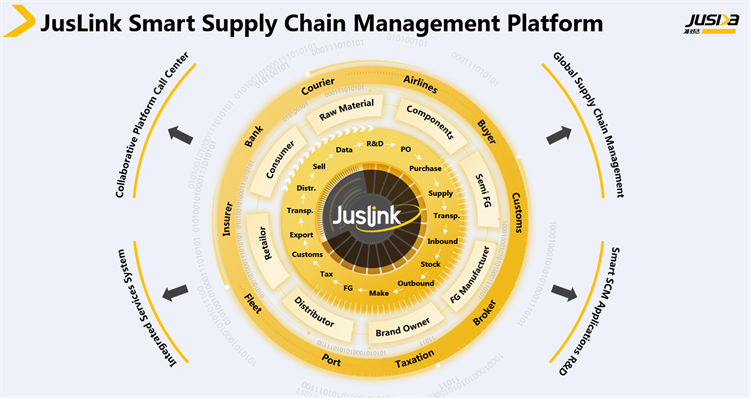

End-to-End Visibility with Platforms Like JusLink

End-to-end visibility has become a cornerstone of modern supply chain management. Platforms like JusLink provide businesses with the tools to achieve seamless transparency across every stage of their supply chain. By integrating advanced technologies such as IoT, cloud computing, and AI, JusLink empowers companies to monitor, analyze, and optimize their operations in real time.

1. Real-Time Data Collection and Monitoring

JusLink utilizes IoT sensors to collect data from various touchpoints within the supply chain. These sensors track critical parameters such as location, temperature, and humidity. For instance, refrigerated containers equipped with IoT devices can transmit real-time data to ensure perishable goods remain in optimal conditions. Businesses can adjust parameters instantly to prevent spoilage and maintain product quality.

"IoT sensors and cloud platforms like Microsoft Azure have revolutionized supply chain monitoring," as noted in a recent industry report. This highlights the transformative impact of real-time tracking on operational efficiency.

2. Centralized Data Management

Cloud computing serves as the backbone of JusLink's platform. It centralizes vast amounts of data, enabling stakeholders to access accurate and up-to-date information from anywhere. This eliminates data silos and fosters collaboration among suppliers, manufacturers, and distributors. By providing a unified view of the supply chain, JusLink ensures that all parties operate with synchronized information, reducing delays and miscommunication.

3. Predictive Analytics for Proactive Decision-Making

JusLink leverages AI-driven predictive analytics to transform raw data into actionable insights. The platform identifies patterns and trends, allowing businesses to anticipate potential disruptions and adjust their strategies proactively. For example, AI models can forecast demand fluctuations or predict transportation delays, enabling companies to allocate resources more effectively. This capability enhances resilience and minimizes risks.

4. Enhanced Security and Transparency

Blockchain technology integrated into JusLink ensures secure and transparent transactions. Each step in the supply chain is recorded on an immutable ledger, providing stakeholders with a trustworthy record of activities. This level of transparency builds confidence among partners and customers, fostering stronger relationships and improving accountability.

Key Benefits of JusLink's End-to-End Visibility

Improved Efficiency: Real-time tracking and centralized data streamline operations, reducing inefficiencies.

Cost Reduction: Predictive analytics and optimized resource allocation lower operational expenses.

Better Risk Management: Proactive insights enable businesses to mitigate potential disruptions.

Customer Satisfaction: Enhanced transparency and timely deliveries improve trust and loyalty.

"Platforms like JusLink redefine supply chain management by combining IoT, AI, and blockchain to deliver unparalleled visibility and efficiency," as highlighted in a recent study.

By adopting JusLink, businesses can transform their supply chains into intelligent ecosystems that drive innovation, operational excellence, and growth.

JUSDA’s Role in Smart Supply Chain Management

How JUSDA Leverages JusLink for Intelligent Supply Chain Solutions

JUSDA has established itself as a leader in providing intelligent supply chain solutions through its innovative platform, JusLink. This platform integrates cutting-edge technologies such as IoT, AI, and blockchain to create a seamless and efficient supply chain ecosystem. By leveraging real-time data and predictive analytics, JusLink empowers businesses to monitor, analyze, and optimize their operations with precision.

JusLink enhances supply chain visibility by utilizing IoT sensors to track goods, vehicles, and inventory across all stages. These sensors provide continuous updates on location, condition, and status, ensuring that businesses maintain control over their supply chain processes. For instance, companies can monitor temperature-sensitive shipments in real time, safeguarding product quality during transit.

AI-driven analytics within JusLink transform raw data into actionable insights. The platform identifies patterns and trends, enabling businesses to anticipate demand fluctuations and mitigate risks proactively. Blockchain technology further strengthens JusLink by ensuring secure and transparent transactions. Each step in the supply chain is recorded on an immutable ledger, fostering trust among stakeholders.

JUSDA’s approach to smart supply chain solutions emphasizes efficiency, accuracy, and scalability. By integrating JusLink into their operations, businesses can reduce costs, improve decision-making, and achieve operational excellence.

Industry-Specific Solutions for Diverse Sectors

JUSDA tailors its smart supply chain solutions to meet the unique needs of various industries. Its expertise spans sectors such as electronic manufacturing, automotive, FMCG, and medical health. Each industry benefits from customized strategies designed to address specific challenges and optimize supply chain performance.

Electronic Manufacturing: JUSDA supports manufacturers by streamlining procurement, production, and distribution processes. JusLink’s predictive analytics tools enable precise demand forecasting, ensuring that production schedules align with market needs.

Automotive and Aftermarket: JUSDA enhances supply chain efficiency for automotive companies by integrating advanced fleet management systems. These systems optimize routes, reduce transportation costs, and ensure timely deliveries.

FMCG: Fast-moving consumer goods companies rely on JUSDA’s smart warehousing solutions to manage inventory effectively. IoT-enabled warehouses provide real-time updates on stock levels, minimizing waste and preventing stockouts.

Medical Health: JUSDA addresses the complexities of the medical supply chain by ensuring the safe and timely delivery of sensitive products. IoT sensors monitor environmental conditions, maintaining the integrity of pharmaceuticals and medical devices.

JUSDA’s industry-specific solutions demonstrate its commitment to delivering value across diverse sectors. By addressing unique challenges, JUSDA helps businesses achieve greater efficiency and resilience.

JUSDA Solutions

To provide you with professional solutions and quotations.

Case Study: Sharp’s Supply Chain Transformation with JUSDA

SHARP, a globally recognized manufacturer of household appliances, faced significant challenges in its supply chain. Complexities in upstream and downstream operations led to inefficiencies, slower response times, and difficulties in forecasting production plans. To overcome these obstacles, Sharp partnered with JUSDA to implement a comprehensive supply chain optimization strategy.

Through the joint venture SHARP JUSDA LOGISTICS (SJL), JUSDA introduced innovative solutions that transformed Sharp’s supply chain. JusLink played a pivotal role by integrating Warehouse Management Systems (WMS) and Transportation Management Systems (TMS). These integrations provided real-time visibility into inventory and logistics, enabling Sharp to streamline operations and reduce costs.

Key achievements of this collaboration included:

A 20% reduction in logistics costs.

A 70% decrease in labor costs.

A 30% improvement in order delivery times.

JUSDA’s solutions also enhanced Sharp’s global e-commerce logistics. Predictive analytics tools optimized inventory levels, while automated systems accelerated order processing. The partnership between JUSDA and Sharp exemplifies the transformative potential of smart supply chain solutions in addressing complex challenges and driving business growth.

"JUSDA’s innovative approach to supply chain management has set new benchmarks for efficiency and reliability," as demonstrated by Sharp’s success story.

A smart supply chain redefines supply chain management by integrating advanced technologies to enhance efficiency, visibility, and decision-making. It transforms traditional processes into dynamic systems that adapt to market demands and mitigate risks effectively. JUSDA exemplifies expertise in this domain through its innovative solutions like JusLink, which combines IoT, AI, and blockchain for seamless operations. Success stories, such as Sharp’s supply chain transformation, highlight the tangible benefits of these advancements. Businesses seeking to optimize their operations should explore JusLink to unlock new levels of efficiency and growth.

See Also

Transforming Industries Through Cloud Supply Chain Innovations

Boosting Supply Chain Efficiency Using Cloud Technologies

Revolutionizing Supply Chains with Advanced Robotics Technology