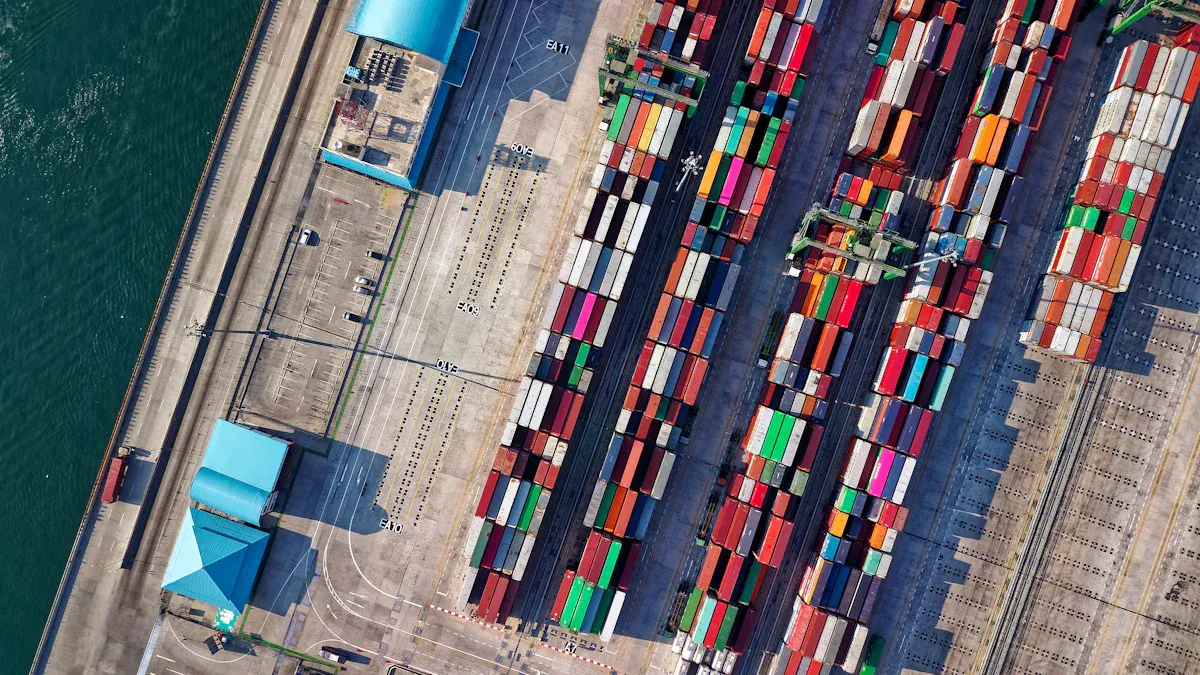

Supply Chain Orchestration AI Agents Shaping the Future of Risk Management

Supply Chain Orchestration AI Agents help you handle risk better. They make your business stronger. Artificial intelligence links live data with smart planning. This helps you act fast when the market changes. You make better decisions. You work together more easily. You manage risks in a stronger way. Old automation does not change much. Artificial intelligence can adjust to surprises. It shows you what is happening right now. You use your skills to guide these agents. You make smart choices with them for the best results.

Key Takeaways

AI agents find risks early in supply chains. This helps people act fast to stop problems. - Predictive analytics help guess what will be needed. They also help manage inventory. This makes sure you have the right stock when you need it. - Real-time data integration lets teams react quickly to changes. This makes the supply chain work better. - AI helps teams work together more easily. This leads to better talking and faster problem-solving. - Using AI in supply chains can cut down recovery times a lot. It also helps service stay good during disruptions.

Impact of AI on Supply Chain Resilience

Early Risk Identification

AI agents help you find risks early in supply chains. Artificial intelligence gathers lots of data from suppliers and shipments. You do not need to wait for reports anymore. You get alerts right away. This lets you act quickly and stop problems.

Here is a table that shows how artificial intelligence agents work compared to manual methods for risk detection:

Aspect | AI Agents | Manual Methods |

|---|---|---|

Data Collection | Automates collection of large volumes of data | Manual review of reports and sources |

Risk Assessment Time | Can take weeks to complete | |

Real-time Monitoring | Continuous tracking of supplier performance | Historical data review |

Predictive Analytics | Uses advanced analytics for risk prediction | Limited to past data analysis |

Artificial intelligence agents help you spot risks you know about and ones you do not. Known risks are things like a supplier going out of business. Unknown risks can be sudden, like a storm stopping shipments. You get warnings early, so you can change your plans and keep your business safe.

Predictive Analytics

Artificial intelligence gives you strong tools to guess what will happen next. You use predictive analytics to see patterns in your supply chain. You can guess how much you will need, manage your stock, and plan delivery routes. This helps you avoid running out or having too much.

Here are some ways predictive analytics help:

Improved inventory management keeps the right amount of stock.

Optimized logistics finds the best delivery routes.

End-to-end visibility links all parts of your supply chain.

Risk reduction lets you spot problems before they happen.

Many companies use artificial intelligence to make supply chains stronger. Amazon uses deep learning to guess demand for many products. Walmart uses machine learning to keep shelves full. DHL uses artificial intelligence to lower transportation costs. These examples show how ai helps with risk management and resilience.

Supply Chain Orchestration AI Agents

Real-Time Data Integration

You need up-to-date data to make good choices. Supply chain orchestration ai agents use artificial intelligence to collect data from many places. These ai agents link systems and remove data barriers. You can see your inventory, orders, and shipments as they happen. This helps you react fast when things change.

Here is a table showing how different technologies help with real-time data integration:

Technology | Functionality |

|---|---|

Connects autonomous ai agents to EDI systems for real-time data interpretation and optimization. | |

Multimodal Data Retrieval Agent | Collects supply chain data from many sources for optimization models. |

Optimization Modeling Agent | Builds custom models using business rules for actionable recommendations. |

Real-time data processing gives you quick answers. You can fix problems fast and change your plans. You spot risks early because you see issues before they get big. You also get a clearer view of your supply chain, which helps you plan better. Supply chain orchestration ai agents use artificial intelligence to keep your work smooth and efficient.

Tip: Real-time data helps you find problems early and fix them before they reach your customers.

Optimization Engines

Optimization helps your supply chain work better. Supply chain orchestration ai agents use artificial intelligence to run optimization engines. These engines help you use resources well, plan routes, and manage inventory. You save money and make more profit. You also make customers happy by delivering faster and more accurately.

Here are ways optimization engines help you:

Save money and make more profit by improving processes and managing inventory.

Make customers happy with quick and correct deliveries.

Stay flexible and ready for changes in the market.

Supply chain orchestration ai agents handle many steps at once. They use real-time data to make choices and change plans. Artificial intelligence lets you test ideas and pick the best ones. You get advice that matches your business needs. Optimization engines make your supply chain stronger and quicker to respond.

Cross-Functional Collaboration

You need teams to work together to solve problems and create new ideas. Supply chain orchestration ai agents help teams share updates right away. Artificial intelligence links people from different departments. You get the right information to everyone, so all teams work together.

Here is a table showing benefits of cross-functional collaboration with ai agents:

Benefit | Description |

|---|---|

AI tools do simple tasks, so teams can focus on important work. | |

Increased Productivity | Better workflows help teams reach goals faster. |

Improved Alignment | AI helps teams sort and study data, making teamwork easier. |

Supply chain orchestration ai agents use artificial intelligence to help people and ai work together. You approve choices and guide what happens next. You also get dashboards to check how things are going. Real-time data and optimization engines help teams work together and try new things. Using ai agents in your supply chain leads to better risk management and stronger results.

Note: Working together with ai agents helps you come up with new ideas and change quickly when needed.

AI-Powered Supply Chains

Autonomous Decision-Making

Supply chain management is changing with artificial intelligence. You can make choices faster and feel more sure about them. AI agents use live data to do more than just look at numbers. They tell you what to do next and help you stop expensive problems. For example, artificial intelligence can move inventory when people want more or change production if a supplier has trouble. Pharmaceutical companies use agentic AI to send ingredients on new routes during big problems, so work does not stop.

Here are some ways autonomous decision-making helps your supply chain:

AI agents figure out the cost of waiting and give you the best idea.

They change plans fast when something new happens.

You see what is happening right now and fix small problems before they get worse.

Artificial intelligence helps you handle risks better. You can find problems early and fix them before they hurt your customers. But you need good data and strong systems. Some problems are bad data, trouble connecting systems, and cyber risks. People trust artificial intelligence more when they see good results and smart choices.

Concurrent Planning

Old supply chains did things one step at a time. Each team finished before the next team started. This way often caused slowdowns and missed chances. Now, artificial intelligence lets teams plan together. You and your teams can make choices at the same time. You can change plans right away and react to new things faster.

Concurrent planning means you do not wait for one step to end before starting another. Artificial intelligence links all parts of your supply chain, so you can make everything better at once. Studies show this way helps you fix problems faster and keep service high.

Here is a table that compares ai-powered supply chains with old supply chains:

Characteristic | AI-Powered Supply Chains | Traditional Supply Chains |

|---|---|---|

Forecasting Accuracy | Better with live data and smart tools | Uses old data |

Data Integration | Live from many places | Sometimes and not always |

Process Automation | Lots of automation | People do most work |

Supply Chain Visibility | Better with finding problems | Not as good and not often |

Resilience to Disruptions | Stronger with smart models | Not as quick to change |

Kinaxis is a leader by using agentic AI for real orchestration. You get better guesses, lower costs, and a stronger supply chain. Artificial intelligence helps you stay ready in a world that changes fast.

Applications and Impact

Industry Use Cases

Supply chain orchestration AI agents work in many fields. These agents help you fix problems and make your business better. Here are some ways you can use them:

Autonomous demand forecasting helps you change plans fast when sales go up or down.

Intelligent procurement agents watch for supplier risks and act right away.

Smart inventory rebalancing moves stock to places where it is needed most.

Dynamic route planning and logistics optimization help you pick the fastest delivery routes.

Exception handling agents fix problems quickly, even if you do not see them.

Supplier negotiation bots handle small buys and save you time.

Returns and reverse logistics automation make sending things back easier.

Production scheduling agents change plans when something unexpected happens.

Order prioritization agents help you pick which orders to fill first.

Sustainability-driven decision making lets you choose options that help the environment.

Tip: These AI agents make your supply chain smarter and help you adapt fast.

Measurable Outcomes

You can see how artificial intelligence helps your supply chain. In 2024, a European logistics company used AI route planning and made trips 18% faster. This saved $12 million in fuel and driver hours in one year. When you use artificial intelligence, you make better choices and automate jobs. You save money and give better service to your customers.

AI-powered procurement orchestration lets your team focus on important work. You spend less time on boring tasks and more time on planning. This means you get more done and give better service. Many companies save money, deliver faster, and have happier customers with these tools.

Note: You can use dashboards and reports to see how much your supply chain gets better.

Implementation Strategies

Data Foundation

You need good data to manage supplier risk with artificial intelligence. Make sure your data is easy to find and well organized. Build systems that let you see what is happening right now. This helps you spot problems before they get worse. Use both structured and unstructured data for a full supply chain view. Retrieval-augmented generation pipelines help ai work better with your data. Role-based access control keeps your data safe from mistakes or leaks. Setting up these systems helps you manage supplier risk and stop problems early.

Make data easy to find and keep it neat

Use real-time data for fast choices

Combine all data types for a full view

Use strong rules to keep data safe

Tip: Seeing data in real time helps you find weak spots and fix them before they cause trouble.

Human-AI Collaboration

You are important in managing supplier risk with ai. Clean and correct data helps you and ai make smart choices. Set clear goals for risk and match them to your business plans. Make a plan for using ai and pick projects that help most. Buy tools that can grow as your needs change. Teach your team to use ai and work well with it. Always check how your systems work and change your plans if new problems show up.

Check if your data is ready to use

Teach your team to work with ai

Ethical Considerations

Ethics are important in supplier risk management. Watch out for bias and make sure things are fair with ai. Keep your systems open so you can explain choices. Balance what people do and what machines do. Keep your data private and safe from harm. Good rules help you avoid problems and manage risk. When you do these things, people trust your supplier risk management more.

Keep systems open and easy to explain

Balance people and machine work

Keep data private and safe

Note: Good ethics in supplier risk management help you stop problems and keep your business safe.

Future Trends

Evolving Technologies

Every year, new technologies change how supply chains work. Artificial intelligence helps you guess problems before they happen. You use smart tools to make better choices and work faster. The Internet of Things (IoT) connects machines and sensors. You get live updates about inventory and shipments. Data management strategies help you see your whole network clearly. You use this data to make good decisions and keep your supply chain strong.

Here is a table showing the most important technologies shaping the future:

Description | |

|---|---|

AI | Transforms supply chains from reactive to predictive models, enhancing decision-making and efficiency. |

IoT | Links real-time data to operations, improving inventory management and reducing downtime. |

Data Management Strategies | Creates unified visibility across networks, enabling meaningful AI-driven decision-making. |

Tip: You can use these technologies together to build a supply chain that is fast, smart, and ready for change.

Outcome-First Orchestration

Supply chains will soon be quicker and ready for change. Companies now build systems that can change fast when things go wrong. You use planning all the time to handle new problems and surprises. AI-powered decision-making helps you spot issues right away and try out different fixes. You do not wait for trouble; you plan ahead and keep your business safe.

Here is a table showing how outcome-first orchestration will change risk management:

Aspect | Description |

|---|---|

Agility | Continuous recomposition allows supply chains to adapt quickly to changes and disruptions. |

Real-time Decision-Making | AI-powered decision-making enables instant detection of issues and simulation of alternatives. |

Proactive Strategies | Companies are expected to shift from reactive to proactive risk management, focusing on resilience and predictive capabilities. |

You will see these changes in the next five years:

Companies will build supply chains that guess problems before they happen.

More money will go into generative AI to change how you manage supply chains.

AI agents will watch suppliers and improve logistics without people, making your supply chain stronger.

Note: You can use outcome-first orchestration to stay ahead of risks and keep your supply chain running smoothly.

You can make your supply chain stronger with orchestration AI agents. These tools help you find problems early and fix them faster. You can recover from trouble 50% quicker and keep service 25% better during hard times. Here are the main benefits:

Benefit | Description |

|---|---|

Predictive Maintenance | Lowers risk by up to 25% |

Supplier Monitoring | Makes risk management almost twice as good |

Recovery Times | Gets better 50% faster after problems |

Service Levels | Stays 25% higher when things go wrong |

To get started, try these steps: Automate your work and use AI to help make choices. Connect AI with your current systems. Use tools like IBM Sterling, AWS Supply Chain, and Google Cloud Supply Chain Solutions.

You can get ready for the future by learning from top companies and always working to get better.

FAQ

What is supply chain risk and why does it matter?

Supply chain risk means anything that can hurt your supply chain. You need to watch for disruptions like weather, strikes, or supplier problems. Managing supply chain risk helps you keep products moving and avoid big losses.

How does ai help you predict disruptions?

Ai uses data from many sources to spot patterns. You get alerts before disruptions happen. Ai helps you with disruption prediction by showing you what might go wrong. You can act early and lower the disruption impact.

Can ai improve supply chain disruption modeling?

Yes. Ai builds models that show how disruptions affect your supply chain. You see where problems might start. Ai helps you test different plans. You use supply chain disruption modeling to find weak spots and fix them.

How do you use ai to lower supply chain risk?

You use ai to watch for disruptions all the time. Ai checks supplier data, weather, and shipping. You get warnings fast. Ai helps you change plans and keep your supply chain safe. You lower supply chain risk by acting before problems grow.

What are the benefits of ai in supply chain management during disruptions?

Ai helps you see disruptions early. You get better supply chain risk control. Ai finds problems and gives you choices. You keep products moving and customers happy. Ai makes supply chain management stronger when disruptions happen.

See Also

Exploring AI's Role in Shaping Future Supply Chains

Enhancing Supply Chain Performance Through AI Innovations

Transforming Logistics for the Future with AI Solutions

Expert Strategies for Effective Risk Management in Supply Chains

Building Resilient Supply Chains with JUSDA's Risk Management