Essential Strategies to Strengthen Supply Chain Resilience in 2025

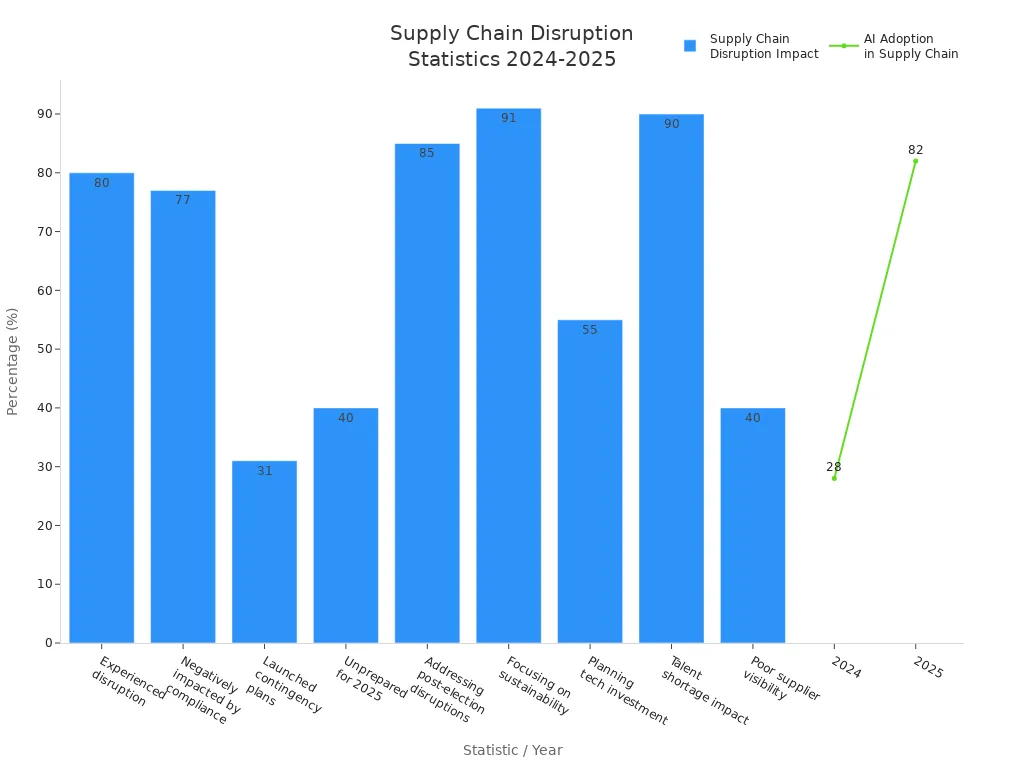

Supply chain resilience remains a top priority as global supply chain disruptions increase in frequency and complexity. Companies now adopt strategic approaches, including digital transformation and regionalization, to strengthen their supply chain strategy. Recent data shows a predicted jump in AI adoption from 28% to 82% in supply chains by 2025.

Many organizations now shift from a global supply chain model to a regional focus. Proactive strategies and technology adoption play a strategic role in building Supply Chain Resilience: From Global to Regional.

Key Takeaways

Shift supply chains closer to key markets through regionalization and nearshoring to reduce risks and improve flexibility during disruptions.

Diversify suppliers across regions to spread risk, recover faster from disruptions, and avoid stockouts or delays.

Use advanced technologies like AI, IoT, and blockchain to enhance supply chain visibility, forecast demand accurately, and manage risks proactively.

Supply Chain Resilience: From Global to Regional

Regionalization and Nearshoring

Regionalization and nearshoring have become central strategies for supply chain resilience: from global to regional. Companies now prioritize building supply networks closer to key markets. This shift reduces risk from geopolitical tensions and supply chain disruptions. For example, Toyota’s strategic move to maintain regional semiconductor inventories after the 2011 Tōhoku earthquake allowed the company to continue production during the 2020-2021 global chip shortage. Toyota gained market share and protected business continuity, demonstrating how resilience investments pay off during disruptions.

Industry reports show measurable benefits of regionalization and nearshoring. These strategies shorten lead times, improve operational flexibility, and reduce exposure to global risks. Consulting firms project that by 2026, most U.S.-serving supply chains will be Americas-based, reflecting a strong trend toward supply chain resilience: from global to regional. Companies also invest in AI-powered analytics to enhance forecast precision and responsiveness.

Regionalization and nearshoring help companies respond quickly to disruptions and maintain supply chain resilience, even in volatile environments.

Diversifying Suppliers

Diversifying suppliers strengthens supply chain resilience: from global to regional by spreading risk across multiple regions and partners. Companies use proactive supplier monitoring, scenario planning, and contingency measures to anticipate disruptions. They analyze supplier reliability, regional dependencies, and past disruptions to quantify risk reduction. Technology tools such as AI and blockchain track inventories and verify compliance, supporting strategic risk management.

Companies reduce reliance on single suppliers or regions, mitigating risk from tariffs and geopolitical tensions.

Resilient supply chains recover up to 40% faster from disruptions, according to McKinsey.

Diversifying the supply base lowers the chance of stockouts and operational interruptions.

These strategies create a robust supply chain resilience: from global to regional framework, enabling companies to withstand disruptions and maintain competitive advantage.

Proactive Supply Chain Risk Management

Risk Assessment Tools

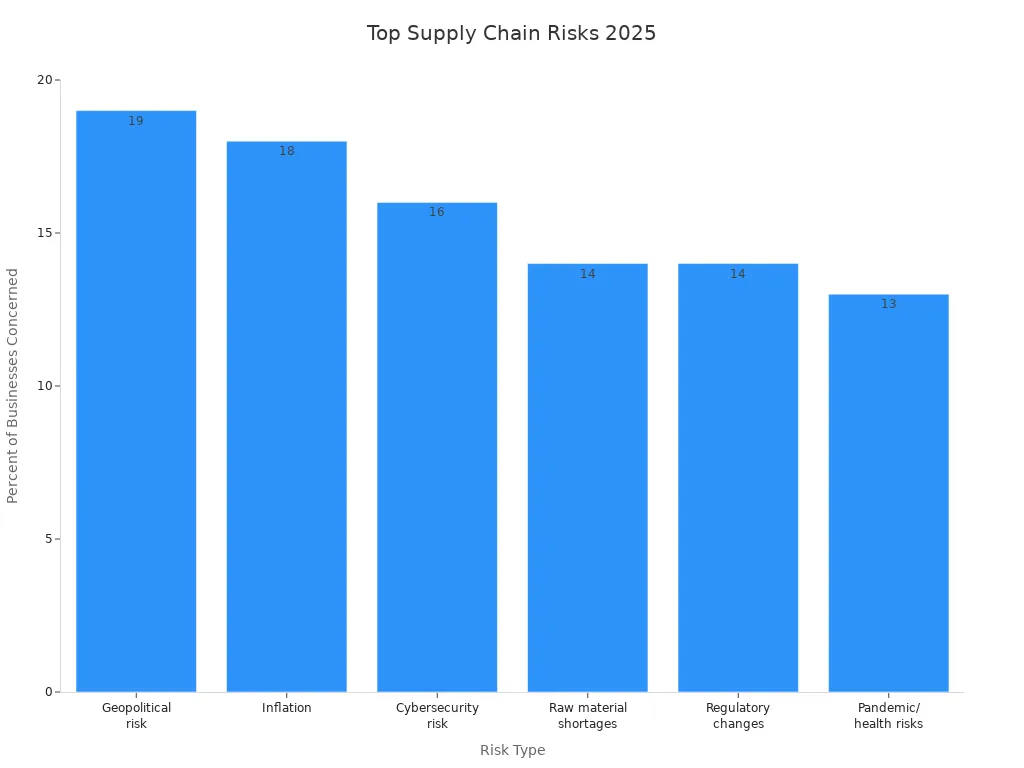

Supply chain risk management relies on a robust risk assessment framework to identify and address risks before they escalate. Companies use advanced tools such as supply chain mapping, environmental risk solutions, and vendor risk management platforms. These tools enhance monitoring and visibility across the entire framework. For example, AI-powered mapping solutions like IBM and Bitsight Discover help organizations visualize supplier relationships and pinpoint vulnerabilities. Environmental risk solutions, such as Riskpulse, predict weather-related disruptions, which accounted for 70% of supply chain risks in 2024. Vendor risk management platforms continuously monitor cybersecurity posture, reducing exposure to cybercrime and regulatory changes.

Tool Category | Description and Effectiveness |

|---|---|

Supply Chain Mapping | AI-powered solutions map supplier relationships, enhancing visibility and risk identification. |

Environmental Risk Solutions | Predict and monitor environmental risks affecting shipments, enabling proactive risk management. |

Vendor Risk Management | Automate workflows and validate vendor cybersecurity posture, improving risk mitigation strategies. |

Regular monitoring and updating of risk mitigation strategies ensure the framework remains effective against evolving risks. Companies also use risk heat maps and value at risk assessments to quantify financial impacts and prioritize contingency plans.

Scenario Planning

Scenario planning forms a critical part of supply chain risk management. Organizations model diverse risks, including climate change, geopolitical instability, and demand volatility. AI-enhanced scenario planning simulates multiple 'what-if' situations, allowing companies to prepare contingency plans for best, worst, and most likely outcomes. This approach helps manage demand volatility and supports long-term risk management strategies.

Scenario planning enables dynamic monitoring and adaptive planning, providing early warnings and improving resilience.

By integrating financial impacts and visualizing data, companies strengthen their risk assessment framework and optimize contingency plans. This proactive approach ensures supply chain risk management remains agile and responsive to emerging risks.

Technology and Digital Transformation

AI and Data Analytics

AI, machine learning, and automation have transformed supply chain management by improving forecasting, transparency, and decision-making. Organizations now rely on AI-driven data analytics to enhance supply chain visibility and respond to risks with greater agility. The following table highlights the adoption rates of AI in supply chain operations as of 2024:

Aspect of AI Adoption in Supply Chain | Percentage of Organizations/Professionals (2024) |

|---|---|

Use of AI-driven data analytics for smarter decision-making | Approximately 75% |

Adoption of AI-driven quality control systems | 82% |

Businesses using AI analytics have increased decision-making accuracy by up to 30%. Machine learning models process real-time data, supporting continuous adaptation and improving demand forecasting. AI-driven forecasting can reduce errors by 20% to 50%, leading to fewer stockouts and lower inventory costs. Enhanced risk management and strategic decision-making provide competitive advantages. Academic research confirms that integrating AI-based predictive analytics optimizes inventory management, reduces costs, and improves demand fulfillment. These technologies enable supply chains to adapt quickly to risks and market changes.

IoT and Blockchain

IoT and blockchain technologies have revolutionized supply chain visibility and transparency. IoT devices monitor shipments, environmental conditions, and equipment status in real time, reducing risks and improving operational efficiency. Blockchain secures data in an immutable ledger, preventing fraud and ensuring traceability. Smart contracts automate compliance and payments, speeding up transactions and reducing errors. Companies like Nestlé and Walmart use blockchain for food traceability, while IoT-driven inventory management reduces waste and stockouts by up to 30%. The synergy of IoT and blockchain creates transparent, auditable supply chains that build stakeholder trust and ensure ethical sourcing. Predictive maintenance via IoT sensors minimizes downtime, supporting smooth supply chain flow and reducing risks.

Collaboration and Communication

Supplier Transparency

Supplier transparency stands as a cornerstone of supply chain collaboration. Companies achieve greater visibility by conducting supplier audits, mapping supply tiers, and collecting data on sourcing and labor practices. Digital tools such as blockchain, IoT, and AI enable real-time tracking and ESG risk detection. Organizations collaborate with suppliers to embed ESG standards and provide training, fostering shared responsibility and compliance. Regular monitoring and reporting reinforce accountability, building trust and operational resilience. Leading companies like Unilever and Patagonia demonstrate that open communication and transparency expose risks early, allowing proactive responses to disruptions. Sharing real-time data reduces misunderstandings and promotes accountability, which strengthens trust and reduces uncertainty. Supplier transparency initiatives help organizations monitor and enforce codes of conduct, sustainability certifications, and performance. This approach mitigates risks related to unethical labor practices or environmental violations, aligning supply chain transparency with customer and investor expectations.

Digital Platforms

Digital platforms drive supply chain collaboration by connecting partners, improving visibility, and enabling agile responses to risks. Cloud-based ERP systems and AI-driven demand forecasting tools enhance supply chain visibility, flexibility, and responsiveness. Academic studies confirm that SMEs in the textile sector have improved procurement, inventory, and distribution management through cloud ERP adoption. Companies use advanced analytics, integrated planning platforms, and digital twins to simulate and optimize operations. Widely adopted platforms such as Amazon Web Services and Microsoft Azure support real-time data sharing, interoperability, and AI-driven analytics. These technologies deliver improved productivity, planning agility, and better risk mitigation. Digital platforms also enhance customer experience through tracking, chatbots, and customizable interfaces. Integrated planning connects demand, supply, and distribution, boosting supply chain collaboration and responsiveness to market shifts. Firms build innovation and dynamic capabilities, gaining competitive advantage in uncertain environments. Overcoming technical language barriers requires communicators fluent in both supply chain operations and corporate communications, ensuring consistent messaging and effective collaboration.

Embedding communications professionals within supply chain teams during major disruptions enables real-time, transparent messaging that maintains customer and investor confidence and increases market share.

Critical success factors for supply chain collaboration include:

Domain-specific communicators linked to senior supply chain leaders

Developing a core supply chain narrative with proof points

Maintaining a dynamic communications strategy

Preparing with crisis playbooks and monitoring programs

Building Resilience and Agility

Flexible Contracts

Flexible contracts play a vital role in building resilience and agility. Companies use these agreements to adjust quickly to demand changes and disruptions. Flexible terms allow organizations to shift order volumes, delivery schedules, and sourcing locations as risks emerge. This approach supports business continuity and helps maintain supply chain stability during unexpected events. Many industry leaders now include clauses for rapid renegotiation, volume adjustments, and alternative sourcing. These features increase flexibility and reduce the impact of risks. Research shows that resilient supply chains rely on adaptability, responsiveness, and efficiency. Flexible contracts enable organizations to respond to disruptions, protect continuity, and support a strong business continuity plan. They also foster collaboration and trust among partners, which strengthens sourcing resilience and flexibility.

Inventory and Logistics Redundancy

Inventory and logistics redundancy ensures resilience against risks and disruptions. Companies maintain safety stock and use multiple logistics providers to reduce the risk of delays or shortages. This strategy allows organizations to meet demand even when disruptions occur. Real-time data from IoT and advanced analytics provides visibility across the supply chain, enabling early detection of risks and informed decision-making. Redundant systems support continuity and help companies adapt to demand shifts. Agility and resilience work together, allowing rapid adjustments to inventory and logistics plans. Proactive risk management, including diversified suppliers and contingency plans, minimizes the impact of disruptions. These practices shorten lead times, improve customer satisfaction, and enhance business continuity.

Companies that invest in resilience, flexibility, and redundancy can respond faster to risks, maintain demand fulfillment, and secure long-term success.

Compliance, Sustainability, and Cybersecurity

Regulatory Adaptation

Supply chain leaders face a rapidly changing regulatory landscape in 2025. New tariffs on imports from Canada, Mexico, China, Vietnam, and Bangladesh increase operational complexity and introduce fresh risks. These tariffs require companies to manage disruptions, adapt documentation, and address compliance challenges. Stricter trade rules and labor regulations add further risk, especially as workforce policies shift and environmental compliance measures tighten. Companies must respond to these risks by mapping vulnerabilities, calculating cost impacts, and evaluating sourcing options. Many organizations use scenario modeling to understand the financial effects of regulatory changes and disruptions. They diversify suppliers, collaborate closely with partners, and monitor for disruptive events using advanced technology. Platforms like Sphera’s SCT provide real-time risk monitoring, helping companies identify risk hotspots and manage compliance efficiently. Automation reduces manual work, allowing teams to focus on strategic risk mitigation and resilience building.

Staying informed and investing in compliance technology helps organizations reduce risks and adapt quickly to disruptions.

ESG and Cyber Risk

Environmental, social, and governance (ESG) risks now play a central role in supply chain sustainability and security. Environmental risks include supplier emissions, ecosystem damage, and regulatory noncompliance. Social risks involve forced labor and unsafe conditions, while governance risks cover corruption and lack of transparency. Companies face significant risk if they ignore these issues, as disruptions can lead to reputational damage and financial loss. Integrating ESG into procurement strategies, conducting supplier audits, and using digital tools like blockchain and AI improve risk management and transparency. Cyber risk also demands attention, with tighter regulations requiring continuous monitoring and adaptive frameworks. Organizations implement zero-trust models, AI-driven threat detection, and blockchain for transparency. These strategies reduce risks, support sustainability, and build resilience against disruptions. Capacity building and knowledge sharing further strengthen defenses, ensuring supply chains remain secure and sustainable.

Supply chain leaders strengthen resilience by embracing digital transformation, regionalization, and proactive risk management. Key strategies include supplier diversification, scenario planning, and real-time data integration. These actions support continuity, reduce disruptions, and ensure business continuity. Immediate action helps organizations maintain resilience, agility, and continuity in a rapidly changing environment.

FAQ

What technologies most improve supply chain resilience in 2025?

AI, IoT, and blockchain lead advancements. Industry reports show these technologies increase transparency, speed, and risk detection across global and regional supply chains.

Gartner research highlights AI-driven analytics as a top driver for supply chain agility.

How does regionalization reduce supply chain risk?

Regionalization shortens supply chains and limits exposure to global disruptions. McKinsey studies confirm companies with regional networks recover faster from shocks and maintain higher service levels.

Why is supplier diversification essential for resilience?

Supplier diversification spreads risk and prevents single points of failure. Academic research shows diversified supply bases reduce disruption impact and improve long-term supply chain stability.

See Also

Top Five Strategies To Secure Your Supply Chain

JUSDA Risk Solutions To Build Strong Supply Chains

Five Key Trends Shaping Tomorrow’s Supply Chain Efficiency