Technological Trends Shaping the Modern Supply Chain

Technology plays a crucial role in shaping the modern supply chain. It enhances efficiency and streamlines operations. The rapid pace of technological change impacts supply chain management significantly. For instance, 93% of companies actively engage in digitalizing their supply chains, seeking a competitive edge. Businesses must adapt to these changes to remain competitive. They constantly seek ways to optimize operations through strategic technology implementation. Predictive analytics, used by 30% of supply chain professionals, exemplifies this trend. As technology evolves, companies must embrace these advancements to thrive in an increasingly dynamic global market.

Historical Context of Supply Chain Technology

Evolution of Supply Chain Management

Early Innovations

The evolution of supply chain management began with early innovations that laid the foundation for modern practices. During World War I and II, logistics advancements transformed how goods were manufactured, stored, and transported. These changes established the groundwork for today's supply chains. The introduction of barcodes and early computer systems further revolutionized inventory tracking and streamlined operations. These technologies paved the way for future advancements by allowing better management of inventories.

In the 1960s and 70s, the development of information technology automated invoicing, tracking, and planning. This era marked the beginning of standalone operational functions in supply chain management. The technological revolution continued with the introduction of sophisticated software platforms like Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP). These platforms provided real-time visibility, data analytics, and automation, significantly enhancing supply chain efficiency.

The Rise of Digital Technologies

The rise of digital technologies has transformed supply chain management into a more efficient, agile, and resilient ecosystem. Digitization and modernization have enabled real-time data access and informed decision-making. Technological advances, such as artificial intelligence, have strengthened supply chains by introducing fully automated factories. These innovations have improved output per employee and reduced energy consumption.

The impact of technology on supply chain velocity, accuracy, and efficiency cannot be overstated. It enables faster decision-making, accurate demand forecasting, and preparation for unexpected events. As a result, supply chains have become more responsive and capable of handling complex challenges.

Impact of Globalization

Increased Complexity

Globalization has significantly increased the complexity of supply chains. As companies expand their operations across borders, they face new challenges in managing diverse markets and regulations. The need for efficient logistics and transportation systems has grown, requiring advanced technological solutions to navigate these complexities.

The integration of global supply chains has also led to increased interdependence among businesses. This interconnectedness demands seamless communication and coordination, which can only be achieved through technological integration.

Need for Technological Integration

The need for technological integration in supply chains has become more critical than ever. As globalization continues to reshape the business landscape, companies must adopt advanced technologies to remain competitive. The transformation of supply chain management through technological innovations has revolutionized operations, enhanced efficiency, reduced costs, and opened up new opportunities.

Current Technological Trends in the Modern Supply Chain

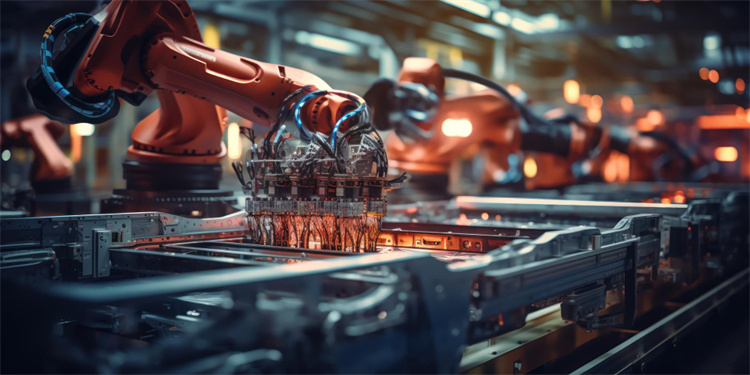

Automation and Robotics in the Modern Supply Chain

Automation and robotics have become integral to the modern supply chain. They enhance efficiency and reduce human error. Companies increasingly rely on these technologies to streamline operations and improve productivity.

Warehouse Automation

Warehouse automation involves using technology to perform tasks traditionally done by humans. Automated systems manage inventory, sort products, and fulfill orders. These systems increase speed and accuracy. They also reduce labor costs. For example, automated guided vehicles (AGVs) transport goods within warehouses, minimizing the need for manual handling. Robotics in warehouses ensures that operations run smoothly and efficiently.

Autonomous Vehicles

Autonomous vehicles represent a significant advancement in the modern supply chain. These vehicles operate without human intervention. They transport goods over long distances. Self-driving trucks and drones are examples of autonomous vehicles. They reduce delivery times and lower transportation costs. By using autonomous vehicles, companies can optimize their logistics operations and improve overall supply chain efficiency.

Internet of Things (IoT) in the Modern Supply Chain

The Internet of Things (IoT) has revolutionized the modern supply chain. IoT devices collect and transmit data in real time. This data provides valuable insights into supply chain operations.

Real-time Tracking

Real-time tracking is a crucial application of IoT in the modern supply chain. IoT devices monitor the location and condition of goods. They provide accurate and up-to-date information. This information helps companies make informed decisions. Real-time tracking enhances visibility and transparency. It allows businesses to respond quickly to changes in demand or supply.

Predictive Maintenance

Predictive maintenance uses IoT data to anticipate equipment failures. It helps companies maintain their machinery proactively. By analyzing data from IoT sensors, businesses can predict when equipment needs maintenance. This approach reduces downtime and extends the lifespan of machinery. Predictive maintenance ensures that supply chain operations remain uninterrupted and efficient.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning play a transformative role in the modern supply chain. They enable companies to analyze vast amounts of data and make data-driven decisions.

Demand Forecasting

AI and machine learning improve demand forecasting. They analyze historical data and identify patterns. This analysis helps companies predict future demand accurately. Accurate demand forecasting reduces excess inventory and minimizes stockouts. It ensures that businesses meet customer needs efficiently.

Inventory Optimization

Inventory optimization is another critical application of AI in the modern supply chain. AI algorithms analyze inventory levels and demand patterns. They recommend optimal inventory levels. This optimization reduces carrying costs and improves cash flow. By using AI for inventory management, companies can enhance their operational efficiency and customer satisfaction.

Future Predictions and Emerging Technologies

Blockchain Technology

Blockchain technology is revolutionizing supply chain management by offering enhanced transparency and improved security. This technology creates a decentralized ledger that records every transaction across the supply chain. Each participant in the network can access this ledger, ensuring that all parties have the same information.

Enhanced Transparency

Blockchain enhances transparency by providing a clear and immutable record of transactions. Companies can trace products from their origin to the final consumer. This traceability reduces fraud and errors, as every transaction is recorded and cannot be altered. Businesses gain a comprehensive view of their supply chains, which helps them identify inefficiencies and areas for improvement.

Improved Security

Blockchain technology improves security by encrypting data and distributing it across a network of computers. This decentralized approach makes it difficult for hackers to alter or delete information. The enhanced security reduces the risk of data breaches and ensures that sensitive information remains protected. Companies can confidently share data with partners, knowing that blockchain safeguards their information.

5G and Connectivity

The advent of 5G technology promises to transform supply chain operations by providing faster data transmission and enhanced communication. This next-generation wireless technology offers unprecedented speed and reliability, enabling real-time data exchange across the supply chain.

Faster Data Transmission

5G technology facilitates faster data transmission, allowing companies to process and analyze information quickly. This speed enables real-time decision-making, which is crucial for managing dynamic supply chain environments. Businesses can respond promptly to changes in demand or supply, ensuring that operations remain efficient and effective.

Enhanced Communication

Enhanced communication is another significant benefit of 5G technology. It supports seamless connectivity between devices, enabling the Internet of Things (IoT) to function optimally. IoT devices can communicate with each other without delays, providing accurate and timely data. This connectivity enhances collaboration among supply chain partners, leading to more coordinated and efficient operations.

Sustainable Technologies

Sustainable technologies are gaining traction in supply chain management as companies strive to reduce their environmental impact. These technologies focus on green logistics and energy-efficient solutions, promoting sustainability throughout the supply chain.

Green Logistics

Green logistics involves implementing environmentally friendly practices in transportation and distribution. Companies are adopting electric vehicles and optimizing delivery routes to reduce carbon emissions. These efforts contribute to a more sustainable supply chain, aligning with global initiatives to combat climate change.

Energy-efficient Solutions

Energy-efficient solutions play a crucial role in reducing the environmental footprint of supply chains. Businesses are investing in renewable energy sources and energy-saving technologies to power their operations. These solutions not only lower energy consumption but also reduce costs, making supply chains more sustainable and economically viable.

Practical Examples and Case Studies

Successful Implementations

Company A's Use of AI

Company A has successfully integrated artificial intelligence into its modern supply chain. They utilize AI to optimize processes, enhance decision-making, and provide real-time visibility. By predicting potential problems and prescribing solutions proactively, Company A has improved forecasting accuracy and optimized inventory levels. This approach enhances operational efficiency, allowing the company to respond swiftly to market demands. The use of AI in their supply chain has revolutionized their operations, setting a benchmark for others in the industry.

Key Outcomes:

Improved forecasting accuracy

Enhanced operational efficiency

Company B's IoT Integration

Company B has embraced the Internet of Things (IoT) to transform its modern supply chain. IoT devices provide real-time data, offering insights into every aspect of their operations. This integration allows Company B to monitor the condition and location of goods continuously. By leveraging IoT, they have achieved greater transparency and efficiency in their supply chain processes. The ability to track products in real time has reduced delays and improved customer satisfaction.

Key Outcomes:

Real-time tracking of goods

Increased transparency

Enhanced customer satisfaction

Lessons Learned

Challenges Faced

Implementing advanced technologies in the modern supply chain presents several challenges. Both Company A and Company B encountered obstacles during their technological transformations. These challenges included high initial costs, the need for skilled personnel, and resistance to change within the organization. Additionally, integrating new technologies with existing systems proved complex and time-consuming.

Common Challenges:

High initial costs

Need for skilled personnel

Resistance to change

Strategies for Overcoming Obstacles

To overcome these challenges, both companies adopted strategic approaches. They invested in training programs to upskill their workforce, ensuring employees could effectively use new technologies. By fostering a culture of innovation, they encouraged acceptance and enthusiasm for technological advancements. Furthermore, they collaborated with technology partners to streamline the integration process, minimizing disruptions to their operations.

Effective Strategies:

Workforce training programs

Fostering a culture of innovation

Collaboration with technology partners

These practical examples and case studies highlight the transformative impact of technology on the modern supply chain. By learning from successful implementations and understanding the challenges faced, businesses can better navigate their technological journeys. Embracing these advancements is crucial for maintaining competitiveness in today's dynamic market.

The blog explored key technological trends shaping the modern supply chain, such as automation, IoT, AI, and blockchain. These technologies enhance visibility, efficiency, and accuracy, enabling businesses to make data-driven decisions and gain a competitive edge. Staying updated with these advancements is crucial for maintaining smooth operations and improving customer satisfaction. Businesses should invest in technology to optimize their supply chain processes and achieve substantial cost savings. Industry professionals must collaborate and share insights to drive innovation and establish sustainable supply chains that cater to the evolving demands of the 21st-century consumer.

See Also

Adapting to Technology: Navigating Changes in Supply Chains

5 Impactful Trends: Future Efficiency in the Supply Chain

Robotics Technology Trends: Exploring Sustainable Supply Chains