Top Supply Chain Management Systems for Businesses of All Sizes

Businesses today want to know which supply chain management systems work best. The right supply chain management software helps companies work better and grow. Many companies lose money when supply chain management does not work well.

Statistic Description | Value/Impact |

|---|---|

Financial losses from supply chain disruptions | |

Productivity increase from IoT adoption | 10-20%, up to 30% in some cases |

Profit impact from reducing supply chain costs | Potential to double profits by cutting costs from 9% to 4% |

Each company should pick solutions that fit its own goals, industry, and size.

Key Takeaways

Picking the best supply chain management software helps companies save money. It also helps them work faster and grow. This happens by making planning, inventory, and working with suppliers better.

New supply chain tools use AI, real-time data, and cloud platforms. These tools help companies see what is happening right now. They lower risks and help companies change fast when the market changes.

Companies should choose software that is flexible and can grow with them. The software should fit their industry needs. It should also give strong support to help with growth and changing customer needs.

Best Supply Chain Management Software

Leading Solutions Overview

The best supply chain management software helps companies do hard tasks. It also helps them work faster and better. Many supply chain software companies now focus on being flexible and easy to grow. They also use data to help make choices. These tools let people see the whole supply chain and work together in real time. Businesses can pick from many types of software. Some help with inventory, some with transportation, and others with demand forecasting. There are also systems for supplier management and warehouse management.

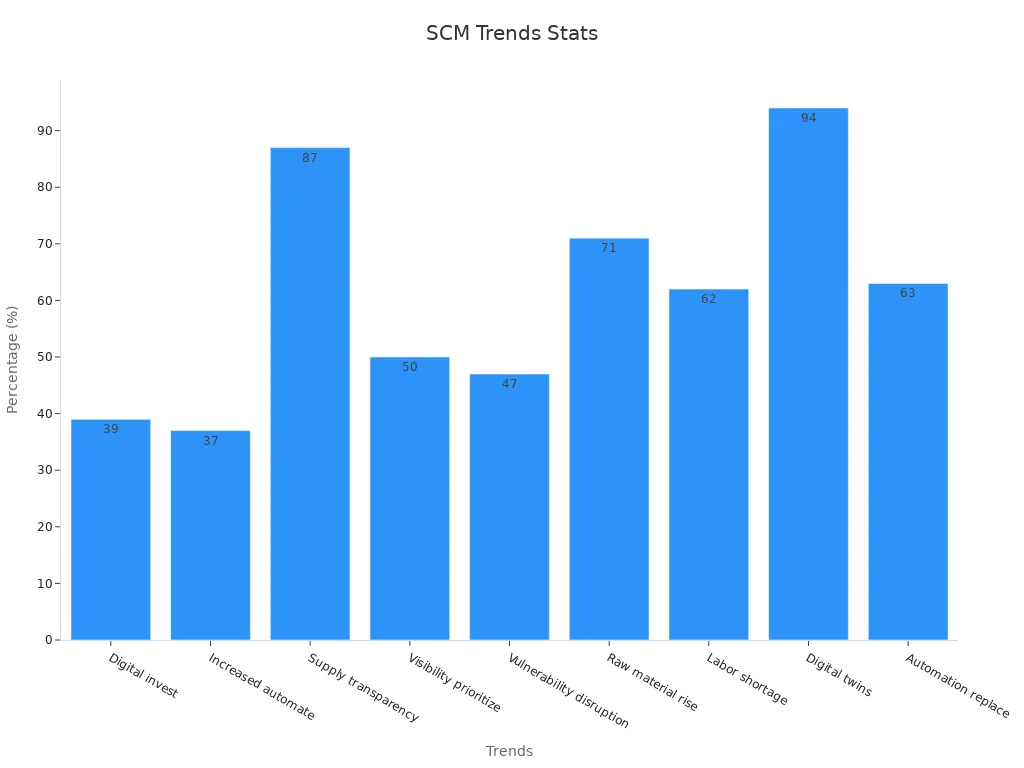

Some new trends in supply chain management software are:

Connecting with ERP systems to make work easier

Using AI and smart tools to guess what is needed

Cloud-based platforms help save money and give more options

Tools that help track how green a company is

Features that help customers get things faster and better

The global supply chain management software market is getting bigger. In 2024, it was worth about USD 21 billion. North America has the biggest share, with over 36%. Experts think the market will reach USD 52 billion by 2033. Some top supply chain software companies are SAP SE, Oracle SCM Cloud, Infor Nexus, and Manhattan Active.

Key Features and Benefits

The best supply chain management software has many helpful features. These features help businesses make their supply chain better from start to finish. These systems use machine learning and math tools to help with planning and inventory. Companies can plan better, spend less money, and work better with suppliers.

SCM System | Key Features & Benefits | Notable Statistics & Benefits |

|---|---|---|

Demand planning, scenario simulation, real-time collaboration | Cloud-based SaaS; integrates with SAP extensions | |

Oracle SCM Cloud | Demand management, supply planning, supply chain visibility | Integrated MES, IoT, AI; Gartner rating 4.6 |

Infor Nexus | Control tower, order/shipment/inventory visibility, supplier management | Used by 85,000+ companies; tracks carbon emissions |

Manhattan Active | Order management, inventory and fulfillment, warehouse and transport management | Leader in Gartner 2024 Magic Quadrant; cloud SaaS platform |

Supply chain management software helps automate tasks and cut costs. It also helps keep customers happy. Using IT in supply chain management makes companies quicker and better at their jobs. During COVID-19, going digital became very important. It helped companies stay strong and compete. Now, companies use these tools to plan, work together, and handle risks in the supply chain.

JUSDA Supply Chain Management Solutions

JUSDA Brand Overview

JUSDA is a top company in supply chain management. It started in China and now has over 155 service points around the world. JUSDA helps many industries like electronics, cars, FMCG, new energy, and healthcare. The company’s goal is to give smart and complete solutions. These solutions help all kinds of businesses work better and grow.

JUSDA values new ideas, working well, and teamwork. The company uses new technology to link every part of the supply chain. JUSDA has more than 2.5 million square meters of warehouse space. It offers trusted logistics and supply chain services by air, land, sea, and rail. Its worldwide network helps companies grow fast and handle tricky supply chains with ease.

JUSDA uses advanced supply chain software and digital tools. This makes it different from other supply chain software companies. JUSDA’s solutions help clients see their supply chain better, save money, and make customers happier.

JUSDA Warehouse Product

JUSDA’s warehouse product gives special solutions for managing inventory. The company runs warehouses in important places like China, Vietnam, the United States, Japan, and Europe. These warehouses offer regular storage, bonded storage, distribution centers, and finished goods storage. JUSDA’s clean rooms meet high standards, so they are good for tech and healthcare items.

The warehouse product uses smart systems like eVMI and JusLink. These systems track inventory in real time. They help companies keep the right amount of stock. This stops having too much or too little. Companies get better at guessing what they need. This matches production with real demand. JUSDA’s way saves money by cutting extra inventory and storage costs.

Vendor Managed Inventory (VMI) and eVMI help suppliers and buyers work together. These systems build trust and teamwork. This is important for a smooth supply chain. JUSDA also offers picking, packing, labeling, kitting, and repacking. The company gives software updates and rework services to make warehouses work better.

JUSDA’s warehouse product helps companies work faster and smarter. Orders get filled quicker. Companies have more control over their supply chain. Real-time data and new technology make everything clear. This helps leaders make good choices.

Note: JUSDA’s staff speak many languages and work closely with customs. This makes shipping across borders easy and dependable.

JusLink AI Solution

JusLink shows JUSDA’s focus on digital change in supply chain management. This AI-powered platform uses IoT, cloud computing, and big data. It lets people work together and share information right away. JusLink’s AI helps with common problems like guessing demand, managing inventory, and watching for risks.

The platform has six main skills: supply chain trend analysis, freight rate prediction, sales demand forecasting, replenishment strategies, risk control tower, and the smart helper JusElsa. JusElsa uses natural language processing. This makes it easy for users to talk to the system. JusElsa helps with tracking shipments, checking orders, and managing risks.

JusLink’s AI gives better choices by using predictions and real-time data. Companies can buy smarter, lower inventory costs, and react fast to changes. The risk control tower watches the whole supply chain. It gives early warnings and helps stop problems before they start.

JUSDA’s AI solution helps companies work better and keep customers happy. The platform fits many industries. It is useful for makers, stores, and logistics companies. JusLink works with other systems. This keeps data moving smoothly and supports modern supply chain goals.

JusLink’s AI helps companies stay ahead in a fast-changing world. It makes supply chain management smarter and more effective.

Best Supply Chain Management Tools for Enhanced Visibility

Real-Time Data and Analytics

The best supply chain management tools let companies see what is happening right now. They help track shipments, inventory, and dock work as it happens. Companies use these tools to watch trucks and goods move. This helps cut down on driver wait times and detention costs. Sometimes, wait times drop from over two hours to less than 45 minutes. With these tools, companies can handle more trucks without needing more workers. This makes docks busier and uses equipment better. Real-time dashboards show important numbers like on-time delivery, order mistakes, and how much inventory there is.

Key Metrics / KPIs | Purpose / Confirmation of Effectiveness | |

|---|---|---|

Order Management Dashboard | On-time delivery, Order error rate, Order cycle time, Backorders, Order fulfillment accuracy | Shows order progress and delivery in real time. This helps companies work faster and keep customers happy. |

Demand Planning Dashboard | Forecast accuracy, Demand variance, Fill rate | Helps guess what will sell and keeps the right amount of stock. This stops running out or having too much. |

Supplier Management Dashboard | Supplier quality rate, On-time delivery, Supplier defect rate | Checks if suppliers send good products on time. This helps companies trust their suppliers more. |

New technology like AI, RFID, and IoT help track goods and study supply chains. These tools let companies spot problems and fix them fast. Seeing things in real time helps people make smart choices. This leads to better plans and happier customers.

Tip: Using real-time data and analytics can save up to half the costs and boost sales by 20% in some businesses.

Integration and Collaboration

Integration and collaboration tools help everyone see what is happening in the supply chain. Cloud-based systems connect TMS, WMS, and ERP. This lets information move easily between systems. These platforms let people talk and share data right away. Everyone knows what is going on.

Using collaboration tools makes work faster and lets people watch the supply chain in real time.

Talking in real time helps everyone fix problems quickly.

Inventory and demand tools help keep the right amount of stock. This stops running out or having too much.

Supplier management features check how well suppliers do their jobs and help build strong partnerships.

Data analytics find problems and suggest ways to make things better.

Cloud-based supply chain tools use AI and blockchain for safe and easy operations. Working together on inventory can cut costs by 10-15% and fill more orders. These top supply chain tools help companies see what is happening, move quickly, and react to changes in the market.

How to Choose the Best Supply Chain Management Software

Scalability and Flexibility

Picking the best supply chain management software starts with two things. These are scalability and flexibility. Companies need systems that can grow as they get bigger. Online sales around the world are growing fast. In 2024, they reached $6.3 trillion. This means supply chain management must handle more orders and new places. Flexible warehouse systems help companies deal with busy times and sudden changes. They let companies change how they work quickly. These systems also help meet different customer needs. A scalable platform lets businesses add new features or move into new areas. They do not have to start from scratch. This helps companies plan for the future and keep things running smoothly.

Tip: Flexible supply chain management software helps companies get ready for changes in the market and what customers want.

Industry Fit and Customization

The best supply chain management software matches the company’s industry and needs. Every industry has its own supply chain steps. For example, food and beverage companies need to track freshness. Retailers need to know their stock levels right away. Customization lets companies set up dashboards, alerts, and reports. These match their supply chain planning goals. The table below shows how different industries get help from special solutions:

Industry | Custom Application | Key Benefit |

|---|---|---|

Food & Beverage | Supplier tracking, demand forecasting | Maintains freshness |

Retail | POS integration, inventory management | Avoids stockouts |

Manufacturing | Production planning, bottleneck analysis | Reduces downtime |

Logistics | Fleet management, route optimization | Improves delivery times |

Cost and Support

Cost and support are important when picking supply chain management software. Companies should look at all supply chain costs. This includes order processing, warehousing, and shipping. Good software helps lower these costs by doing tasks automatically. It also makes supply chain steps better. Support is important too. Good support helps companies fix problems fast. This keeps supply chain management working well. Companies should check if the software gives training, updates, and help when needed.

Companies that use the best supply chain management software work better, spend less, and plan their supply chain more strongly.

Overcoming Supply Chain Management Challenges

Inventory and Warehouse Optimization

Companies have many problems in supply chain management. Some problems are following rules, changing what customers want, not enough workers, and changes in the world economy. Technology helps fix these problems and makes supply chains better.

Using advanced analytics in inventory management can lower stockouts by 20%. It can also cut extra stock by 15%.

Centralized automated systems help retail stores save 25% on storage costs.

Predictive analytics can make order fulfillment rates go up by 30%.

About 73% of warehouses want to use mobile stock control solutions. This shows more companies want to use technology for better work.

Many supply chain leaders use dashboards to see everything. This helps them make better choices.

Changing how a warehouse is set up and using automation can help a lot. Automated Storage and Retrieval Systems can give 25% more storage space. They can also make picking items 20% faster. Using third-party logistics and a Warehouse Management System helps control inventory better. These ideas help companies meet customer needs and keep costs down.

Note: Only 22% of small businesses use stock tracking software. But cheap solutions can give a good return on investment.

Risk Management and AI Solutions

Risk management is very important in supply chain management. Companies use technology to deal with risks from rules, cyber threats, and world events. AI-powered forecasting tools and machine learning help guess problems and make supply chains stronger.

Company | Impact on Supply Chain Resilience | |

|---|---|---|

Maersk | Real-time risk monitoring and dynamic rerouting | Avoids delays and ensures timely delivery |

UPS | AI-powered route optimization | Reduces delivery times and fuel use |

DHL | AI-based fleet management and predictive maintenance | Minimizes breakdowns and downtime |

General Motors | AI-enhanced risk visualization | Enables dynamic decision-making |

Amazon | Predictive analytics for demand and inventory | Minimizes stockouts and shipping costs |

Siemens | AI systems for supplier and geopolitical risk monitoring | Allows proactive procurement adjustments |

AI and machine learning help people make better choices and adapt fast. These tools let companies react quickly to changes and keep working well. As more companies use these tools, making supply chains better gets easier and works well.

JUSDA Solutions

To provide you with professional solutions and quotations.

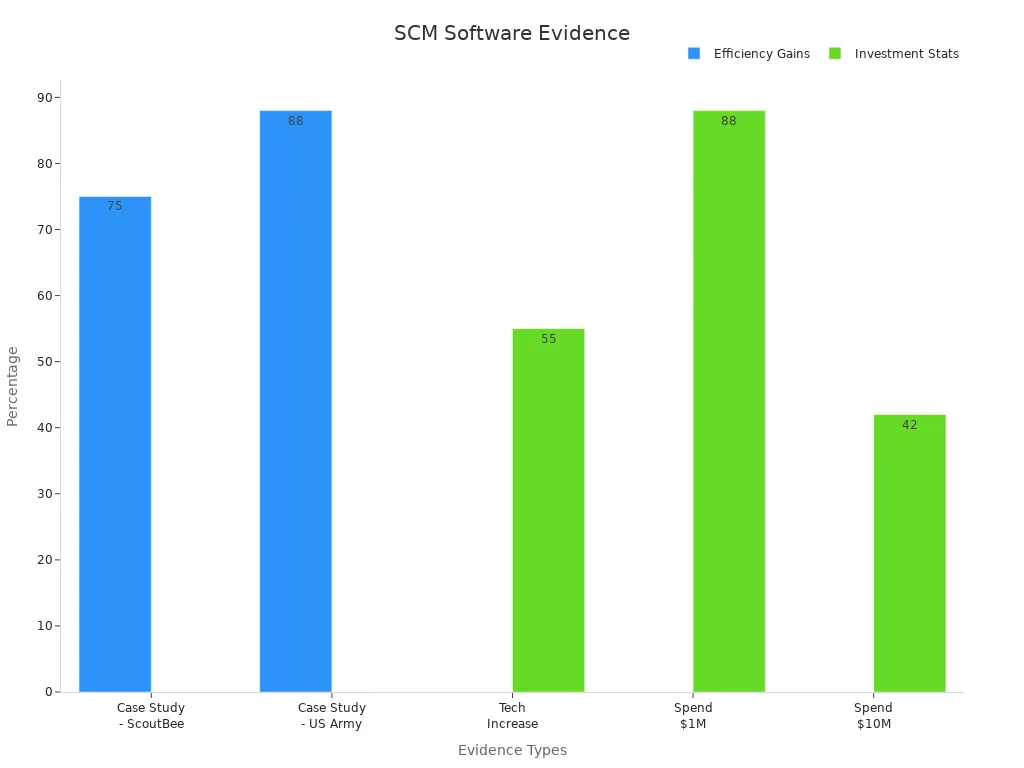

Picking the right solution helps a business grow and work better. JUSDA is special because it works all over the world. It uses smart AI and knows a lot about different industries. Business leaders spend more money on new technology. They want things like automation and analytics.

Evidence Type | Description |

|---|---|

Case Study - ScoutBee | Used mapping technology and found suppliers 75% faster. |

Case Study - US Army | Used a graph database and cut data work from 60 hours to 7. |

Investment Statistics | 55% of leaders spend more on tech; 88% plan to invest over $1 million. |

Companies should look at what they need, try out demos, and talk to experts to find the best choice.

See Also

Effective Strategies To Optimize Supply Chains For Success

How Cloud Technology Is Transforming Supply Chain Management

Improving Supply Chain Challenges In Advanced Manufacturing

The Impact Of Cloud Solutions On Industry Supply Chains

Boosting Supply Chain Efficiency Through Cloud-Based Technologies