Top Ways to Optimize Your Supply Chain Process

Optimizing your supply chain needs good planning, technology, and constant improvement. U.S. business logistics costs were $2.3 trillion, or 8.7% of GDP. Better supply chain processes help work get done faster, save money, and make customers happier. Top brands like JUSDA use special plans and digital tools to help their supply chain and do well.

Key Takeaways

Use data-driven forecasting to make inventory better. This helps you save money. It lets you react fast to market changes.

Build strong supplier relationships with open communication. Pay suppliers on time. This lowers disruptions. It makes product quality better.

Use real-time inventory tracking to stop stock problems. This keeps your supply chain working well. It helps you spend less money.

Demand Planning in Supply Chain

Data-Driven Forecasting

You can make your supply chain work better by using data-driven forecasting. When you use real-time data and smart analytics, you make better choices. You can also react faster when the market changes. Many companies use special software with AI and machine learning. This helps them guess demand very well. Data analytics tools help you see what customers want and spot market trends. These methods let you change inventory levels quickly. You can avoid having too much or too little stock.

Tip: Try inventory management systems that update stock levels automatically with real-time data. This helps lower storage costs and keeps your supply chain flexible.

Here are some ways data-driven forecasting helps supply chain management:

Better inventory management saves money and cuts waste.

Faster responses help you keep up with market changes.

Smarter demand planning gives you clear ideas for using resources.

You should set key performance indicators (KPIs) and check your forecasts often. Getting feedback from sales and client service teams helps you change your supply chain plan. This keeps you ahead of other companies.

Collaborative Planning

A collaborative supply chain strategy makes your business stronger and helps teams work together. You can use online platforms to connect departments and partners. This makes talking and making decisions easier and faster. Collaborative planning models like CPFR (Collaborative Planning, Forecasting, and Replenishment) help supply chains work better, especially in dropshipping.

Evidence Description | Key Findings |

|---|---|

CPFR as a model | Helps supply chain partners work together and talk more, so they can respond faster. |

Inter-firm collaboration | Needed for better supply chain efficiency. |

CPFR program | Gives a plan for working together and joining demand and supply planning. |

Good partnerships and sharing information make things run smoother, lower costs, and help supply chains work better. When you match production schedules and inventory levels, you build a supply chain that can change with the market and help your business grow.

Supplier Partnerships

Relationship Management

You make your supply chain stronger by working with suppliers. Good relationships help stop problems and make products better. When your supply chain plan matches your business goals, teams work together well. Talking openly and paying on time helps suppliers trust you. You can visit supplier sites and give awards to push for new ideas and better work.

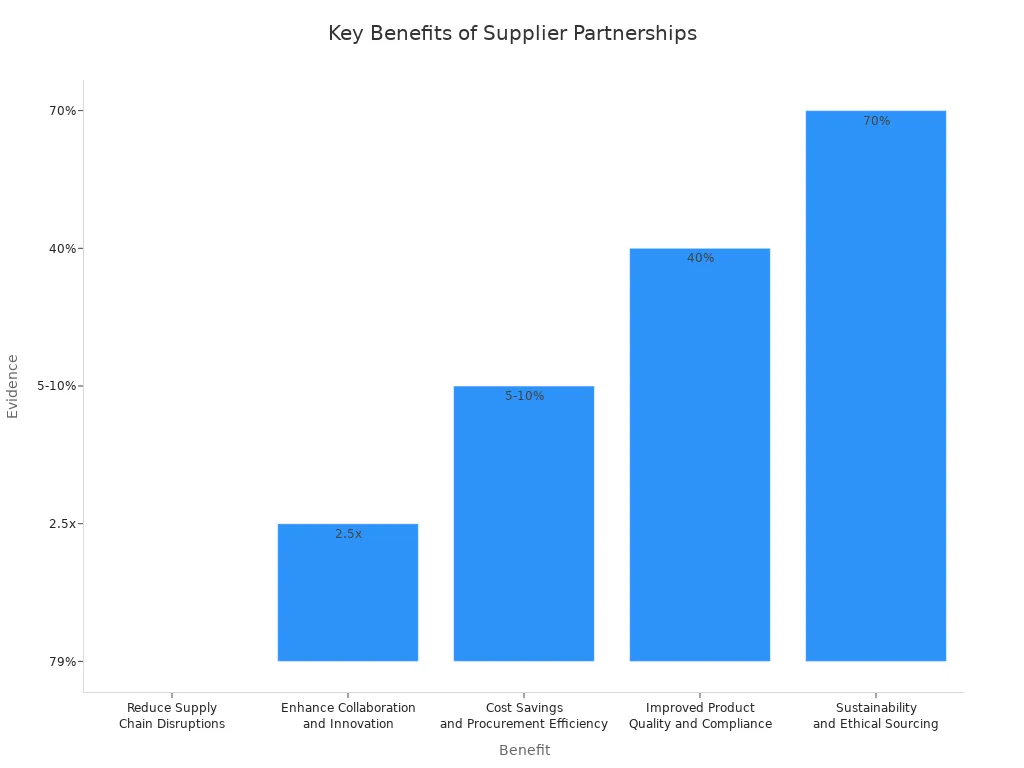

Benefit | Evidence |

|---|---|

Reduce Supply Chain Disruptions | 79% of businesses with established SRM procedures encountered fewer disruptions during COVID-19. |

Enhance Collaboration and Innovation | Companies with strong supplier collaboration are 2.5 times more likely to introduce innovative products quicker. |

Cost Savings and Procurement Efficiency | Optimized SRM processes can reduce procurement costs by 5-10%. |

Improved Product Quality and Compliance | Businesses with solid SRM practices are 40% more likely to report high supplier quality levels. |

Sustainability and Ethical Sourcing | 70% of companies with mature SRM programs report that their suppliers contribute to sustainability goals. |

Try these ways to manage supplier relationships:

Description | |

|---|---|

Strategic Alignment | Aligning SRM strategy with business objectives enhances partnerships and performance. |

Performance Monitoring | Regularly reviewing supplier performance helps assess capabilities and address challenges. |

Effective Communication | Open communication through site visits fosters problem-solving and innovation. |

Timely Payments | Ensuring on-time payments builds trust and maintains strong supplier relationships. |

Supplier Awards Program | Recognizing good performance encourages continuous improvement and reinforces positive behaviors. |

Annual Supplier Appraisals | Conducting appraisals helps identify areas for improvement and strengthens strategic alliances. |

A good distribution network uses these ideas. You can work better with suppliers and build a supply chain you can count on.

Performance Evaluation

You must check how well suppliers do to keep things running well. Clear rules help you see if suppliers are good and reliable. Use the same steps for every supplier. Giving feedback helps everyone know what to do and get better. Technology makes it easy to watch numbers and collect data.

Use the same steps for all suppliers.

Share feedback and what you expect.

Use technology to track and collect data.

Work together for better results.

Follow these steps to help suppliers improve:

Use KPIs and give scores for supplier work.

Check often to make sure standards are met.

Ask for feedback about how reliable and good suppliers are.

Meet to talk about results and set new goals.

Compare supplier work to others in the industry.

You make your supply chain stronger by working with suppliers and checking their work. These steps help you build a team that works well and can handle problems.

Inventory Optimization with JUSDA Warehouse

Real-Time Inventory Tracking

You can make your supply chain better by using JUSDA’s smart warehouse tools. Systems like eVMI and Juslink show you your inventory in real time. You always know what you have at every step. This helps you find problems and change inventory fast. You do not run out of stock or have too much. This saves money and keeps things working well. Real-time tracking helps you make production smoother and deliver on time. You can make good choices and stop risks before they get big.

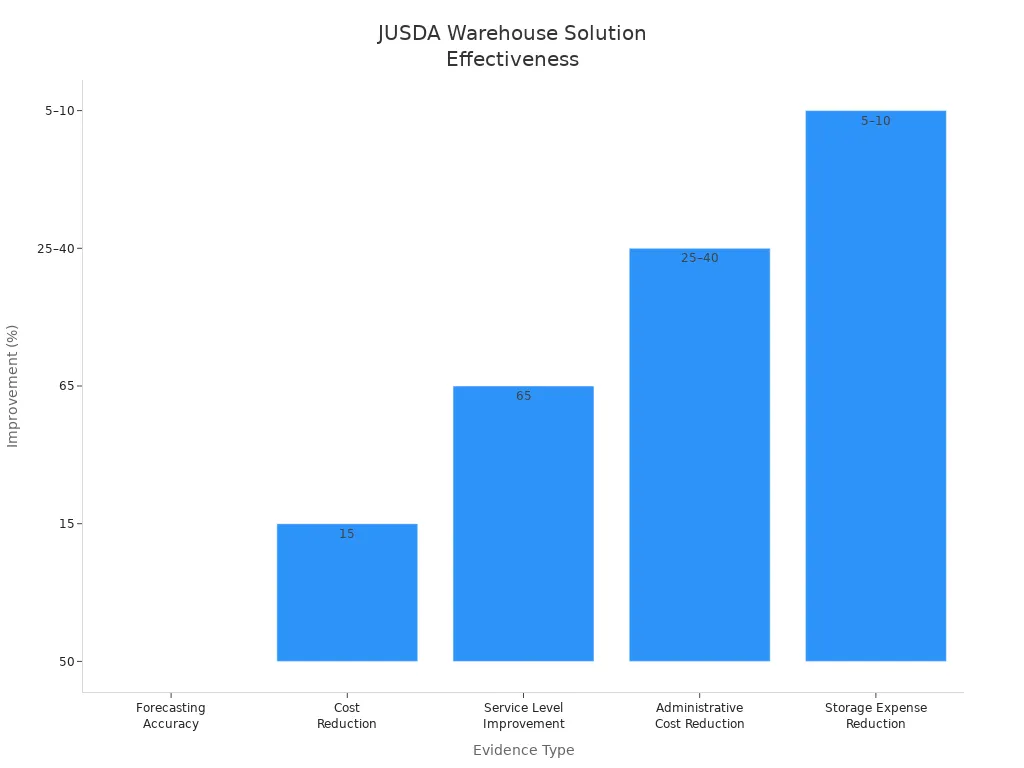

Evidence Type | Description |

|---|---|

Forecasting Accuracy | Studies show mistakes in forecasting can drop by half. |

Cost Reduction | Users say supply-chain costs go down by about 15%. |

Service Level Improvement | Service levels can get better by up to 65%. |

Administrative Cost Reduction | Admin costs can go down by 25–40%. |

Storage Expense Reduction | Storage costs can fall by 5–10%. |

You use these ways to make your supply chain work faster and better. Real-time tools also help you waste less stock and avoid making too much.

Value-Added Services

JUSDA’s warehouses give extra services that help your supply chain and teamwork. You get picking, packing, labeling, kitting, cross-docking, and returns. These services let you change products, bundle things, and make special packages. You meet rules and make customers happy. Kits and special labels make your supply chain plan more flexible. You can stand out and react quickly when the market changes.

JUSDA’s warehouse network is in many places and works with many industries. You get teamwork solutions for electronics, cars, and consumer goods. IoT tracking and AI forecasting make transport better and lower emissions. You see your supply chain get faster, cheaper, and more reliable.

Tip: Use JUSDA’s extra services to make your work easier and your supply chain better.

Technology in Supply Chain Management

AI and Automation

AI and automation are changing supply chains quickly. These tools help you guess demand and watch for risks. They also make it easier to see what is happening in the supply chain. JUSDA’s JusLink AI Solution gives you ways to predict problems and see real-time updates. You can find issues early and fix them fast. Predictive analytics lets you watch for risks all day and night. You get alerts before problems get worse. Automated risk scoring and tips help you choose what to do next.

Evidence Type | Description |

|---|---|

Continuous Monitoring | Predictive analytics checks for risks all the time. |

Early Warning Signals | AI analytics warn you about problems early. |

Automated Risk Scoring | Automated scoring makes decisions easier. |

You also use machine learning, drones, and robots. These tools help the supply chain work better and let you make custom products. Digital twins and real-time tracking help you see what is going on. They also help you make your work better. You can use these ideas to stay ahead when things change.

Integrated Platforms

Integrated platforms help bring new technology into supply chain management. IoT, cloud computing, and big data work together to make your supply chain stronger. You can watch things in real time, use GPS to track items, and manage inventory better. There will be over 30 billion IoT devices by 2025. This gives you more ways to use data and improve your work.

Real-time monitoring helps you see what is happening and keeps everyone honest.

IoT lets you use GPS to track things and cut down on waste.

70% of companies using IoT say they can see and control inventory better.

IoT can help supply chain companies save up to $2 trillion each year.

You get better visibility and your supply chain works better. Integrated platforms help you change your supply chain plan and reach your goals.

Effective Logistics Management

Route Optimization

You make logistics better by picking the best routes. Route optimization helps you save money and deliver faster. You check traffic, distance, and delivery times to find the best way. This method uses less fuel and keeps vehicles in good shape. Drivers finish more deliveries in less time, so you save on labor.

Benefit | Description |

|---|---|

Better routes use less fuel and cut down on waiting. | |

Mileage Reduction | Smart routing means fewer miles and less wear on vehicles. |

Labor Cost Savings | Drivers do more deliveries quickly, so you need fewer workers. |

Improved Customer Satisfaction | Fast deliveries make customers happy and loyal. |

You can use strategies like mode optimization and load planning. These help you lower delivery costs and make drivers work better. You also get more deliveries done on time. Technology helps you plan routes and see your logistics clearly.

Warehouse Efficiency

Warehouse efficiency is very important for good logistics. You use vertical storage and zone picking to save space. Automation like Goods-to-Person systems makes orders faster. A Warehouse Management System helps track goods and organize the warehouse. This makes everything run smoother.

Metric Name | Description |

|---|---|

Shows how often new items go to the right spot. | |

Inventory Accuracy | Checks if inventory numbers match what is really there. |

Order Picking Accuracy | Tells if the right items are picked for each order. |

Perfect Order Rate | Counts orders that are picked right and arrive on time. |

Percentage On-Time Deliveries | Tracks how many orders get to customers when promised. |

You make your supply chain better by watching these numbers. When you use good logistics strategies, your supply chain works well and keeps customers happy.

Risk Management in Supply Chain

Identifying Risks

There are many risks in your supply chain. Some risks come from inside your company. Others come from outside forces. Common risks are financial, geopolitical, operational, compliance, demand, cybersecurity, and environmental. Each risk can cause problems for your business. These risks can slow down your work.

You can use tools to find risks:

SWOT Analysis helps you see strengths and weaknesses.

FMEA shows weak spots and how bad they can be.

ISO 31000 gives rules for risk management.

Predictive modeling and simulation show problems early.

You should follow these steps:

Find risks in your supply chain.

Check your partners well.

Protect your business from currency changes.

Make contracts that last a long time.

Use different ways to get money.

These steps help you build a strong supply chain. You can see problems early and fix them fast.

Contingency Planning

You need good plans to handle problems. Start by checking for weak spots. See how they might hurt your business. Use more than one supplier to avoid trouble. Technology helps you get updates fast. It lets you react quickly.

A good plan does three things:

Cuts delays by giving backup choices.

Saves money by stopping surprise losses.

Makes you flexible so you can act fast.

A strong supply chain keeps your business running. You stay in control, even when things go wrong. Your supply chain gets stronger and more reliable.

Sustainability in Supply Chain

Green Logistics

You help make a supply chain that is good for the planet. Green logistics means doing less harm to nature and still working well. Many companies try to use less energy and lower their carbon footprints. You can pick machines that use less power and choose clean energy. These choices help you use fewer fossil fuels and make less pollution. Taking care of waste and recycling helps keep the earth clean. When you plan better routes for trucks, you use less gas and make less pollution.

Practice | Contribution to Sustainability |

|---|---|

Makes less greenhouse gas go into the air | |

Using energy-efficient technologies | Saves energy and uses less power |

Adopting renewable energy sources | Uses less oil and gas |

Responsible waste management | Makes less trash and helps recycling |

Optimizing transportation routes | Uses less fuel and makes less pollution |

More companies now care about doing the right thing, treating people fairly, and protecting nature. These steps help you follow new rules and make customers trust you.

Supplier Standards

You need strong rules for suppliers to have a good supply chain. Seeing every step and tracking things helps you spot problems. You can use maps to see where risks are and make smart choices. Many groups now want suppliers to follow tough rules for being green and fair. These rules talk about carbon, water, recycling, human rights, and doing the right thing.

Metric | What it measures | Why it matters |

|---|---|---|

How suppliers make less pollution and use clean energy | It helps fight climate change and follow the law | |

Water management | How well water is used and kept safe | Using water wisely is important for farms and factories |

Circular economy | How much is recycled and reused | This helps make less trash and saves resources |

Human rights/diversity | Treating workers fairly and with respect | Stops bad things like forced labor and unfair treatment |

Ethics and compliance | Following the rules and being honest | Makes people trust you and keeps you out of trouble |

You build a strong supply chain by working with suppliers and using smart data. This way, you can handle problems and stay ready for changes.

Improve Supply Chain Continuously

Monitoring KPIs

You need to watch key performance indicators, or KPIs, to make your supply chain better. Real-time visibility platforms, like FourKites, show you important numbers on a dashboard. You can see problems early and fix them before they get worse. When you check KPIs like Supplier Quality and Order Cycle Time, you find weak spots in your plan. This helps you know where to focus and what to fix.

Many companies use new ways to handle data. For example, Principal Component Analysis, or PCA, can help you track fewer KPIs. Instead of looking at 28 numbers, you can just watch the 8 most important ones. This makes it easier to see how you are doing and what to change.

Here are some common ways to keep getting better:

Methodology | Description |

|---|---|

Lean | Focuses on getting rid of waste and making things work better. |

Six Sigma | Uses data to find and fix problems in processes. |

Kaizen | Makes small changes all the time with help from everyone. |

Total Quality Management (TQM) | Tries to make customers happy by improving quality everywhere. |

Value Stream Mapping | Shows how materials and information move so you can make it better. |

You can use these ideas to keep your supply chain working well and reach your goals.

Innovation and Feedback

You help your supply chain grow by using new ideas and listening to feedback. When you ask your team and customers for feedback, you find ways to make things better. Data analytics can help you spot new chances for better products and services. You should use transportation management software to see what is happening and make shipping faster.

Use KPIs to check how things are going and find new ideas.

Try feedback loops in AI tools to keep learning and improving.

Listen to what users say to make steady changes.

Let what happens each day help you decide what to do next.

Innovation gets stronger when everyone shares their ideas. You build a place where small changes lead to big results. This helps your supply chain stay flexible and ready for anything.

JUSDA Solutions

To provide you with professional solutions and quotations.

You can make your supply chain better with smart plans. Digital tools help you work faster and share information. Strong partnerships help teams trust each other and solve problems.

Using digital tools helps you get data quickly and work better.

Description | |

|---|---|

Assess Current Operations | Look at your supply chain and see how it works. |

Begin today to get better results and make customers happy.

See Also

Discover 5 Cutting-Edge Techniques for Supply Chain Optimization

Essential Strategies for Successful Supply Chain Optimization

Understanding the Financial Aspects of Supply Chain Efficiency

Effective Strategies for High-Tech Manufacturing Supply Chain Challenges

Transforming Logistics Through Innovative Supply Chain Solutions