Traditional and Digital Supply Chains A Comparative Analysis

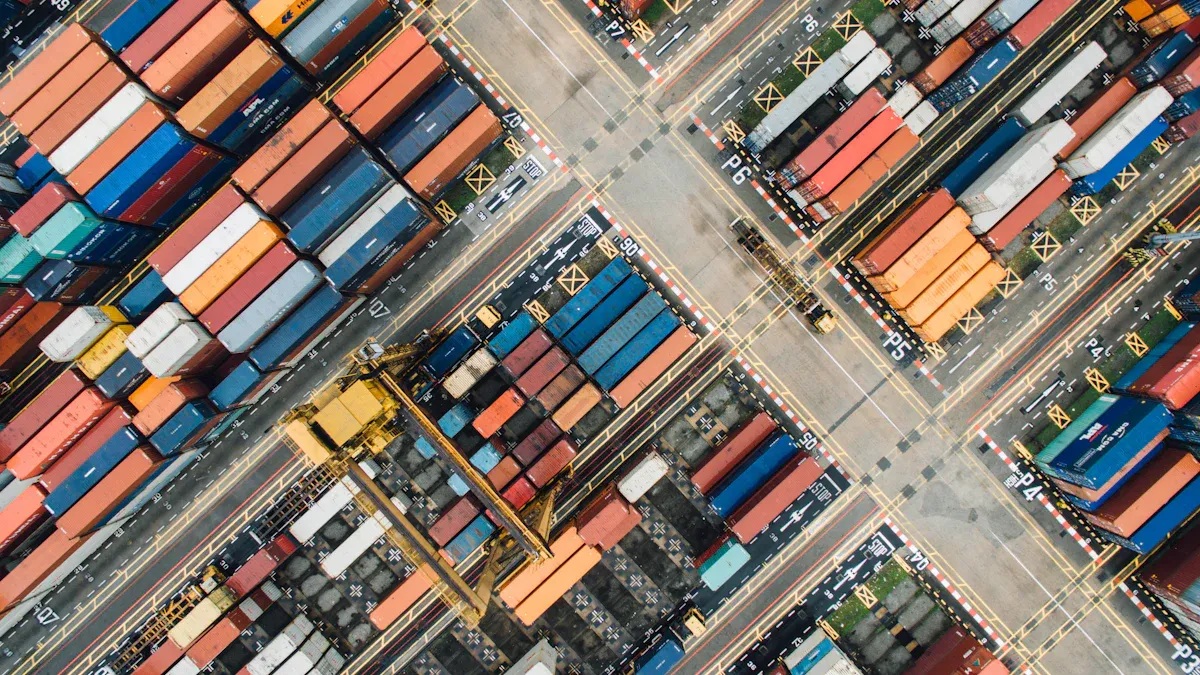

Managing supply chain management is very important for businesses today. It helps move goods and share information easily. This lowers costs and makes customers happier. Changing from old to digital supply chain management has transformed how things work. Understanding these systems helps you choose wisely in a tough market.

Key Takeaways

Traditional supply chains are steady but change slowly. They are good for long-term partnerships but have trouble with quick market shifts.

Digital supply chains use real-time data and machines to work better. They let businesses decide faster and save money.

Moving to digital supply chains can be hard. Good planning, learning, and working together are key for an easy switch.

Traditional Supply Chain Management Explained

Key Parts of Traditional Supply Chains

Traditional supply chains use old methods to work smoothly. They group customers by needs and adjust services to fit. Listening to market trends helps plan better and share resources. Products are customized near the customer for faster delivery. Buying smartly lowers costs, which is key for these systems. Technology helps track products and make decisions easier. Checking performance with service and money goals keeps things improving.

Strengths of Traditional Supply Chain Management

Traditional supply chains are steady and reliable. Their clear steps give consistent results. They work well for businesses that build long-term supplier and customer ties. Cutting costs through smart buying and resource use makes them dependable. These systems focus on physical setups, giving control over operations. For companies liking proven ways, they are a solid choice.

Weaknesses of Traditional Supply Chains

Traditional supply chains have some problems. They struggle with sudden market changes, causing delays. Higher costs for shipping and workers are tough to handle. They also harm the environment by using too many resources and creating waste. These problems show the need for greener and more flexible supply chains.

Digital Supply Chain Management and Its Advantages

Core Technologies Driving Digital Supply Chains

Digital supply chains use smart tools to work better. The Internet of Things (IoT) gives live updates on products. This helps track items and plan deliveries well. Artificial intelligence (AI) studies data to guess demand and improve schedules. Blockchain keeps records safe and builds trust by tracking goods. Enterprise Resource Planning (ERP) links inventory and schedules for smooth work. Digital twins copy supply chain steps to test ideas without stopping work.

Technology | What It Does |

|---|---|

Internet of Things (IoT) | Shares live updates on product locations and conditions, helping with tracking and planning. |

Artificial Intelligence | Uses data to improve planning, production, and delivery decisions. |

Blockchain | Keeps records safe and tracks goods, reducing risks and building trust. |

Enterprise Resource Planning (ERP) | Combines inventory and schedules for smooth and connected operations. |

Creates virtual copies of supply chains to test and improve processes. |

Benefits of Digital Supply Chain Management

Digital supply chains bring many good changes. They help teams work together by sharing data in one place. Automation saves time and reduces mistakes by doing tasks automatically. Live data helps make smart choices and plan ahead. After the pandemic, more companies saw the need for digital tools. AI is growing fast, with many leaders planning to use it soon. This could make supply chains 40% better and grow the market to $10 billion by 2025.

Main benefits of digital supply chains:

Better teamwork with shared data.

Automation saves time and lowers mistakes.

Live data helps with smarter decisions.

More visibility and flexibility in work.

Addressing Challenges in Digital Adoption

Switching to digital tools can be hard, but it’s possible. Working with others in the industry helps share ideas and grow faster. Governments can help by giving money or making helpful rules. Teaming up with tech companies gives access to better tools at lower costs. Clear talks between suppliers and workers make changes smoother. Teaching workers new skills helps them use the tools well. Easy-to-use tools also make people more willing to try them.

Strategy | What It Does |

|---|---|

Shares ideas and speeds up progress by working together. | |

Government Incentives and Supportive Policies | Helps businesses switch to digital with money and helpful rules. |

Establishing Partnerships with Technology Providers | Lowers costs and gives access to better tools. |

Improved Communication Between Suppliers and Contractors | Makes changes smoother with clear communication. |

Promoting a Culture of Continuous Learning | Teaches workers new skills to use digital tools. |

User-Friendly Digital Supply Management Tools | Encourages people to use tools by making them easy to understand. |

By solving these problems, businesses can use digital supply chains fully and succeed for a long time.

Comparing Traditional and Digital Supply Chains

How Traditional and Digital Models Work Differently

Traditional supply chains use old data and manual work to operate. They move goods step-by-step from suppliers to buyers. Digital supply chains, however, use live data to make quick decisions. These systems connect all parts, allowing smooth communication.

Traditional systems rely on people to decide using machine data. Digital systems use automation with people checking the process.

Digital models collect quality data from suppliers to fix issues early.

Digital systems improve results like perfect orders, happy customers, and faster inventory turnover.

Aspect | Traditional Supply Chain | Digital Supply Chain |

|---|---|---|

Operation | Uses live data for quick actions. | |

Structure | Step-by-step and linear. | Connected network of systems. |

Problem Detection | Finds problems slowly and reacts later. | Predicts and fixes problems early. |

Costs and Growth Potential

Traditional supply chains cost more due to wasted stock and transport issues. Digital systems save money by matching stock to demand. This stops overstocking and running out of items. Live data also cuts emergency shipping costs.

Benefit | Description |

|---|---|

Fewer Stock Shortages | Live data helps avoid running out of items. |

Better Demand Predictions | Accurate data matches stock to what’s needed. |

Cuts extra shipping and storage expenses. |

Digital supply chains grow better with market changes. They adjust quickly, keeping things running smoothly even when demand rises.

Being Flexible and Quick in Supply Chains

Traditional supply chains are slow to adapt. They can’t handle sudden changes well, causing delays. Digital systems are fast and flexible. Live data lets them adjust instantly. Predictive tools help spot problems early and prevent them.

Digital systems also focus on customers. They build strong relationships by delivering on time and offering personalized services. This flexibility makes digital supply chains great for staying competitive in changing markets.

Aspect | Traditional Supply Chain | Digital Supply Chain |

|---|---|---|

Agility | Slow to adapt to changes. | Quick and flexible to adjust. |

Customer Focus | Focuses on making products, not customer needs. | Builds strong, long-term customer relationships. |

Transitioning from Traditional to Digital Supply Chains

Reasons for Moving to Digital Supply Chains

Many reasons push companies to go digital. Matching digital plans with business goals brings the best results. Combining data and tasks into one system makes work easier. Automating boring tasks saves time and avoids mistakes. Real-time data helps make smart choices and fix problems early. Teaching teams and working together helps them succeed in a digital world.

New technology also encourages digital changes. Tools like predictive models guess demand and spot risks early. AI and IoT improve delivery routes and cut costs. Many companies now focus on being eco-friendly, lowering their carbon use.

Solving Problems During the Switch

Switching to digital supply chains can be hard, but it’s doable. Make a clear plan and get leaders to guide the change. Train workers so they can use new tools well. Keep up with market trends to meet customer needs. Build a workplace that welcomes change and involves everyone. Protect your data with strong security during the switch. Plan your budget wisely to handle costs without stress.

Tips for a Smooth Digital Change

Set clear goals that match your business needs. Use smart tools to learn more about your supply chain. Cloud systems make sharing and using data easier. Find tasks to automate for faster and better results. Use live tracking and IoT to see your supply chain clearly. Invest in security to protect your digital systems. Encourage teamwork with tools that improve communication and train your team to adapt to changes.

Impact on Business Operations and Customer Satisfaction

How Traditional and Digital Supply Chains Work Differently

Traditional supply chains use old data and manual work. This often causes delays and makes work less efficient. Digital supply chains use live data and automation to work faster. They help make better decisions and improve how things run.

Aspect | Traditional Supply Chain | Digital Supply Chain |

|---|---|---|

Decision-Making | Uses old data to react | Uses live data to act fast |

System Integration | Systems work separately | Systems work together |

Process Optimization | Focuses on single shipments | Focuses on the whole chain |

Decision-Making Process | People decide with machine help | Machines decide with checks |

Digital supply chains connect all parts to work as one. This saves money and boosts performance. It ensures every step runs smoothly.

How Digital Supply Chains Help Customers

Digital supply chains make customers happier. They deliver faster, keep products in stock, and share clear updates. For example:

Good delivery systems make customers happy.

Live updates build trust and loyalty.

Smart planning keeps items ready for customers.

Benefit | Description |

|---|---|

Faster Delivery Times | Quick deliveries make customers happier. |

Improved Product Availability | Products are ready when customers need them. |

Enhanced Transparency | Clear updates build trust and satisfaction. |

Digital tools like smart predictions and customer dashboards help meet customer needs. These tools make sure customers have a great experience.

JUSDA’s Role in Better Supply Chains

JUSDA is a top company in supply chain management. Its JusLink platform uses IoT, cloud tech, and big data to improve supply chains. JUSDA’s tools give live tracking and smart predictions to save time and money.

For example, JUSDA helps businesses cut costs and deliver faster. They focus on keeping customers happy at every step. With JUSDA, your supply chain becomes a strong advantage in business.

Future Trends in Supply Chain Management

New Technologies in Supply Chains

Supply chains are changing with new technologies. Artificial Intelligence (AI) studies data to improve delivery and guess demand. The Internet of Things (IoT) gives live updates on shipments and stock. Blockchain keeps transactions safe and tracks goods from start to end. These tools work together to make supply chains faster and better.

Technology | What It Helps With |

|---|---|

AI | Improves delivery and predicts demand. |

IoT | Tracks shipments and inventory live. |

Blockchain | Secures transactions and builds trust. |

Businesses and schools are teaming up to shape the future. Research and real-world experience help companies learn and improve.

Going Green with Digital Supply Chains

Companies now care more about helping the planet. Many are using eco-friendly ideas to cut waste and save resources. For example, recycling and reusing materials is part of the circular economy. Digital tools help track waste and lower it. Reports say 80% of leaders are working harder on green practices. Doing this can save money and make customers happier.

What’s Next for Supply Chains?

Smart tools are changing how supply chains work. By studying past data, companies can guess demand and manage stock better. Machine learning helps businesses make smarter choices. Experts think the supply chain market will grow to $78.5 billion by 2033. This growth comes from the need for better tools and clear processes. Following these trends will help businesses stay strong in a fast-changing world.

JUSDA Solutions

To provide you with professional solutions and quotations.

Knowing how traditional and digital supply chains differ helps you choose wisely. Traditional supply chains use strict setups and local connections. Digital supply chains are flexible and work globally. The table below shows their differences:

Aspect | Traditional Supply Chain | Digital Supply Chain |

|---|---|---|

Structure | Clear roles in a strict setup | Flexible and less centralized |

Interaction | Focus on in-person meetings | Mostly online communication |

Reach | Limited to nearby areas | Worldwide reach using digital tools |

Adaptability | Slow to adjust to changes | Quick to adapt to market needs |

Decision-making speed | Slower due to many steps | Faster with real-time data and tools |

Customer engagement | Focused on local customers | Reaches a larger audience through online methods |

Innovation | Restricted by old ways | Grows with new technology |

Pick the method that fits your business goals best. Digital tools make supply chains faster and more flexible. Technology and innovation will keep improving supply chains, making them better and more responsive.

See Also

Revolutionizing Supply Chains Through Advanced Robotics Technology

In-Depth Analysis of Jusda Supply Chains and Consumer Needs

Enhancing Supply Chain Efficiency in High-Tech Manufacturing

The Role of Digital Twins in Supply Chain Innovation

Transforming Industries with Cloud-Based Supply Chain Solutions