Types of Intelligent Warehouse Equipment

Modern warehouses rely on intelligent warehouse equipment to stay competitive in a fast-paced industry. These advanced tools use automation and technology to streamline operations, saving time and reducing errors. For example:

Labor cost reduction occurs when automated systems allow your team to complete more tasks in less time.

Error rates drop significantly, leading to better efficiency and customer satisfaction.

Optimized inventory management ensures you maintain the right stock levels, avoiding costly overstocking or shortages.

By adopting intelligent warehouse equipment, you can transform your operations, achieving precision, speed, and cost savings.

Key Takeaways

Smart warehouse tools save time by automating work and cutting costs.

Robots like AGVs and AMRs help move items and fill orders. They adjust to changing spaces easily.

Smart belts and AS/RS systems use space better and speed up work. This helps deliver items faster.

WMS software tracks inventory and orders, making them more accurate. It also keeps customers happy.

Using IoT tech gives live updates, helping make smarter choices and work faster in warehouses.

Automated Guided Vehicles (AGVs)

Overview of AGVs

Automated Guided Vehicles (AGVs) are self-driving machines designed to transport goods within warehouses and distribution centers. These vehicles rely on advanced technologies like sensors, cameras, and navigation systems to move efficiently without human intervention. AGVs are a cornerstone of intelligent warehouse equipment, helping businesses streamline operations and reduce manual labor.

The market for AGVs has grown significantly in recent years, reflecting their importance in modern warehousing. According to industry data:

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2023 | N/A | |

2024 | 4.12 | N/A |

2031 | 7.97 | 9.6 |

This growth highlights the increasing adoption of AGVs as businesses seek smarter solutions for their supply chain operations.

Key Features and Capabilities

AGVs come equipped with cutting-edge features that make them indispensable for warehouse operations. These include:

Autonomous Navigation: AGVs use AI and machine learning to map routes and avoid obstacles.

IoT Integration: Real-time data sharing enables predictive maintenance and optimized resource allocation.

Scalability: AGVs can handle seasonal demand fluctuations and large order volumes with ease.

These capabilities allow AGVs to execute complex tasks, such as transporting goods across vast warehouse spaces or assisting in inventory management. Their ability to integrate seamlessly with warehouse management systems further enhances operational efficiency.

Benefits for Warehouse Operations

AGVs offer numerous advantages that transform warehouse operations:

Efficiency: They streamline processes, improving speed and accuracy in material handling.

Labor Reduction: AGVs minimize reliance on manual labor, addressing labor shortages and reducing costs.

Error Reduction: Their precision reduces mistakes, ensuring smoother workflows and fewer disruptions.

Integration: Real-time tracking of inventory and shipments enhances visibility and decision-making.

The advancements in robotics and AI have made AGVs more autonomous and efficient than ever. By adopting these vehicles, you can optimize resource allocation and achieve smarter supply chain operations.

Tip: Investing in AGVs not only boosts productivity but also positions your business for long-term growth in a competitive market.

Autonomous Mobile Robots (AMRs)

How AMRs Work

Autonomous Mobile Robots (AMRs) are advanced machines designed to navigate warehouse environments independently. Unlike Automated Guided Vehicles (AGVs), AMRs don’t rely on fixed paths or physical guides. Instead, they use sensors, cameras, and onboard software to map their surroundings and make real-time decisions. These robots adapt to dynamic environments, avoiding obstacles and optimizing routes for faster operations.

AMRs operate using artificial intelligence and machine learning algorithms. These technologies enable them to analyze data, predict movements, and adjust their actions accordingly. For example, when an AMR encounters a crowded aisle, it reroutes itself to maintain efficiency. This flexibility makes AMRs ideal for modern warehouses that require agility and adaptability.

Key Applications in Warehousing

AMRs play a crucial role in various warehouse tasks. Material handling is one of their primary applications, accounting for approximately 39% of the AMR market in 2024. These robots transport goods between storage areas, packing stations, and shipping docks, reducing the need for manual labor.

Another key application is order picking. AMRs assist workers by bringing items directly to them, speeding up the fulfillment process. They also contribute to inventory management by scanning barcodes and updating stock levels in real time. This ensures accurate tracking and minimizes errors.

The logistics and warehousing sector dominates AMR adoption, holding a market share of about 42% in 2024. The rise of e-commerce has driven this trend, as businesses seek automation to meet growing demands for faster delivery and improved operational efficiency.

Advantages Over Traditional Systems

AMRs offer several advantages over traditional warehouse systems. Their ability to navigate dynamically eliminates the need for fixed infrastructure, reducing setup costs. They also adapt to changes in warehouse layouts, making them more versatile than AGVs.

These robots enhance productivity by working alongside human employees, handling repetitive tasks while freeing workers for more complex activities. Their precision reduces errors, ensuring smoother workflows and higher customer satisfaction. Additionally, AMRs integrate seamlessly with intelligent warehouse equipment like Warehouse Management Systems (WMS), enabling real-time data sharing and smarter decision-making.

Note: Investing in AMRs helps you future-proof your warehouse operations, ensuring scalability and efficiency in a rapidly evolving industry.

Smart Conveyor Systems

What Makes Conveyors "Smart"

Smart conveyor systems use advanced technologies to improve material handling in warehouses. These systems integrate sensors, automation, and real-time monitoring to optimize performance. Unlike traditional conveyors, smart systems can adapt to changing conditions and handle complex tasks with precision.

The growing demand for automation has fueled the adoption of smart conveyors. The global conveyor system market is projected to reach USD 16.14 billion by 2032, with a compound annual growth rate (CAGR) of 5.7% from 2025 to 2032. This growth reflects the increasing need for efficient and streamlined supply chain operations.

Features for Enhanced Material Handling

Smart conveyor systems come with features that enhance material handling efficiency:

Automated Control: These systems use AI to adjust speed and direction based on workload.

Real-Time Monitoring: Sensors track the movement of goods, ensuring smooth operations.

Customizable Configurations: You can modify these systems to suit specific warehouse layouts.

These features eliminate inconsistencies and improve throughput. For example, an automotive manufacturer reduced assembly time by 30% after implementing an automated pallet conveyor system. By using smart conveyors, you can achieve faster production cycles and reduce labor costs.

Benefits for Sorting and Distribution

Smart conveyor systems play a vital role in sorting and distribution. They improve the flow of goods, making order fulfillment faster and more accurate. Automated systems reduce human errors, ensuring repeatability and precision. This is especially important in e-commerce, where quick and accurate deliveries are essential.

Adopting smart conveyors also enhances operational efficiency. Personnel can focus on critical tasks while the system handles repetitive processes. This leads to higher production volumes and faster deliveries, helping you meet customer demands effectively.

Tip: Investing in intelligent warehouse equipment like smart conveyors can transform your operations, making them more efficient and cost-effective.

Warehouse Management Systems (WMS)

Core Functionalities of WMS

Warehouse Management Systems (WMS) are software solutions designed to optimize warehouse operations. These systems handle tasks like inventory tracking, order processing, and workflow management. A WMS ensures that every item in your warehouse is accounted for and accessible when needed.

Core functionalities include:

Inventory Management: Tracks stock levels in real time, preventing overstocking or shortages.

Order Fulfillment: Automates picking, packing, and shipping processes for faster delivery.

Data Analytics: Provides insights into operational performance, helping you make informed decisions.

WMS also integrates with other intelligent warehouse equipment, creating a seamless ecosystem for efficient operations.

Role in Inventory and Order Management

A WMS plays a critical role in managing inventory and orders. By integrating IoT sensors, it enhances visibility, ensuring accurate stock levels and preventing stockouts. Predictive analytics powered by AI and ML helps you forecast demand and optimize inventory placement.

For order management, WMS automation reduces manual errors and speeds up processing times. This is especially valuable in high-demand sectors like e-commerce, where quick and accurate order fulfillment is essential.

Key benefits include:

Improved order accuracy through real-time tracking.

Faster processing times, enabling same-day shipping guarantees.

Enhanced customer satisfaction due to reliable deliveries.

Benefits for Operational Efficiency

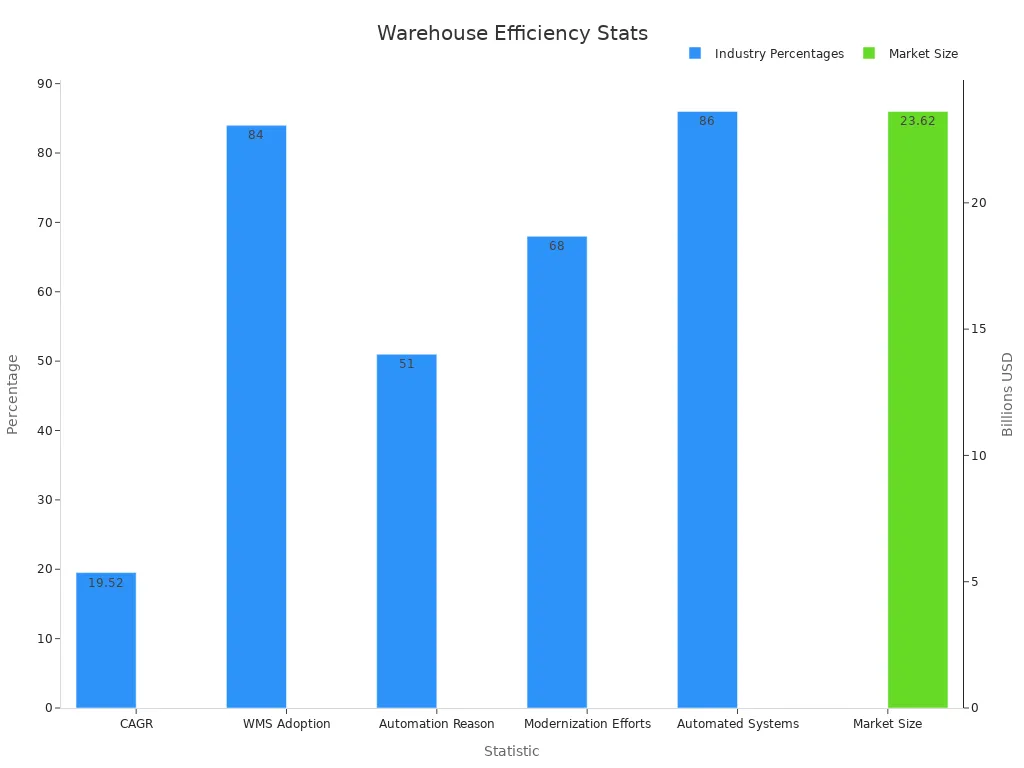

Implementing a WMS significantly boosts operational efficiency. It streamlines workflows, reduces errors, and improves throughput. According to industry statistics:

Metric | Improvement |

|---|---|

Throughput | |

Fulfillment errors | 70% reduction |

Same-day shipping guarantee | Yes |

The adoption of WMS technologies continues to grow. The market is projected to expand at a CAGR of 19.52% from 2024 to 2033, reaching $23.62 billion. This growth reflects the increasing recognition of WMS benefits.

By modernizing your warehouse with a WMS, you can achieve higher productivity, lower costs, and better customer satisfaction. This makes it an essential component of intelligent warehouse equipment.

Automated Storage and Retrieval Systems (AS/RS)

Types of AS/RS Technologies

Automated Storage and Retrieval Systems (AS/RS) use advanced machinery and software to store and retrieve goods efficiently. These systems come in various types, each tailored to specific warehouse needs:

Unit Load AS/RS: Handles large items or pallets, ideal for bulk storage.

Mini-Load AS/RS: Designed for smaller items, offering high-speed retrieval for lightweight goods.

Carousel Systems: Rotating shelves that bring items directly to the operator, reducing retrieval time.

Shuttle Systems: Use robotic shuttles to move goods within racks, ensuring quick and precise operations.

Each type serves a unique purpose, allowing you to choose the best solution based on your inventory and operational requirements.

Features for Space and Time Optimization

AS/RS technologies maximize warehouse efficiency by optimizing space and time. These systems use vertical storage to make the most of available space, enabling high-density storage. They also automate retrieval processes, speeding up operations and reducing delays.

Key benefits include:

Reduction in labor costs: Automation decreases the need for manual workforce.

Minimization of errors: Precise systems reduce mistakes and injuries associated with manual tasks.

Increased productivity: Faster operations improve throughput and efficiency.

Maximized space utilization: Vertical storage designs free up floor space for other activities.

To design an effective AS/RS solution, you need to analyze inventory data and stock keeping unit (SKU) profiles over at least one year. Systems are typically sized to handle the 90th percentile of daily volume, ensuring they meet demand while allowing manual processes as a backup during peak times.

Benefits for Modern Warehousing

AS/RS systems transform warehouse operations by enhancing scalability, efficiency, and accuracy. These systems adapt to changing business needs, making them a future-proof investment.

Benchmark | Description |

|---|---|

Scalability | Easily expandable to meet growing demands. |

Optimized space use | Enables high-density storage, maximizing warehouse capacity. |

Enhanced efficiency | Speeds up storage and retrieval processes, boosting productivity. |

Reduced labor costs | Lowers operational costs by reducing manual labor. |

Improved accuracy | Minimizes human errors, ensuring better inventory control. |

By automating repetitive tasks, AS/RS systems reduce reliance on manual labor and enable continuous operations with minimal supervision. This optimization lowers costs and improves productivity, helping you stay competitive in a fast-paced industry.

Tip: Investing in AS/RS solutions not only streamlines your operations but also ensures long-term scalability and efficiency.

Collaborative Robots (Cobots)

What Are Cobots?

Collaborative robots, or cobots, are robots designed to work alongside humans in shared environments. Unlike traditional industrial robots, cobots prioritize safety and adaptability. They use advanced sensors and algorithms to detect human presence and adjust their actions accordingly. This makes them ideal for tasks requiring precision, speed, and flexibility.

Cobots are not meant to replace human workers. Instead, they complement human efforts by handling repetitive or physically demanding tasks. This partnership allows you to focus on more complex and creative activities, enhancing overall productivity. As a result, cobots are becoming a cornerstone of modern warehouse operations.

Applications in Warehouse Tasks

Cobots excel in various warehouse tasks, making them versatile tools for improving efficiency. Some common applications include:

Order Picking: Cobots optimize picking routes, reducing unnecessary walking and speeding up fulfillment.

Packing and Sorting: They assist in packing items and sorting them for shipment, ensuring accuracy and consistency.

Inventory Management: Cobots scan barcodes and update stock levels in real time, minimizing errors.

Material Handling: They transport goods across the warehouse, reducing the physical strain on workers.

By integrating cobots into your operations, you can streamline workflows and achieve faster, more accurate results.

Benefits of Human-Robot Collaboration

Human-robot collaboration offers numerous advantages for warehouse operations:

Increased Productivity: Cobots can double or even triple productivity by sharing tasks with human workers.

Enhanced Efficiency: They reduce idle time and optimize workflows, ensuring smoother operations.

Improved Safety: Cobots handle physically demanding tasks, reducing the risk of injuries and employee strain.

Better Job Satisfaction: By taking over repetitive tasks, cobots allow you to focus on strategic and creative work.

Metric | Description |

|---|---|

Success rate | Measures the percentage of successful interactions between humans and robots. |

Interaction force | Assesses the force exerted during human-robot interactions to ensure safety and efficiency. |

Timings (idle & total) | Evaluates the time spent in idle states versus total operational time, indicating efficiency. |

Joint effort | Analyzes the collaborative effort required from both humans and robots during tasks. |

Cobots are reshaping warehouse operations by fostering a safer and more efficient working environment. This trend emphasizes collaboration, not replacement, making cobots an essential part of the future of warehousing.

Automated Picking Tools

Overview of Picking Automation

Automated picking tools revolutionize order fulfillment by using robotics and AI to streamline the picking process. These tools identify, retrieve, and prepare items for shipment without manual intervention. They rely on technologies like barcode scanning, vision systems, and machine learning to ensure precision.

You can use automated picking tools to handle high volumes of orders efficiently. For example, companies like Amazon have integrated over 750,000 robots into their warehouses to meet growing demand. These tools operate continuously, reducing reliance on human labor and minimizing errors. Their ability to adapt to dynamic inventory makes them essential for modern warehouses.

IoT Implementation in Warehousing

Role of IoT in Intelligent Warehouses

IoT, or the Internet of Things, transforms warehouses into interconnected ecosystems. IoT devices collect and share data across systems, enabling smarter operations. These devices include sensors, RFID tags, and GPS trackers that monitor inventory, equipment, and shipments in real time.

You can use IoT to eliminate inefficiencies like stockouts and overstocking. Real-time visibility into inventory ensures better control over stock levels. IoT also enhances resource allocation by providing actionable insights. For example, companies using IoT analytics report a 25% increase in workforce productivity, according to research by Boston Consulting Group (BCG, 2022).

IoT applications improve decision-making by reducing errors and enabling data-driven strategies. Managers can optimize workflows, predict demand, and allocate resources effectively. This technology ensures your warehouse operates at peak efficiency, even during high-demand periods.

Features for Real-Time Data Collection

IoT devices excel at collecting real-time data, which is crucial for modern warehouses. These features include:

Asset Tracking: Sensors and RFID tags monitor goods and equipment, providing instant updates on their location.

Predictive Maintenance: IoT identifies potential equipment issues early, preventing costly breakdowns.

Inventory Monitoring: Devices track stock levels continuously, ensuring accurate inventory management.

Route Optimization: GPS trackers help plan efficient delivery routes, reducing delays.

The benefits of these features are substantial:

Benefit | Description |

|---|---|

Enhanced Visibility | IoT devices provide real-time tracking of assets, allowing logistics managers to monitor goods closely. |

Efficient Planning | Real-time data helps optimize route planning and resource allocation, reducing potential delays. |

Improved Inventory Management | Visibility into inventory status enables better control over stock levels, minimizing stockouts. |

Predictive Maintenance | Identifying potential issues early helps avoid costly breakdowns, enhancing productivity. |

By leveraging these features, you can streamline operations and improve warehouse efficiency.

Benefits for Decision-Making and Efficiency

IoT enhances decision-making by providing accurate, real-time data. This data allows you to make informed choices about inventory, resource allocation, and order fulfillment. Companies using IoT solutions report significant improvements in operational metrics:

Metric | Improvement |

|---|---|

Air shipping time | Decreased by 54% |

Inventory accuracy | Improved from 98% to 99.52% |

Order processing efficiency | Improved by 50% |

Customer complaints | Reduced by 11% |

IoT also improves visibility and reduces errors in warehouse operations. It enables managers to optimize workflows and eliminate inefficiencies. For example, IoT applications help prevent stockouts and overstocking, ensuring smooth operations.

Tip: Adopting IoT technology positions your warehouse for long-term success by improving productivity and decision-making capabilities.

The adoption of intelligent warehouse equipment has revolutionized modern warehousing. From Automated Guided Vehicles (AGVs) to IoT-enabled systems, these technologies enhance efficiency, accuracy, and scalability. For example, tools like robotic palletization and AI-driven systems significantly improve operational performance, as shown below:

Technology | Significance | |

|---|---|---|

Automated packaging system | 0.000379296 | Strongly significant |

Warehouse Management System | 0.008350201 | Significant |

Artificial Intelligence and machine learning | 0.00000388704 | Strongly significant |

These advancements not only streamline workflows but also reduce costs and errors. Technologies like robotics and AI provide actionable insights, while IoT ensures real-time data collection for better decision-making.

The integration of AI and machine learning is transforming warehouse operations, improving productivity and reducing inefficiencies.

Big data analytics in warehousing, valued at $274 billion, highlights the growing trend toward data-driven strategies.

By embracing these innovations, you can future-proof your operations and stay competitive in a rapidly evolving industry.

Tip: Start exploring these technologies today to unlock their full potential and transform your warehouse into a high-performing ecosystem.

FAQ

What is the difference between AGVs and AMRs?

AGVs follow fixed paths using markers or wires, while AMRs navigate dynamically using sensors and AI. AMRs adapt to changing environments, making them more flexible for modern warehouses.

Tip: Choose AMRs if your warehouse layout changes frequently or requires high adaptability.

How do IoT devices improve warehouse efficiency?

IoT devices provide real-time data on inventory, equipment, and shipments. This data helps you track assets, predict maintenance needs, and optimize workflows, reducing errors and delays.

Example: RFID tags can instantly update stock levels, ensuring accurate inventory management.

Are cobots safe to use around humans?

Yes, cobots are designed with safety in mind. They use sensors to detect human presence and adjust their actions to avoid collisions or injuries.

Emoji Insight: 🤝 Cobots work with you, not against you, ensuring a safe and productive environment.

What are the main benefits of using AS/RS systems?

AS/RS systems save space, reduce labor costs, and improve accuracy. They store items vertically and automate retrieval, speeding up operations and minimizing errors.

Benefit | Description |

|---|---|

Space Optimization | Vertical storage saves floor space. |

Cost Reduction | Automation lowers labor expenses. |

How can a WMS help with order fulfillment?

A WMS automates picking, packing, and shipping processes. It tracks orders in real time, ensuring faster and more accurate deliveries. This improves customer satisfaction and reduces operational errors.

Note: Integrating a WMS with IoT devices enhances its capabilities even further.

See Also

Understanding Robotic Automation's Role in Warehouse Efficiency

The Importance of Automating Your Warehouse Operations

Exploring Benefits of Automation in Modern Manufacturing Warehouses

Boosting Warehouse Productivity Through Logistics Robotics Solutions

Transform Your Business Using Innovative Inventory Management Strategies