Navigating the Complexities of the Semiconductor Supply Chain

Semiconductors play a crucial role in modern technology. These tiny chips power almost every electronic device used today, from smartphones to advanced computing systems. The semiconductor industry's supply chain management holds immense global significance. With worldwide sales reaching $574.1 billion in 2022 and projections indicating a rise to $607.40 billion by 2024, the importance of this industry cannot be overstated. Exploring the complexity of this supply chain reveals the intricate processes and challenges involved in delivering these essential components to the market.

Overview of the Semiconductor Industry

Historical Context

Evolution of Semiconductor Technology

The semiconductor industry has a rich history. The journey began with the invention of the rectifier and the point-contact transistor. These innovations marked the start of the transistor era. The development of the point contact transistor and junction-type transistor followed. These were the first transistors ever constructed.

The invention of the bipolar integrated circuit (IC) came next. This event marked the dawn of the IC era. Each of these milestones paved the way for modern semiconductor technology. The evolution of semiconductor technology showcases rapid advancements and groundbreaking discoveries.

Key Milestones in the Industry

Several key milestones have defined the semiconductor industry. The invention of the rectifier and point-contact transistor heralded the arrival of the transistor era. The development of the bipolar integrated circuit marked the beginning of the IC era.

Other significant events include the creation of the first microprocessor by Intel in 1971. This innovation revolutionized computing. The introduction of the first dynamic random-access memory (DRAM) chip in 1969 also stands out. These milestones highlight the industry's continuous innovation and growth.

Current Market Landscape

Major Players in the Industry

The semiconductor industry features several major players. Companies like Intel, Samsung, and TSMC lead the market. Intel is known for its microprocessors. Samsung excels in memory chips. TSMC specializes in contract manufacturing.

Other notable companies include Qualcomm, NVIDIA, and AMD. Qualcomm dominates the mobile chip market. NVIDIA leads in graphics processing units (GPUs). AMD competes in both CPUs and GPUs. These companies drive innovation and set industry standards.

Market Trends and Predictions

The semiconductor market continues to evolve. One major trend is the rise of artificial intelligence (AI). AI demands more powerful and efficient chips. Another trend is the growth of the Internet of Things (IoT). IoT devices require specialized semiconductors.

Market predictions indicate continued growth. Analysts project global sales to reach $607.40 billion by 2024. Generative AI is expected to turbocharge this growth. The semiconductor industry will likely see increased demand and innovation.

Components of the Semiconductor Supply Chain

Raw Material Sourcing

Key Raw Materials

Semiconductor manufacturing relies on several key raw materials. Silicon serves as the primary material for wafer production. Gallium arsenide and silicon carbide also play crucial roles in specific applications. Copper, gold, and aluminum are essential for wiring and connections. Rare earth elements like neodymium and dysprosium enhance magnetic properties.

Global Sources and Suppliers

The global supply chain sources these materials from various regions. Silicon comes mainly from China and the United States. Gallium arsenide often originates from Germany and Japan. Copper mines in Chile and Peru provide a significant portion of the world's supply. Rare earth elements primarily come from China, which controls a large share of the market. Companies must navigate this complex web of suppliers to secure the necessary materials.

Manufacturing Process

Wafer Production

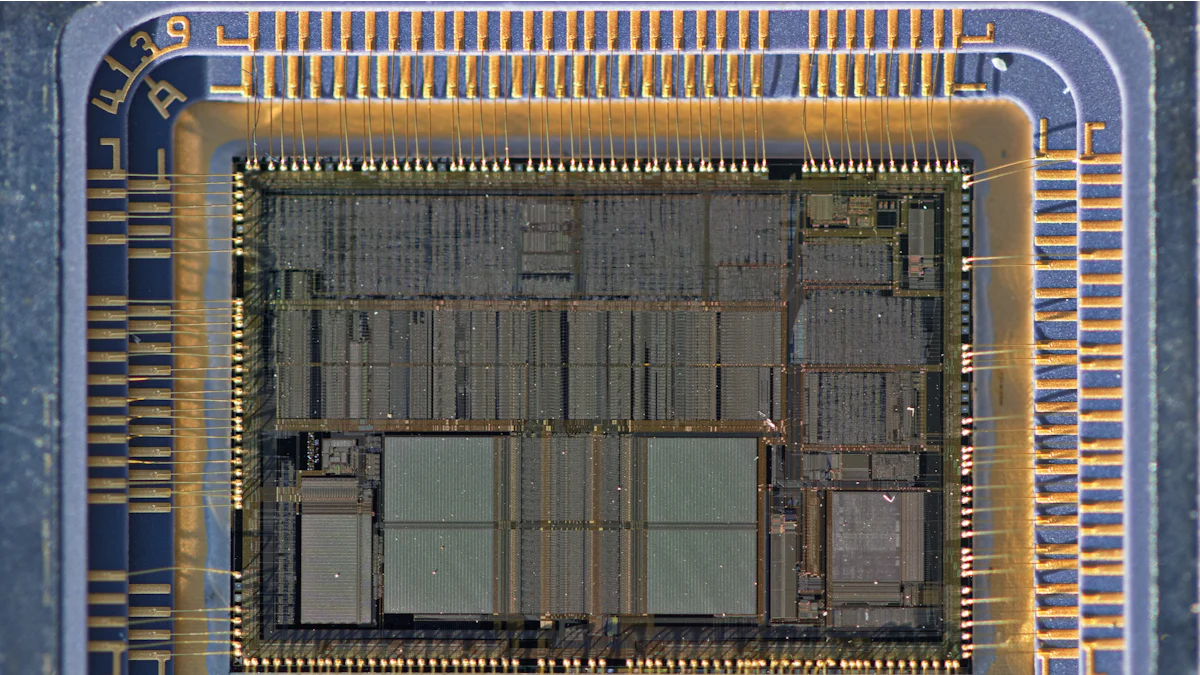

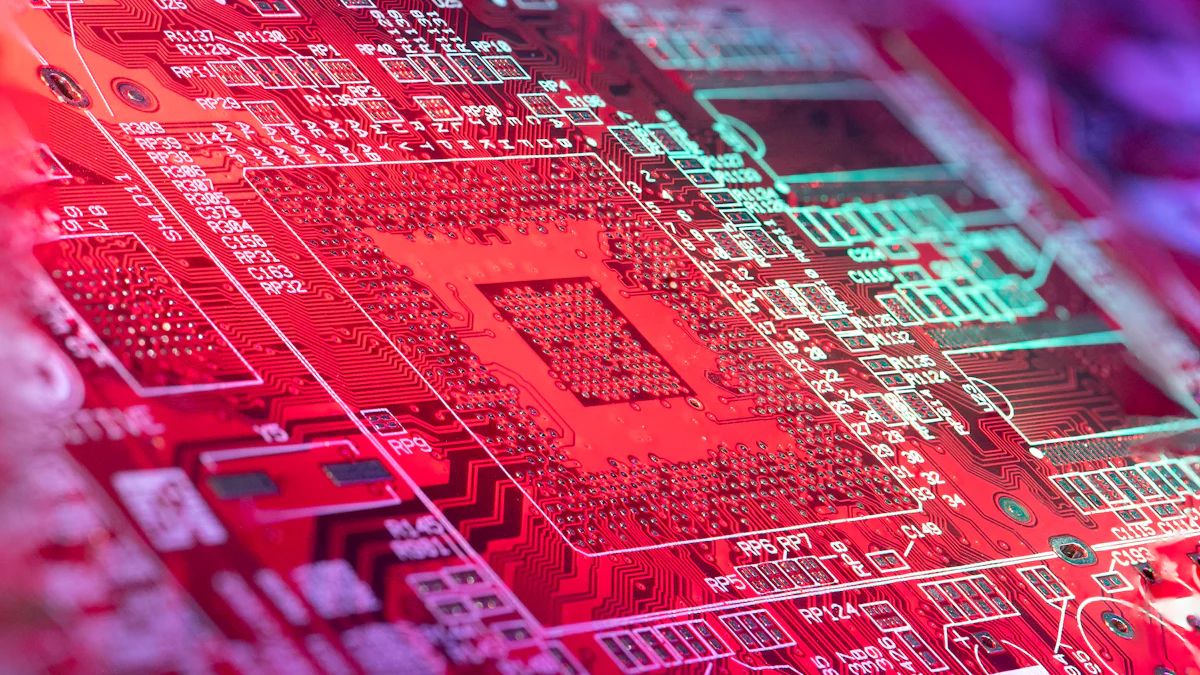

Wafer production marks the first step in semiconductor manufacturing. Manufacturers start with raw silicon, which undergoes purification. The purified silicon forms into cylindrical ingots. These ingots get sliced into thin wafers. Each wafer serves as the foundation for multiple chips.

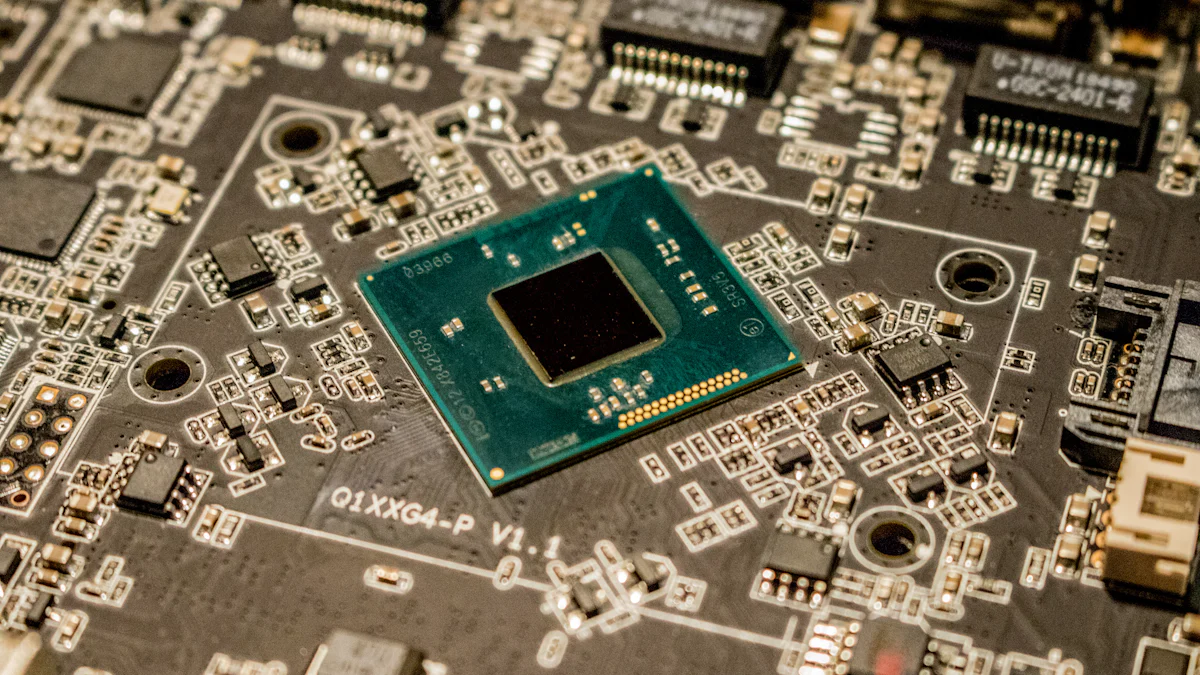

Chip Fabrication

Chip fabrication involves several intricate steps. Photolithography patterns the wafers with circuit designs. Etching removes unwanted material, leaving behind the desired circuit paths. Doping introduces impurities to modify electrical properties. This process requires extreme precision and advanced technology.

Packaging and Testing

Packaging protects the delicate chips and prepares them for use. Manufacturers encase the chips in protective materials. This step ensures durability and reliability. Testing follows packaging to verify functionality. Each chip undergoes rigorous tests to meet quality standards. Only the best-performing chips move forward to distribution.

Distribution and Logistics

Global Distribution Networks

Global distribution networks ensure that chips reach their destinations. Major companies like Intel and TSMC operate extensive logistics systems. These networks span multiple continents and involve various transportation modes. Air freight, sea freight, and ground transport all play roles. Efficient logistics keep the supply chain moving smoothly.

Challenges in Logistics

Logistics face several challenges in the semiconductor industry. Geopolitical tensions can disrupt trade routes. Natural disasters may damage infrastructure and delay shipments. The COVID-19 pandemic highlighted vulnerabilities in global supply chains. Companies must adapt to these challenges to maintain a steady flow of materials and products.

Understanding these components provides insight into the complexity of the semiconductor supply chain. Each step, from raw material sourcing to distribution, involves meticulous planning and execution. The industry's success hinges on managing these intricate processes effectively.

Semiconductor Industry's Supply Chain Management

Supply Chain Disruptions

Causes of Disruptions

Supply chain disruptions in the semiconductor industry stem from various factors. Natural disasters like earthquakes and floods can damage manufacturing facilities. Trade disputes between countries often lead to tariffs and restrictions, affecting material flow. Pandemics, such as COVID-19, disrupt global logistics and workforce availability. Manufacturing capacity constraints also pose significant challenges. Companies sometimes struggle to meet high demand due to limited production capabilities.

Impact on the Industry

Disruptions in the supply chain have profound effects on the semiconductor industry. Production delays lead to chip shortages, impacting various sectors like automotive and consumer electronics. Financial losses occur due to halted operations and unmet orders. Stress and low morale among employees result from constant pressure to resolve issues. Relationships between manufacturers and suppliers deteriorate, causing long-term instability. The industry faces increased costs as companies invest in alternative solutions and risk mitigation strategies.

Geopolitical Factors

Trade Policies and Regulations

Trade policies and regulations significantly influence the semiconductor supply chain. Governments impose tariffs and export controls to protect national interests. These measures affect the availability and cost of raw materials and finished products. Intellectual property concerns lead to stricter regulations, impacting innovation and collaboration. Companies must navigate complex legal landscapes to maintain compliance and avoid penalties. Trade agreements between countries can either facilitate or hinder the smooth flow of goods.

International Relations and Their Impact

International relations play a crucial role in the semiconductor industry's supply chain management. Diplomatic tensions between countries can disrupt trade routes and create uncertainty. Alliances and partnerships between nations influence market dynamics and competitive advantages. Countries with strained relations may impose sanctions, limiting access to critical resources. Collaborative efforts in research and development can foster innovation and growth. Companies need to stay informed about geopolitical developments to adapt their strategies accordingly.

Technological Advancements

Innovations in Manufacturing

Technological advancements drive continuous improvements in semiconductor manufacturing. Innovations like extreme ultraviolet (EUV) lithography enhance precision in chip fabrication. Automation and robotics streamline production processes, reducing human error and increasing efficiency. Advanced materials like graphene and carbon nanotubes promise higher performance and energy efficiency. Companies invest in cutting-edge equipment to stay competitive and meet evolving market demands. Research and development efforts focus on overcoming current limitations and exploring new possibilities.

Future Trends and Their Implications

Future trends in the semiconductor industry hold significant implications for supply chain management. The rise of artificial intelligence (AI) and machine learning increases demand for specialized chips. The growth of the Internet of Things (IoT) requires diverse and adaptable semiconductor solutions. Generative AI is expected to turbocharge the industry's growth, reaching $600 billion by 2024. Companies must anticipate these trends and adjust their strategies to stay ahead. Investing in new technologies and diversifying suppliers can enhance resilience and sustainability.

The semiconductor supply chain involves intricate processes and numerous challenges. Understanding this complexity proves crucial for maintaining a steady flow of essential components. Addressing supply chain disruptions requires robust strategies like bottleneck management and optimization-based systems. Companies should invest in technological advancements and diversify suppliers to enhance resilience. The future of the semiconductor industry looks promising with innovations driving growth. Staying informed and adaptable will help navigate this dynamic landscape.

See Also

Insider Tips for Semiconductor Industry Quality Control

Efficient Fixes for High-Tech Manufacturing's Supply Chain Challenges

Discovering Robotics: Supply Chain Innovation