Unleashing the Potential of Your Automotive Supply Chain

Enhancing automotive supply chain efficiency is paramount in driving success within the industry. The blog will delve into the critical aspects of this transformation, shedding light on key strategies and technologies that can revolutionize the way organizations operate. Amidst the current landscape, challenges like component shortages and global disruptions present opportunities for innovation and resilience. By exploring these dynamics, automotive stakeholders can unlock new potentials and stay ahead in an ever-evolving market.

Understanding the Automotive Supply Chain

When delving into the automotive supply chain, it becomes evident that various components and stakeholders play crucial roles in ensuring the seamless operation of this intricate network.

Components and Stakeholders

Manufacturers: These entities are responsible for producing vehicles, ranging from cars to commercial trucks, and play a pivotal role in shaping the industry's landscape.

Suppliers: The suppliers provide essential components and parts required for vehicle assembly, ensuring that manufacturers have access to the necessary resources for production.

Service Providers: Service providers offer a range of services vital to the automotive supply chain, including logistics, transportation, and warehousing solutions that facilitate the smooth flow of operations.

Current Challenges

Component Shortages: Recent events such as the COVID-19 pandemic and semiconductor shortage have significantly impacted global automotive output. Approximately 12% of global automotive output vanished from 2020 to 2022 due to these shortages.

Global Disruptions: The auto supply chain has faced unprecedented disruptions leading to a substantial decline in global production. Markets have been left grossly undersupplied due to these disruptions.

Supply Chain Instability: Challenges within the automotive industry have led to dwindling sales, resulting in losses of an estimated 7.7 million vehicles in 2021 alone. Supply chain issues have been dominant in the news affecting the auto industry since as far back as 1984.

Strategies for Optimization

Segmenting Suppliers

Segmenting suppliers based on emissions, criticality, and carbon maturity is a strategic approach to enhancing the efficiency of the automotive supply chain. By categorizing suppliers according to their environmental impact, importance, and sustainability practices, organizations can prioritize collaborations with key partners. This segmentation strategy enables companies to focus on suppliers that align with their values and business objectives, fostering long-term relationships built on shared goals.

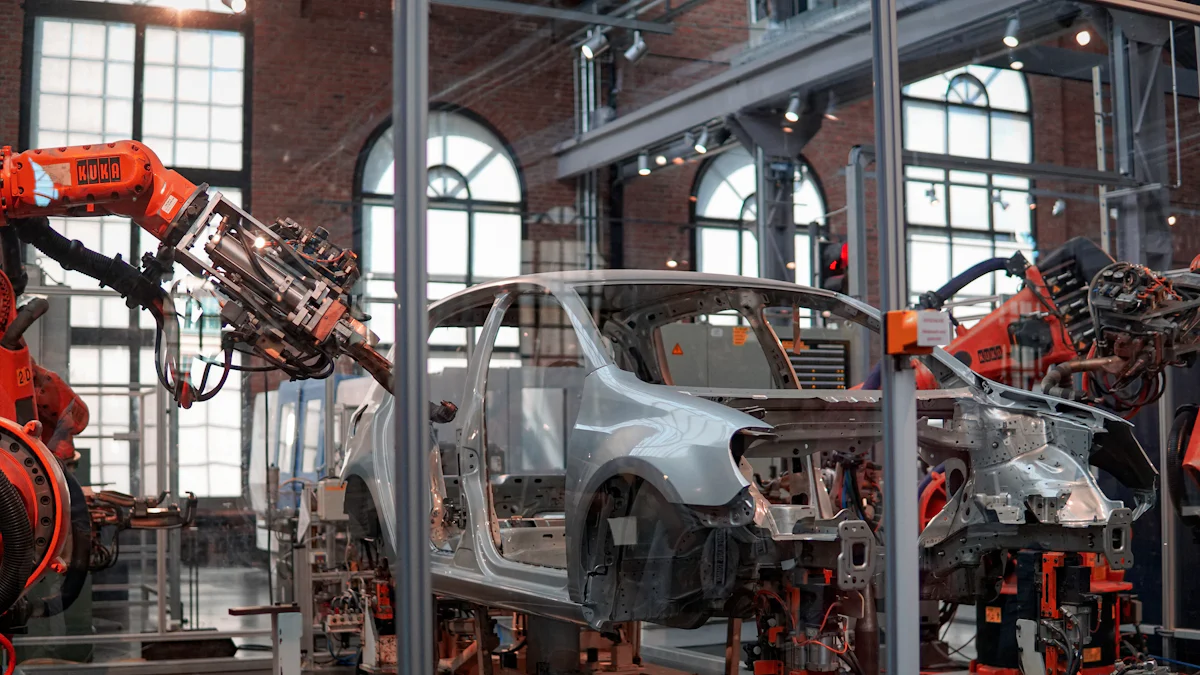

Embracing Automation

The automotive industry is increasingly embracing automation to streamline operations and drive productivity. The benefits of automation are manifold, including improved efficiency, reduced lead times, and enhanced quality control. Through automation technologies such as robotics and artificial intelligence (AI), manufacturers can optimize production processes and minimize errors. Case studies have demonstrated the transformative power of automation in revolutionizing traditional manufacturing practices, leading to cost savings and competitive advantages.

Leveraging AI Technology

Leveraging AI technology is paramount for mitigating risks, enhancing visibility, and improving efficiency in the automotive supply chain. AI-powered solutions offer real-time insights into supply chain dynamics, enabling proactive decision-making and risk management strategies. By harnessing AI algorithms for demand forecasting and inventory optimization, organizations can minimize disruptions and maximize operational performance. The integration of AI technology not only enhances operational efficiency but also empowers organizations to adapt swiftly to market fluctuations.

Case Studies:

End-to-end Visibility: Implementing AI-driven platforms for end-to-end visibility enabled a leading automaker to reduce lead times by 20%.

Data-enabled Decision-making: By leveraging AI analytics tools, a global supplier enhanced its decision-making processes, resulting in a 15% increase in operational efficiency.

AI Risk Mitigation: An automotive manufacturer utilized AI algorithms for risk mitigation strategies during global disruptions, safeguarding its supply chain integrity.

Efficiency Enhancements: Through AI-powered process optimizations, a logistics provider achieved a 30% improvement in overall efficiency.

Future Trends and Technologies

As the automotive industry continues to evolve, the emergence of electric vehicles (EVs) is reshaping the dynamics of the automotive supply chain. The transition towards sustainable and efficient EV supply chains presents both challenges and opportunities for stakeholders across the globe.

Electric Vehicles and Supply Chain Uncertainty

The integration of electric vehicles into the automotive market has a profound impact on the traditional supply chain model. With EVs gaining momentum, manufacturers and suppliers are faced with a paradigm shift that demands innovative solutions to address emerging complexities.

Impact on Supply Chain

The adoption of electric vehicles introduces a series of disruptions to the conventional automotive supply chain. From sourcing raw materials for battery production to reconfiguring assembly lines for EV manufacturing, every aspect of the supply chain undergoes transformation to accommodate the shift towards electrification.

Material Procurement: The demand for lithium-ion batteries in electric vehicles necessitates a strategic approach to sourcing raw materials like lithium, cobalt, and nickel. Suppliers must establish robust supply chains to ensure a steady flow of essential components for battery production.

Manufacturing Processes: Traditional manufacturing processes are being reimagined to align with the unique requirements of electric vehicle production. Manufacturers are investing in advanced technologies and automation systems to enhance efficiency and scalability in EV manufacturing.

Logistics and Distribution: The logistics landscape is evolving to support the distribution of electric vehicles and related components. From charging infrastructure deployment to last-mile delivery solutions, logistics providers are adapting their operations to meet the growing demands of an electrified transportation ecosystem.

Strategies to Mitigate Risks

To navigate the uncertainties associated with electric vehicles in the supply chain, organizations must implement proactive strategies that mitigate risks and capitalize on opportunities presented by this transformative trend.

Diversification of Suppliers: Embracing a diverse supplier base reduces dependency on specific sources, enhancing resilience against potential disruptions in the EV supply chain.

Investment in Innovation: Continuous innovation is key to staying competitive in an evolving market driven by electric vehicle technologies. Organizations that invest in research and development initiatives position themselves as industry leaders poised for long-term success.

Collaborative Partnerships: Building strong partnerships with key stakeholders fosters collaboration and knowledge sharing within the EV supply chain ecosystem. By working closely with suppliers, manufacturers can streamline operations and drive collective growth in an increasingly electrified industry landscape.

Long-term Resilience

Achieving long-term resilience in the face of evolving trends requires a strategic approach centered on innovation, adaptability, and sustainability within the automotive supply chain.

Reimagining the Supply Chain

The transition towards electric vehicles presents an opportunity for organizations to reimagine their existing supply chain models through a lens of sustainability and efficiency. By integrating renewable energy sources, optimizing transportation routes, and embracing circular economy principles, companies can create resilient supply chains capable of meeting future demands while minimizing environmental impact.

Overcoming Challenges

While transitioning towards electrification poses challenges for traditional automotive players, overcoming these obstacles is essential for long-term success in a rapidly changing industry landscape. By addressing issues such as battery technology advancements, charging infrastructure expansion, and regulatory compliance, organizations can proactively tackle challenges head-on and emerge stronger in an era defined by electric mobility.

To ensure operational success in the automotive industry amidst global disruptions and evolving consumer demands, optimizing the supply chain is imperative. By segmenting suppliers strategically, embracing automation, and leveraging AI technology, organizations can enhance efficiency and mitigate risks effectively. Looking ahead, staying responsive to market changes and integrating resilience capabilities will be key for long-term competitiveness and adaptability. Embracing innovation and sustainable practices will drive future developments in the automotive supply chain landscape.

See Also

Expert Advice for Overcoming Automotive Supply Chain Challenges

Tomorrow's Logistics Revolution: AI in the Supply Chain

AI Supply Chain Innovations: Efficiency Unleashed

Revolutionizing the Supply Chain with Robotics Technology

Efficient Solutions for Supply Chain Challenges in High-Tech Manufacturing