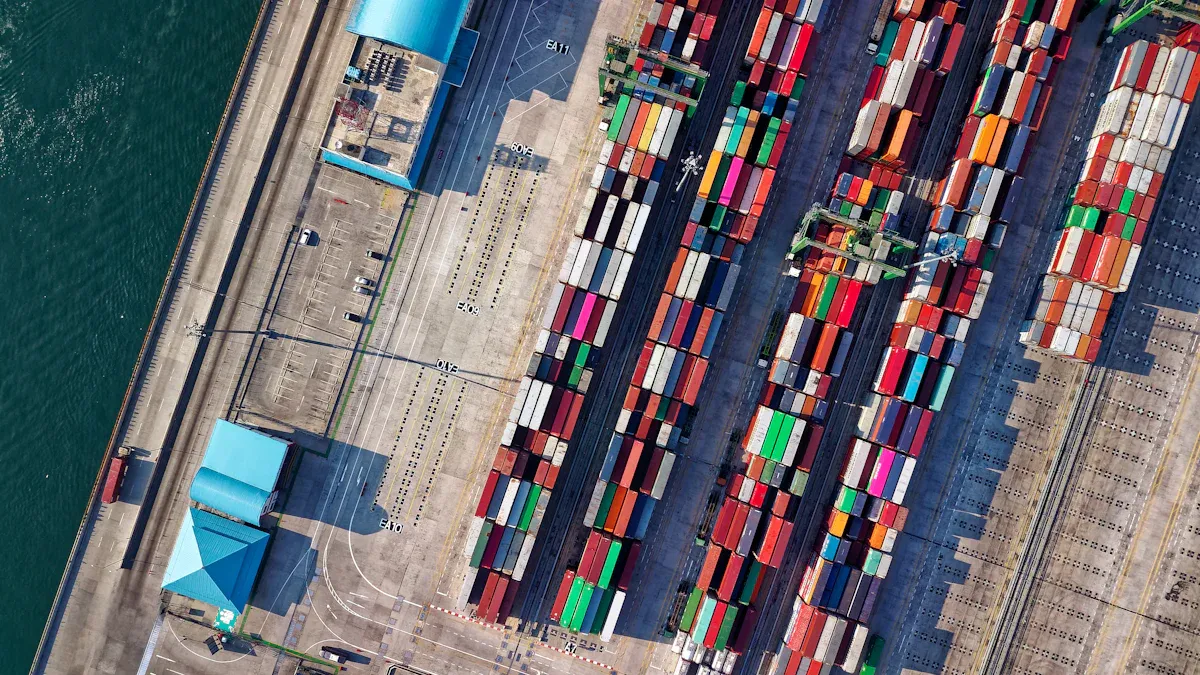

From Forecast to Fulfillment: Generative AI’s Role in Optimizing the Supply Chain Lifecycle

Generative AI’s role is revolutionizing supply chain management by addressing complex challenges and driving efficiency. Its ability to analyze vast datasets and generate predictive insights empowers businesses to make informed decisions. For instance, McKinsey estimates that AI-driven logistics could generate $1.3 trillion to $2 trillion annually over the next two decades. Companies are leveraging this technology to optimize processes across the supply chain lifecycle. Nearly 40% of supply chain organizations are investing in generative AI’s role, particularly for knowledge management, while 62% use it for sustainability tracking. This transformative technology ensures faster, more reliable delivery in an era of rising e-commerce demand.

Generative AI’s Role in Supply Chain Management

What is Generative AI

Generative AI refers to advanced machine learning models capable of creating new content, such as text, images, or simulations, based on patterns in existing data. Unlike traditional AI, which focuses on analyzing and predicting, generative AI produces outputs that mimic human creativity. These models rely on neural networks, such as Generative Adversarial Networks (GANs) and transformers, to process vast datasets and generate realistic results. For example, in supply chain management, generative AI can simulate demand scenarios or optimize production schedules by analyzing historical trends.

Applications of Generative AI Across the Supply Chain Lifecycle

Demand Forecasting and Predictive Insights

Generative AI transforms demand forecasting by analyzing historical data and simulating future scenarios. Businesses use this technology to predict market trends and customer behavior with greater accuracy. For example, it identifies seasonal demand patterns, enabling companies to adjust production schedules proactively.

Generative AI significantly enhances forecasting accuracy by simulating and analyzing numerous scenarios.

It helps businesses anticipate market changes effectively, improving decision-making processes.

Its ability to understand and recreate complex patterns represents a major advancement in demand forecasting.

By leveraging these capabilities, companies can reduce stockouts and overproduction, ensuring a more balanced supply chain. This predictive power allows organizations to stay ahead of market fluctuations and meet customer expectations efficiently.

Inventory Management and Waste Reduction

Effective inventory management is crucial for minimizing waste and optimizing resources. Generative AI plays a pivotal role in this area by analyzing inventory levels and predicting future needs. It helps businesses maintain optimal stock levels, reducing excess inventory and associated costs.

For instance, AI-powered systems can identify slow-moving products and recommend strategies to clear them. Additionally, they can forecast demand spikes, ensuring sufficient stock availability during peak periods. This approach not only reduces waste but also improves cash flow and operational efficiency. Companies that adopt generative AI for inventory management often experience significant cost savings and enhanced sustainability.

Manufacturing and Quality Control

Generative AI enhances manufacturing processes by improving quality control and reducing production inefficiencies. It is applied across all stages of the product life cycle, from design to final inspection. In factories, AI systems detect defects in real-time, ensuring consistent product quality.

Generative AI leads to a 200% improvement in productivity in quality control labs.

It reduces lead times by up to 70%, streamlining production workflows.

Companies like Tesla use generative AI for demand forecasting and material delivery, which enhances quality control.

Additionally, Mahindra & Mahindra employs AI for robot maintenance, troubleshooting machine malfunctions, and reducing equipment downtime. These applications demonstrate how generative AI optimizes manufacturing operations, ensuring higher efficiency and reliability.

Logistics, Route Optimization, and Delivery

Generative AI enhances logistics by optimizing routes and improving delivery efficiency. It analyzes real-time data, such as traffic patterns and weather conditions, to recommend the fastest and most cost-effective delivery routes. Companies use this technology to reduce fuel consumption, minimize delays, and improve customer satisfaction. For example, AI-powered systems can dynamically reroute delivery trucks during traffic congestion, ensuring on-time deliveries.

Route optimization also plays a critical role in reducing carbon emissions. By identifying the shortest paths and consolidating shipments, businesses achieve significant environmental benefits. A logistics company using generative AI reported a 15% reduction in delivery times and a 20% decrease in fuel costs. These improvements not only enhance operational efficiency but also align with sustainability goals.

Generative AI’s role extends to last-mile delivery, where it predicts delivery windows with high accuracy. This capability allows businesses to provide customers with precise updates, improving trust and loyalty. As e-commerce demand grows, generative AI ensures that logistics operations remain scalable and reliable.

Risk Management and Disruption Mitigation

Supply chains face constant risks, including natural disasters, geopolitical tensions, and pandemics. Generative AI helps businesses mitigate these disruptions by analyzing vast datasets and identifying potential vulnerabilities. It simulates various scenarios, enabling companies to prepare contingency plans and respond swiftly to unexpected events.

Several organizations have successfully leveraged generative AI for risk management. IBM transformed its supply chain during the COVID-19 pandemic, achieving a 100% order fulfillment rate while significantly reducing costs. Similarly, a global automotive manufacturer used AI to analyze over 80 data sources, reducing inventory levels by 35% and increasing service reliability by 65%.

Generative AI also enhances visibility across the supply chain. By monitoring supplier performance and tracking shipments in real time, it identifies bottlenecks and suggests corrective actions. A consumer goods company employed AI-driven demand forecasting during the pandemic, allowing for rapid adjustments to production and distribution strategies. This approach minimized revenue losses and ensured business continuity.

By integrating generative AI into risk management strategies, businesses build more resilient supply chains capable of withstanding disruptions.

Challenges in Adopting Generative AI

Data Security and Privacy Concerns

Generative AI relies on vast amounts of data, often including sensitive information, which raises significant security and privacy concerns. The Federal Trade Commission (FTC) has highlighted issues with companies using consumer data for AI development without explicit consent. Transparency and user consent are critical to addressing these challenges.

Organizations face risks such as data leaks, unauthorized access, and exploitation of AI models by malicious actors. Strong access controls and regular risk assessments are essential to mitigate these threats. Employee education on cybersecurity also plays a vital role in safeguarding sensitive information.

Note: Companies must comply with regulations requiring user consent for biometric data usage and delete algorithms trained without proper authorization. These measures ensure ethical AI practices and protect consumer trust.

Talent Shortages and Expertise Gaps

The rapid growth of generative AI has outpaced the availability of skilled professionals, creating a significant talent gap. AI-related job postings have increased by 21% annually since 2019, yet 43% of tech leaders rate their employees' AI skills as low. This shortage hinders businesses from fully leveraging AI's potential.

Compensation for AI roles has risen by 11% annually, reflecting the high demand for expertise. However, one-third of tech leaders identify hiring skilled AI professionals as a primary challenge. Without the right talent, companies struggle to transition from ambition to implementation. Sarah Elk from Bain & Co. emphasizes that this gap limits innovation and competitiveness, with the issue expected to persist until 2027.

Tip: Businesses can address this challenge by investing in upskilling programs and collaborating with academic institutions to nurture future talent.

Regulatory and Ethical Challenges

Generative AI introduces significant regulatory and ethical challenges, especially in supply chain management. Governments and organizations face difficulties in creating policies that keep pace with the rapid evolution of AI technologies. These challenges stem from the need to balance innovation with accountability and fairness.

1. Lack of Clear Regulations

Many countries lack comprehensive regulations for AI applications. This absence creates uncertainty for businesses adopting generative AI. For example, companies may struggle to determine whether their AI systems comply with existing data protection laws, such as the General Data Protection Regulation (GDPR) in Europe.

Note: Non-compliance with regulations like GDPR can result in fines of up to €20 million or 4% of annual global turnover, whichever is higher.

2. Bias and Fairness Issues

Generative AI models often inherit biases from the data used to train them. These biases can lead to unfair outcomes, such as favoring certain suppliers or regions over others. For instance, an AI system might prioritize suppliers from wealthier countries due to biased historical data, disadvantaging smaller or developing markets.

3. Accountability and Transparency

AI systems operate as "black boxes," making it difficult to understand how they arrive at decisions. This lack of transparency raises accountability concerns. If an AI-driven decision leads to a supply chain disruption, determining responsibility becomes challenging.

4. Ethical Use of Data

Generative AI relies on vast amounts of data, often collected from various sources. Ethical concerns arise when businesses use data without proper consent. For example, using customer data to train AI models without informing users violates privacy rights.

Challenge | Impact |

|---|---|

Lack of Regulations | Creates uncertainty and increases compliance risks. |

Bias in AI Models | Leads to unfair decisions and potential reputational damage. |

Transparency Issues | Makes it hard to hold systems accountable for errors or unethical actions. |

Data Privacy Violations | Erodes customer trust and exposes businesses to legal penalties. |

To address these challenges, businesses must adopt ethical AI practices. They should prioritize transparency, ensure data fairness, and comply with evolving regulations. Collaboration with policymakers and industry experts can also help establish robust frameworks for responsible AI use.

Callout: Ethical AI adoption is not just a regulatory requirement; it is a competitive advantage in building trust and long-term success.

Steps to Implement Generative AI in Supply Chains

Build a Robust Data Ecosystem

A robust data ecosystem is essential for generative AI to perform effectively. High-quality data ensures accurate predictions and reliable insights. Key practices for building this ecosystem include:

Integrating generative AI into data quality management to enhance accuracy and efficiency.

Transforming unstructured data into numerical formats for meaningful insights extraction.

Developing scalable data pipelines to enable real-time data access for AI applications.

Monitoring and optimizing AI systems to improve accuracy and robustness.

Empirical studies highlight the strong relationship between AI and ecosystem-based business models. For example, a retail company improved forecasting accuracy by 30% after implementing scalable data pipelines. Additionally, established evaluation regimes from other industries provide valuable lessons for ensuring the reliability of generative AI systems.

Note: Investing in data infrastructure not only supports AI adoption but also strengthens overall organizational efficiency.

Collaborate with AI Experts and Partners

Collaborating with AI experts and technology partners accelerates the successful implementation of generative AI in supply chains. These partnerships bring specialized knowledge and tools that enhance operational efficiency and innovation. Businesses benefit from:

Accelerated Time-to-Use: Experts prototype and deploy AI solutions quickly, delivering faster results.

Access to Advanced Expertise and Tools: Companies leverage cutting-edge AI frameworks to optimize supply chain processes.

Optimal Use of Data Infrastructure: Skilled professionals design efficient data pipelines, ensuring seamless data flow and analysis.

Enhanced Security and Compliance: Tech partners implement robust security measures and adhere to regulatory standards, safeguarding sensitive information.

AI partnerships also improve supply chain visibility and performance. Intelligent algorithms analyze large datasets to provide insights into logistics networks. This capability enhances transparency, traceability, and bottleneck management. For example, AI tools outperform traditional systems in tracking supplies in real time, enabling businesses to address delays proactively.

Tip: Collaborating with AI experts ensures that businesses maximize the potential of generative AI while minimizing risks. These partnerships create a foundation for long-term success in an increasingly competitive market.

Monitor, Measure, and Iterate for Success

Monitoring and measuring performance are critical for ensuring the success of generative AI in supply chains. Businesses must track key metrics to evaluate the effectiveness of AI models and identify areas for improvement. Common metrics include:

Metric Type | Description |

|---|---|

Model Accuracy | Measures the proportion of correct predictions made by the AI model. |

Precision | Evaluates the proportion of true positives among all positive predictions. |

Recall | Assesses the proportion of true positives among all actual positives. |

F1 Score | Balances precision and recall to provide a comprehensive performance measure. |

AUC-ROC | Indicates the likelihood of the model ranking a random positive instance higher than a negative one. |

Domain-Specific Metrics | Includes on-time delivery rates, inventory turnover, and order fulfillment times. |

Model Training Time | Tracks the time required to train the AI model, reflecting efficiency. |

Data Drift | Monitors changes in input data distribution over time. |

Prediction Drift | Tracks variations in the model’s output distribution. |

Model Stability | Evaluates the consistency of the model’s performance over time. |

Iterative improvement is essential for maintaining AI effectiveness. Businesses should regularly assess these metrics and refine their models to adapt to changing conditions. For instance, monitoring data drift helps identify when retraining is necessary to maintain accuracy.

Note: Continuous monitoring and iteration ensure that AI systems remain reliable and aligned with business objectives. This approach fosters resilience and adaptability in dynamic supply chain environments.

Generative AI’s role has redefined supply chain management by enhancing efficiency, sustainability, and customer satisfaction. Its ability to optimize processes across the lifecycle ensures businesses remain competitive in dynamic markets. Strategic implementation is crucial for long-term success. Companies must align AI initiatives with organizational goals, prioritize impactful use cases, and build robust data ecosystems.

Future trends highlight the transformative potential of generative AI. By 2024, half of supply chain organizations will invest in AI-driven analytics. By 2035, autonomous supply chains powered by generative AI will dominate industries, enabling faster and more sustainable product delivery. These advancements promise a future where supply chains operate with unprecedented precision and resilience.

FAQ

Is generative AI expensive to implement?

The cost of implementing generative AI depends on the scale and complexity of the project. While initial investments may seem high, businesses often achieve significant cost savings through improved efficiency, reduced waste, and better decision-making.

What data is required for generative AI in supply chains?

Generative AI requires high-quality data, including historical demand, inventory levels, supplier performance, and logistics information. Clean, structured data ensures accurate predictions and reliable insights, making it essential for successful AI implementation.

Can small businesses adopt generative AI for supply chains?

Small businesses can adopt generative AI by starting with scalable, cloud-based solutions. These tools offer cost-effective ways to optimize inventory, forecast demand, and improve logistics. Partnering with AI experts can further simplify the adoption process.

See Also

Exploring AI's Role in Shaping Future Supply Chains

Enhancing Supply Chain Performance Through AI Innovations

Transforming Logistics for Tomorrow with AI Supply Chains

Leveraging Big Data to Innovate Supply Chain Management

Turning Data Into Insights for Automotive Demand Forecasting