How to Make Your Warehouse the Backbone of Your Supply Chain

A warehouse serves as the warehouse backbone of a successful supply chain, ensuring seamless operations and strategic alignment with business goals. By optimizing warehousing processes, businesses can enhance efficiency, reduce costs, and improve customer satisfaction. Efficient warehousing not only minimizes lead times but also mitigates risks associated with inventory mismanagement. Modern warehouses go beyond storage, acting as hubs for inventory tracking, order fulfillment, and operational planning. This pivotal role in supply chain management highlights the importance of designing workflows that maximize productivity and scalability. A well-structured warehouse empowers businesses to adapt to market demands while driving sustainable growth.

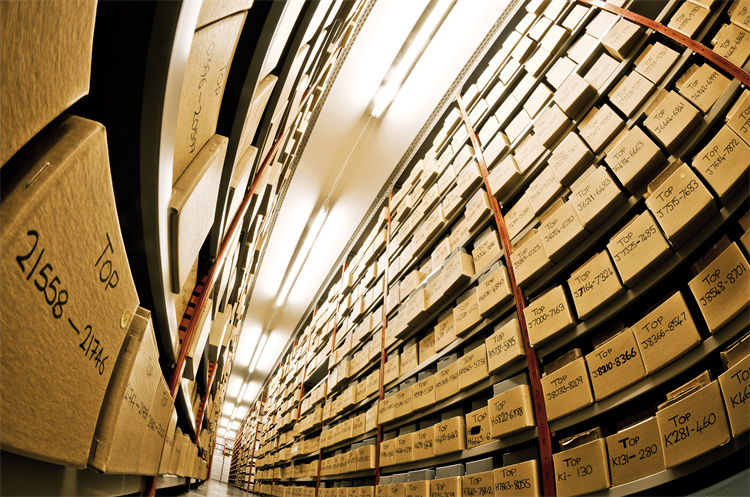

The Role of a Warehouse Backbone in the Supply Chain

A warehouse serves as the cornerstone of any effective supply chain, ensuring that goods flow seamlessly from production to the end customer. By acting as a centralized hub, it supports inventory management, order fulfillment, and supply chain efficiency.

How Warehousing Supports Supply Chain Efficiency

Warehousing plays a pivotal role in streamlining supply chain operations. It ensures that inventory is stored, tracked, and managed efficiently, reducing the likelihood of errors such as stockouts or overstocking. A well-organized warehouse minimizes lead times by enabling faster picking, packing, and shipping processes. This efficiency not only meets customer demands promptly but also reduces operational costs.

"Optimized warehouses refine operations for maximum efficiency and profitability, avoiding financial losses due to mis-ships, out-of-stocks, and returns."

Additionally, warehousing enhances visibility across the supply chain. By tracking inbound and outbound shipments, businesses can maintain better control over their logistics. This visibility helps mitigate risks, such as delays or disruptions, ensuring that the supply chain remains resilient and adaptable to market changes.

Key Benefits of a Successful Warehouse Setup

A successful warehouse setup offers numerous advantages that directly impact business performance and customer satisfaction.

Enhancing Operational Efficiency

An optimized warehouse improves the organization and flow of operations. Efficient workflows reduce the time required to complete orders, making it easier for employees to perform their tasks effectively. By streamlining processes at every stage, businesses can lower operational expenses and minimize waste. For example, proper inventory organization ensures that products are easily accessible, reducing the time spent searching for items.

Enabling Scalability and Flexibility

A well-structured warehouse adapts to changing business needs. Scalability allows businesses to handle increased demand during peak seasons without compromising efficiency. Flexible warehousing solutions, such as dynamic storage systems, accommodate diverse product types and sizes. This adaptability ensures that businesses remain competitive in a rapidly evolving market.

Aligning with Strategic Business Objectives

Warehousing aligns closely with broader business goals by supporting cost reduction and revenue growth. By storing goods for later use, warehouses help stabilize prices and mitigate revenue losses caused by supply chain disruptions. Furthermore, efficient warehousing operations enhance customer satisfaction by ensuring timely deliveries and accurate order fulfillment.

"Optimized warehousing operations lower operational expenses, reduce shipping costs, and minimize costs related to product returns and exchanges."

Designing a Successful Warehouse Setup

A well-designed warehouse setup forms the foundation for efficient warehousing operations. By focusing on layout principles and effective storage systems, businesses can maximize productivity, reduce operational costs, and ensure seamless inventory management. Proper planning and execution in this area enable companies to meet customer demands while maintaining flexibility for future growth.

Principles of Effective Warehouse Layout

Optimizing Space Utilization

Optimizing space utilization is critical for enhancing warehouse efficiency. Businesses should evaluate their available space and allocate it strategically to accommodate inventory and operational needs. For instance, high-density storage systems, such as pallet racking or mezzanine floors, can help maximize vertical space. This approach minimizes wasted areas and ensures that every square foot contributes to operational goals.

"Properly using warehouse space can reduce travel time, enhance inventory visibility, and improve operational efficiency during the design phase." – QMH Inc.

Additionally, implementing a Warehouse Management System (WMS) can assist in optimizing space utilization. A WMS analyzes inventory data to determine the best locations for storing items based on size, weight, and picking frequency. This digital solution not only improves space allocation but also enhances overall warehouse performance.

Streamlining Workflows for Productivity

Streamlined workflows are essential for maintaining high productivity levels in warehousing. A well-organized layout reduces unnecessary movement and ensures that employees can access inventory quickly. For example, placing frequently picked items closer to packing stations minimizes travel time and accelerates order fulfillment.

Businesses should also design clear pathways for equipment and personnel to prevent bottlenecks. Allocating dedicated zones for receiving, storage, and shipping activities further enhances workflow efficiency. These measures create a structured environment where tasks are completed with precision and speed.

Zoning and Storage Systems for Inventory Management

Organizing Inventory for Accessibility

Effective inventory organization ensures that products are easily accessible when needed. Strategic zoning divides the warehouse into specific areas based on product categories, demand levels, or storage requirements. Fast-moving items should occupy prime locations near dispatch zones, while slower-moving goods can be stored in less accessible areas.

"Strategic placement of inventory ensures fast-moving items are easily accessible, optimizing storage for slower-moving products." – AutoStore System Insights

Labeling systems and digital tools, such as barcode scanners, further enhance accessibility. These technologies enable employees to locate items quickly, reducing errors and improving order accuracy.

Implementing Dynamic Storage Solutions

Dynamic storage solutions provide the flexibility needed to adapt to changing inventory demands. Systems like adjustable shelving or automated storage and retrieval systems (AS/RS) allow businesses to accommodate various product sizes and shapes. This adaptability ensures that the warehouse remains efficient even as inventory profiles evolve.

Flexible storage solutions also support seasonal fluctuations by enabling rapid reconfiguration of storage spaces. For instance, during peak seasons, businesses can allocate additional space for high-demand products without disrupting existing workflows. This approach ensures that warehousing operations remain agile and responsive to market changes.

"Transitioning to digital systems like Warehouse Management Software (WMS) improves inventory management, reduces overstock, and streamlines order fulfillment." – Material Handling Solutions Blog

By combining strategic zoning with dynamic storage solutions, businesses can create a robust inventory management system that supports long-term success.

Best Practices for Warehouse Management

Effective warehouse management is essential for ensuring seamless operations and meeting customer expectations. By leveraging technology, implementing robust inventory management strategies, and investing in workforce training, businesses can optimize warehouse operations and drive long-term success.

Leveraging Technology in Warehousing Supply Chain

Benefits of Warehouse Management Systems (WMS)

These systems streamline warehouse operations by automating tasks such as inventory tracking, picking, and packing. By centralizing inventory data, WMS enhances operational efficiency and reduces errors. Businesses benefit from improved order fulfillment accuracy which directly impacts customer satisfaction and best practices.

"WMS provides real-time visibility into inventory levels, enabling businesses to make informed decisions and optimize their supply chain operations."

Additionally, WMS integrates with other systems, such as Enterprise Resource Planning (ERP) software, to ensure synchronization between inventory and order information. This integration minimizes manual data entry and accelerates the fulfillment process. By adopting WMS, businesses can reduce operational costs and improve overall productivity.

Role of Automation and Robotics in Operations

Automation and robotics play a pivotal role in transforming warehouse operations. Automated tracking systems, such as barcode scanners and RFID technology, enhance inventory accuracy and reduce the time spent on manual tasks. Robotics, including automated guided vehicles (AGVs) and robotic arms, streamline picking and packing processes, ensuring faster order fulfillment.

Smart warehousing solutions leverage automation to handle repetitive tasks, allowing employees to focus on more strategic activities. For instance, automated storage and retrieval systems (AS/RS) optimize space utilization and improve inventory accessibility. These technologies not only boost efficiency but also enhance safety by minimizing human intervention in hazardous tasks.

"Automation in warehousing reduces operational bottlenecks, improves accuracy, and ensures scalability during peak demand periods."

Inventory Management Strategies

Real-Time Tracking and Monitoring

Real-time tracking is pivotal in managing inventory effectively. By using advanced systems, businesses can monitor inventory levels and movements with precision. This approach ensures that stock discrepancies are identified and resolved promptly, reducing the risk of stockouts or overstocking.

"Real-time visibility into inventory enables businesses to respond quickly to market demands and maintain optimal stock levels."

Digital tools, such as WMS and IoT-enabled devices, provide accurate data on inventory status. These tools help businesses track inbound and outbound shipments, ensuring smooth operations across the supply chain. Real-time tracking also supports better decision-making by offering actionable insights into inventory trends.

Demand Forecasting for Stock Optimization

Demand forecasting is a critical component of inventory management. By analyzing historical data and market trends, businesses can predict future demand and adjust their inventory levels accordingly. This proactive approach minimizes excess stock and reduces carrying costs.

"Accurate demand forecasting ensures that businesses maintain the right inventory levels, optimizing storage space and improving cash flow."

Advanced analytics tools integrated with WMS enable businesses to forecast demand with greater accuracy. These tools consider factors such as seasonal fluctuations and consumer behavior, helping businesses align their inventory with market needs. Effective demand forecasting enhances order fulfillment rates and prevents disruptions in the supply chain.

Workforce Training for a Successful Warehouse Setup

Developing Skilled Labor for Warehouse Operations

A skilled workforce is essential for efficient warehouse operations. Employees must understand the systems and processes involved in inventory management, order fulfillment, and equipment handling. Regular training programs ensure that workers stay updated on the latest technologies and best practices.

"Investing in workforce development enhances operational efficiency and reduces the likelihood of errors in warehousing tasks."

Hands-on training sessions and workshops help employees gain practical experience in using tools like WMS and automated systems. Skilled labor not only improves productivity but also contributes to a safer working environment.

Training Programs to Enhance Safety and Efficiency

Safety is a top priority in warehouse management. Comprehensive training programs educate employees on proper equipment usage, hazard identification, and emergency response protocols. These programs reduce workplace accidents and ensure compliance with safety regulations.

"Well-trained employees contribute to a safer and more efficient warehouse environment, minimizing downtime caused by accidents."

Efficiency-focused training emphasizes time management, workflow optimization, and teamwork. By fostering a culture of continuous learning, businesses can build a resilient workforce capable of adapting to evolving operational demands.

Strategies for Future-Proofing Your Warehouse

Future-proofing a warehouse ensures its ability to adapt to evolving business demands and technological advancements. By embracing emerging technologies, building scalable models, and adopting sustainable practices, businesses can maintain operational efficiency and remain competitive in the dynamic logistics landscape.

Embracing Emerging Technologies in Warehousing

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are revolutionizing warehousing by enabling data-driven decision-making. AI-powered analytics platforms process vast amounts of data to optimize warehouse layouts, predict inventory demand, and enhance operational workflows. These technologies reduce inefficiencies and improve accuracy in inventory management.

Machine learning algorithms identify patterns in historical data, allowing businesses to forecast demand with precision. This predictive capability minimizes overstocking and stockouts, ensuring that inventory levels align with market needs. AI also supports automation by powering robotic systems that handle repetitive tasks, such as picking and packing, with speed and accuracy.

"AI-driven analytics platforms analyze data from connected devices to optimize warehouse layout, predict demand, and enhance inventory management." – GlobeNewswire

Internet of Things (IoT) for Warehouse Optimization

The Internet of Things (IoT) transforms warehousing by connecting devices and systems for real-time data exchange. IoT-enabled sensors and RFID tags track inventory movements, providing accurate and up-to-date information on stock levels. This visibility enhances inventory control and reduces errors in order fulfillment.

Automated guided vehicles (AGVs) and robotic systems integrated with IoT sensors streamline the movement of goods within warehouses. These technologies reduce reliance on manual labor and improve operational efficiency. IoT also supports predictive maintenance by monitoring equipment performance, minimizing downtime, and extending the lifespan of machinery.

"Advancements in RFID and Bluetooth Low Energy (BLE) beacons are improving real-time asset tracking, ensuring that goods are accurately located and managed throughout the supply chain." – GlobeNewswire

Building a Scalable and Flexible Warehouse Model

Preparing for Business Growth and Market Changes

A scalable and flexible warehouse model allows businesses to adapt to growth and fluctuating market demands. Scalability ensures that the warehouse can accommodate increased inventory during peak seasons without compromising efficiency. Flexible storage solutions, such as adjustable shelving and modular layouts, support diverse product types and sizes.

Businesses should design warehouses with future expansion in mind. Allocating space for additional storage or integrating automation systems ensures readiness for growth. Flexibility in warehousing operations enables companies to respond swiftly to market changes, maintaining a competitive edge in the industry.

"Automation helps reduce manual errors, speed up processes, and increase overall efficiency." – B-eye

Sustainability in Warehouse Operations

Reducing Energy Consumption

Sustainable warehousing practices prioritize energy efficiency to minimize environmental impact. Installing energy-efficient lighting systems, such as LED fixtures, reduces electricity consumption. Optimizing HVAC systems and using renewable energy sources, like solar panels, further decrease energy usage.

Smart energy management systems monitor and control energy consumption in real time. These systems identify areas of inefficiency and recommend adjustments to reduce waste. By adopting energy-saving measures, businesses lower operational costs while contributing to environmental conservation.

Implementing Eco-Friendly Practices

Eco-friendly practices in warehousing promote sustainability and reduce carbon footprints. Using recyclable packaging materials and minimizing waste generation align with green initiatives. Businesses can also implement water-saving technologies and adopt environmentally friendly cleaning products.

Sustainable transportation methods, such as electric vehicles for deliveries, complement eco-friendly warehousing efforts. These practices enhance a company’s reputation as an environmentally responsible organization, attracting customers who value sustainability.

"Sustainable practices in warehousing not only reduce environmental impact but also improve operational efficiency and cost-effectiveness." – Material Handling Solutions Blog

A warehouse remains the backbone of a robust supply chain, driving efficiency and ensuring seamless operations. By optimizing warehouse layout, businesses can enhance storage capacity, streamline workflows, and improve the flow of goods. Effective warehousing management integrates advanced technologies, skilled labor, and strategic inventory practices to boost productivity and reduce costs. Companies that adopt innovative warehousing solutions position themselves for long-term growth and adaptability. Prioritizing warehouse optimization not only strengthens supply chain performance but also fosters customer satisfaction and operational excellence.

See Also

The Importance of Automating Your Warehouse Operations

Boosting Warehouse Efficiency with Robotics in Logistics

Maximizing Your Automotive Supply Chain's Full Potential

Transforming Future Logistics with AI in Supply Chains

Understanding Robotic Automation for Enhanced Warehouse Efficiency