Warehouse/DC Automation & Technology: Time to Gain A Competitive Advantage

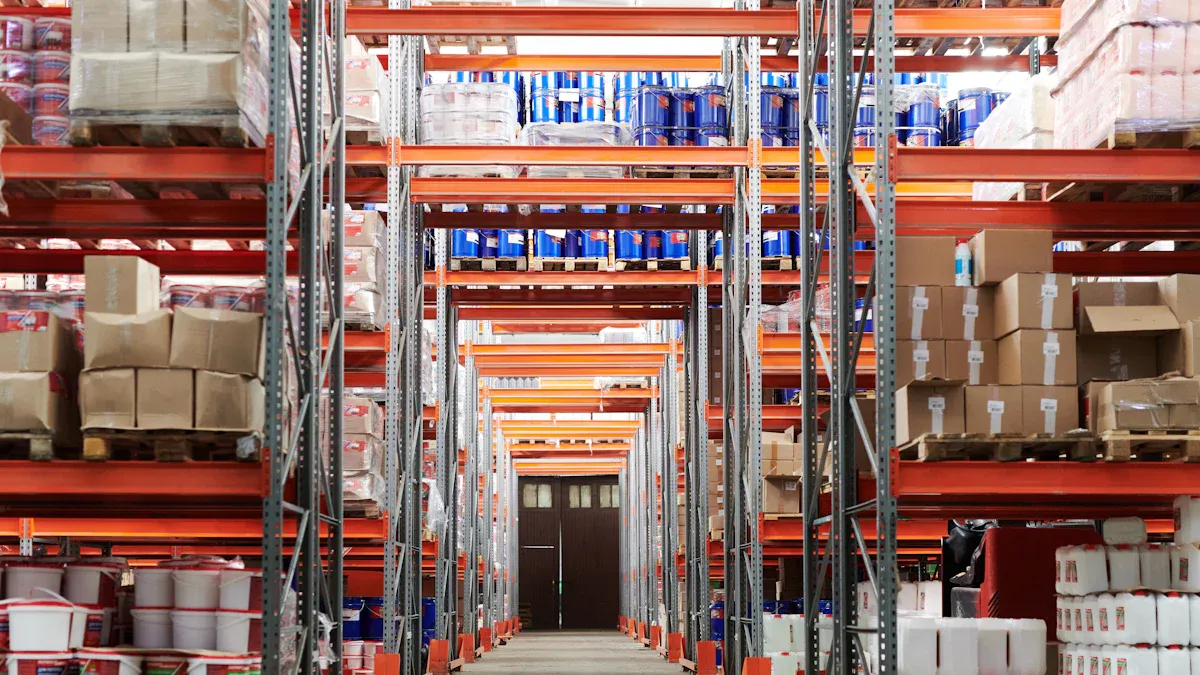

In today’s fast-paced logistics world, staying competitive means embracing Warehouse/DC Automation. The rise of e-commerce and consumer demand for faster deliveries has made automation a necessity. Companies are turning to advanced technologies to solve labor shortages and improve efficiency.

Robotics now handle repetitive tasks, freeing workers to focus on complex roles.

Real-time inventory tracking ensures accurate decisions and prevents delays.

AI-powered demand forecasting helps businesses adapt to market changes with ease.

By adopting automation, you can future-proof operations and gain a critical edge in this evolving landscape.

Key Takeaways

Use Warehouse/DC Automation to work faster and get more done. Automation cuts down on manual work, letting your team focus on bigger goals.

Solve worker shortages by using robots for simple, repeated tasks. This makes work smoother and helps keep skilled workers happy.

Track inventory in real-time to avoid running out of stock. It also makes orders more accurate and keeps customers happy while saving money.

Add automation step by step. Start small with test programs, gather ideas, and slowly grow to avoid problems.

Train workers to use new technology. Learning new skills makes employees feel good and helps the switch to automation go smoothly.

Challenges Facing Warehouses and Distribution Centers

Labor Shortages and Retention Issues

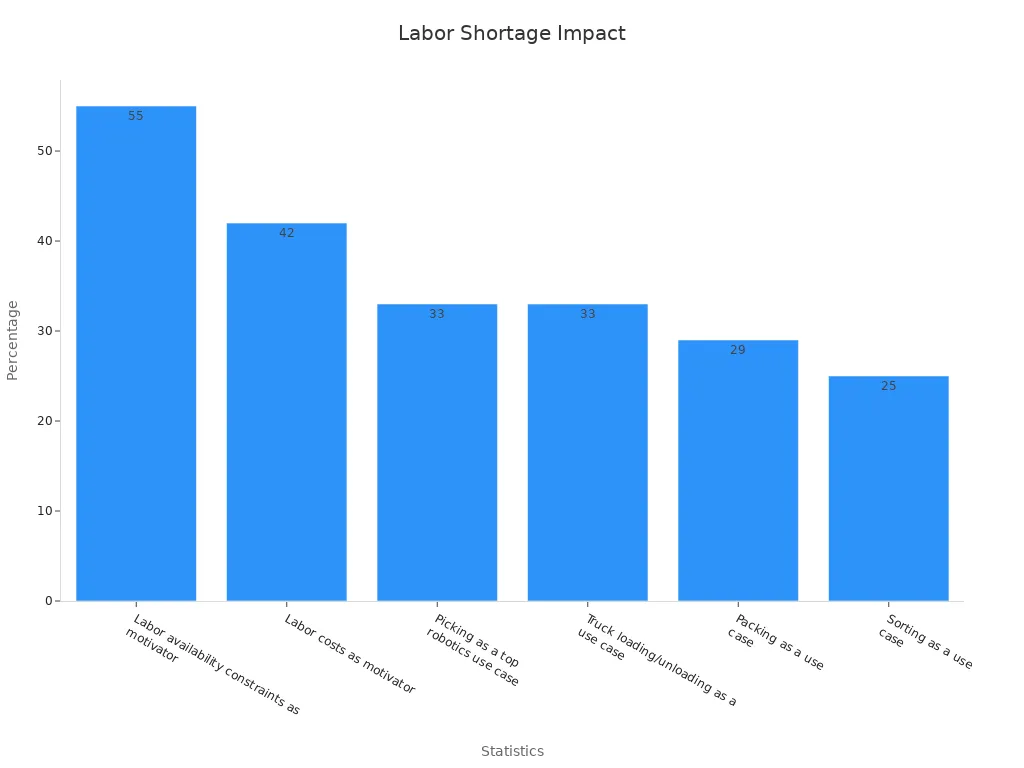

Labor shortages remain one of the most pressing challenges for warehouses and distribution centers. You may find it increasingly difficult to hire and retain skilled workers, especially during peak seasons. A recent survey revealed that 55% of operations cite labor availability constraints as a key motivator for adopting automation. Labor costs also account for 42% of the motivation to automate, highlighting the financial strain caused by workforce shortages.

To address these challenges, many facilities are turning to robotics for tasks like picking (33%), truck loading/unloading (33%), and packing (29%). These technologies not only reduce dependency on manual labor but also improve operational efficiency.

Rising Costs and Budget Constraints

Operational costs are rising, and budget constraints are becoming more common. Labor costs alone can make up nearly 65% of your total warehouse budget. Inefficiencies, such as underutilized warehouse capacity (averaging only 68%), further strain resources. Delays in receiving and putaway processes often lead to higher labor costs and reduced productivity.

You may also face challenges like congestion at docks, which occurs when receiving and putaway teams lack coordination. This results in increased costs and slower order processing. Addressing these inefficiencies through Warehouse/DC Automation can help you optimize workflows and reduce expenses.

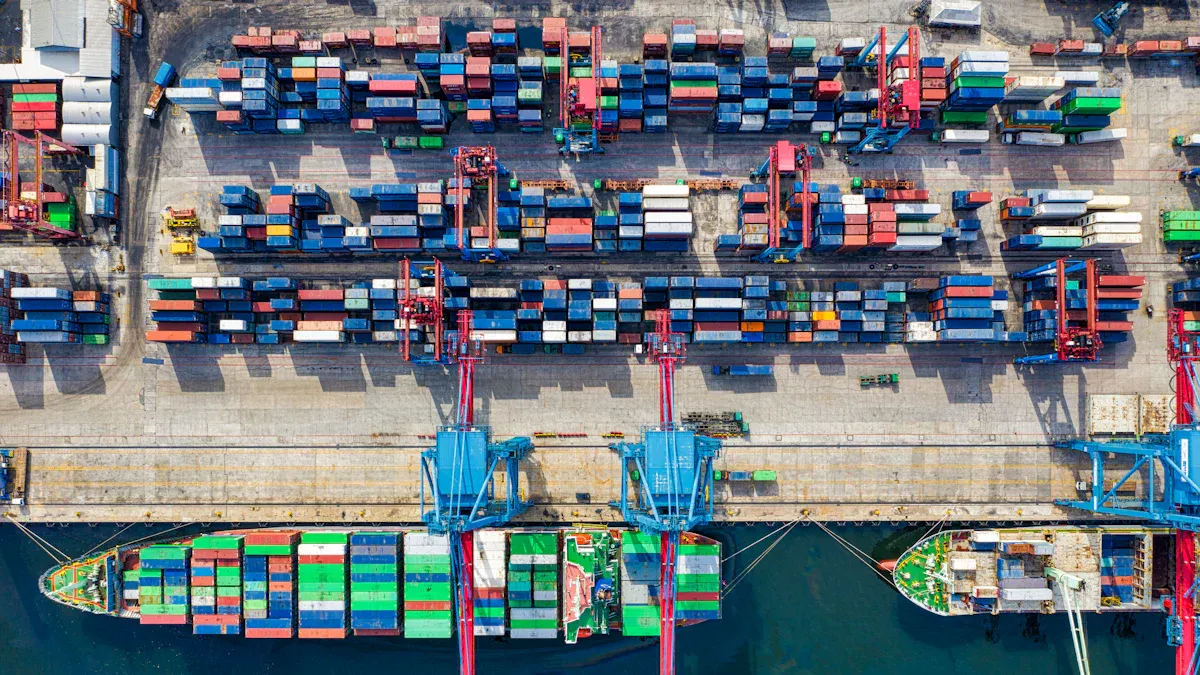

Supply Chain Complexities and Congestion

The modern supply chain is more complex than ever. You must navigate issues like port delays, fluctuating demand, and limited storage space. These factors contribute to congestion in key areas of your warehouse, such as storage (30%), receiving (22%), and shipping (20%).

Metrics like order lead time and backorder rate highlight the impact of these challenges. For example, a high backorder rate indicates inventory management issues, while long order lead times can frustrate customers. By leveraging automation, you can streamline processes and adapt to these complexities more effectively.

Metric | Description |

|---|---|

Order Lead Time | Measures the average time it takes for an order to reach a client after being placed. |

Perfect Order Rate | Indicates the percentage of orders delivered without errors, reflecting operational efficiency. |

Back Order Rate | Tracks the rate of orders for out-of-stock items, highlighting inventory management issues. |

Picking Accuracy | Measures the percentage of orders picked and packed correctly, essential for reducing errors. |

Labor and Equipment Utilization | Indicates how effectively workforce and equipment are used in fulfilling orders. |

Meeting E-Commerce and Customer Expectations

E-commerce has revolutionized the way customers shop, creating new challenges for warehouses and distribution centers. Customers now expect faster deliveries, real-time tracking, and error-free orders. Meeting these demands requires you to rethink traditional operations and embrace innovative solutions.

The rapid growth of e-commerce has placed immense pressure on warehousing operations. A study from MIT's Center for Transportation & Logistics predicts that by 2026, warehouses will undergo significant transformations driven by automation and digitalization. This shift is essential for businesses to stay competitive. Additionally, with global e-commerce sales projected to reach $4.9 trillion, the need for efficient last-mile logistics has never been greater.

To meet these heightened expectations, you can leverage Warehouse/DC Automation to streamline processes and improve accuracy. Automated systems, such as robotic picking and packing, ensure faster order fulfillment while reducing errors. Real-time inventory tracking allows you to maintain stock levels and avoid backorders, keeping customers satisfied.

Another critical factor is scalability. As e-commerce continues to grow, your warehouse must adapt to handle fluctuating order volumes. Automation provides the flexibility to scale operations up or down based on demand. This adaptability not only enhances efficiency but also ensures you can meet customer expectations during peak seasons.

By adopting these technologies, you can transform your warehouse into a high-performing operation. Automation not only helps you meet customer demands but also positions your business for long-term success in the competitive e-commerce landscape.

Competitive Advantages of Warehouse/DC Automation

Boosting Efficiency and Productivity

Warehouse/DC Automation significantly enhances efficiency and productivity by streamlining operations and reducing manual intervention. Automated systems handle repetitive tasks like picking, packing, and sorting, allowing you to focus on strategic activities. For instance, robotics can process orders faster than human workers, ensuring quicker turnaround times.

Automation also improves accuracy, minimizing errors in order fulfillment. This leads to fewer returns and higher customer satisfaction. Consider the following benefits:

Benefit Category | Description |

|---|---|

Automation solutions improve order accuracy, reducing return rates and increasing customer satisfaction. | |

Increased Efficiency | Automation speeds up warehouse processes, handling tasks faster than human workers. |

Cost Savings | Long-term savings can be substantial, with positive ROI often achieved in 12–18 months. |

By implementing these technologies, you can achieve faster workflows, reduce bottlenecks, and maintain a competitive edge in the logistics industry.

Reducing Costs and Maximizing ROI

Adopting Warehouse/DC Automation offers substantial cost-saving opportunities while maximizing your return on investment (ROI). Automated systems reduce dependency on manual labor, leading to significant labor cost reductions. Additionally, these systems optimize space utilization, potentially lowering facility costs.

Here are some key financial advantages:

Labor Reengineering: Automation reduces manual labor costs by automating routine tasks.

Mitigation of Errors: Improved accuracy decreases costs related to returns and replacements.

Optimized Space Utilization: Automated systems maximize warehouse space, leading to potential savings on facility costs.

Moreover, automation delivers measurable ROI through metrics like simple payback, net present value (NPV), and internal rate of return (IRR). For example:

Simple Payback: Time taken to recover the initial investment.

Net Present Value (NPV): The value of future cash flows discounted back to present value.

Internal Rate of Return (IRR): The rate at which the net present value of costs equals the net present value of benefits.

These financial benefits make automation a strategic investment for long-term success.

Enhancing Safety and Employee Satisfaction

Warehouse/DC Automation not only improves operational efficiency but also enhances workplace safety and employee satisfaction. Automated systems reduce the risk of workplace injuries by handling physically demanding tasks. This creates a safer environment for your workforce.

Ergonomics play a crucial role in preventing injuries and enhancing worker comfort. By providing ergonomic solutions and proper safety protocols, you can ensure workers are less fatigued and more focused on their tasks. Additionally, automation frees up employees to take on more strategic roles, boosting job satisfaction.

Benefit | Description |

|---|---|

Improved Accuracy | Reduces human errors and ensures accurate inventory levels. |

Enhanced Efficiency | Streamlines operations and frees up time for strategic tasks. |

Real-Time Visibility | Provides up-to-date inventory data for better decision-making. |

Investing in workforce training and creating a supportive environment further improves employee retention. High turnover rates can be costly due to recruitment and training expenses. By fostering a positive work culture, you can retain skilled employees and maintain a productive workforce.

Tip: Automation doesn't replace your workforce; it empowers them to work smarter and safer.

Adapting to Market Demands with Scalability

Scalability is essential for your warehouse or distribution center to thrive in today’s dynamic market. As customer demands fluctuate, your ability to adapt quickly can determine your success. Warehouse/DC Automation provides the tools you need to scale operations efficiently without overburdening your resources.

Automation enables you to handle increasing workloads without requiring proportional increases in staff. For example, smart automation tools can adjust to higher order volumes during peak seasons. These systems optimize resource allocation, ensuring you meet customer expectations without compromising quality. By automating repetitive tasks, you free up your workforce to focus on strategic activities, enhancing overall productivity.

Market responsiveness is another critical advantage of automation. Automated processes reduce manual tasks and errors, allowing you to respond to market changes faster than competitors. Whether it’s adjusting prices, modifying services, or launching new products, automation ensures you stay ahead of the curve. Real-time dashboards and data-driven insights provide instant visibility into key metrics, enabling quick decision-making.

The adaptability of automation also extends to supply chain management. Automated systems provide instant inventory updates and trigger reordering when stock levels run low. This ensures you can meet changing customer demands efficiently. For instance, if a product suddenly becomes popular, your automated system can adjust inventory levels to prevent stockouts.

Here’s a closer look at how automation supports scalability and market responsiveness:

Aspect of Automation | Description |

|---|---|

Business Agility | Automation creates agile operations that respond swiftly to market shifts. |

Automated processes allow faster adjustments to prices and services. | |

Supply Chain Adaptability | Instant inventory updates and reordering help meet changing demands. |

Data-Driven Insights | Real-time dashboards track trends, enabling quick decision-making. |

Scalable Processes | Smart tools manage workloads without proportional staff increases. |

By leveraging these capabilities, you can future-proof your operations. Automation not only helps you scale but also ensures you remain competitive in a rapidly evolving market. As e-commerce continues to grow, scalable solutions will become even more critical for maintaining efficiency and meeting customer expectations.

Tip: Start small by automating specific processes, then expand as your needs grow. This phased approach minimizes disruption while maximizing scalability.

Strategies for Implementing Warehouse/DC Automation

Conducting Operational Assessments

Before implementing automation, you need to evaluate your current operations thoroughly. Operational assessments help identify inefficiencies, bottlenecks, and areas where automation can deliver the most value. By analyzing key metrics, you can make informed decisions and prioritize automation efforts effectively.

Start by examining labor productivity. Metrics like pick rates and order accuracy reveal how well your workforce performs and where improvements are needed. Facility space utilization is another critical area. Assess your warehouse layout and storage policies to uncover inefficiencies that hinder productivity.

Performance metrics provide valuable insights into how your operations align with set goals. For example, tracking order lead times and backorder rates can highlight areas requiring optimization. Additionally, evaluating employee turnover and training effectiveness ensures your workforce is prepared for automation.

Use the table below to guide your operational assessment:

Description | |

|---|---|

Labor Productivity | Tracking metrics like pick rates and order accuracy to optimize staffing levels and training needs. |

Facility Space Utilization | Assessing layout and storage policies to identify performance gaps and improve efficiency. |

Performance Metrics | Measuring performance parameters against set goals to evaluate automation effectiveness. |

Bottlenecks and Inefficiencies | Identifying operational bottlenecks to enhance productivity and resource allocation. |

Employee Turnover and Training | Evaluating turnover rates and training effectiveness to improve operational efficiency. |

Local Labor Market Dynamics | Understanding local workforce conditions to shape effective staffing strategies. |

By conducting a detailed assessment, you can pinpoint areas where automation will have the greatest impact. This step ensures your investment aligns with your operational goals and delivers measurable results.

Creating a Phased Automation Roadmap

Implementing automation all at once can overwhelm your operations. A phased roadmap allows you to introduce automation gradually, minimizing risks and ensuring smoother adoption. This approach helps you manage expectations and reduce resistance from employees.

Begin with a pilot program. Select a specific area of your warehouse, such as order picking or inventory tracking, and test automation technologies there. This allows you to evaluate performance and gather feedback before expanding. Incremental rollouts ensure you can address challenges early and refine processes as needed.

A phased roadmap also enables you to allocate resources effectively. By automating one process at a time, you avoid overburdening your budget and workforce. This strategy ensures each phase is successful before moving to the next.

Consider these benefits of a phased approach:

Gradual introduction of features reduces disruption.

Pilot programs allow for testing and feedback.

Incremental rollouts minimize risks and ensure smoother adoption.

By following a phased roadmap, you can build confidence in automation and achieve long-term success. This strategy ensures your warehouse adapts to new technologies without compromising efficiency.

Selecting the Right Automation Technologies

Choosing the right automation technologies is crucial for optimizing your warehouse operations. Each technology offers unique benefits, so you must evaluate them based on your specific needs and goals.

Start by comparing efficiency gains. Automation significantly improves order fulfillment times and accuracy compared to manual processes. Lower labor costs are another advantage. Automated systems reduce the need for a large workforce, leading to substantial savings.

Safety is a key consideration. Automation minimizes workplace accidents by handling physically demanding tasks. Additionally, faster and more accurate order fulfillment enhances customer satisfaction.

Here are some benchmarks to guide your selection:

Increased Efficiency: Automation enhances order fulfillment times and accuracy.

Lower Labor Costs: Reduces workforce requirements, saving costs.

Improved Safety: Decreases workplace accidents.

Increased Customer Satisfaction: Faster and error-free fulfillment boosts satisfaction.

Cost Considerations: Initial investment may be high, but long-term savings outweigh costs.

A study by McKinsey & Company found that 83% of logistics executives view automation as essential for the future of the industry. Similarly, Bank of America Merrill Lynch reports that over 83% of sectors reliant on overseas supply chains are shifting to automation to enhance resilience.

By selecting technologies that align with your operational goals, you can maximize efficiency and achieve a competitive edge. Focus on solutions that deliver measurable ROI and support scalability to future-proof your warehouse.

Integrating Lean Principles for Optimization

Lean principles focus on eliminating waste and maximizing value in your operations. By integrating these principles into your warehouse or distribution center, you can optimize workflows, reduce inefficiencies, and improve overall performance. Lean practices align perfectly with automation, creating a streamlined and efficient environment.

Identifying and Eliminating Waste

Waste in your warehouse can take many forms, such as excess inventory, unnecessary motion, or overproduction. Lean principles help you identify these inefficiencies and address them systematically. For example, automating repetitive tasks like picking and packing reduces wasted time and effort. This allows your team to focus on value-added activities.

Tip: Use real-time data from automated systems to pinpoint bottlenecks and areas of waste. This insight helps you make informed decisions and continuously improve your processes.

Standardizing Processes for Consistency

Standardization is a core aspect of lean principles. It ensures that every task follows a consistent method, reducing errors and improving efficiency. Automation plays a key role in standardizing processes. Automated systems perform tasks with precision, ensuring consistent results every time. For instance, robotic picking systems follow predefined paths, minimizing variability and increasing accuracy.

By standardizing your workflows, you can achieve measurable improvements in key performance indicators (KPIs). Consider the following metrics to evaluate the impact of lean principles on your operations:

KPI | Description |

|---|---|

Lines per hour | Measures the efficiency of order picking. |

Orders per day | Indicates overall throughput of the warehouse. |

Labor costs | Assesses the cost-effectiveness of labor usage. |

Percentage of mis-picks | Tracks accuracy in order fulfillment. |

Cost of fine backs | Evaluates the financial impact of errors. |

Tracking these KPIs helps you monitor progress and identify areas for further optimization.

Empowering Your Workforce

Lean principles emphasize the importance of empowering employees. Automation complements this by reducing the physical strain on workers and enabling them to focus on strategic tasks. For example, automated storage and retrieval systems handle heavy lifting, while your team manages inventory planning and quality control.

Providing training and upskilling opportunities ensures your workforce adapts to new technologies. This not only boosts morale but also enhances productivity. A motivated and skilled team is essential for sustaining lean practices in your warehouse.

Continuous Improvement Through Kaizen

Kaizen, or continuous improvement, is a fundamental lean principle. It encourages you to make small, incremental changes that lead to significant long-term benefits. Automation supports Kaizen by providing real-time data and analytics. These insights help you identify trends, measure performance, and implement improvements.

For example, if you notice a high percentage of mis-picks, you can adjust your automated picking system to address the issue. Similarly, analyzing labor costs may reveal opportunities to reallocate resources more effectively. By embracing Kaizen, you create a culture of continuous improvement that drives success.

Note: Lean principles and automation work best when combined. Together, they create a dynamic system that adapts to changing demands and delivers consistent results.

Achieving Operational Excellence

Integrating lean principles with automation transforms your warehouse into a high-performing operation. You eliminate waste, standardize processes, and empower your workforce. By tracking KPIs and embracing continuous improvement, you ensure your operations remain efficient and competitive.

Lean principles are not just a methodology—they are a mindset. When paired with automation, they enable you to achieve operational excellence and stay ahead in the ever-evolving logistics landscape.

Emoji Insight: 🚀 Lean principles + Automation = A streamlined, efficient, and future-ready warehouse!

Key Technologies in Warehouse/DC Automation

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) revolutionize how you manage inventory. These systems use advanced robotics to store and retrieve items with precision, reducing human error and increasing productivity. By implementing AS/RS, you can achieve accuracy rates exceeding 99%, which minimizes costly returns and boosts customer satisfaction.

AS/RS also enhances operational efficiency. It speeds up picking and handling processes, allowing you to fulfill orders faster. Additionally, these systems lower warehouse costs by up to 40%, making them a cost-effective solution for modern warehouses.

Tip: Use AS/RS to optimize space utilization and reduce labor dependency. This technology ensures your warehouse operates at peak efficiency.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are transforming warehouse operations. These robots navigate your facility independently, handling tasks like transporting goods and assisting with order picking. AMRs increase productivity by up to 50%, enabling you to process more orders in less time.

AMRs also reduce labor costs significantly. For example, Amazon has cut order fulfillment costs by 25% using AMRs, with plans to save $10 billion by 2030. John Lewis achieved £1 million in operational cost savings and expanded storage space by 75% through AMR deployment.

Metric | Impact |

|---|---|

Order Fulfillment Cost Reduction | 25% |

Productivity Increase | Up to 50% |

Labor Cost Reduction | 40% |

Operational Cost Savings | £1 million (John Lewis) |

Storage Space Expansion | 75% |

AMRs provide flexibility and scalability, ensuring your warehouse adapts to fluctuating demands. By integrating AMRs, you can streamline operations and stay competitive in the evolving logistics landscape.

Warehouse Management Systems (WMS) and Analytics

Warehouse Management Systems (WMS) and analytics improve inventory management and order accuracy. Real-time inventory tracking allows you to avoid stockouts and excess inventory, ensuring high inventory turnover. This capability helps you respond quickly to market demand and maintain operational efficiency.

WMS also enhances forecasting accuracy. By integrating WMS data with sales and finance systems, you can predict inventory needs more effectively. Optimized order fulfillment processes reduce errors, increasing order accuracy and customer satisfaction.

Note: High order accuracy reduces costs associated with returns and builds trust with your customers.

With WMS, you gain real-time visibility into inventory movements, enabling faster decision-making. This technology ensures your warehouse operates smoothly and meets customer expectations consistently.

Internet of Things (IoT) and Predictive Maintenance

The Internet of Things (IoT) transforms warehouse operations by connecting devices and systems to share real-time data. Predictive maintenance uses this data to forecast equipment issues before they occur. You can prevent disruptions and improve productivity by adopting these technologies.

IoT sensors monitor equipment performance continuously. Machine learning analyzes this data to identify anomalies. When a potential issue arises, the system alerts you to take action. This proactive approach avoids unexpected failures and keeps your operations running smoothly.

Tip: Use IoT-powered predictive maintenance to reduce downtime and extend equipment lifespan.

Predictive maintenance offers measurable benefits. It reduces downtime by 50% and increases productivity by 30%. Regular maintenance prolongs machinery life, saving costs on replacements. Better planning of spare parts inventory ensures you have what you need without overstocking.

Improvement Area | Statistic/Impact |

|---|---|

Productivity Increase | 30% increase due to smart systems |

Downtime Reduction | 50% reduction through predictive maintenance |

Cost Savings | Preventive interventions are more economical than unplanned repairs |

Extended Equipment Lifespan | Regular maintenance prolongs machinery life |

Optimized Inventory | Better planning of spare parts inventory |

Here’s how predictive maintenance helps:

Prevents unexpected equipment failures, ensuring smooth production lines.

Catches problems early, extending equipment lifespan.

Reduces overall maintenance costs by avoiding unnecessary repairs.

IoT also enhances inventory management. Sensors track stock levels and movement, providing real-time visibility. This data helps you optimize storage and avoid shortages. By integrating IoT, you can streamline operations and make informed decisions.

Predictive maintenance powered by IoT creates a smarter, more efficient warehouse. You save time, reduce costs, and improve reliability. These technologies ensure your operations stay ahead in a competitive market.

Emoji Insight: 📈 IoT + Predictive Maintenance = A future-ready warehouse with fewer disruptions!

Best Practices for Successful Automation Implementation

Cross-Functional Collaboration and Planning

Collaboration across departments is essential for successful automation. You need to bring together diverse teams, such as operations, IT, and logistics, to align goals and ensure smooth implementation. Building trust among these groups fosters effective communication and reduces resistance to change.

To enhance collaboration, consider these best practices:

Establish a Center of Excellence (CoE) to centralize knowledge and set clear objectives.

Form cross-functional teams to incorporate diverse perspectives and align automation goals with departmental needs.

Standardize processes and metrics to ensure consistency and reduce barriers during the transition.

Best Practice | Description |

|---|---|

Center of Excellence (CoE) | Centralizes knowledge, establishes clear objectives, and drives consistency. |

Build a Cross-Functional Team | Ensures diverse perspectives and aligns goals with departmental needs. |

Standardize Processes and Metrics | Facilitates consistent adoption and reduces transition barriers. |

Tracking metrics like cycle time from concept to delivery and first-time acceptance rates of features can help you measure collaboration success.

Workforce Training and Upskilling

Automation transforms roles within your warehouse. To prepare your workforce, you must invest in training and upskilling programs. These initiatives help employees adapt to new technologies and take on more strategic responsibilities.

Focus on hands-on training for operating automated systems. Offer workshops and certifications to build confidence and competence. Upskilling programs should emphasize problem-solving and data analysis, enabling employees to make informed decisions.

Tip: Highlight the benefits of automation to your team, such as reduced physical strain and opportunities for career growth.

A well-trained workforce ensures smoother adoption of automation and boosts employee satisfaction.

Continuous Monitoring and Performance Optimization

Automation is not a one-time effort. You must continuously monitor performance to ensure long-term success. Real-time data from automated systems provides valuable insights into operational efficiency.

Key metrics to track include order accuracy, warehouse utilization, and delivery time. For example:

Metric | Description |

|---|---|

Order Accuracy | Evaluate the percentage of orders fulfilled accurately. |

Warehouse Utilization | Assess the amount of space used versus available space. |

Delivery Time | Measure the time goods take to reach customers. |

Regularly reviewing these metrics helps you identify areas for improvement. Use predictive analytics to anticipate challenges and optimize processes. This proactive approach ensures your warehouse remains efficient and competitive.

Emoji Insight: 📊 Continuous monitoring = Improved performance and sustained success!

Partnering with Trusted Solution Providers

Choosing the right solution provider plays a critical role in the success of your warehouse automation journey. Trusted providers bring expertise, proven technologies, and ongoing support to ensure smooth implementation and long-term results.

Why Partnering Matters

A reliable partner helps you navigate the complexities of automation. They assess your unique needs and recommend tailored solutions. Their experience minimizes risks and ensures your investment delivers measurable results. Without expert guidance, you may face delays, cost overruns, or underperforming systems.

Tip: Look for providers with a strong track record in your industry. Their familiarity with similar challenges ensures they can deliver effective solutions.

Key Benefits of Trusted Providers

Expertise and Guidance: Trusted providers offer in-depth knowledge of automation technologies. They help you select systems that align with your goals.

Seamless Integration: They ensure new technologies integrate smoothly with your existing processes.

Ongoing Support: Reliable partners provide training, maintenance, and updates to keep your systems running efficiently.

Scalability: They design solutions that grow with your business, ensuring long-term adaptability.

Questions to Ask Potential Providers

Question | Why It’s Important |

|---|---|

What industries have you worked with? | Ensures they understand your specific operational challenges. |

Do you offer post-implementation support? | Confirms they will assist with maintenance and troubleshooting. |

Can your solutions scale with my business? | Verifies their technology can adapt to future growth. |

What is your approach to training? | Ensures your workforce will be prepared to use the new systems. |

Partnering with a trusted solution provider simplifies your automation journey. Their expertise ensures you achieve efficiency, cost savings, and scalability. By asking the right questions, you can choose a partner who aligns with your goals and sets your warehouse up for success.

Emoji Insight: 🤝 A trusted partner = A smoother path to automation success!

Warehouse/DC Automation is reshaping logistics and supply chains. Rising labor costs, cloud-based systems, and mobile robots are driving this transformation. For example, companies using cloud-based warehouse management systems report a 20% improvement in inventory accuracy. Mobile robots reduce warehouse floor traffic by 40%, enhancing safety and efficiency. Major retailers like Walmart are investing in automated storage systems, signaling a shift toward smart warehouses.

Adopting automation now positions your business for future success. Smart warehouses and human-robot collaboration will define the next era of logistics. By embracing these innovations, you can stay competitive and meet evolving market demands.

FAQ

What is Warehouse/DC Automation?

Warehouse/DC Automation uses technology to streamline operations. It includes robotics, software, and IoT systems that handle tasks like picking, packing, and inventory management. Automation reduces errors, boosts efficiency, and saves costs.

How can automation improve warehouse safety?

Automation reduces physical strain and workplace injuries. Robots handle heavy lifting and repetitive tasks, creating a safer environment. You can also use IoT sensors to monitor equipment and prevent accidents.

Is automation expensive to implement?

Automation requires upfront investment, but it delivers long-term savings. Reduced labor costs, improved accuracy, and optimized space utilization ensure a positive ROI within months. Start small and scale gradually to manage costs effectively.

What technologies should I prioritize for automation?

Focus on technologies like Warehouse Management Systems (WMS), Autonomous Mobile Robots (AMRs), and Automated Storage and Retrieval Systems (AS/RS). These solutions enhance efficiency, accuracy, and scalability.

How do I prepare my workforce for automation?

Train employees on new systems and provide upskilling opportunities. Highlight benefits like reduced physical strain and career growth. A well-trained team adapts quickly and ensures smooth implementation.

Tip: Use workshops and certifications to build confidence in operating automated systems.

See Also

Exploring Advantages of Automation in Modern Manufacturing Warehouses

Understanding How Robotics Enhance Efficiency in Warehousing

Maximizing Warehouse Productivity Through Advanced Robotics Solutions

The Importance of Automation in Today's Warehouse Operations