Warehouse Management Strategies in JUSDA's Case Study

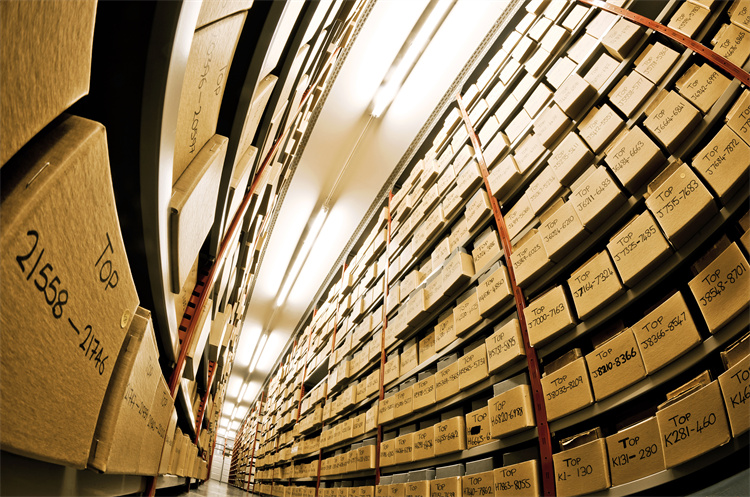

Warehouse management plays a crucial role in the supply chain, ensuring products are available when needed, reducing delays, and enhancing customer satisfaction. Efficient management minimizes costs and maximizes operational efficiency. JUSDA, a global leader in supply chain services, exemplifies excellence in this field. Their advanced systems optimize the flow of goods, enhance inventory control, and streamline distribution processes. This case study aims to analyze JUSDA's strategies, highlighting their impact on the industry and offering insights into effective warehouse management practices.

Understanding Warehouse Management

Warehouse management serves as a cornerstone in the logistics and supply chain industry. It involves overseeing the storage and movement of goods within a warehouse, ensuring that products are available when needed. This process not only enhances customer satisfaction but also reduces operational costs. JUSDA exemplifies excellence in this domain by implementing advanced systems that optimize the flow of goods and streamline distribution processes.

Definition and Key Concepts

Importance of Warehouse Management

Warehouse management is crucial for maintaining an efficient supply chain. It ensures that inventory levels are optimal, reducing the risk of stockouts or overstocking. Effective management leads to improved order accuracy and faster delivery times, which directly impacts customer satisfaction. Companies like JUSDA leverage technology to enhance these aspects, using tools such as Warehouse Management Systems (WMS) to track inventory in real-time and automate various processes.

Core Functions and Operations

The core functions of warehouse management include receiving, storing, and shipping goods. Each function requires meticulous planning and execution to ensure smooth operations. For instance, receiving involves inspecting and verifying incoming shipments, while storage requires organizing products in a way that maximizes space and accessibility. Shipping, on the other hand, focuses on picking and packing orders accurately and efficiently. JUSDA's approach to these operations involves utilizing automation and IoT technologies to minimize errors and increase productivity.

Role in Supply Chain

Integration with Logistics

By coordinating with transportation services, warehouses can optimize delivery routes and schedules, reducing transit times and costs. JUSDA's strategies highlight the importance of this integration, as they employ advanced logistics solutions to enhance overall supply chain efficiency.

Impact on Efficiency and Cost

JUSDA's case study demonstrates how leveraging technology and best practices can lead to substantial cost savings and enhanced operational efficiency. Their commitment to innovation ensures that they remain at the forefront of the industry, setting benchmarks for others to follow.

JUSDA's Approach to Warehouse Management

Overview of JUSDA's Operations

Company Background

JUSDA stands as a prominent player in the logistics industry, managing over 2.5 million square meters of warehousing space across more than 155 service locations worldwide. This extensive network allows JUSDA to provide comprehensive supply chain solutions tailored to various industries. Their commitment to innovation and efficiency has positioned them as a leader in warehouse management.

Industry Position

In the competitive landscape of logistics, JUSDA excels by integrating advanced technologies into their operations. They leverage cutting-edge systems to enhance supply chain visibility and streamline order fulfillment processes. This strategic approach not only optimizes warehouse management but also sets benchmarks for service reliability and operational excellence.

Specific Strategies Employed

Technology Utilization

JUSDA employs state-of-the-art technologies to revolutionize warehouse management. Their JusLink Smart Supply Chain Management Platform provides end-to-end visibility and control, utilizing tools like Radio-Frequency Identification (RFID) and Warehouse Management Systems (WMS). These technologies enable real-time tracking and analytics, allowing JUSDA to proactively address potential issues and enhance operational efficiency.

Automation plays a crucial role in JUSDA's strategy. By using robotics technology, they automate repetitive tasks, significantly reducing manual labor and increasing productivity. This approach not only cuts down on operational expenses but also ensures accuracy and speed in order processing.

Process Optimization

JUSDA focuses on maximizing resource utilization through efficient layout designs and storage techniques. They prioritize smart inventory management to meet customer demands effectively. By implementing the i-Inventory System, JUSDA streamlines inventory tracking and optimizes stock levels with precision.

Their cloud-based platforms support dynamic warehousing strategies, allowing for scalable and adaptive storage solutions. This flexibility enhances warehouse management by enabling real-time inventory tracking and data analysis, ensuring that JUSDA remains responsive to changing market needs.

JUSDA's commitment to process optimization eliminates bottlenecks and enhances overall operational flow. By integrating these strategies, they empower businesses to achieve maximum efficiency and streamline their warehouse operations.

Benefits of JUSDA's Strategies

JUSDA's innovative warehouse management strategies offer significant advantages, enhancing both operational efficiency and customer satisfaction. Their approach sets a benchmark in the logistics industry, demonstrating how technology and strategic planning can transform warehouse operations.

Improved Efficiency

Time and Resource Management

JUSDA excels in time and resource management by integrating advanced technologies such as IoT and AI into their warehouse management systems. These technologies automate routine tasks, reducing manual intervention and freeing up resources for more strategic activities. The i-Inventory System plays a crucial role in this process, enabling real-time inventory tracking and ensuring optimal stock levels. This system minimizes delays and enhances the speed of operations, allowing JUSDA to meet customer demands promptly.

Cost Reduction

Cost reduction remains a key benefit of JUSDA's warehouse management strategies. By employing automation and machine learning, JUSDA reduces labor costs and minimizes errors in order processing. Their smart inventory management techniques, including Vendor Managed Inventory (VMI) and Consignment Managed Inventory (CMI) services, further optimize stock levels, reducing excess inventory and associated holding costs. These strategies not only lower operational expenses but also contribute to a more sustainable and efficient supply chain.

Enhanced Customer Satisfaction

Service Quality

JUSDA's commitment to service quality is evident in their meticulous warehouse management practices. By leveraging cutting-edge technologies, they ensure high accuracy in order fulfillment, reducing errors and enhancing the overall customer experience. The use of Warehouse Management Systems (WMS) allows for precise tracking and management of goods, ensuring that customers receive exactly what they ordered. This attention to detail fosters trust and reliability, key components of customer satisfaction.

Delivery Timeliness

Timely delivery is a critical aspect of customer satisfaction, and JUSDA's strategies excel in this area. Their integration of logistics and warehouse management ensures seamless coordination between storage and transportation. By optimizing delivery routes and schedules, JUSDA reduces transit times, ensuring that products reach customers promptly. This efficiency not only enhances customer satisfaction but also strengthens JUSDA's reputation as a reliable logistics partner.

JUSDA's warehouse management strategies exemplify how innovation and strategic planning can lead to improved efficiency and enhanced customer satisfaction. Their use of advanced technologies and smart inventory management sets them apart in the industry, offering valuable insights for businesses aiming to optimize their warehouse operations.

Challenges Faced by JUSDA

Operational Challenges

Inventory Management

JUSDA encounters significant challenges in inventory management. Maintaining optimal stock levels requires precise control and monitoring. They employ AI-driven systems to provide real-time insights into inventory status. This technology ensures that stakeholders can make informed decisions quickly, reducing the risk of stockouts or overstocking. However, balancing supply and demand remains a complex task, demanding constant vigilance and adaptation.

Workforce Management

Workforce management presents another critical challenge for JUSDA. The company invests heavily in training and development programs to enhance employee skills. Skilled workers contribute significantly to warehouse efficiency. Proper workforce management ensures that staff can handle daily operations effectively. JUSDA's commitment to employee development fosters a productive work environment, yet managing a diverse workforce requires ongoing effort and strategic planning.

External Challenges

Market Fluctuations

Market fluctuations pose external challenges that JUSDA must navigate. Changes in consumer demand and economic conditions can impact supply chain dynamics. JUSDA employs advanced market analysis techniques to anticipate and respond to these fluctuations. By staying informed about market trends, they can adjust their strategies to maintain stability and meet customer needs.

Regulatory Compliance

Regulatory compliance remains a crucial concern for JUSDA. Adhering to international trade regulations and standards requires meticulous attention to detail. JUSDA implements comprehensive compliance strategies to ensure that all operations align with legal requirements. This proactive approach minimizes risks and enhances the company's reputation as a reliable logistics partner.

Solutions and Best Practices

Overcoming Operational Challenges

Advanced Inventory Systems

JUSDA employs advanced inventory systems to tackle operational challenges effectively. These systems provide real-time data on stock levels, enabling precise inventory control. By utilizing technologies such as AI and IoT, JUSDA ensures that inventory management remains efficient and accurate. This approach minimizes the risk of stockouts and overstocking, which can disrupt operations. The integration of these systems allows JUSDA to maintain optimal stock levels, ensuring that products are available when needed.

Employee Training Programs

Employee training programs play a crucial role in overcoming workforce management challenges. JUSDA invests in comprehensive training initiatives to enhance the skills and knowledge of their employees. These programs focus on equipping staff with the necessary tools and techniques to handle daily operations efficiently. By fostering a culture of continuous learning, JUSDA ensures that their workforce remains competent and adaptable. This commitment to employee development not only boosts productivity but also contributes to a positive work environment.

Adapting to External Changes

Market Analysis Techniques

JUSDA utilizes advanced market analysis techniques to adapt to external changes. These techniques involve monitoring market trends and consumer behavior to anticipate shifts in demand. By staying informed about market dynamics, JUSDA can adjust their strategies accordingly. This proactive approach allows them to remain competitive and responsive to changing market conditions. The use of data analytics and predictive modeling further enhances their ability to make informed decisions, ensuring stability in their operations.

Compliance Strategies

Regulatory compliance is a critical aspect of JUSDA's operations. They implement robust compliance strategies to ensure adherence to international trade regulations and standards. These strategies involve regular audits and assessments to identify potential compliance issues. By maintaining a thorough understanding of legal requirements, JUSDA minimizes risks associated with non-compliance. Their proactive approach to compliance not only safeguards their operations but also reinforces their reputation as a reliable logistics partner.

JUSDA’s comprehensive approach to warehouse management reflects this principle. By focusing on key components and integrating advanced technologies, JUSDA ensures optimal performance in its warehouses.

JUSDA's solutions and best practices demonstrate how strategic planning and technology integration can address operational and external challenges effectively. Their commitment to innovation and excellence sets a benchmark for others in the industry, offering valuable insights into optimizing warehouse management.

JUSDA

More than your expectation

JUSDA's warehouse management strategies showcase their commitment to efficiency, cost reduction, and customer satisfaction. By integrating advanced technologies and optimizing processes, they set a benchmark in the logistics industry. Their approach not only enhances operational performance but also aligns with global standards for environmental responsibility. Businesses should consider adopting these best practices to elevate their supply chain operations. Embracing JUSDA's transformative solutions can lead to improved forecasting, planning accuracy, and overall supply chain performance.

See Also

JUSDA's Smart Logistics: A Case Study in Action

JUSDA's Expertise Unveiled: Inventory Optimization in Focus

Efficiency Redefined: JUSDA's Logistics Fine-tuning