Warehousing Game for Retail Enterprises: Self - operation VS Outsourcing

Retail enterprises face a pivotal decision in managing their supply chain: whether to self-operate their warehousing or outsource it. This choice impacts cost efficiency, scalability, and customer satisfaction. Outsourcing often reduces upfront investments and provides flexibility during demand fluctuations. Third-party logistics providers (3PLs) bring expertise and advanced technologies, enhancing order fulfillment processes and customer experiences. However, self-operation offers direct control, faster decision-making, and robust brand perception.

Coyote Logistics research highlights the growing trend of balancing in-house operations with outsourcing. Retailers increasingly rely on 3PLs for inventory management, reflecting the complexities of modern logistics. The Warehousing Game involves navigating these options to align with business goals and operational needs.

Key Takeaways

Running your own warehouse gives more control and flexibility. It helps businesses match operations to their specific needs.

Hiring another company for warehousing can save money and grow easily. This works well for businesses with changing demand.

Think about your business's needs and future plans to pick the best warehousing method for growth.

Check for risks often and make backup plans to keep warehouse operations strong.

Use technology and data to make warehouse work better and decisions faster.

The Warehousing Game: Self-operation Explained

Defining Self-operation Warehousing

Self-operation warehousing refers to a model where retail enterprises manage and control their storage facilities independently. This approach involves owning or leasing warehouse spaces, hiring staff, and implementing systems to handle inventory, order fulfillment, and logistics. Companies adopting this model prioritize direct oversight of operations, ensuring alignment with their business strategies and customer expectations.

In the context of the Warehousing Game, self-operation allows businesses to maintain full control over their supply chain. This control ensures that processes like inventory management, order accuracy, and customer service meet the company’s standards. For example, enterprises like JD.com have successfully leveraged self-operated warehousing to enhance their brand reputation and customer experience.

Advantages of Self-operation Warehousing

Self-operation warehousing offers several benefits that can significantly impact a retail enterprise's performance. These advantages include:

Enhanced Control: Businesses can directly oversee every aspect of their warehousing operations. This control enables faster decision-making and immediate adjustments to meet market demands.

Improved Brand Perception: A self-operated warehouse ensures consistent service quality, which strengthens customer trust and loyalty.

Data Security: Companies retain ownership of their data systems, reducing the risk of breaches and ensuring sensitive information remains protected.

Customization: Enterprises can tailor their warehousing processes to align with unique business needs, such as specialized packaging or inventory management systems.

Capability Building: Over time, self-operated warehouses can evolve into profit centers. For instance, JD Logistics transformed its warehousing operations into a service offered to other businesses.

Key performance indicators (KPIs) validate these benefits by measuring the efficiency and accuracy of self-operated warehousing. The table below highlights some critical KPIs:

KPI | Description |

|---|---|

Dock Door Utilization | Percentage of dock hours in use compared to maximum capacity. |

Average Truck Dwell Time | Time a driver waits at the facility before leaving. |

Errors by Volume | Proportion of inventory volume needing additional action due to errors. |

Space Utilization | Productivity of the building calculated by inventory volume stored divided by total area. |

Pick Accuracy | Accuracy of picking items against orders. |

Packing Error Rate | Tracks errors in the packing process, including incorrect items or packaging. |

Incorrect item returns per order | Measure of picking accuracy; a lower number indicates higher accuracy. |

These metrics provide insights into operational efficiency, helping businesses optimize their self-operated warehouses.

Disadvantages of Self-operation Warehousing

While self-operation offers numerous benefits, it also presents challenges that retail enterprises must address. These disadvantages include:

High Initial Costs: Setting up a self-operated warehouse requires significant investment in infrastructure, technology, and personnel. This financial burden can strain cash flow, especially for small businesses.

Operational Complexity: Managing a warehouse involves coordinating multiple processes, such as inventory tracking, order fulfillment, and staff management. Poor execution can lead to inefficiencies and customer dissatisfaction.

Limited Scalability: Expanding self-operated warehousing to accommodate business growth often requires additional resources, which can be costly and time-consuming.

Data Management Risks: Inconsistent datasets and gaps in validation processes can result in costly errors. Manual data handling increases the likelihood of mistakes, leading to inefficiencies and misallocated resources.

Seasonal Demand Challenges: Fluctuations in demand require businesses to maintain excess capacity during peak seasons. This approach often results in underutilized resources during off-peak periods, reducing profitability.

Operational issues, such as warehouse design and quality control, further complicate self-operation. Poor data quality can also lead to inaccurate analyses, negatively impacting business decisions. Retail enterprises must carefully assess these risks before committing to a self-operated warehousing model.

The Warehousing Game: Outsourcing Warehousing

What is Outsourcing Warehousing?

Outsourcing warehousing involves delegating storage, inventory management, and order fulfillment tasks to third-party logistics providers (3PLs). These external service providers specialize in supply chain management, offering businesses access to advanced infrastructure, technology, and expertise. Retail enterprises often choose this model to focus on core activities like sales and marketing while leaving logistics to professionals.

Key considerations for outsourcing include defining the scope of services, establishing performance metrics, and ensuring seamless technology integration. Businesses must also evaluate the scalability and flexibility of 3PL providers to adapt to changing demands. Quality control protocols and clear communication channels further ensure that outsourced operations align with business goals.

Outsourcing warehousing allows companies to leverage economies of scale, reduce operational complexity, and enhance customer satisfaction. This approach is particularly beneficial for businesses experiencing rapid growth or seasonal demand fluctuations.

Benefits of Outsourcing Warehousing

Outsourcing warehousing offers several strategic advantages that can significantly improve a retail enterprise's efficiency and profitability. These benefits include:

Cost Savings: Third-party providers share resources like labor, equipment, and facilities across multiple clients, reducing overall costs. Businesses also avoid the high upfront investments required for self-operated warehouses.

Scalability: Outsourced warehousing enables companies to adjust their storage capacity based on demand. This flexibility is crucial during peak seasons or market expansions.

Expertise and Technology: 3PL providers utilize advanced Warehouse Management Systems (WMS) and Transportation Management Systems (TMS). These technologies enhance supply chain visibility, real-time inventory tracking, and trend forecasting, improving operational efficiency.

Geographic Reach: Partnering with 3PLs allows businesses to expand their market presence without investing in physical facilities. Providers often have networks of warehouses in strategic locations, ensuring faster delivery times.

Operational Efficiency: Specialized providers optimize warehouse layouts, adopt automation, and implement lean methodologies. These practices streamline processes, reduce errors, and improve productivity.

Strategic Advantage | Description |

|---|---|

Cost Savings | Outsourcing warehousing can lead to significant cost reductions by leveraging economies of scale. |

Scalability | Third-party providers allow businesses to easily adjust their warehousing capacity based on demand. |

Expertise | Access to specialized knowledge and advanced technology improves operational efficiency. |

Geographic Reach | Enables businesses to expand their market presence without the need for physical facilities. |

Industry benchmarks highlight the importance of outsourcing in modern logistics. For example, utilizing advanced WMS and TMS systems through 3PLs enhances supply chain efficiency and customer service. These technologies enable businesses to track inventory in real time and forecast trends, ensuring timely and accurate order fulfillment.

Drawbacks of Outsourcing Warehousing

Despite its advantages, outsourcing warehousing comes with challenges that businesses must address to ensure success. These drawbacks include:

Limited Control: Companies relying on 3PLs may face restrictions in customizing operations to meet specific needs. Providers often operate within fixed capabilities, which can limit flexibility.

Data Security Risks: Granting access to sensitive information, such as inventory levels and customer data, increases the risk of breaches. Businesses must implement robust security measures to protect their data.

Misaligned KPIs: Third-party providers may prioritize high-volume clients, potentially neglecting smaller accounts. This misalignment can lead to inconsistent service quality.

Instability: The 3PL industry often faces financial challenges, with some providers going bankrupt. Such disruptions can severely impact a company's supply chain operations.

Compliance Issues: Some providers may cut corners to reduce costs, risking non-compliance with labor laws, safety standards, or tax regulations.

Retail enterprises must weigh these challenges against the benefits of outsourcing. Establishing clear service level agreements (SLAs), performance metrics, and quality control protocols can help mitigate risks and ensure successful partnerships with 3PL providers.

Comparing Self-operation and Outsourcing

Cost Implications

Cost plays a pivotal role in the Warehousing Game, influencing whether businesses opt for self-operation or outsourcing. Self-operated warehousing demands substantial upfront investments, including salaries, equipment, and training. These direct costs, combined with indirect expenses like administrative overhead and insurance, can total $570,000 annually. However, potential savings from optimized resource utilization and long-term asset investments can offset these costs, yielding net savings of $60,000 and a benefit-cost ratio of 1.105.

Outsourcing, on the other hand, offers a leaner financial model. Third-party logistics providers charge service fees and handle operational costs, reducing the financial burden on businesses. With total costs estimated at $270,000, outsourcing delivers higher net savings of $130,000 and a benefit-cost ratio of 1.48. This model benefits smaller enterprises or those seeking cost efficiency during growth phases.

Scalability and Flexibility

Scalability and flexibility define the adaptability of warehousing models to fluctuating market demands. Self-operated warehouses often struggle with scalability due to high operational costs and infrastructure limitations. Expanding capacity requires significant investments, making it challenging for businesses to respond to seasonal demand spikes or rapid growth.

Outsourcing excels in flexibility. Third-party providers leverage economies of scale to adjust storage capacity and operational resources efficiently. Their ability to adapt to market changes ensures businesses can meet demand fluctuations without incurring excessive costs. For example:

High operational costs hinder self-fulfillment scalability.

Outsourcing offers cost-efficient scalability and adaptability.

This flexibility makes outsourcing ideal for enterprises experiencing unpredictable demand patterns or entering new markets.

Control and Customization

Control and customization differentiate self-operation from outsourcing in the Warehousing Game. Self-operated warehouses provide businesses with complete oversight of operations. This control enables rapid decision-making, tailored inventory management, and enhanced customer service. Companies can customize processes to align with unique business needs, such as specialized packaging or branding.

Outsourcing sacrifices some control for convenience. Third-party providers operate within predefined frameworks, limiting customization options. While outsourcing ensures operational efficiency, businesses may face challenges in aligning outsourced processes with their specific requirements. For enterprises prioritizing brand identity and customer experience, self-operation remains the preferred choice.

Expertise and Resource Allocation

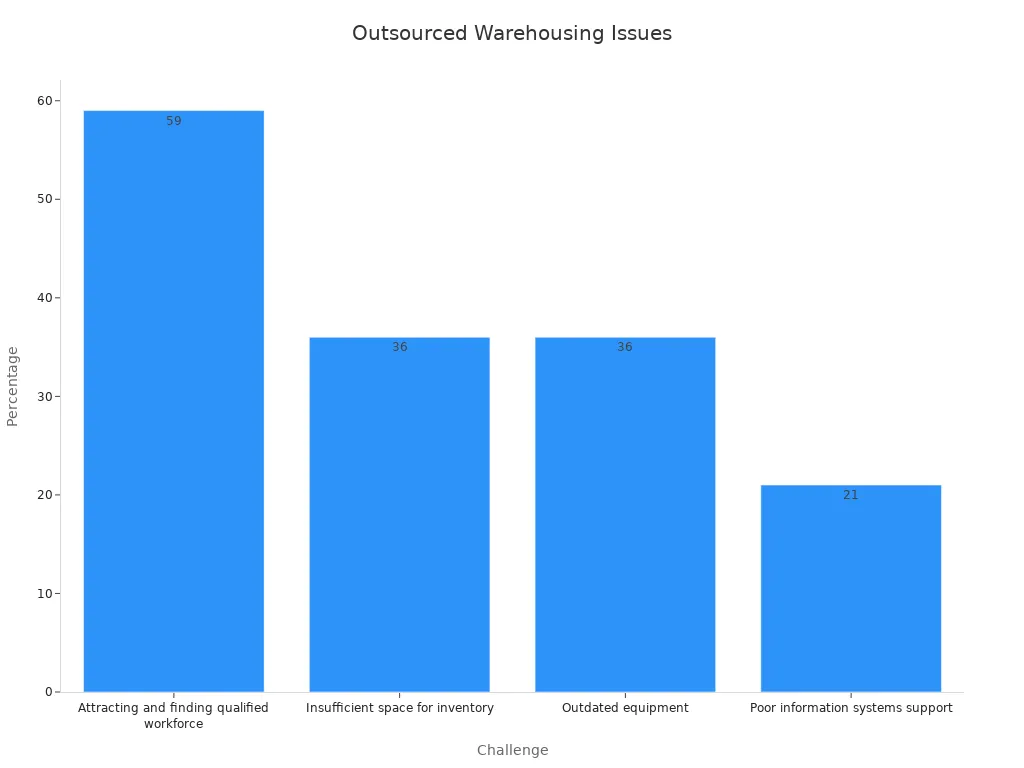

Expertise and resource allocation play a critical role in determining the success of warehousing strategies. Self-operated warehouses require businesses to invest heavily in hiring skilled personnel, developing systems, and maintaining infrastructure. This approach ensures direct control over operations but demands significant resources to attract and retain talent. Companies often face challenges in finding qualified workers and managing specialized tasks, such as inventory optimization and logistics planning.

Outsourcing warehousing provides access to specialized expertise without the need for internal investments. Third-party logistics providers (3PLs) employ professionals trained in advanced warehousing techniques, including automation and lean methodologies. These providers allocate resources efficiently across multiple clients, reducing operational costs while maintaining high service standards. Businesses benefit from the expertise of 3PLs, which enhances supply chain efficiency and customer satisfaction.

Industry surveys highlight the differences in expertise availability and resource allocation between self-operation and outsourcing. The table below summarizes insights from the US Transportation, Logistics, and Warehousing Industry Survey:

Aspect | Details |

|---|---|

Survey Name | US Transportation, Logistics, and Warehousing Industry Survey |

Coverage | |

Focus | Salary and benefit data, specialized expertise availability, resource allocation differences |

Purpose | To understand market trends for attracting and retaining employees in warehousing strategies |

These findings emphasize the importance of aligning warehousing strategies with available expertise and resources. Businesses must evaluate their ability to manage specialized tasks internally or leverage external providers for optimal results.

Business Size and Growth Considerations

The size and growth stage of a business significantly influence its warehousing strategy. Startups and small enterprises often lack the financial and operational capacity to manage self-operated warehouses. Outsourcing becomes a practical choice, allowing these businesses to focus on core activities while minimizing costs. Third-party providers offer scalable solutions that adapt to fluctuating demand, making them ideal for early-stage companies.

Mid-sized businesses face a different set of challenges. As order volumes increase, they require more robust warehousing systems to maintain efficiency. Many opt for hybrid models, combining self-operation for critical tasks with outsourcing for non-core activities. This approach balances cost, control, and scalability, ensuring smooth operations during growth phases.

Large enterprises with established market presence often prefer self-operated warehousing. Their financial strength and operational expertise enable them to invest in infrastructure and technology. These businesses prioritize control and customization to enhance customer experience and brand perception. However, even mature companies may outsource specific tasks, such as regional distribution, to optimize costs and reduce risks.

Choosing the right warehousing strategy depends on understanding the business's current size and growth trajectory. Enterprises must assess their operational needs, financial capacity, and long-term goals to determine whether self-operation, outsourcing, or a hybrid model aligns best with their objectives.

Choosing the Right Warehousing Strategy

Assessing Your Business Needs

Every retail enterprise has unique operational requirements. Identifying these needs is the first step in selecting the right warehousing strategy. Businesses should evaluate their order volumes, product types, and customer expectations. For instance, companies handling perishable goods may require temperature-controlled storage, while those with high SKU diversity need advanced inventory systems.

A detailed analysis of supply chain bottlenecks can also provide valuable insights. Enterprises should ask questions like:

What are the peak and off-peak order volumes?

How critical is delivery speed to customer satisfaction?

Are there specific compliance or regulatory requirements?

Tip: Conducting a SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis can help businesses understand their operational strengths and areas for improvement.

Aligning with Long-term Goals

Warehousing decisions should align with the company’s vision and growth trajectory. Enterprises aiming for rapid expansion may benefit from outsourcing, as it offers scalability and flexibility. On the other hand, businesses focused on building a strong brand identity might prioritize self-operation to maintain control over customer experience.

Long-term goals often include market expansion, cost optimization, or technological innovation. Retailers should consider how their warehousing strategy supports these objectives. For example, a company planning to enter international markets might partner with 3PL providers to leverage their global networks.

Note: Aligning warehousing strategies with long-term goals ensures that short-term decisions do not hinder future growth.

Budget and Resource Management

Financial planning plays a crucial role in warehousing strategy. Self-operation requires significant upfront investments in infrastructure, technology, and personnel. Businesses must calculate whether these costs align with their cash flow and ROI expectations.

Outsourcing offers a cost-effective alternative, especially for startups or small enterprises. By sharing resources with other clients, 3PL providers reduce operational expenses. However, businesses should account for service fees and potential risks, such as data security concerns.

Factor | Self-operation | Outsourcing |

|---|---|---|

Initial Investment | High | Low |

Operational Costs | Moderate to High | Shared, Lower |

Scalability | Limited | High |

Tip: Regularly reviewing budgets and resource allocation ensures that warehousing strategies remain financially sustainable.

Risk Mitigation and Contingency Planning

Risk mitigation and contingency planning are essential components of any warehousing strategy. Retail enterprises must prepare for potential disruptions to minimize operational downtime and financial losses. Effective planning ensures business continuity and protects customer satisfaction during unforeseen events.Effective risk mitigation not only minimizes losses but also strengthens customer trust. Enterprises that demonstrate preparedness and adaptability are better positioned to thrive in a competitive market.

Retail enterprises must weigh the pros and cons of self-operated and outsourced warehousing to make informed decisions. Self-operation offers control, customization, and brand enhancement, while outsourcing provides scalability, cost efficiency, and access to expertise. Aligning these choices with business goals ensures operational success and long-term growth.

FAQ

What factors should businesses consider when choosing between self-operation and outsourcing?

Businesses should evaluate their order volume, budget, scalability needs, and long-term goals. They must also assess their ability to manage warehousing operations effectively or rely on third-party expertise. A SWOT analysis can help identify strengths and weaknesses for informed decision-making.

How does outsourcing improve scalability for retail enterprises?

Outsourcing allows businesses to adjust storage capacity and resources based on demand. Third-party logistics providers (3PLs) offer flexible solutions, enabling enterprises to handle seasonal spikes or market expansions without significant investments in infrastructure or personnel.

Can hybrid warehousing models benefit growing businesses?

Yes, hybrid models combine the strengths of self-operation and outsourcing. Businesses can maintain control over critical operations while outsourcing non-core tasks. This approach balances cost, risk, and scalability, making it ideal for mid-sized enterprises experiencing growth.

Tip: Use hybrid models to optimize costs during peak seasons while retaining control over key processes.

What are the risks of outsourcing warehousing?

Outsourcing risks include limited control, data security concerns, and dependency on third-party providers. Misaligned KPIs and compliance issues may also arise. Businesses should establish clear contracts and performance metrics to mitigate these challenges.

How can technology enhance warehousing strategies?

Technology like Warehouse Management Systems (WMS) improves inventory tracking, order accuracy, and operational efficiency. Data analytics provides actionable insights for resource allocation and process optimization. Retailers leveraging advanced tools gain a competitive edge in supply chain management.

Emoji Insight: 📊 Data-driven decisions lead to smarter warehousing strategies!

See Also

Enhancing Warehouse Operations Through Robotic Automation Solutions

Logistics Robotics: A Game Changer for Warehouse Efficiency

Discover JUSDA's Innovative Warehousing Facilities for Greater Efficiency

Transforming Supply Chain Management with Cloud Technology Solutions

Exploring Advantages of Automation in Modern Manufacturing Warehouses