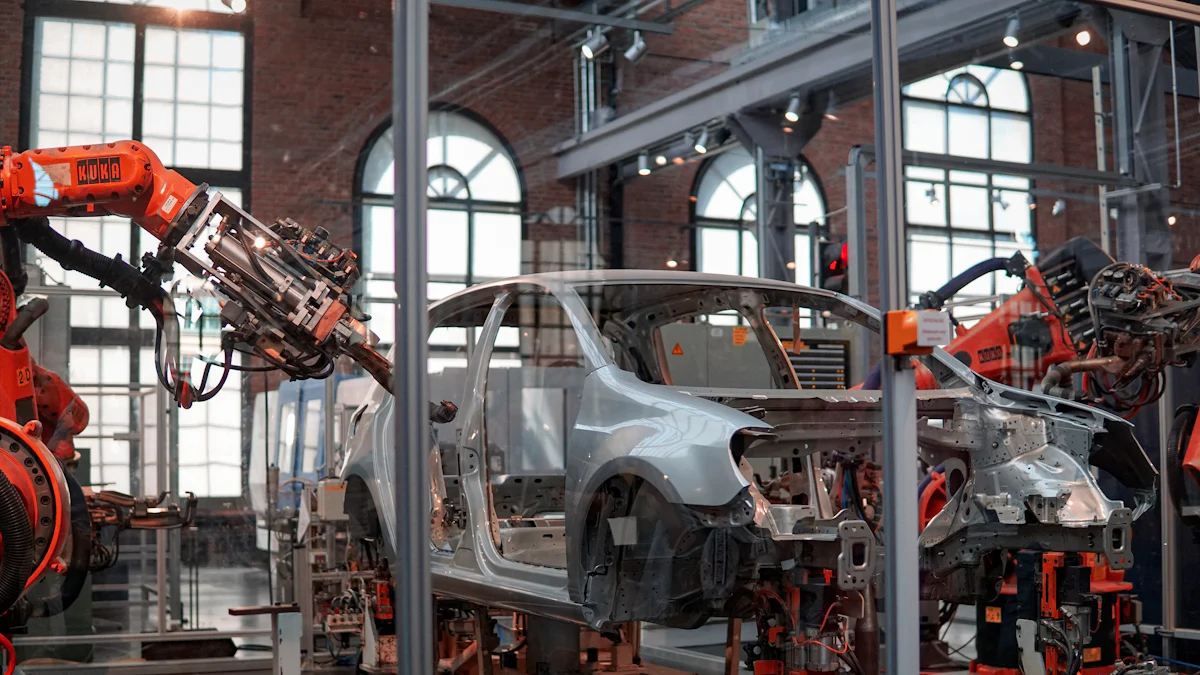

How JusLink Empowers Innovation in the Manufacturing Industry Supply Chain

Innovation drives the manufacturing industry forward. Manufacturers in the United States perform 53% of all private-sector research and development, highlighting the sector's commitment to progress. JusLink plays a pivotal role in the supply chain by utilizing digital-driven smart manufacturing collaboration solutions. This platform enhances connectivity and information sharing through IoT and big data analytics. Digital transformation has revolutionized the innovation model, allowing quick testing and development of creative ideas. JusLink empowers innovation by enabling organizations to refine strategies based on real-time insights and data analytics.

Understanding Digital Transformation in Manufacturing

Defining Digital Transformation

Key Components

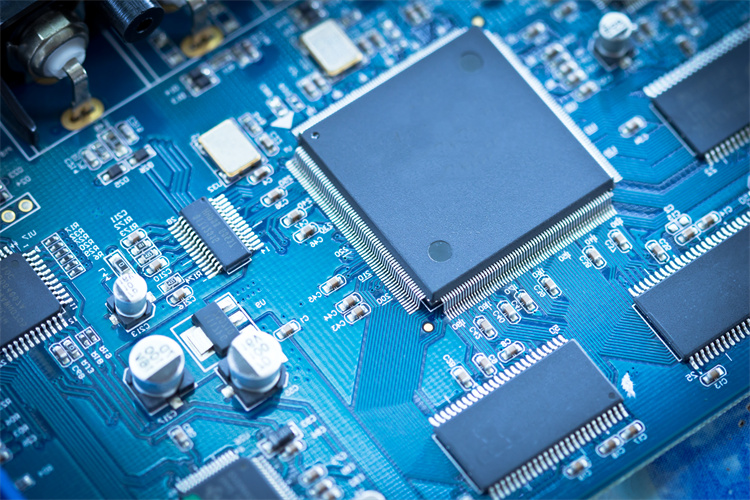

Digital transformation involves integrating digital technology into all areas of manufacturing. This process includes the use of IoT, big data analytics, and cloud computing. These technologies enable real-time data collection and analysis. The goal is to enhance decision-making and operational efficiency.

Impact on Manufacturing

Digital transformation reshapes manufacturing processes. It fosters innovation and streamlines operations. The adoption of digital technology leads to improved resource allocation. In China, for example, digital advancements have significantly upgraded the manufacturing sector. This progress highlights the global impact of digital transformation.

Importance in Supply Chain Management

Enhancing Efficiency

Digital transformation enhances supply chain efficiency. IoT devices provide real-time tracking of goods. Big data analytics optimize inventory management. These technologies reduce delays and improve overall productivity.

Reducing Costs

Cost reduction is a major benefit of digital transformation. Automation minimizes manual labor expenses. Data-driven insights help in identifying cost-saving opportunities. Efficient resource utilization lowers operational costs. This approach ensures a more profitable supply chain.

How JusLink Empowers Innovation in the Supply Chain

Overview of JusLink

Features and Capabilities

JusLink offers a comprehensive suite of features designed to enhance supply chain management. The platform utilizes IoT and big data analytics to provide real-time insights. These technologies enable seamless connectivity across the entire supply chain network. JusLink's cloud-based infrastructure supports improved operational efficiency. The platform facilitates end-to-end intelligent supply chain collaboration, driving innovation in manufacturing processes.

Integration with Existing Systems

Integration with existing systems remains a key strength of JusLink. The platform's flexible architecture allows smooth incorporation into current supply chain operations. This adaptability ensures minimal disruption during implementation. JusLink enhances existing processes by providing advanced analytics and connectivity. Organizations benefit from a unified system that supports strategic decision-making.

Case Studies

Success Stories

Case Study: JusLink Smart Supply Chain Management

A leading manufacturing enterprise adopted JusLink's solutions. The company achieved significant improvements in supply chain collaboration. Real-time data sharing led to enhanced decision-making capabilities. The organization reported increased efficiency and reduced operational costs.

Case Study: JUSDA's Cutting-Edge Supply Chain Solutions

JUSDA implemented JusLink to solidify its position as a leader in supply chain integration. The company leveraged JusLink's innovative solutions to streamline operations. The result was a more cohesive and responsive supply chain network. This success story highlights JusLink's role in empowering innovation.

Lessons Learned

Successful integration of JusLink requires careful planning. Organizations must prioritize clear communication and alignment with stakeholders. Continuous monitoring and adaptation ensure sustained benefits. Companies should focus on leveraging real-time insights for strategic advantage. These lessons underscore the transformative potential of JusLink in the supply chain.

Benefits of Innovation in the Supply Chain

Increased Productivity

Streamlined Operations

Innovation in the supply chain leads to streamlined operations. Manufacturers achieve a 20% increase in inventory turnover within the first quarter of implementation. Advanced technologies optimize transportation routes and inventory management. This results in significant cost savings, enhancing overall productivity.

Improved Quality Control

Quality control improves with innovative supply chain solutions. Real-time data analytics enable precise monitoring of production processes. Manufacturers can quickly identify and rectify defects. This ensures higher quality products and reduces waste.

Enhanced Collaboration

Supplier Relationships

Innovation fosters stronger supplier relationships. Digital platforms facilitate seamless communication between partners. This enhances transparency and builds trust. Suppliers and manufacturers collaborate more effectively, leading to a more resilient supply chain.

Customer Satisfaction

Customer satisfaction increases through innovation. Efficient supply chain processes ensure timely delivery of high-quality products. Companies meet customer expectations consistently. This strengthens brand loyalty and drives business growth.

Comparative Data:

74% of supply chain leaders increase technology investments.

36% plan to spend over $10 million on innovation.

These investments focus on resiliency, transparency, and sustainability. The ongoing workforce shortage also drives this trend.

Essential Strategies for Implementing JusLink

Planning and Execution

Setting Clear Objectives

Organizations must establish clear objectives when implementing JusLink. Clear objectives guide the integration process and ensure alignment with business goals. Companies should identify specific outcomes that JusLink aims to achieve. These outcomes may include improved supply chain efficiency or enhanced data analytics capabilities. A well-defined goal provides a roadmap for successful implementation.

Resource Allocation

Effective resource allocation is crucial for JusLink's implementation. Companies need to allocate sufficient resources, including technology, personnel, and finances. Proper allocation ensures that the necessary tools and expertise are available. Organizations should assess existing resources and identify gaps that JusLink can fill. This assessment helps in optimizing the use of JusLink's features and capabilities.

Overcoming Challenges

Common Obstacles

Several obstacles may arise during JusLink's implementation. Integration with legacy systems poses a significant challenge. Companies often face resistance to change from employees accustomed to traditional processes. Data security concerns also present potential hurdles. Addressing these challenges requires proactive strategies and thorough planning.

Organizations can adopt best practices to overcome implementation challenges. Comprehensive training programs help employees adapt to new technologies.

Continuous monitoring and feedback loops enable organizations to refine their strategies. These practices ensure a smooth transition to JusLink's intelligent supply chain platform.

JUSDA, a leader in supply chain management, emphasizes the importance of strategic planning and execution. The development of JusLink since 2018 showcases the potential for end-to-end intelligent supply chain collaboration.

Leadership's Role in Driving Innovation

Vision and Strategy

Aligning Goals

Leadership plays a crucial role in aligning organizational goals with innovation strategies. Leaders must ensure that every department understands the objectives. Clear communication fosters a unified approach. Alignment creates a cohesive environment where innovation thrives.

Inspiring Teams

Leaders inspire teams by fostering a culture of creativity and collaboration. Motivation stems from recognizing individual contributions. Encouragement leads to increased engagement and productivity. Leaders who champion innovation drive teams toward excellence.

JUSDA Solutions

To provide you with professional solutions and quotations.

Measuring Success

Key Performance Indicators

Key Performance Indicators (KPIs) provide measurable insights into innovation success. Leaders select KPIs that reflect strategic objectives. Regular evaluation of these indicators guides decision-making. KPIs ensure that innovation efforts align with organizational goals.

Continuous Improvement

Continuous improvement remains essential for sustaining innovation. Leaders implement feedback loops to identify areas for enhancement. Adaptation to new challenges ensures ongoing progress. A commitment to improvement fosters a dynamic and innovative supply chain.

Mary Blenn, an expert in supply chain leadership, emphasizes the importance of collaboration. Her insights highlight how leadership drives innovation through strategic alignment and team inspiration.

JusLink transforms innovation in the manufacturing supply chain. The platform enhance efficiency and collaboration through IoT and big data analytics. JUSDA's commitment to intelligent supply chain solutions exemplifies this impact. Future trends indicate a shift towards seamless connectivity and real-time data sharing. Organizations must embrace digital transformation to stay competitive. Investing in these technologies fosters resilience and growth. JusLink provides the tools necessary for achieving end-to-end intelligent supply chain collaboration. Embracing these innovations ensures a robust and dynamic manufacturing ecosystem.

See Also

Exploring JUSDA's Cutting-Edge Supply Chain Solutions

Unveiling JUSDA's Impact on Supply Chain Sustainability

Understanding JUSDA's Revealed High-Tech Manufacturing Logistics

Optimizing Visibility: JUSDA's Complete Supply Chain Efficiency

Collaborative Innovation: Strengthening High-Tech Manufacturing Partnerships