Essential Guidelines for Quality Assurance within the Semiconductor Industry Supply Chain

Quality assurance is pivotal in the semiconductor supply chain, which encounters various challenges due to its intricate production processes and the necessity for precision. Upholding high standards is essential for ensuring product reliability and customer satisfaction. Rigorous data analysis methodologies are employed to enhance decision-making and minimize waste. Implementing both parametric and non-parametric testing is crucial for maintaining quality. Statistical analysis plays a significant role in achieving cost efficiency and product reliability. Quality assurance practices must be seamlessly integrated into every stage of the semiconductor supply chain, ensuring that products adhere to stringent quality and compliance specifications.

Establishing Expertise in Quality Assurance within the Semiconductor Supply Chain

Team Credentials and Experience

A proficient team forms the backbone of effective quality assurance in the semiconductor supply chain. Industry Certifications play a pivotal role in establishing credibility. Certifications such as ISO 9001 and AEO enterprise senior certification demonstrate adherence to international standards. These certifications assure stakeholders of the team's commitment to maintaining high-quality standards.

Years of experience in semiconductor quality control further enhance the team's expertise. Experienced professionals bring valuable insights into the intricacies of semiconductor manufacturing. Their knowledge helps in identifying potential issues and implementing preventive measures. This experience ensures that each step, from silicon ingot forging to circuit design stamping, undergoes meticulous checks.

Continuous Training and Development

Continuous training and development are crucial for staying updated with the latest advancements in quality assurance. Regular workshops and seminars provide opportunities for team members to learn new techniques and methodologies. These sessions cover various aspects of quality control, including defect rate monitoring and yield improvement strategies.

Collaboration with industry experts enriches the team's knowledge base. Engaging with professionals like Patrick Bangert, an expert in Semiconductor Manufacturing QA/QC, offers valuable insights. Patrick emphasizes the importance of rigorous quality checks at every production stage. Such collaborations foster a culture of continuous learning and innovation within the team.

Rigorous Quality Processes in the Semiconductor Supply Chain

Standard Operating Procedures (SOPs)

Standard Operating Procedures (SOPs) form the backbone of Quality Assurance in the Semiconductor Supply Chain. SOPs ensure consistency and reliability across all production stages. Each procedure outlines specific steps to maintain high-quality standards.

Development and Implementation

Development of SOPs involves collaboration among experts in the Semiconductor Supply Chain. Teams focus on creating detailed guidelines that cover every aspect of production. Implementation requires strict adherence to these guidelines to prevent deviations. Regular training ensures that all personnel understand and follow SOPs accurately.

Regular Audits and Updates

Regular audits play a crucial role in maintaining effective SOPs. Auditors assess compliance with established procedures. Findings from audits lead to necessary updates, ensuring continuous improvement. Updates reflect technological advancements and changes in industry standards.

Quality Control Metrics

Quality Control Metrics provide measurable insights into the effectiveness of Quality Assurance processes. These metrics help identify areas for improvement within the Semiconductor Supply Chain.

Defect Rate Monitoring

Defect rate monitoring is essential for maintaining product integrity. Teams track defects at each production stage. Data-driven analysis identifies patterns and root causes. This proactive approach minimizes defects and enhances overall quality.

Yield Improvement Strategies

Yield improvement strategies focus on maximizing production efficiency. Teams analyze production data to identify bottlenecks. Implementing targeted solutions increases yield rates. Continuous monitoring ensures that improvements are sustained over time.

Case Studies:

Quality Control in the Semiconductor Industry: Emphasizes the importance of stringent quality control practices. Highlights successful implementation of SOPs and metrics.

Electronic Device Supply Chain: Demonstrates effective defect rate monitoring techniques. Showcases yield improvement through strategic interventions.

Global Infrastructure Supporting Quality Assurance

Advanced Technology and Equipment

State-of-the-art testing facilities play a crucial role in the Semiconductor Supply Chain. These facilities ensure that each semiconductor chip meets industry quality standards. KEYENCE’s LM-X Multisensor Measurement System exemplifies advanced technology. This system inspects 5,000 locations on up to 1,000 parts simultaneously. The inspection process reduces time and cost per inspection. A 20-megapixel CMOS camera and low-pressure probes are ideal for detailed semiconductors. The white confocal laser inspects height and depth dimensions instantaneously.

Automation in quality checks enhances efficiency in the Semiconductor Supply Chain. Automated systems perform consistent and precise inspections. Automation minimizes human error and increases throughput. Automated quality checks ensure that semiconductor products meet stringent specifications. The integration of automation in testing facilities supports continuous improvement in Quality Assurance.

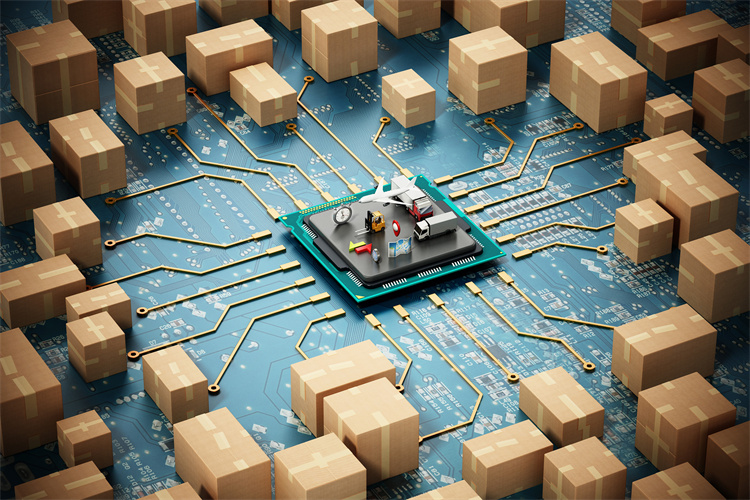

JUSDA's Role in the Semiconductor Supply Chain

JUSDA enhances logistics and distribution efficiency within the Semiconductor Supply Chain. Efficient logistics ensure timely delivery of semiconductor components. JUSDA's global network supports seamless movement across borders. The company provides comprehensive end-to-end supply chain solutions. These solutions integrate raw material procurement, manufacturing, and distribution.

Real-time tracking and reporting are vital for maintaining Quality Assurance. JUSDA's JusLink platform offers real-time collaborative capabilities. This platform integrates suppliers, manufacturers, and service providers. Real-time data enables precise business decision-making. Tracking and reporting ensure transparency throughout the Semiconductor Supply Chain. JUSDA's innovative platforms streamline international trade and empower cross-border logistics.

JUSDA Solutions

To provide you with professional solutions and quotations.

Commitment to Quality and Call to Action

Continuous Improvement Initiatives

Continuous improvement initiatives play a vital role in the Semiconductor Supply Chain. These initiatives focus on enhancing Quality Assurance processes. Feedback loops provide valuable insights from customers. Customer engagement helps identify areas for improvement. This proactive approach ensures that products meet customer expectations.

Innovation drives advancements in Quality Assurance techniques. The Semiconductor Supply Chain benefits from new methodologies. Advanced technologies improve inspection accuracy. Automation reduces errors and increases efficiency. The industry constantly seeks innovative solutions to maintain high standards.

Encouraging Further Engagement

The Semiconductor Supply Chain thrives on collaboration. An invitation to connect with experts fosters knowledge sharing. Industry professionals offer valuable insights into Quality Assurance practices. Engaging with experts enhances understanding of complex processes. This interaction encourages continuous learning and development.

Opportunities for collaboration abound within the Semiconductor Supply Chain. Joint ventures lead to shared success. Partnerships drive innovation and improvement. Collaborative efforts strengthen Quality Assurance initiatives. The industry benefits from collective expertise and resources.

The semiconductor industry remains steadfast in its commitment to Quality Assurance. This dedication ensures that every product meets the highest standards. Industry leaders, like JUSDA, emphasize continuous improvement and innovation in Quality Assurance practices. Paul Romano, COO at Fusion Worldwide, states, “We are committed to continuous improvement and making sure our customers always receive the highest quality products and the best possible experiences.” Engaging with expert teams provides invaluable insights into advanced Quality Assurance techniques. Collaboration within the industry fosters shared success and innovation. SBT emerges as a valued partner in enhancing Quality Assurance across the supply chain.

See Also

Insider Tips for Semiconductor Industry Quality Control

Mastering Supply Chain Quality with JUSDA's Guide

Key Strategies for Successful Supply Chain Cybersecurity

Expert Advice for Overcoming Automotive Supply Chain Hurdles