USA Supply Chain News and Expert Analysis

Supply chains play a crucial role in the USA and globally. Efficient logistics ensure products reach consumers on time. The USA supply chain impacts economic stability. U.S. business logistics costs reach $2.3 trillion, accounting for 8.7% of the national GDP. This significant figure highlights the importance of streamlined operations. Supply chains connect manufacturers, suppliers, and consumers. These networks drive commerce and innovation. Understanding supply chain dynamics helps businesses adapt to challenges. Effective supply chain management enhances competitiveness and resilience.

Current Challenges and Trends

Inflation and Economic Pressures

Inflation presents a significant challenge for the USA supply chain. Rising costs impact every stage of the supply chain, from raw materials to transportation. Businesses face increased expenses, which affect profitability. High inflation rates contribute to these rising costs. Economic pressures also play a role. Companies must adapt to maintain competitiveness.

Impact on Supply Chain Costs

Supply chain costs rise due to inflation. Transportation and labor expenses increase. Fuel prices contribute to higher shipping costs. These factors strain the usa supply chain. Companies must find ways to manage these costs. Efficient logistics become crucial in this environment.

Strategies for Mitigation

Businesses employ various strategies to mitigate inflation's impact. Cost-cutting measures help reduce expenses. Companies optimize routes to save on fuel. Technology plays a role in improving efficiency. Automation reduces labor costs. Data analysis aids in decision-making. These strategies help businesses navigate economic pressures.

Unpredictable Consumer Demand

Consumer demand remains unpredictable in the USA supply chain. Several factors contribute to this uncertainty. Geopolitical conflicts disrupt supply chains. Climate change affects shipping lanes. High inflation and interest rates also play a role. These elements create challenges for businesses.

Causes and Effects

Unpredictable demand stems from various causes. Geopolitical tensions impact global trade. Climate change alters shipping routes. Inflation and interest rates affect consumer spending. These factors lead to fluctuating demand. Businesses struggle to forecast accurately. Inventory management becomes challenging.

Adaptive Strategies

Companies adopt adaptive strategies to address demand fluctuations. Flexibility becomes essential in the usa supply chain. Businesses diversify suppliers to reduce risks. Agile inventory management helps meet changing demands. Data-driven insights guide decision-making. These strategies enhance resilience in uncertain times.

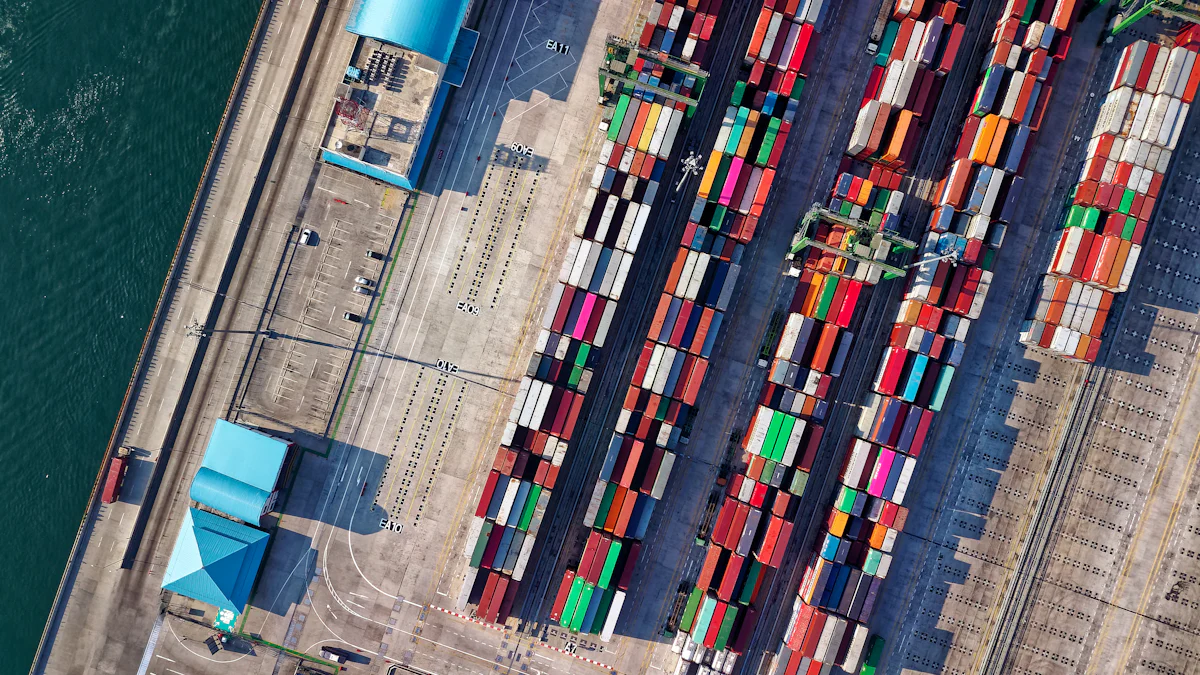

Port Congestion

Port congestion poses a significant challenge for the USA supply chain. Key areas experience delays and disruptions. Ports on the East Coast and Gulf Coast face particular challenges. Congestion affects shipping schedules and delivery times. Businesses must adapt to these conditions.

Key Affected Areas

Several ports experience congestion issues. East Coast ports face worker strikes. Gulf Coast ports deal with high traffic volumes. These areas see significant delays. Congestion impacts shipping efficiency. Businesses face longer wait times for goods.

Solutions and Innovations

Innovations offer solutions to port congestion. Technology improves logistics efficiency. Real-time tracking enhances visibility. Automation speeds up cargo handling. Companies explore alternative routes. These innovations help alleviate congestion. The usa supply chain benefits from these advancements.

Expert Analysis

Insights from Industry Leaders

Perspectives from Supply Chain Dive

Supply Chain Dive provides valuable insights into the supply chain industry. The platform focuses on impactful news and trends. Experts analyze economic pressures and their effects on logistics. Supply Chain Dive highlights innovative strategies for overcoming challenges. The platform serves as a resource for industry professionals seeking knowledge.

Insights from FreightWaves

Experts discuss the implications of rising freight prices. FreightWaves emphasizes the importance of adapting to market changes. The platform helps businesses understand complex logistics dynamics.

Data-Driven Analysis

Role of Data in Decision Making

Data-driven insights support strategic planning and risk management. Businesses gain a competitive edge through effective data utilization.

Case Studies and Examples

Case studies illustrate successful data-driven strategies. Ahold Delhaize USA's Supply Chain ADvantage showcases growth through innovation. The company leverages technology to improve efficiency. Data analysis aids in forecasting and inventory management. These examples demonstrate the transformative power of data in supply chains.

Role of Digitization and Technology

IoT and AI in USA Supply Chains

The usa supply chain landscape embraces IoT and AI technologies. Companies implement IoT sensors to track shipments in real-time. This technology enhances visibility across supply networks. AI algorithms analyze data to predict demand patterns. Businesses use these insights to optimize inventory management.

Implementation Examples

Several companies showcase successful IoT and AI integration. A major retailer uses IoT devices to monitor warehouse conditions. This approach ensures optimal storage environments for perishable goods. An automotive manufacturer employs AI to streamline production schedules. These examples highlight the transformative impact of technology on the usa supply chain.

Benefits and Challenges

IoT and AI offer numerous benefits to the usa supply chain. Enhanced efficiency reduces operational costs. Improved accuracy leads to better decision-making. However, challenges exist. High implementation costs deter some businesses. Data security concerns require robust measures. Companies must balance these factors to achieve success.

Case Study: Ahold Delhaize USA's Supply Chain ADvantage

Ahold Delhaize USA demonstrates effective supply chain strategies. The company leverages technology to enhance operations. This approach positions Ahold Delhaize as a leader in the industry.

Overview of Strategy

Ahold Delhaize USA focuses on digital transformation. The company integrates advanced analytics into its supply chain. This strategy improves forecasting accuracy. Efficient logistics ensure timely product delivery. Ahold Delhaize prioritizes sustainability in its operations.

Outcomes and Learnings

Ahold Delhaize USA achieves significant improvements. The company reports increased efficiency across its supply network. Enhanced data utilization supports strategic planning. Ahold Delhaize gains a competitive edge in the usa supply chain. These outcomes demonstrate the value of embracing technology.

Future Outlook

Potential Disruptions

Port Worker Strikes

Port worker strikes threaten the USA supply chain. Labor disputes disrupt operations at key ports. Delays in shipments affect businesses nationwide. Companies face challenges in maintaining schedules. Strikes lead to increased costs and inefficiencies.

Ongoing Impact of COVID-19

COVID-19 continues to impact the USA supply chain. Supply networks face disruptions from health measures. Businesses struggle with labor shortages and transportation delays. The pandemic emphasizes the need for resilience. Companies adapt to maintain supply chain stability.

JUSDA's Role and Expertise

Innovative Solutions

JUSDA offers innovative solutions for the USA supply chain. Advanced technologies streamline logistics processes. Real-time data enhances decision-making and efficiency. JUSDA's platforms support complex supply chain demands. Businesses benefit from improved resource utilization.

Global Reach and Influence

JUSDA's global reach strengthens the USA supply chain. Extensive service points provide comprehensive coverage. International routes ensure reliable logistics solutions. JUSDA supports diverse industries with tailored services. The company's influence drives supply chain innovation.

JUSDA Solutions

To provide you with professional solutions and quotations.

Supply chains in the USA will continue to evolve. Organizations will leverage technological advancements. Efficiency and transparency will become priorities. Data analytics will drive proactive strategies. Supply chain leadership will embrace a holistic approach. This shift will address modern demands. Innovation will play a crucial role. Adaptation will ensure resilience. Future supply chains in the USA will focus on customer satisfaction. The C-suite will prioritize supply chain functions. This focus will enhance operational effectiveness.

See Also

Tomorrow's Logistics Revolutionized by AI in Supply Chain

Reshaping Industries with Cloud Solutions for Supply Chain

Unlocking Your Automotive Supply Chain's Full Potential

Leading the Industry: JUSDA's Superior Supply Chain Solutions