JUSDA Shenzhen G9 Central Warehouse Re-Certified Under China’s Five-star Warehouse Classification

JUSDA Shenzhen G9 Central Warehouse Re-Certified Under China’s Five-star Warehouse Classification

Lean Operations and Talent as Dual Engines for a More Predictable Supply Chain

As supply chain competition shifts from cost arbitrage to a contest of efficiency and resilience, warehouses are no longer simple transfer points. They are becoming the operational foundation for predictable fulfillment—the ability to perform consistently under peak stress, complex SKU profiles, and disruption.

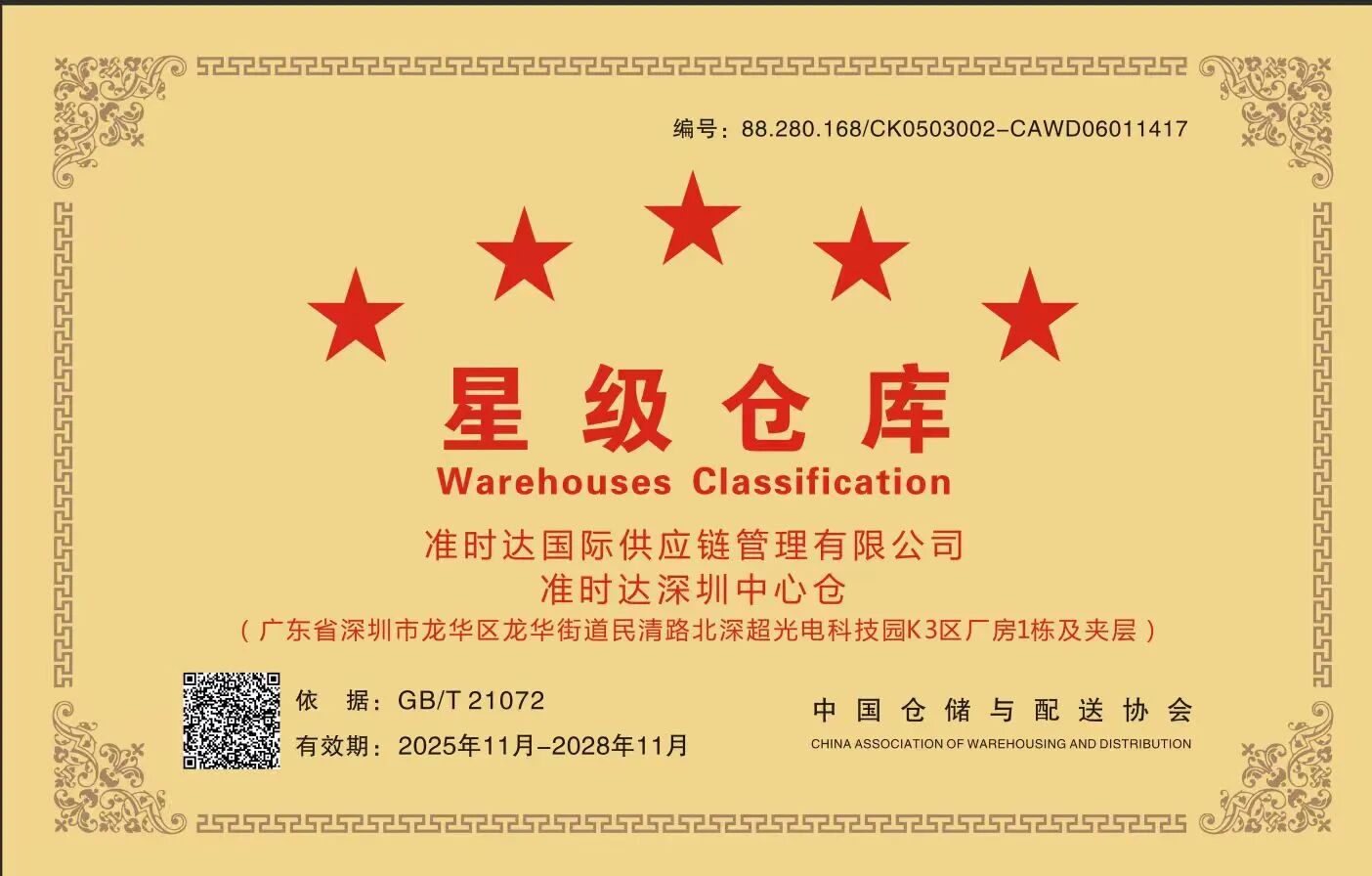

Recently, JUSDA’s G9 Central Warehouse at the Shenzhen Longhua campus was re-certified at the Five-star level in the 2025 reassessment, following its first Five-star recognition in 2022. The classification was jointly evaluated by the China General Warehouse Grading & Evaluation Committee and the CHINA ASSOCIATION OF WAREHOUSING AND DISTRIBUTION.

Warehouses Classification: Why “Five-star” Matters—and Why Re-Certification Is Harder

China’s Five-star Warehouse Classification is widely regarded as a top benchmark of warehousing operational maturity. What makes Five-star difficult is not one standout capability, but end-to-end system readiness: facilities and equipment, intelligent systems, workforce capability, service functions, and management practices must work together as a stable operating ecosystem.

Re-certification raises the bar further. It does not only validate configuration—it validates long-term operational evidence: whether capacity output, system rules, continuous improvement mechanisms, and safety/resilience controls can remain stable over time and under volatility.

Lean Management: From “Hardware Stacking” to a Data-Driven Intelligent Brain

As the fully intelligent demonstration warehouse in JUSDA’s Longhua campus, G9 has built an integrated capability of an “automation backbone + digital brain” within a 10,680㎡ footprint. It adopts a dual-zone design of ASRS automated storage + Kiva/AGV intelligent goods-to-person operations, supported by sorting walls at the dock. Its automation stack spans stacker cranes, AGVs, automated racking, conveyors, robotic arms, and warehouse control/scheduling/management systems—enabling automated putaway and picking with 95% mechanization utilization.

Over the past three years of live operations, G9 has progressed from equipment deployment to lean equipment operations by integrating IMS-WMS (intelligent warehouse management) with JUSDA’s self-developed JusLink Intelligent Supply Chain Platform. This transforms automation capability into repeatable, sustainable capacity output, keeping goods-to-person throughput stable at 300–350 order lines per hour. More importantly, G9 operates like a “schedulable network”: uncertainty from peaks, variability, and SKU complexity is absorbed by system logic and converted into stable, predictable performance.

Talent Leanification: From Task Proficiency to Multi-Skilled, System-Ready Operators

At G9, people are being redefined as part of the operating system. Through lean workforce management, JUSDA implements JIS standard work and targeted skill certifications to increase multi-skilled coverage and build a composite model of “skills matrix + standard operations.” Frontline roles are designed to understand system logic, coordinate equipment operations and basic maintenance, and interpret operational signals from dashboards to identify anomalies and respond quickly—ensuring elasticity during peaks and fast recovery during disruptions.

This deeper human-machine collaboration improves productivity while strengthening resilience: standards remain consistently executed, knowledge becomes structurally transferable, and operational quality and management consistency stay stable even as staffing and demand patterns change.

Replication at Scale: From a Single Benchmark to Cross-Region Consistency

JUSDA has distilled G9’s mature practices into a transferable “standard package” and replicated it across sites including Zhengzhou, Chengdu, Ganzhou, and Shenzhen Guanlan—moving high-standard capability from a single benchmark to cross-regional consistency.

Replication is not about moving equipment; it is about exporting an operational system that is runnable, re-auditable, and continuously improvable, built around four core components: process SOPs, system parameters and rules, slotting and flow-path strategy, and multi-skilled workforce capability frameworks. Even with SKU structure shifts, demand volatility, or staffing rotation, sites can generate stable operating strategies under the same models—maintaining consistent execution, floor rhythm, and risk controls. This “system replication” approach is the key pathway to scaling Five-star-level warehousing capability across a network.

Looking Ahead: Making the Warehouse the Foundation for a Predictable Supply Chain

If the 2022 recognition proved the system was built, the 2025 re-certification proves the system can run, remain stable, and continuously improve. It marks a clear shift from “technology stacking” to capability engineering: embedding efficiency into rules, bringing quality forward into mechanisms, locking risk into systems, and codifying experience into reusable standards.

Going forward, JUSDA will continue using G9 as a benchmark to scale replication and standard outputs across sites and regions—turning warehousing into the foundational capability for a predictable supply chain, and delivering more resilient, controllable, and sustainable fulfillment assurance for global manufacturing customers.